Autoclaved aerated concrete slab external wall and construction method thereof

A technology of autoclaved gas filling and construction method, which is applied in the direction of walls, building components, buildings, etc., can solve the problems that have not been applied on a large scale, the concrete outer wall panels are easy to crack, and the cost of construction and transportation is high, so that no maintenance is required, Reduce the cost and period, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

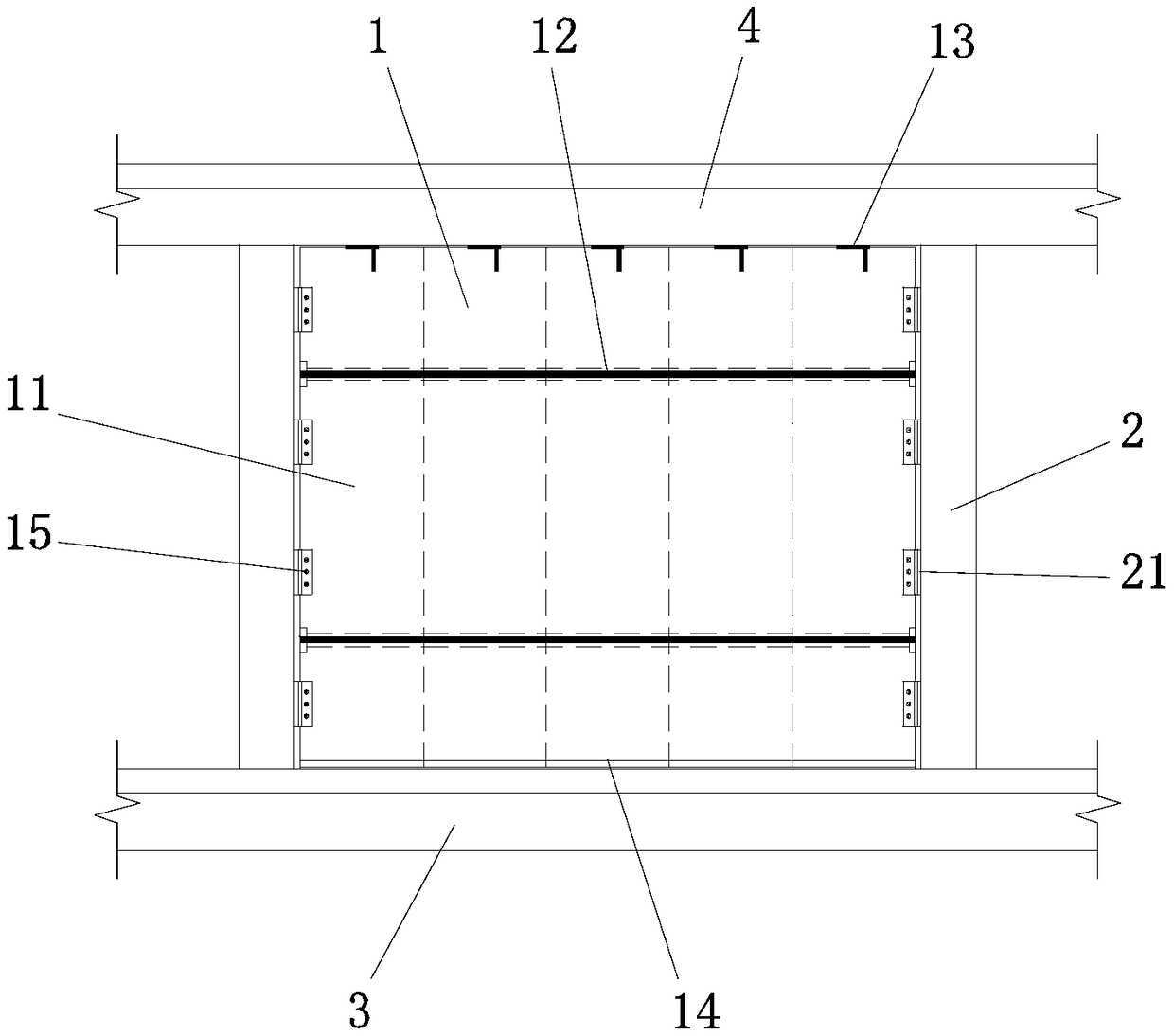

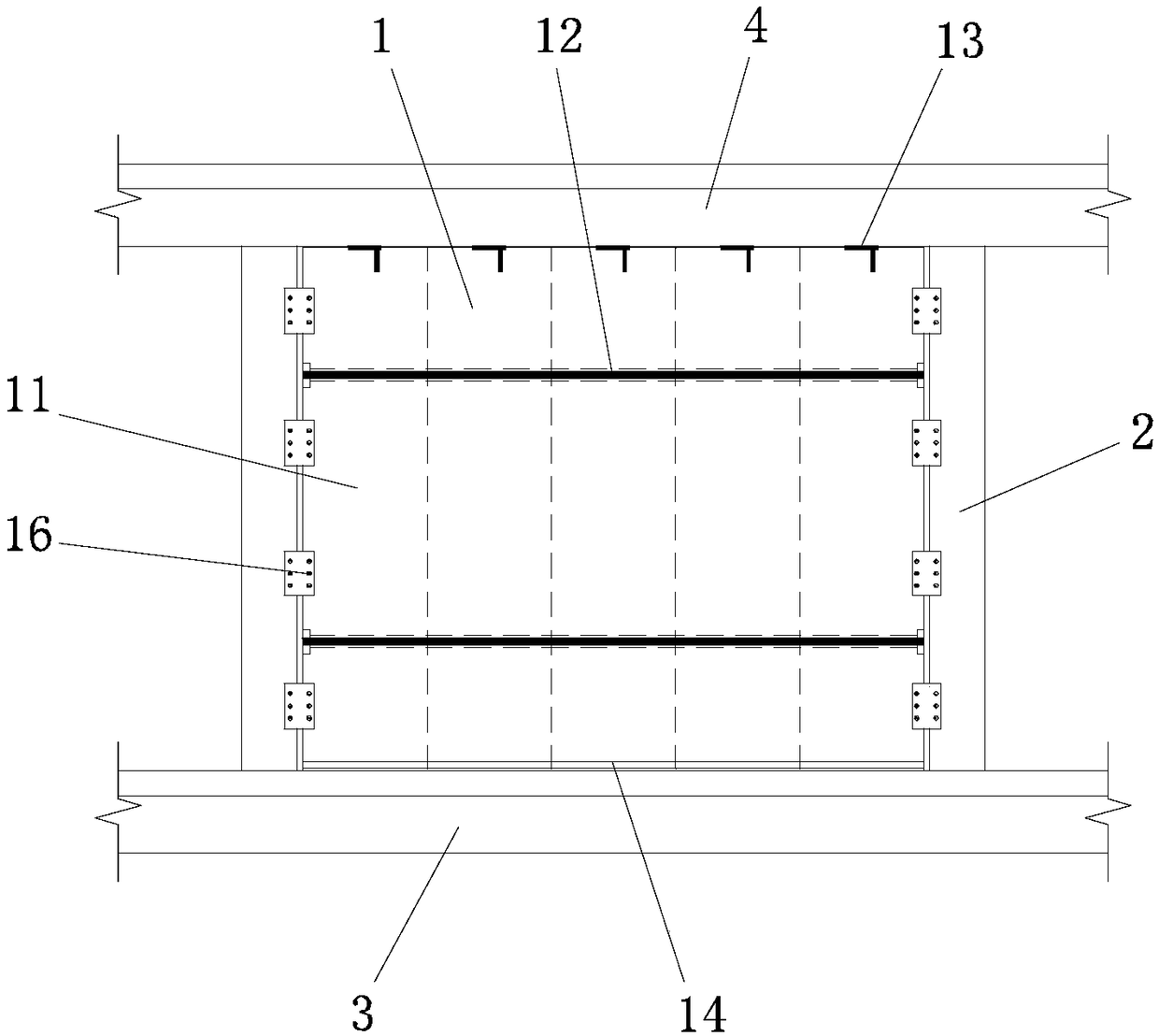

[0042] combined with figure 1 And attached figure 2 As shown, an autoclaved aerated concrete slab exterior wall related to the present invention includes an integral wall panel 1 , a frame column 2 , a lower main structure 3 and an upper main structure 4 .

