Inspection device for defect inspection

A detection equipment, defect detection technology, applied in the direction of measuring device, measuring perimeter, using optical devices, etc., can solve the problems of steep brightness gradient, not providing brightness gradient, unable to obtain accurate images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

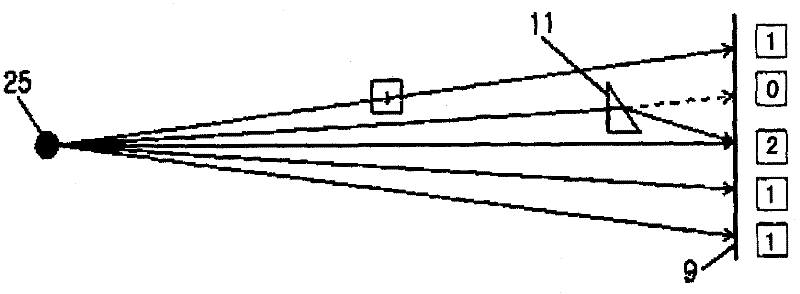

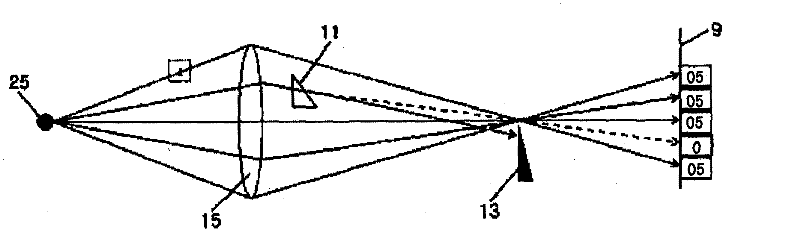

[0035] image 3 is an optical diagram explaining the principle of the knife edge in the detection device according to the present invention.

[0036] A point light source 25 is located at the left focus of the field lens 15 , and light emitted from the light source 25 is irradiated onto the screen 9 through the right focus of the field lens 15 . When there is a defect 11 between the field lens 15 and the right focal point of the field lens 15, the optical path of the light passing through the defect 11 is refracted and deviates from the normal optical path shown by the dotted line, thereby terminating at rather than passing through Through the knife edge (ie the knife edge 13, which may have a sharp plate-shaped end) located at this right focus.

[0037] Also, assuming from image 3 The intensity of the light emitted by the shown ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com