All-solid-state battery with silicon negative electrode and sulfide solid electrolyte

A solid electrolyte, all-solid-state battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing battery energy density, SEI film thickness, and large lithium consumption of lithium-ion batteries, and improve electrical contact stability. improve the bonding tightness and reduce the effect of cracking and pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

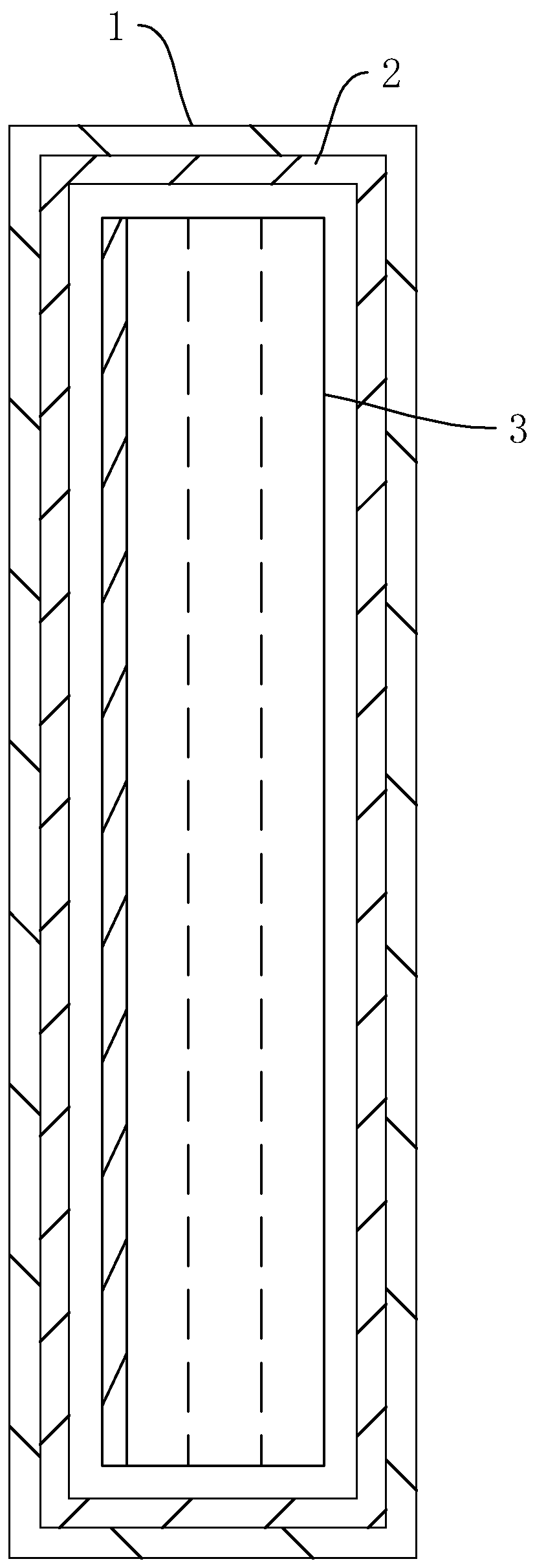

[0043] as attached figure 1 As shown, an all-solid-state battery with a silicon negative electrode and a sulfide solid electrolyte includes a casing 1 , an aluminum-plastic film 2 and a cell 3 . The battery cell 3 is covered with the aluminum-plastic film 2 and housed in the casing 1 . The shapes of the aluminum-plastic film 2 and the casing 1 can be determined according to the shape and size of the electric core 3 in the actual situation, which is not an inventive point of the present invention, so it will not be described in detail here.

