Concrete face for rockfill dam

A technology for concrete face slabs and rockfill dams, which is applied in dams, barrages, and weirs, etc., can solve the problems of easy cracking of the dam's peripheral joints, cracking of the face plate joints, leakage, landslides, etc. The effect of reducing the possibility of dislocation and the possibility of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with specific embodiment:

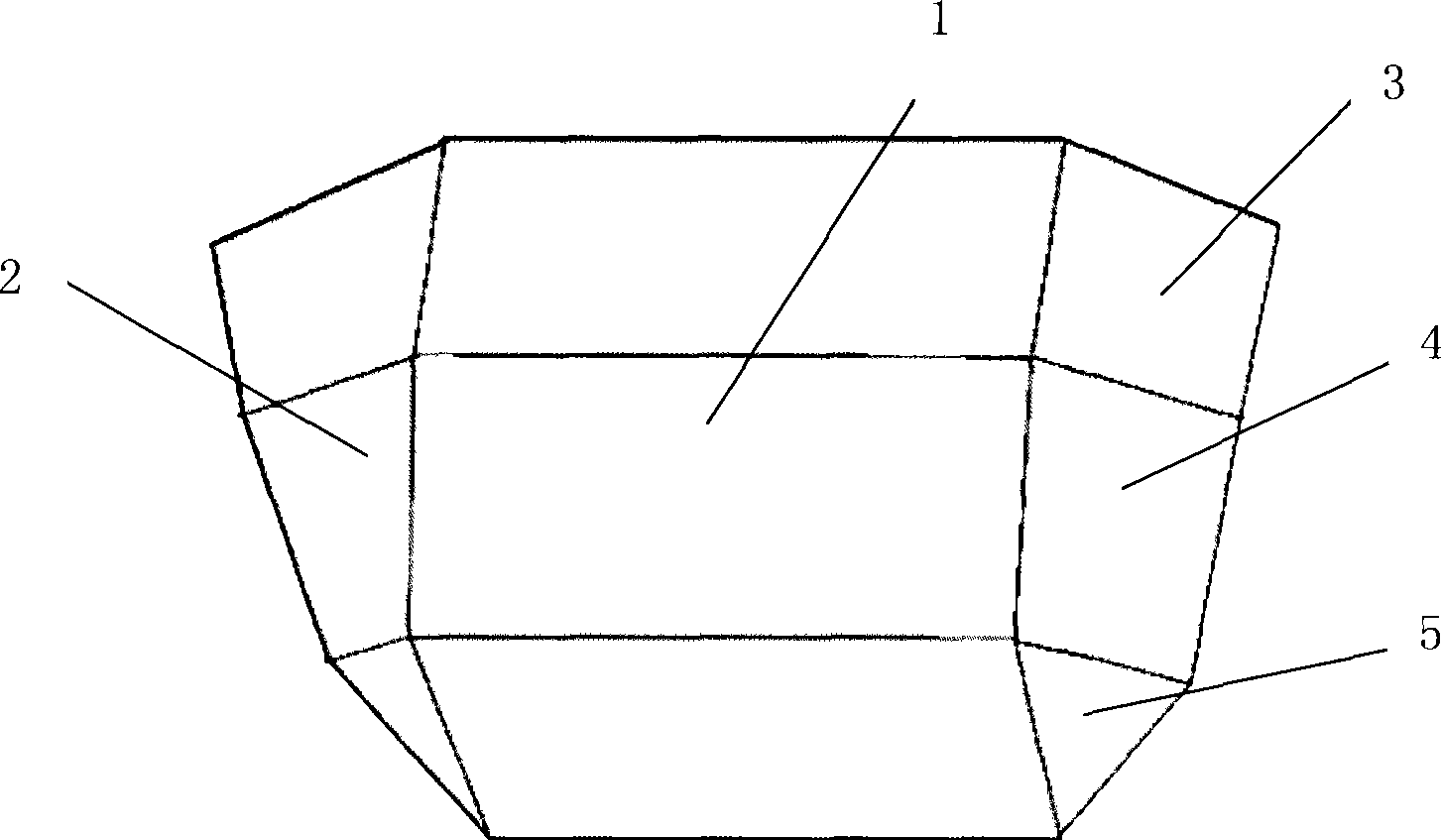

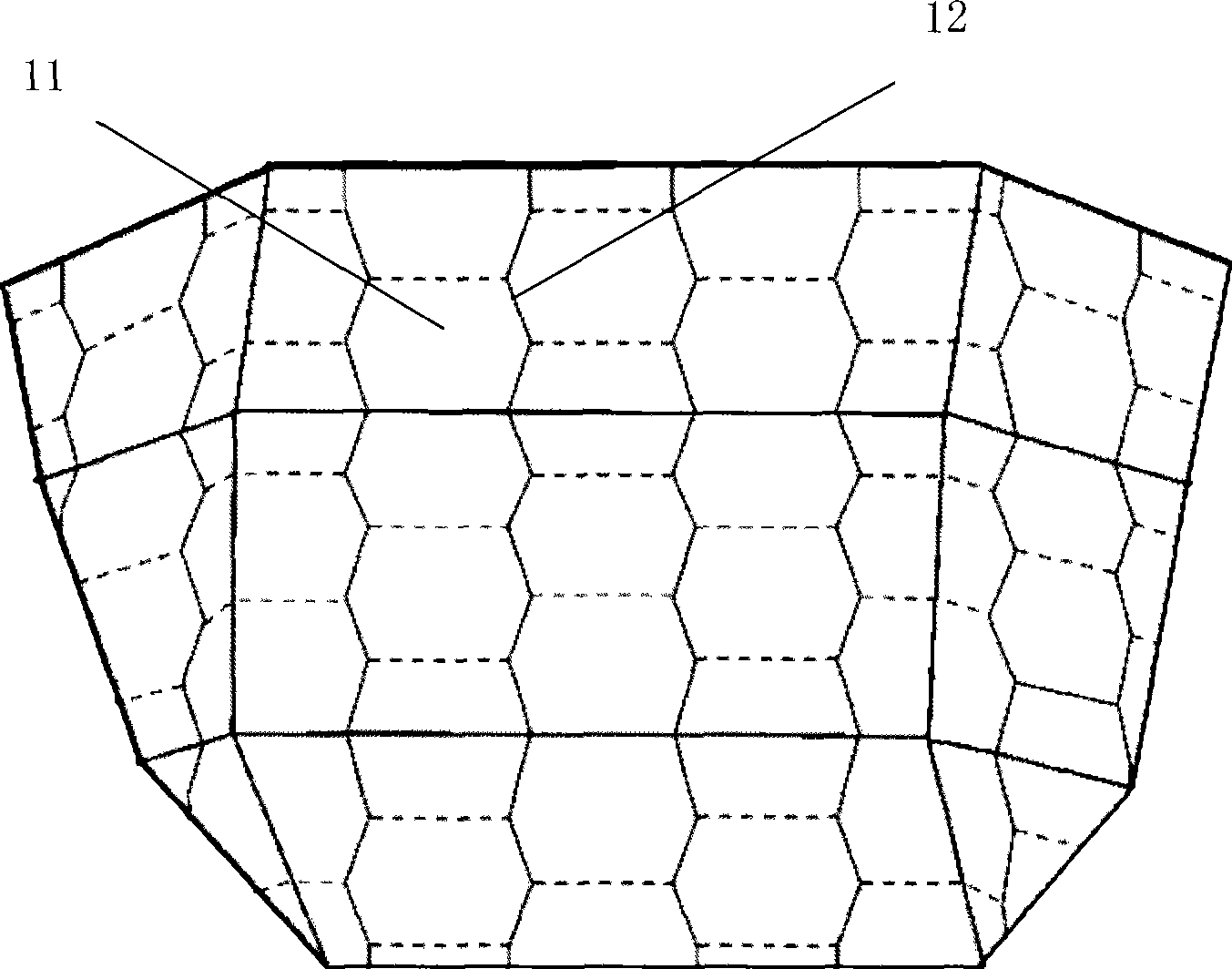

