Diaphragm wall reinforcing cage dovetail type sealing head structure

A steel cage and dovetail technology, which is applied to underwater structures, infrastructure engineering, sheet pile walls, etc., can solve the problems of large pulling force, large friction, and the inability of joint pipes or steel cages to be lowered to the bottom of the groove. , to achieve the effect of facilitating cleaning and reducing the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

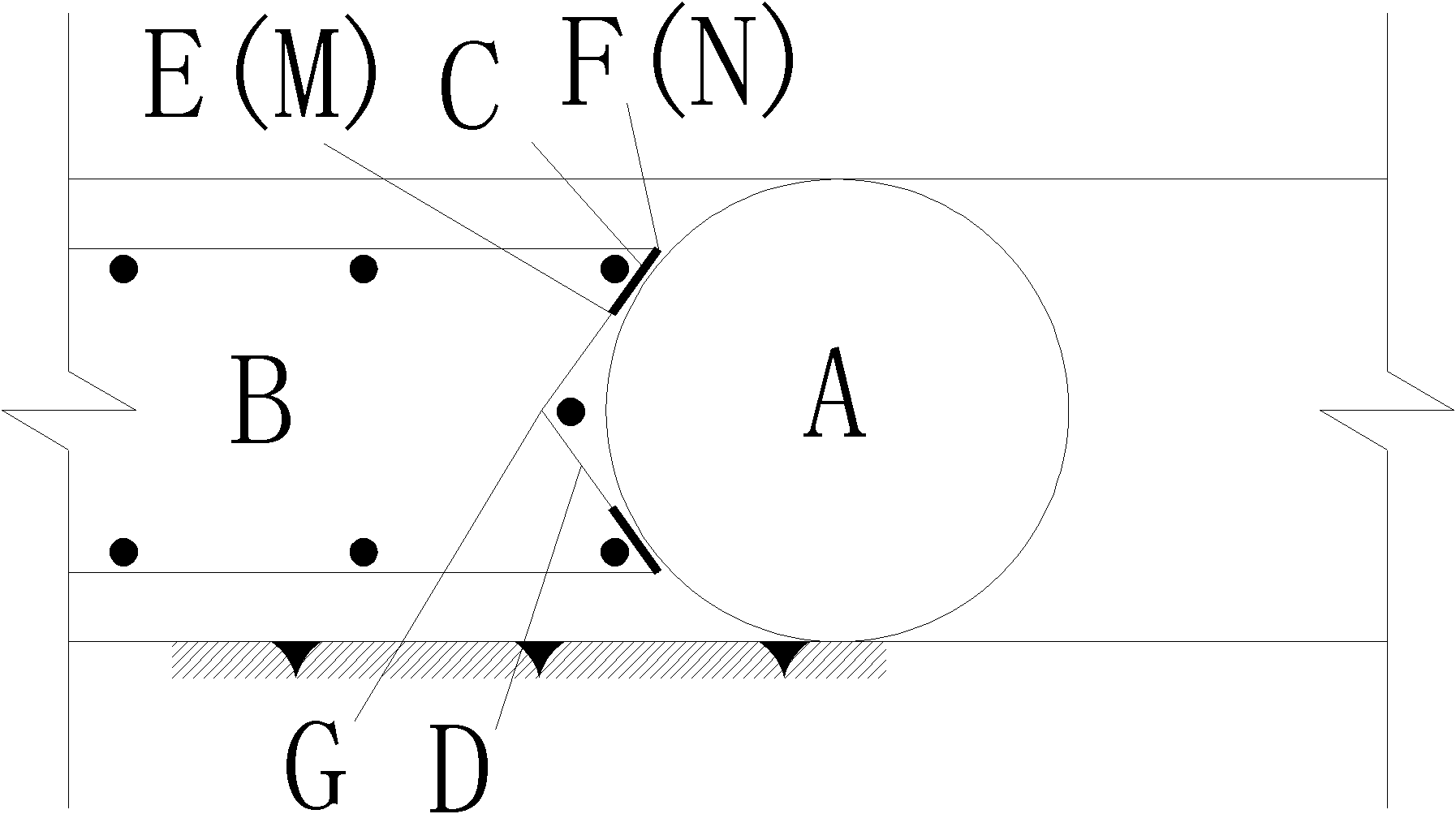

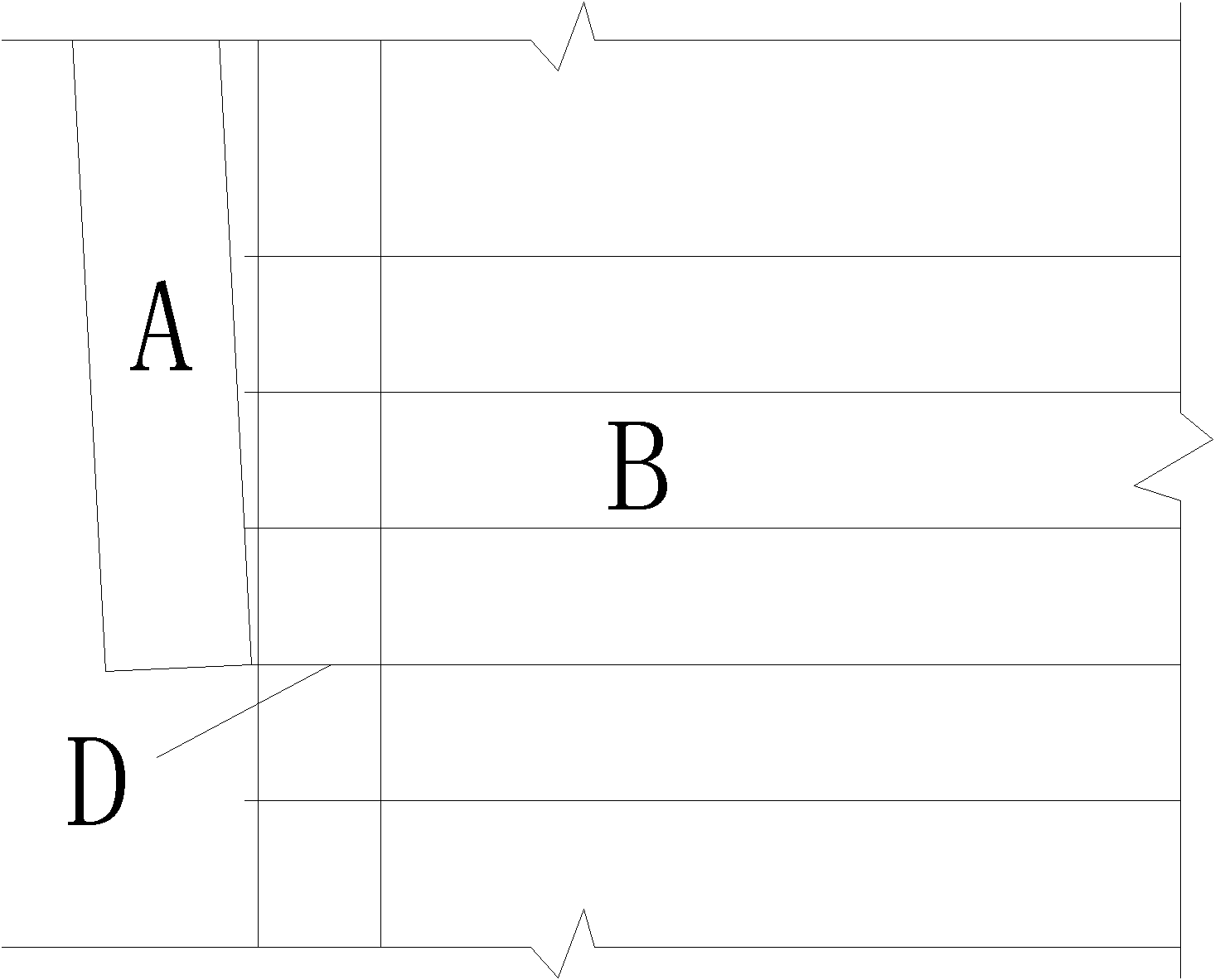

