Calibration device, method, and program for onboard camera

A calibration device and camera technology, applied in optical observation devices, vehicle parts, transportation and packaging, etc., can solve the problems of unstable calibration accuracy and time required for calibration by operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

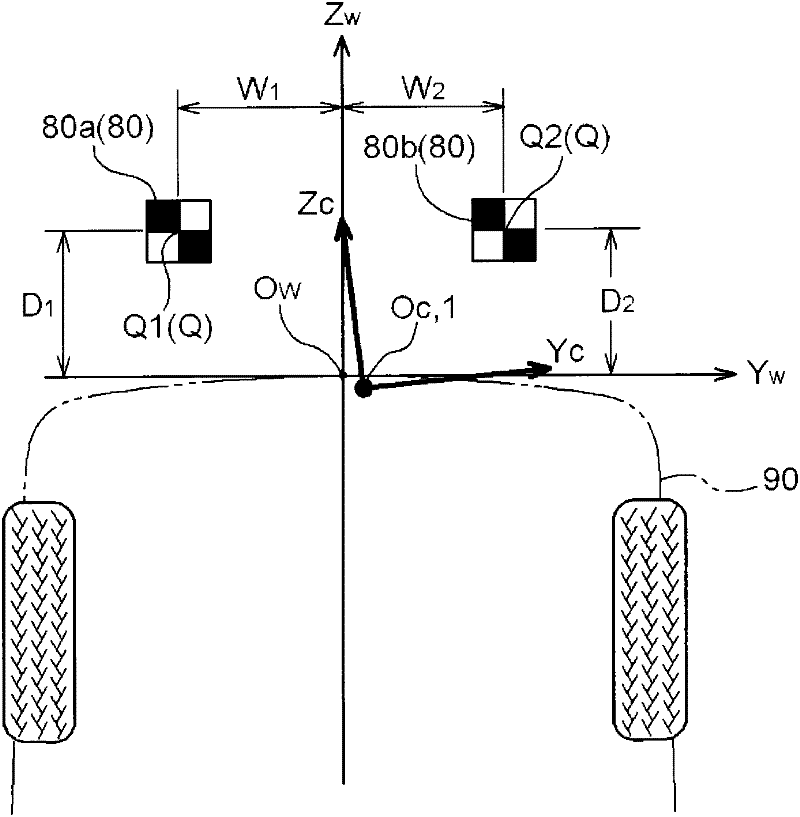

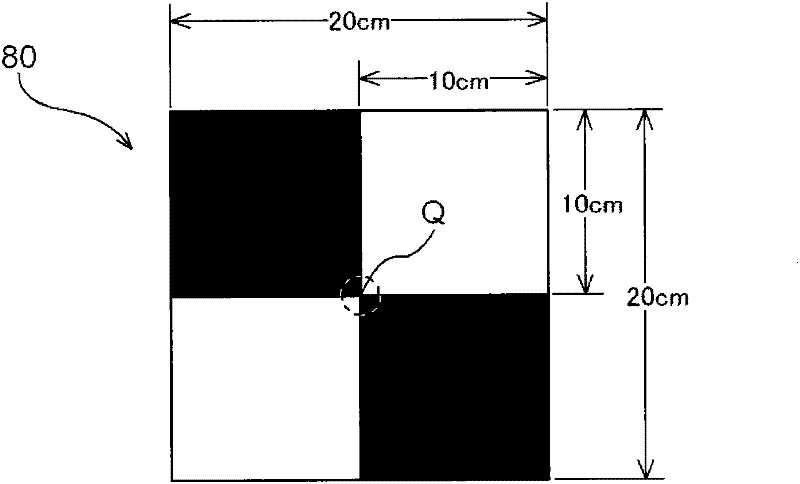

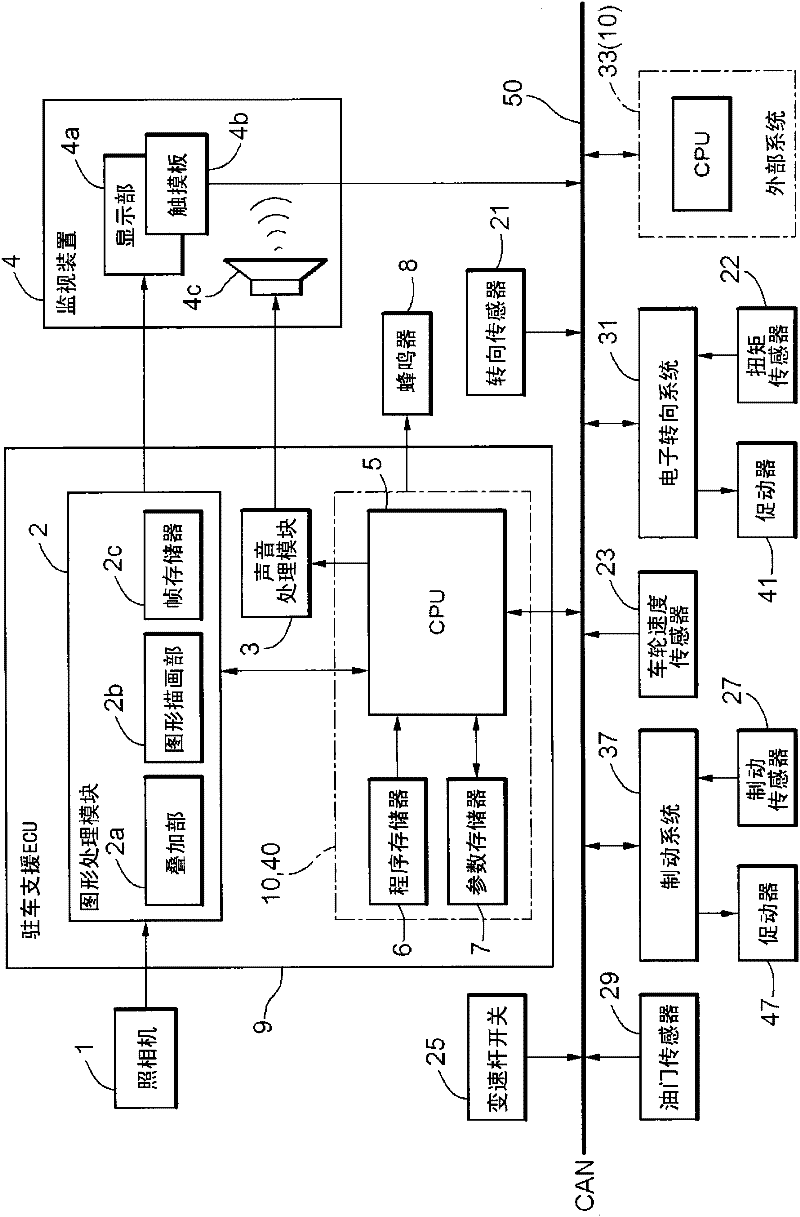

[0112] Next, an embodiment of the calibration device of the present invention will be described based on the drawings, taking as an example the calibration of the camera 1 (vehicle camera) that photographs the scene behind the vehicle 90 . The camera 1 (vehicle camera) is arranged behind the vehicle 90 above the license plate and at a position offset laterally from the vehicle axis, with its optical axis directed downward (for example, 30° downward from the horizontal). The camera 1 has, for example, a wide-angle lens with an angle of view of 110° to 120°, and can capture an area approximately 8 m behind. The camera 1 is calibrated for the purpose of absorbing mounting errors when it is mounted on the vehicle 9 in a vehicle production plant or the like. In addition, this correction is also used in a repair shop or the like to correct the deviation of the camera 1 due to the accumulation of running vibrations, impacts, and the like.

[0113] Such as figure 1 As shown, in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com