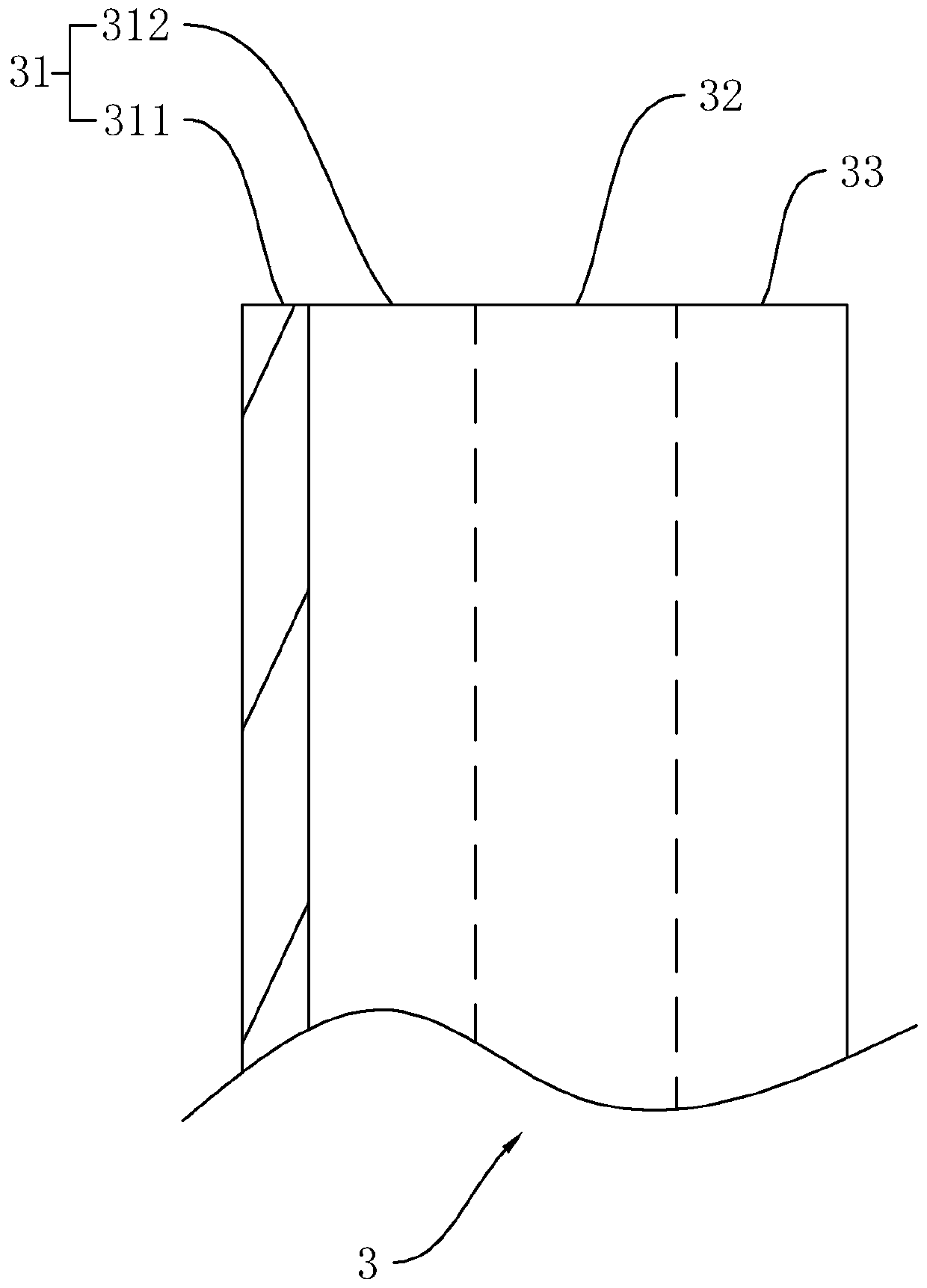

[0044] as attached figure 2 As shown, the cell 3 includes a negative electrode 31 , a solid electrolyte layer 32 and a positive electrode 33 .

[0045] The negative electrode 31 includes a current collector 311 and a lithium intercalation layer 312 . The current collector 311 is a conductive material, which can be determined according to actual design requirements. Here, it is copper foil with a thickness of 8 μm.

[0046] The lithium...

