Uniform material distribution apparatus of color sorter

A technology of uniform cloth and color sorting machine, applied in sorting and other directions, can solve problems such as the influence of employee operation level, hidden dangers of cloth safety, and noise hazards of operators, so as to avoid unsafety, improve work efficiency, and improve color sorting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

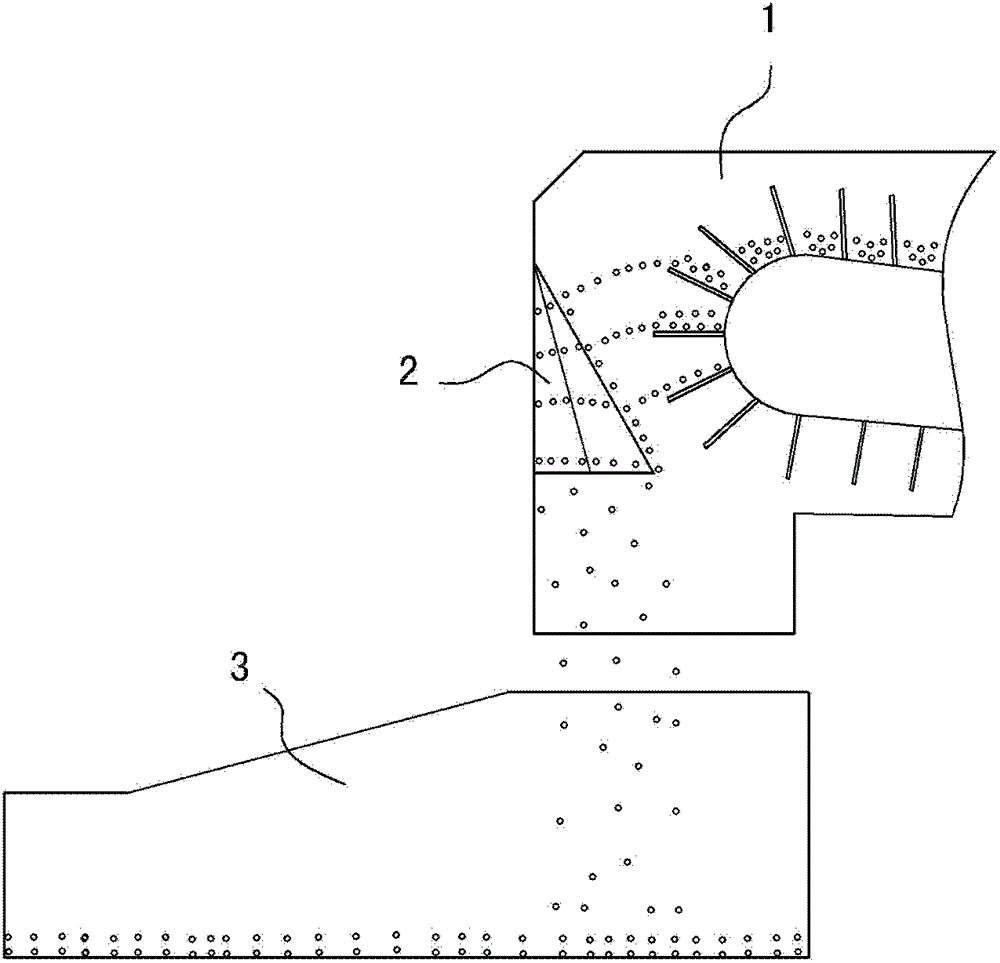

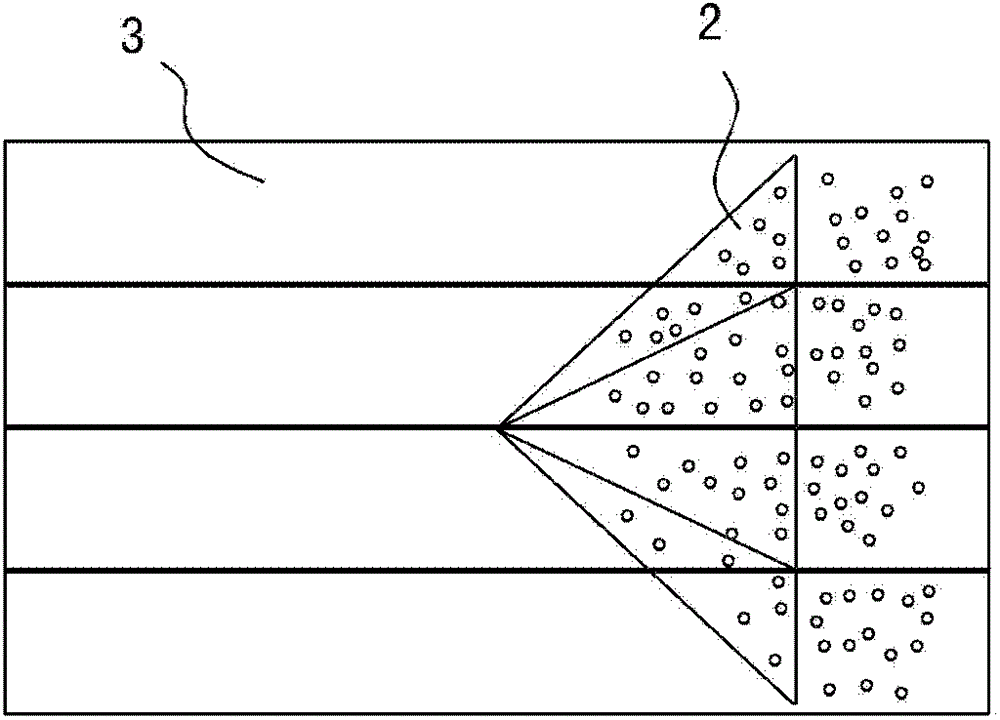

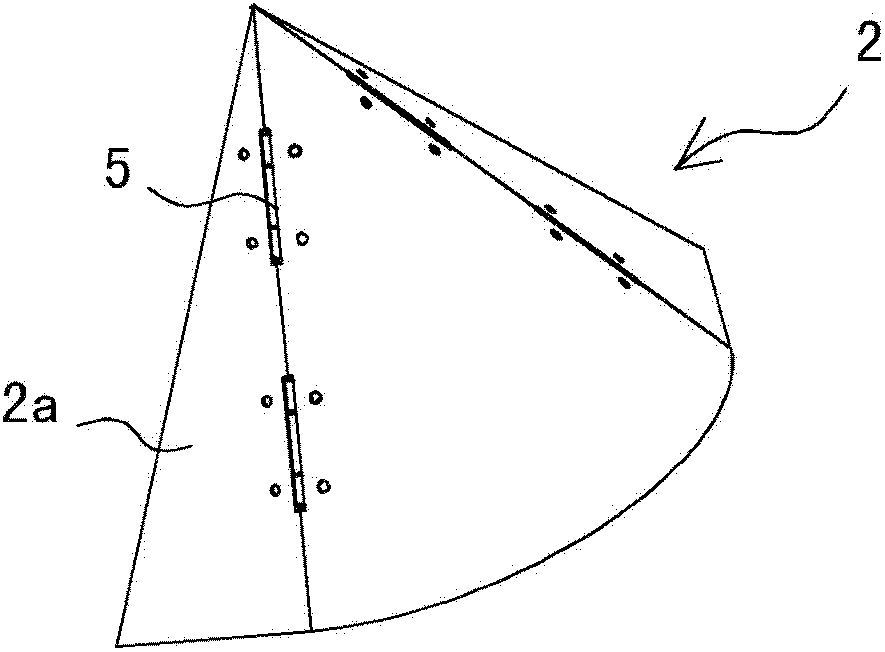

[0028] see figure 1 , figure 2 and image 3 , the uniform distribution device of the color sorter in this embodiment is to set an umbrella-shaped surface distribution plate 2 on the material falling track of the elevator discharge port 1, and the umbrella-shaped surface distribution plate 2 is used as the blanking of the elevator discharge port. On the receiving surface, the blanking falls through the umbrella-shaped distribution of the umbrella-shaped surface cloth plate 2 and falls in the vibrating hopper 3 that is accepted under the umbrella-shaped surface cloth plate.

[0029] Utilize the gravity and inertial force of the blanking itself, use the umbrella-shaped surface cloth plate 2 as the receiving surface for the blanking of the discharge port of the hoist, and evenly drop to the bottom of the umbrella-shaped surface cloth plate through the umbrella-shaped distribution of the umbrella-shaped surface cloth plate. In the vibrating hopper, no energy is consumed in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com