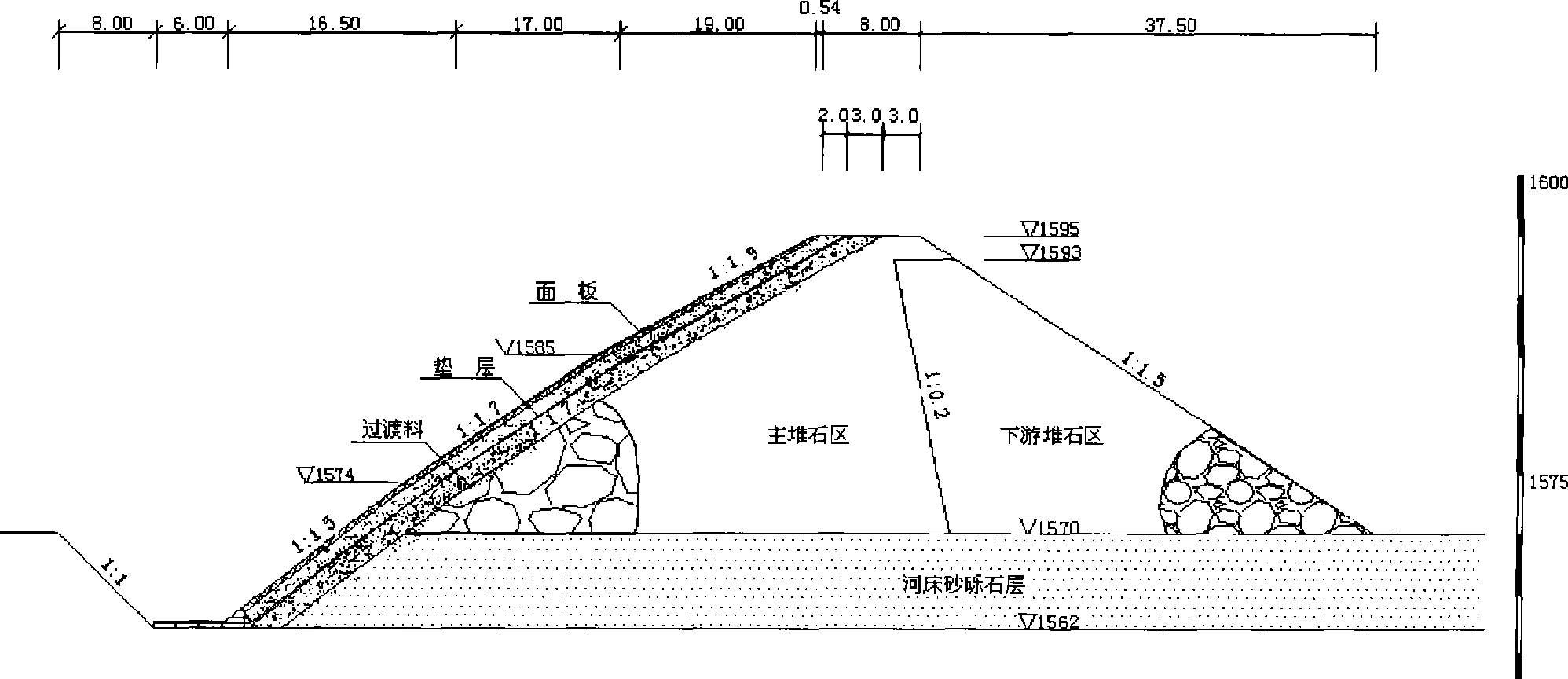

[0026] Taking Dakai Power Station as an example, the concrete panel of Dakai Power Station is designed as three flat panels, and the three flat panels are bow-shaped. The arch is composed of the main plate part 1 in the middle and the rib plate parts 2 on both sides. From the perspective of reasonable force analysis, the structure of circular arc or elliptical arc is the most reasonable force, and considering the needs of construction, the main plate part 1 and The rib plate part 2 is designed as a plane type, the schematic diagram is shown in figure 1 , it consists of two side rib parts 2 and a main board part 1 arranged between the two side rib parts 2, and each part (the main board part and the rib part) is divided into upper 3, middle 4 and lower 5 three pieces, Each piece is a flat plate, forming a bow shape with each other; the angles between the main board part 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com