Heliostat calibration system of solar power station and calibration method

A calibration system and heliostat technology, applied in the field of solar power generation, can solve the problems of complex calibration action of the heliostat calibration system, and achieve the effects of fast calibration action, small mechanical error and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

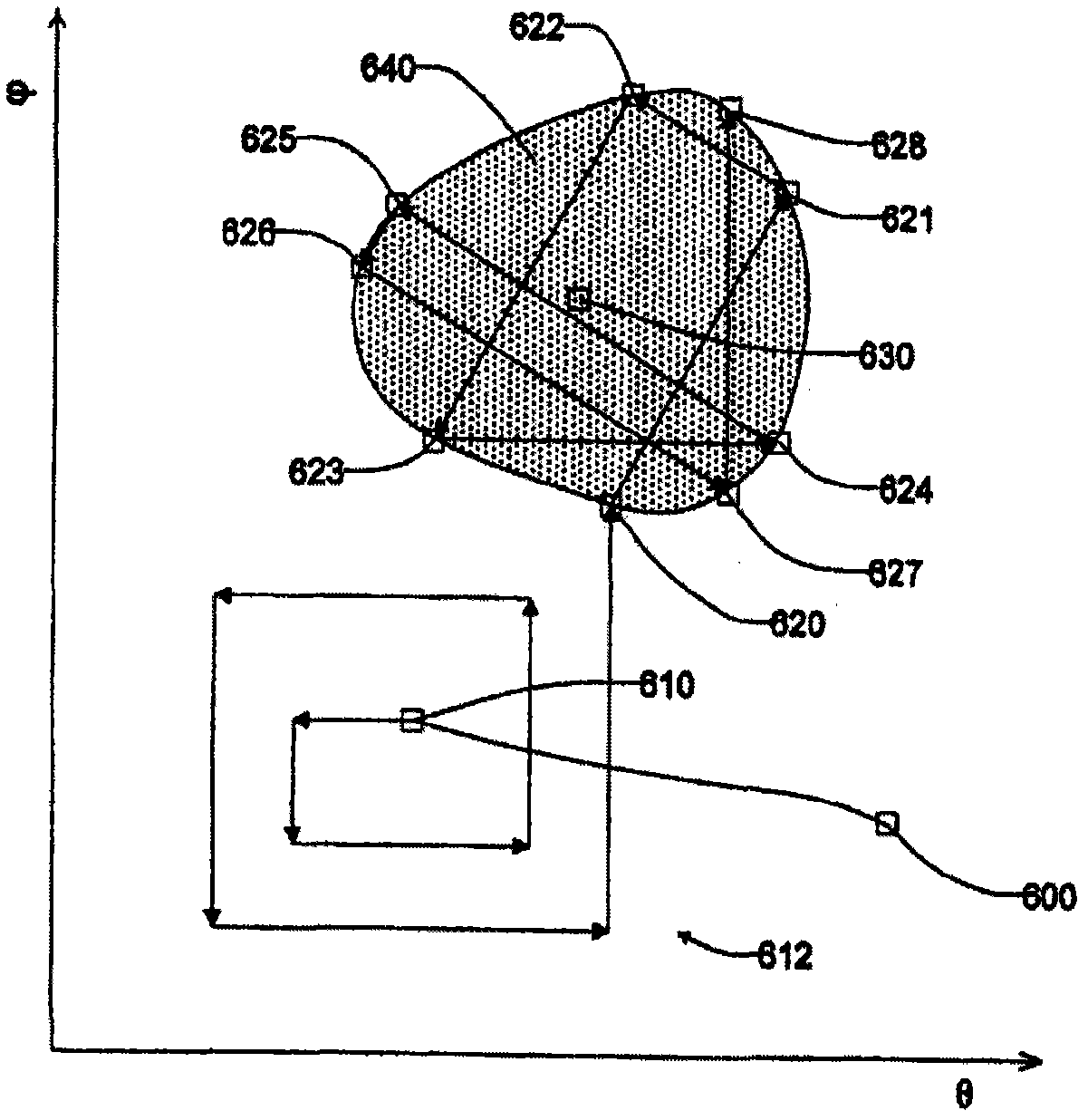

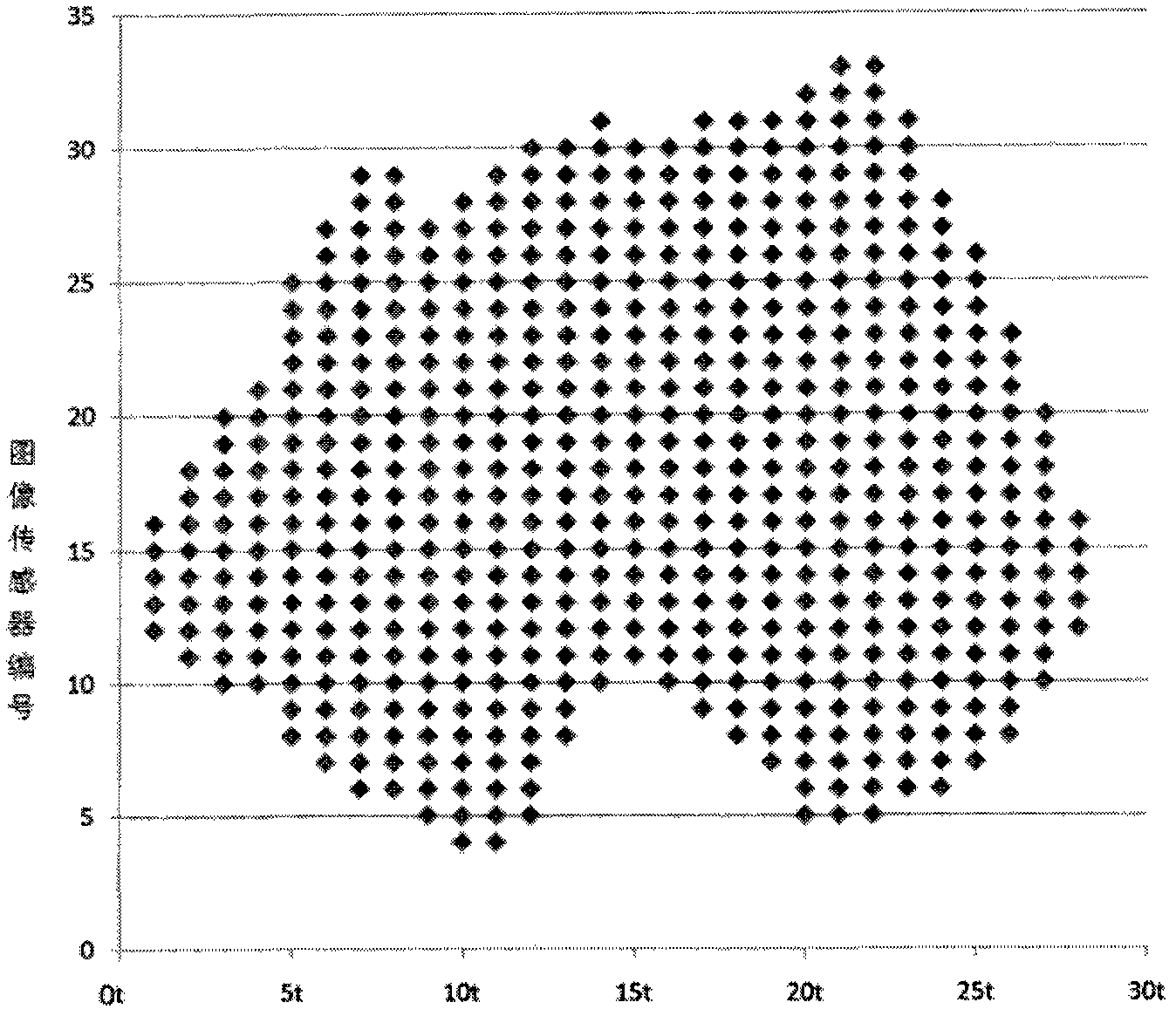

Method used

Image

Examples

Embodiment 1

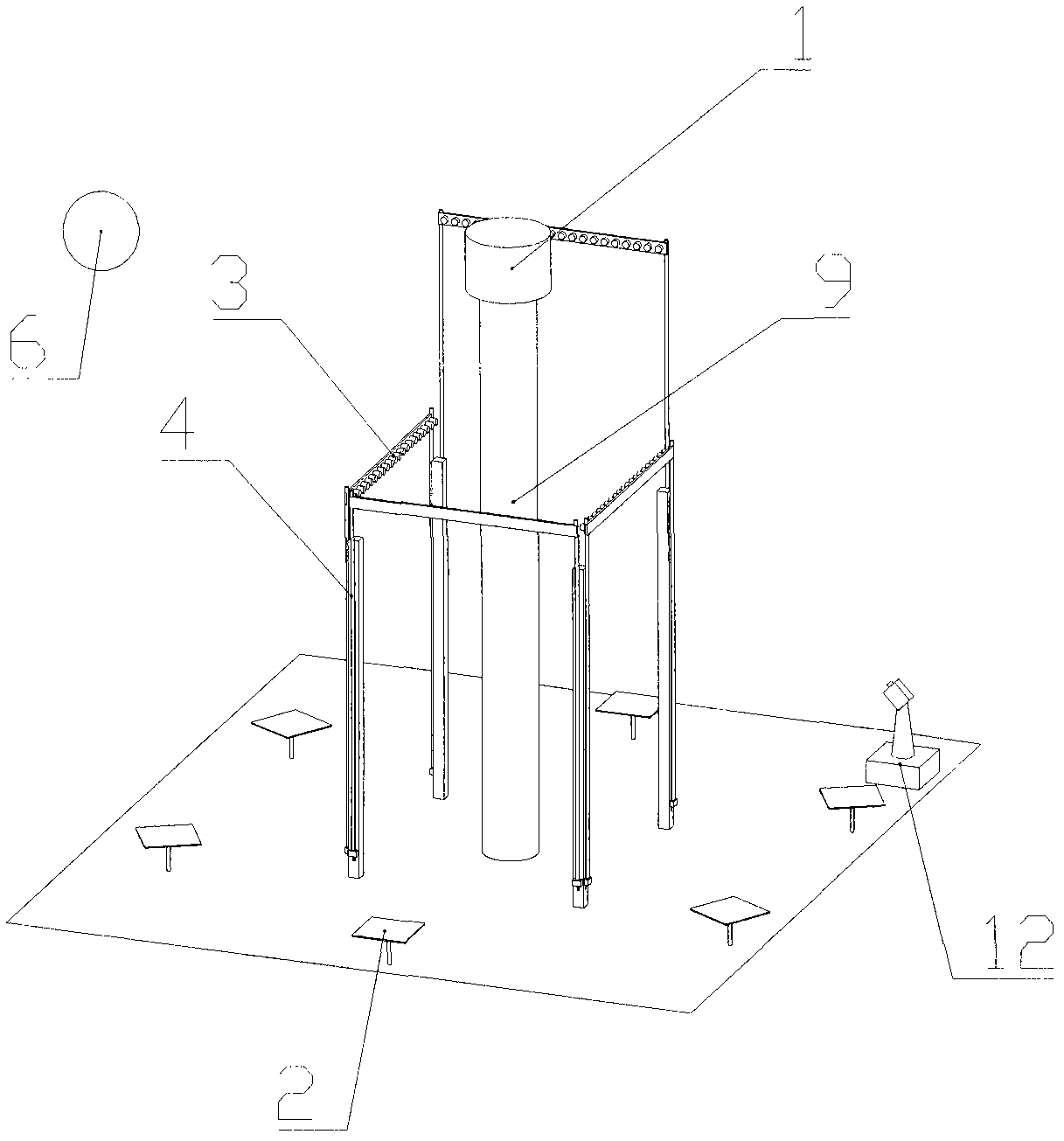

[0049] figure 2 Shown is a heliostat calibration system for a solar power plant, which includes a receiver 1 mounted on a support tower 9 that receives sunlight reflected by a heliostat 2 to directly generate steam or electricity; The height of the receiver 1 from the ground ensures that all the heliostats 2 in the heliostat field can be reflected onto the receiver 1 .

[0050] It also includes a heliostat field installed around the receiver; the heliostat field includes at least one heliostat 2; the heliostat 2 is configured with two rotation axes, and the heliostat 2 revolves The rotating shaft performs pitching rotation and panning