An all-solid-state battery with silicon anode and sulfide solid electrolyte

A solid electrolyte and all-solid-state battery technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reduced significance of commercial application of silicon negative batteries, limited improvement of battery energy density, and uneven distribution of silicon surface conductivity. Uniformity and other issues to achieve the effect of improving electrical contact stability, reducing interface impedance, and reducing expansion and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] as attached figure 1 As shown, an all-solid-state battery with a silicon negative electrode and a sulfide solid electrolyte includes a casing 1 , an aluminum-plastic film 2 and a cell 3 . The battery cell 3 is covered with the aluminum-plastic film 2 and housed in the casing 1 . The shapes of the aluminum-plastic film 2 and the casing 1 can be determined according to the shape and size of the electric core 3 in the actual situation, which is not an inventive point of the present invention, so it will not be described in detail here.

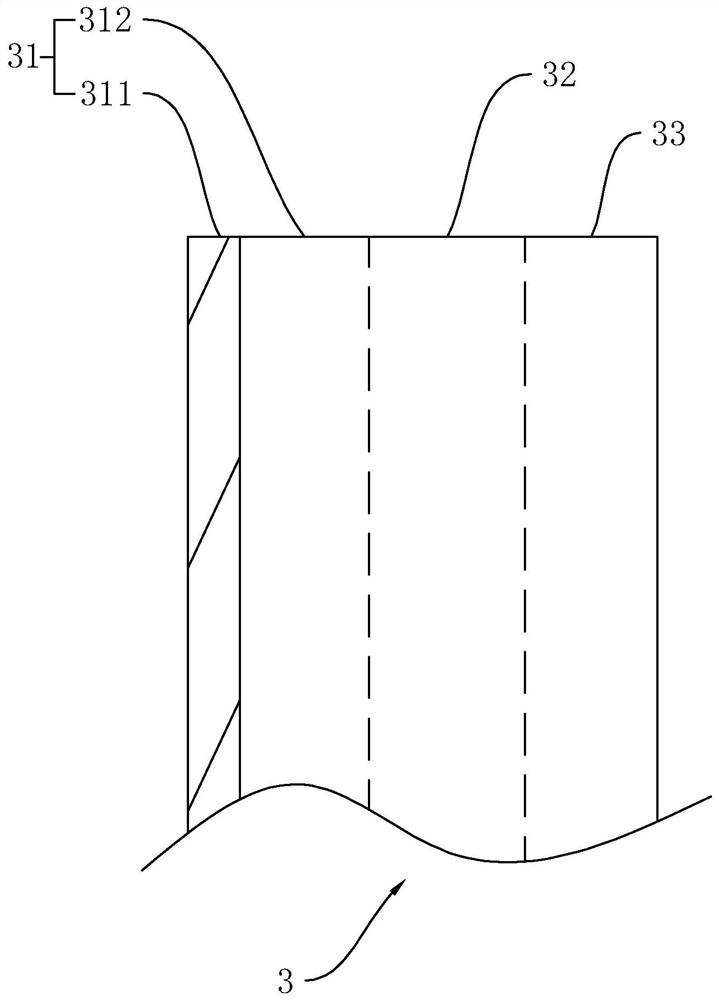

[0044] as attached figure 2 As shown, the cell 3 includes a negative electrode 31 , a solid electrolyte layer 32 and a positive electrode 33 .

[0045] The negative electrode 31 includes a current collector 311 and a lithium intercalation layer 312 . The current collector 311 is a conductive material, which can be determined according to actual design requirements. Here, it is copper foil with a thickness of 8 μm.

[0046] The lithium...

Embodiment 2~4

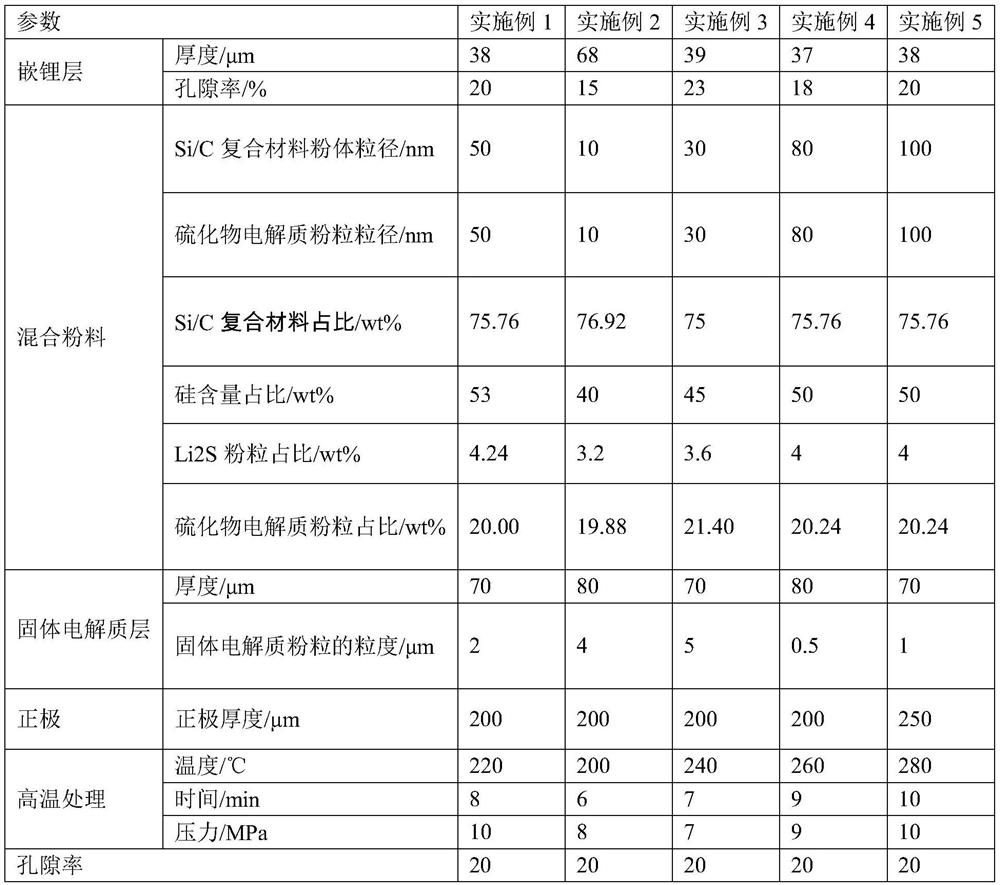

[0061] Examples 2-4, an all-solid-state battery with a silicon negative electrode and a sulfide solid electrolyte, based on Example 1, the parameters are adjusted to obtain Examples 2-5. The parameters of Examples 1-5 are shown in Table 1.

[0062]

Embodiment 5

[0084] Example 5 uses silicon-containing negative electrode material particles with a large size of 100 nm, and its initial discharge capacity and capacity retention rate are significantly inferior to those of Examples 1 to 4 that use small-sized silicon-containing negative electrode material particles. The preferred Si particle size of this application is 50 ~100 nm, and more preferably 50 nm.

[0085] Example 2 uses a very small amount of Li 2 S-coated electrolytes are used for lithium supplementation. Due to insufficient lithium supplementation, although the capacity retention rate is relatively excellent, its initial discharge capacity is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com