Embodiment 2~4

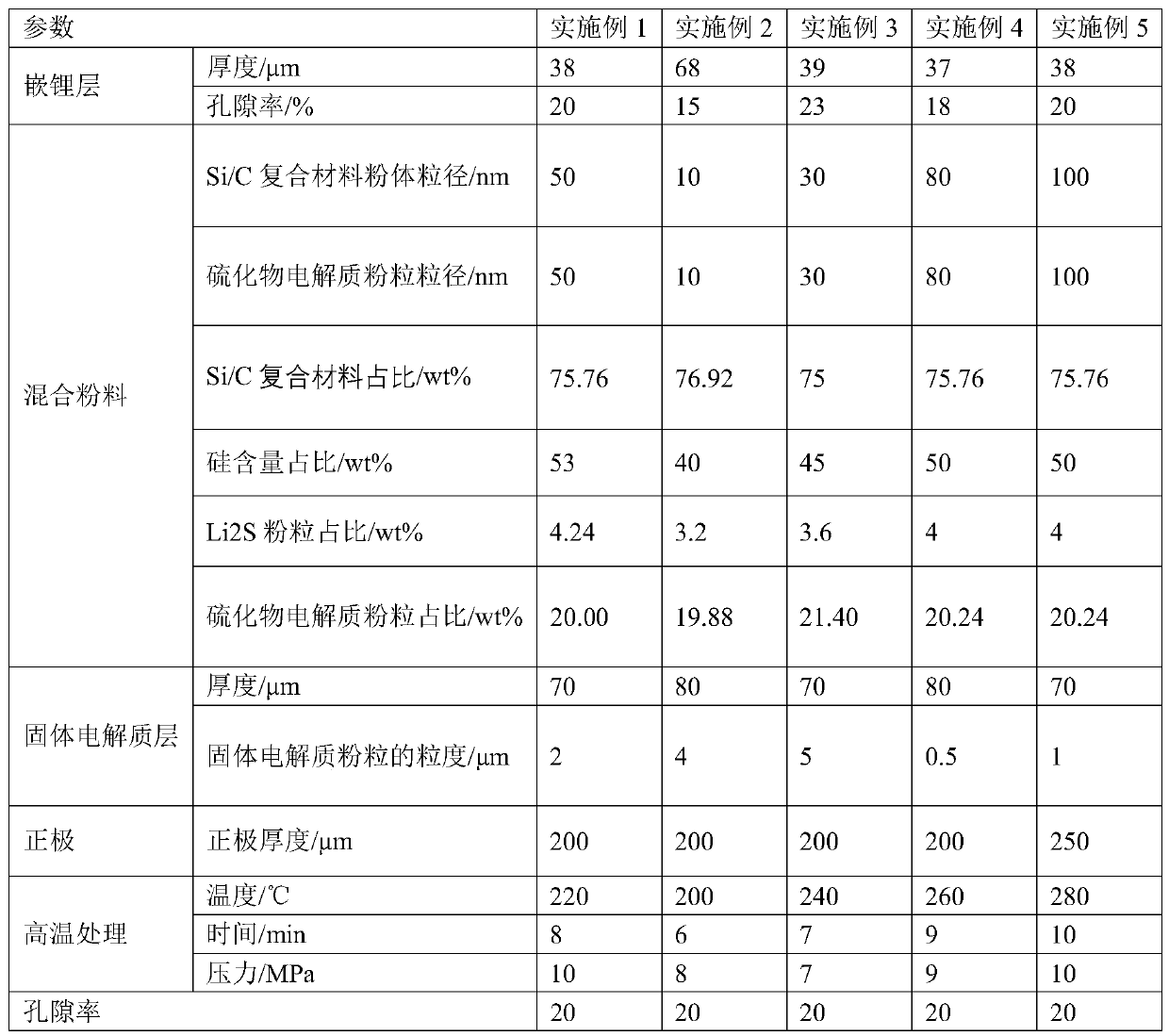

[0062] An all-solid-state battery with a silicon negative electrode and a sulfide solid electrolyte. On the basis of Example 1, the parameters are adjusted to obtain Examples 2-5. The parameters of Examples 1-5 are shown in Table 1.

[0063]

Embodiment 5

[0088] Example 5 uses silicon-containing negative electrode material particles with a large size of 100 nm, and its initial discharge capacity and capacity retention rate are significantly inferior to those of Examples 1 to 4 that use small-sized silicon-containing negative electrode material particles. The preferred Si particle size of this application is 50 ~100 nm, and more preferably 50 nm.

[0089] Example 2 uses a very small amount of Li 2 S-coated electrolytes are used for lithium supplementation. Due to insufficient lithium supplementation, although the capacity retention rate is relatively excellent, its initial discharge capacity is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com