Fuel oil and fuel gas oxygen rich mixed combustion nozzle for oxygen rich local oxygenation jet combustion supporting

A technology of oxygen-enriched gas and fuel nozzles, which is applied in the field of burner nozzles and fuel gas oxygen-enriched mixed combustion nozzles. It can solve the problems of many side effects, different positions and angles, and large investment in oxygen-increasing and combustion-supporting, so as to improve the efficiency of combustion heat radiation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

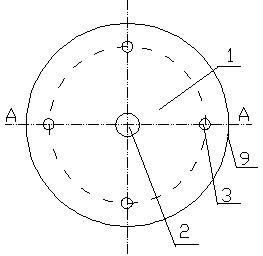

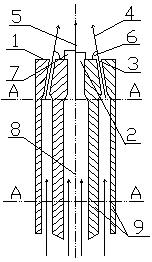

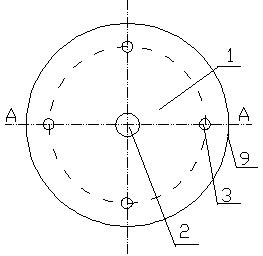

[0016] exist figure 1 In the embodiment shown in —2: the oxygen-enriched gas nozzle hole 2 and the fuel nozzle hole 3 are in the same spray gun 9, and the shower head of the spray gun 9 becomes a plane and is perpendicular to the spray gun 9, and the center of the spray gun 9 is the oxygen-enriched gas nozzle hole 2, surrounding A number of fuel nozzle holes 3 are evenly distributed around the oxygen-enriched gas nozzle hole 2. The central axis 4 of the fuel nozzle hole and the central axis 8 of the spray gun form an inward angle of 0o~10o, that is, the central axis 4 of the fuel nozzle hole and the plane of the spray gun head 1 into an inward 90o~80o included angle, so that the fuel stream sprayed from the fuel nozzle hole 3 can gather to form an oxygen-lean combustion flame after leaving the spray gun 9 for a certain distance, and the oxygen-lean combustion flame area A large amount of carbon monoxide can be formed; after the oxygen-enriched gas is input from the center of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap