Static pressure reinforcing treatment method for pile with unqualified bearing capacity

A technology of bearing capacity and static pressure, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of long construction period, broken pile or pile body mud defects, high cost, etc., to achieve low project cost and short processing period , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

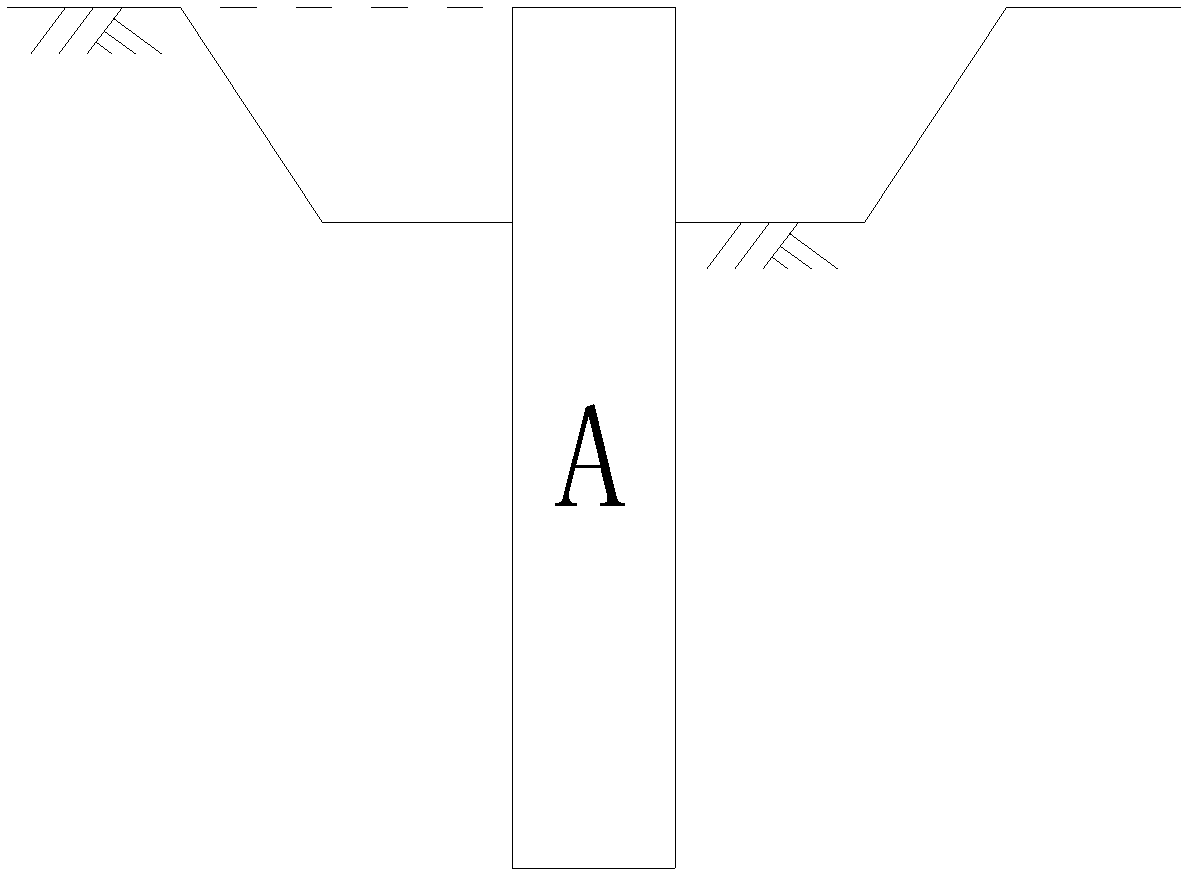

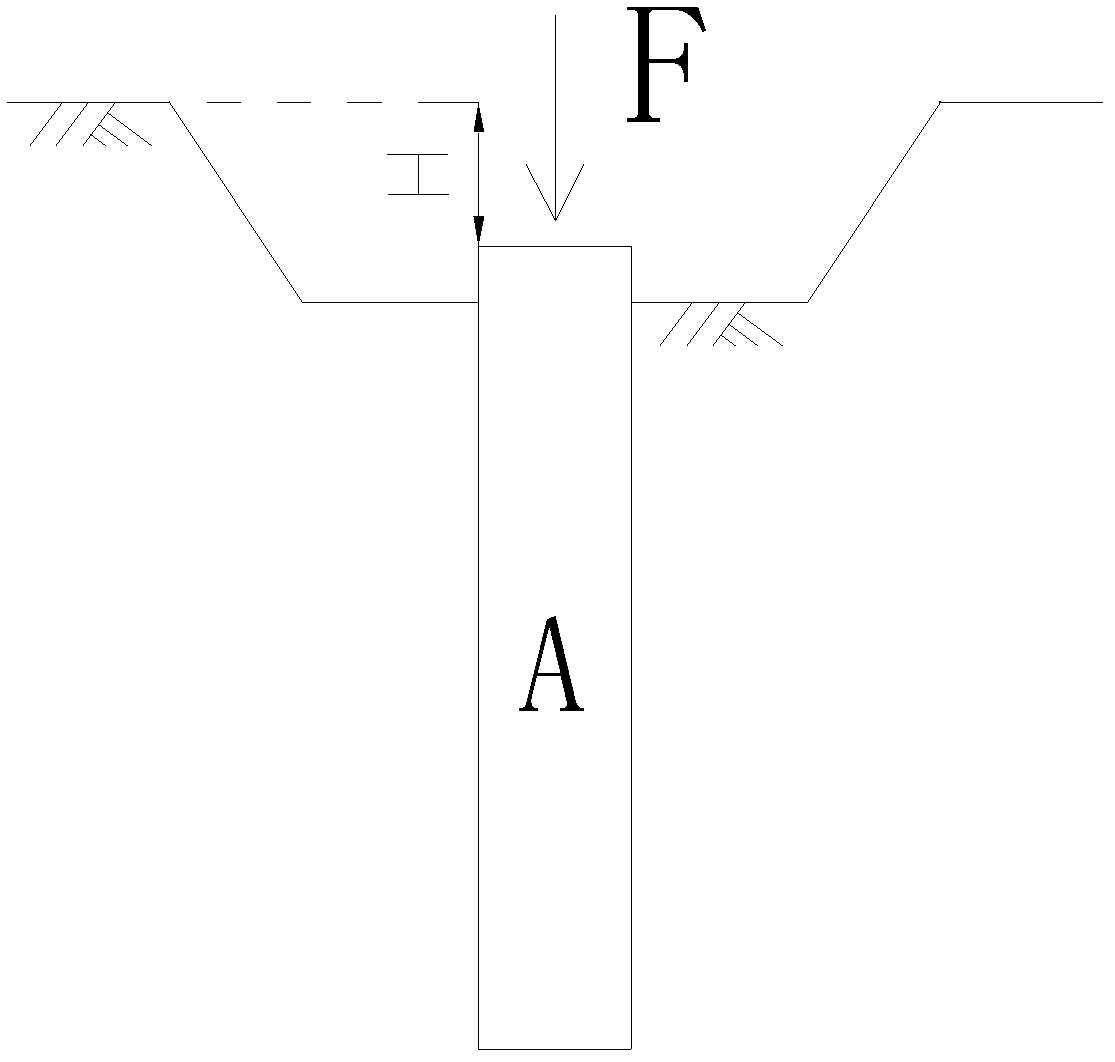

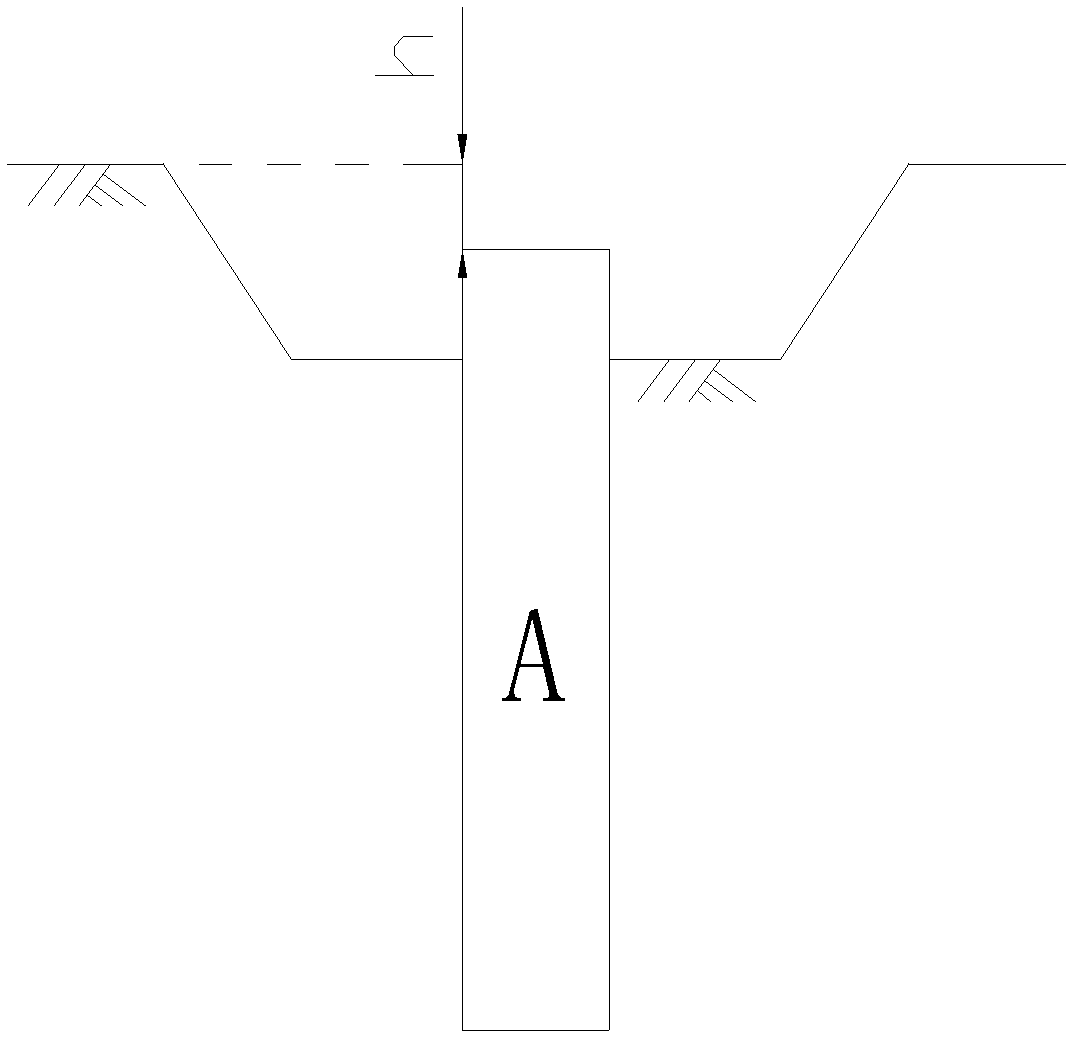

[0051] A multi-storey office building in a port in southern my country, the foundation is in a soft soil area, and the newly filled muddy soil layer is 12m thick. The lower part is medium dense sand layer and strongly weathered granite layer. In order to eliminate the possible negative friction of the pile foundation, a 2m thick sand cushion is laid on the upper part, and the vacuum preloaded foundation is strengthened. According to geological drilling data, bored cast-in-place pile foundation is selected. The diameter of the pile foundation is 700mm. The bearing layer at the pile end is a strong weathered granite layer. The pile is about 25-31m long and enters the strong weathered granite layer 5m. Ultimate force 3400Kn.

[0052] After the construction of cast-in-situ piles, when the static load test was carried out, none of the selected test piles met the design requirements, and the selection of test piles by expanding the scope again did not meet the design requirements. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com