rotation; the dual rotating shafts are equipped with angle sensors, which are used to accurately measure the actual pitching angle that the two rotating shafts rotate through and the pan angle ω. The heliostat 2 tracks the moving sun by adjusting the orientation of the mirror, so that the sunlight is continuously reflected to the receiver 1 ....

Embodiment 2

[0079] Figure 8 Shown is the heliostat calibration system of this embodiment. The difference between this calibration system and the calibration system in Embodiment 1 is that the heliostat field in this embodiment is located at one side of the receiver 1 . The image sensor group is fixedly mounted on a fixed mounting bracket 7 around the receiver 1 . The collection range is all the reflected light spots of the heliostat that do not irradiate the receiver 1 . The image sensors are evenly arranged on the fixed mounting bracket 7 , and in this embodiment, the image sensors are evenly arranged vertically and horizontally.

[0080] When the error of the heliostat is small, it is only necessary to calibrate the pitch angle and pan angle error of the heliostat. In this embodiment, the errors that need to be calibrated are: the pitch angle and pan angle of the heliostat error, the calibration process of the heliostat calibration system includes the following steps:

[0081] a. Th...

Embodiment 3

[0088] Figure 9 It is the heliostat calibration system in this embodiment, which is basically the same as the calibration system in Embodiment 1. The difference is that the image sensor 3 is mounted on the rotating mounting bracket 8 so that it can move up and down, and the image sensor 3 Arranged along the horizontal direction and its collection surface is set facing the receiver 1 , the rotating mounting bracket 8 can rotate around the supporting tower 9 of the receiver. The control unit obtains the central position of the light spot reflected by the heliostat through the up and down movement and rotation of the image sensor group.

[0089] The heliostat is equipped with two rotation axes X-axis and Y-axis parallel to the horizontal plane, and the heliostat performs pitch rotation around the two rotation axes respectively; the two rotation axes are respectively equipped with angle sensors for It is used to accurately determine the pitch angle through which the two rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com