Remote debugging method of excvavtor

A remote debugging and excavator technology, which is applied to earth movers/excavators, construction, etc., can solve problems such as high costs, and achieve the effect of increasing reliability and reducing the possibility of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

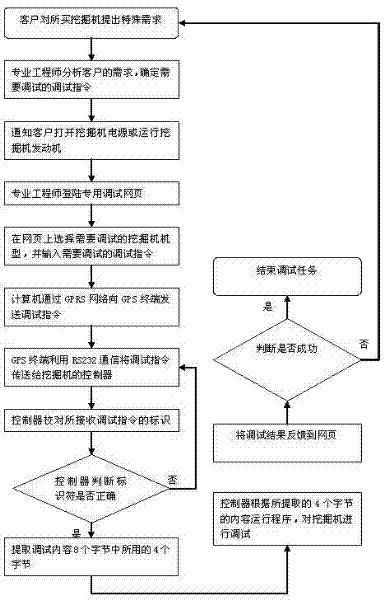

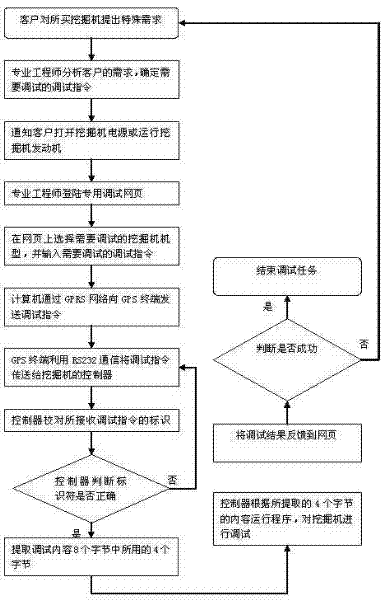

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] Such as figure 1 As shown, an excavator remote debugging method includes the following steps:

[0029] (1) The customer puts forward special requirements for the purchased excavator;

[0030] (2) Professional engineers analyze the needs of customers and determine the debugging instructions that need to be debugged;

[0031] (3) Notify the customer to turn on the power of the excavator or run the engine of the excavator;

[0032] (4) Professional engineers log in to the special debugging web page;

[0033] (5) Select the excavator model that needs to be debugged on the webpage, and input the debugging instructions that need to be debugged;

[0034] (6) The computer sends debugging instructions to the GPS terminal through the GPRS network;

[0035] (7) The GPS terminal uses RS232 communication to transmit the debugging instructions to the controller of the excavat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com