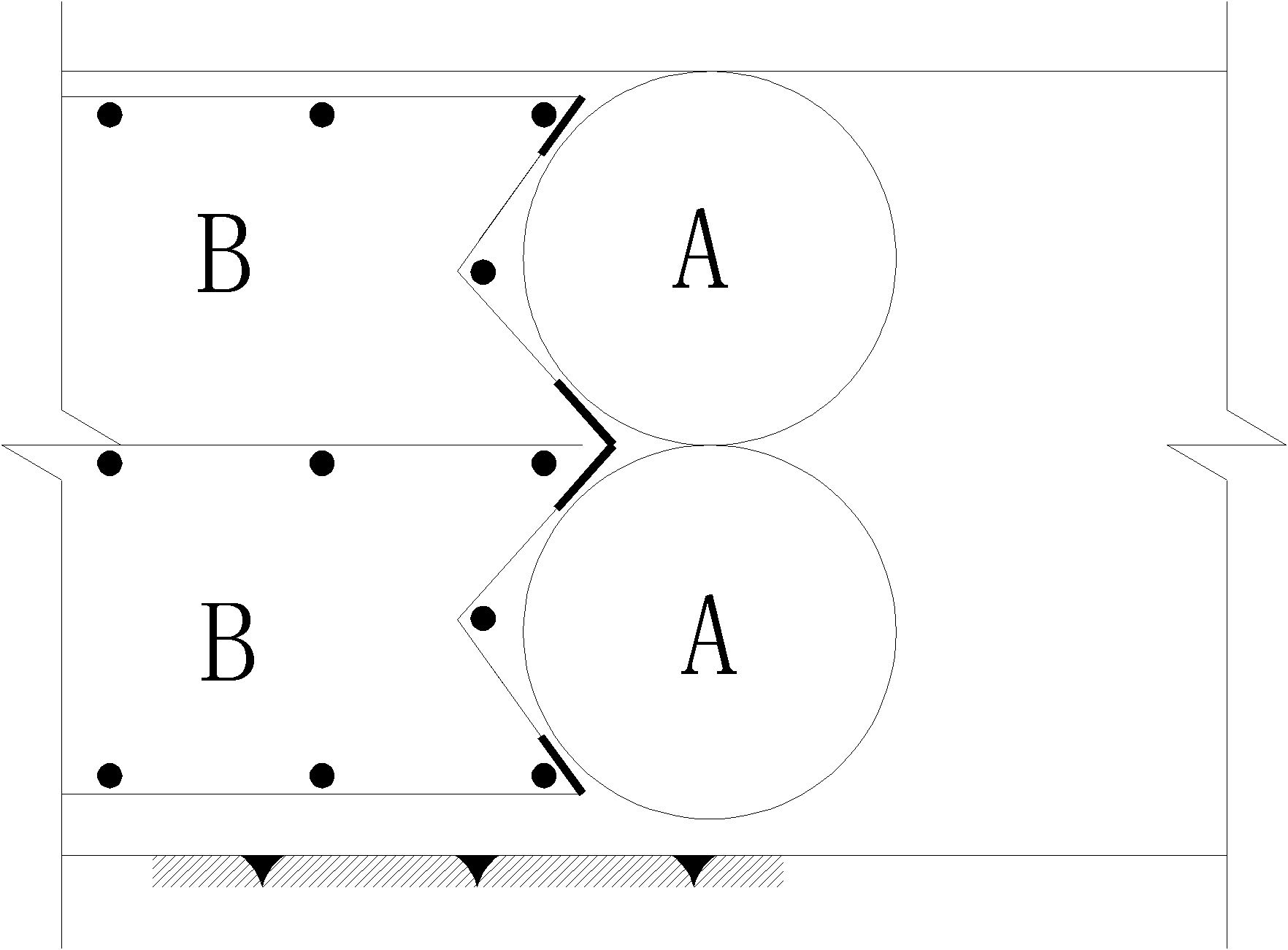

[0013] Below in conjunction with accompanying drawing, the dovetail type head structure of ground connecting wall reinforcement cage of the present invention is further described.

[0014] In order to reduce the friction between the joint pipe A of the ground connection wall and the reinforcement cage B during the lowering process, reduce the friction between the joint pipe A and the concrete when the joint pipe A is pulled up, and reduce the possibility that the joint pipe A is stuck on the horizontal steel bar D of the reinforcement cage, the invention The treatment method for the new structure of the dovetail head of the reinforced cage with the ground and the wall is established. This structure promotes the development of the ground connection wall to a deeper and thicker direction, provides a guarantee for the smooth lowering of the joint pipe and the reinforcement cage, and also provides a guarantee for the smooth uplift of the joint pipe, and provides a new idea for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com