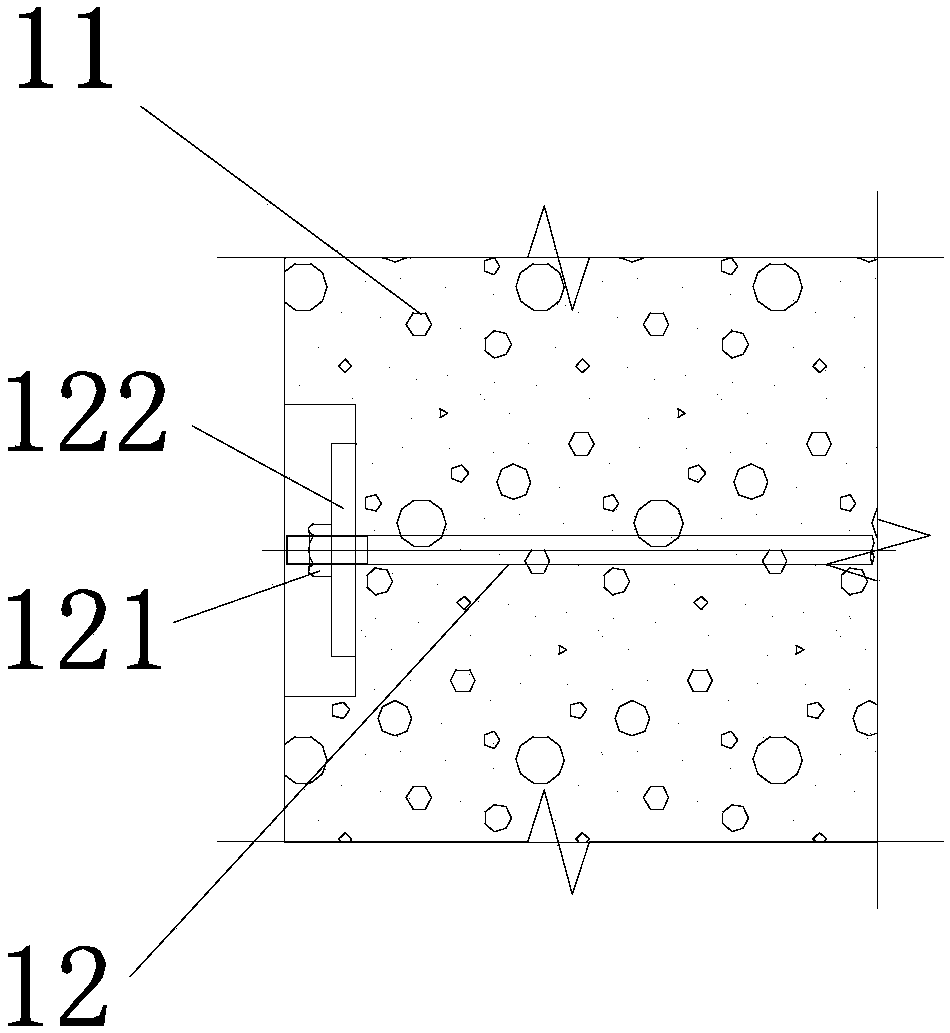

[0043] The integral wall panel 1 is formed by connecting several vertically arranged autoclaved aerated concrete slabs 11 sequentially, and the adjacent autoclaved aerated concrete slabs 11 are bonded and connected by an adhesive. The aerated concrete slabs 11 are provided with locking screw holes corresponding to each other. After the autoclaved aerated concrete slabs 11 are assembled and bonded firmly, tensioned steel bars 12 are inserted into the locking screw holes. image 3As shown, the two ends of the tensioning steel bar 12 are locked by the gasket 122 and the nut 121, and the tensioning steel bar 12 makes each autoclaved aerated concrete slab 11 form a whole.

[0044] The top of the integral wallboard 1 is provi...

Embodiment 2

[0050] What this embodiment sets forth is the construction method of the autoclaved aerated concrete slab exterior wall described in Embodiment 1, which includes the following steps:

[0051] Step 1, constructing the frame column 2 and the lower main structure 3, wherein, when the internal reinforcement cage is tied to the frame column 2, the pre-embedded steel plate 21 is welded on the outer ring of the reinforcement cage, the frame column 2 is molded and cast, and the formwork is removed after maintenance , the embedded steel plate 21 is formed on the surface of the frame column 2, and the embedded steel plate 21 is used for installing the integral wallboard;

[0052] Step 2: prepare a plurality of autoclaved aerated concrete slabs 11 of the same size, drill holes at the positions of the tensioned steel bars 12 to form tensioned steel bar holes, splice the autoclaved aerated concrete slabs 11 in the factory, and bond them with an adhesive Assemble the integral wallboard 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com