Device for processing straw

A technology of straw and stirring device, which is applied in non-pollution treatment device and low-carbonization field of straw, which can solve problems such as pollution, no one-time overcoming of straw processing problems, straw odor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

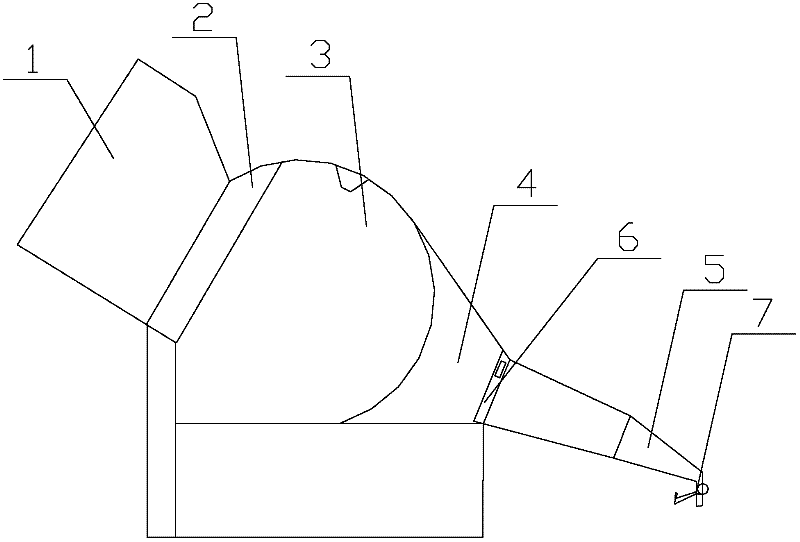

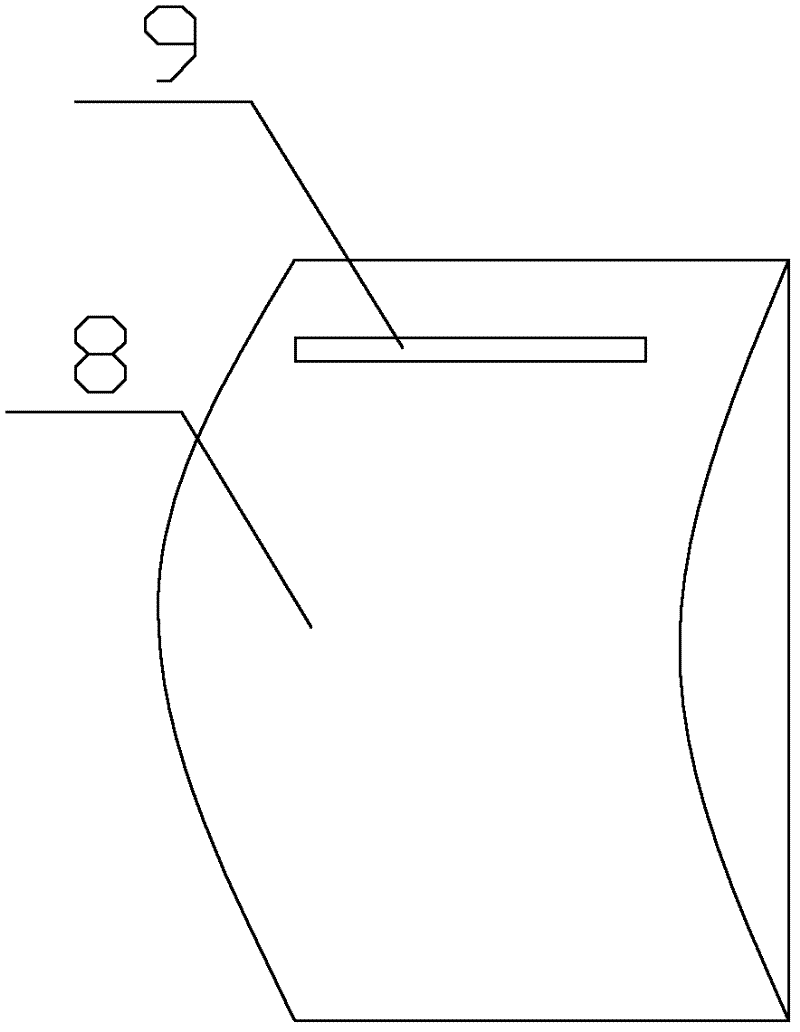

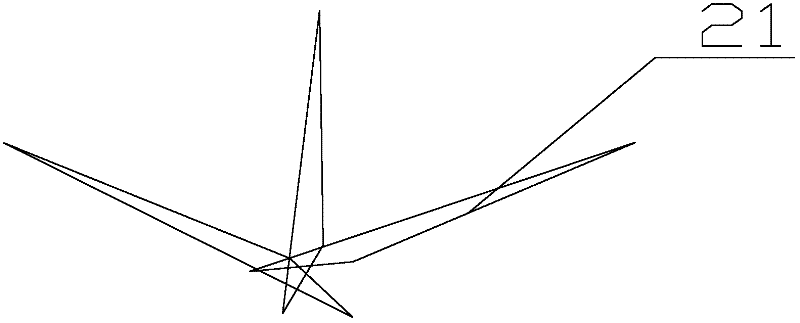

[0015] Such as figure 1 As shown, a device for processing straw includes a feed port 1, the feed port 1 is connected to the stirring device 3 through the cutting assembly 2, the stirring device 3 is connected to the compression device 4, and the cutting assembly 2 is reached by the feed port 1 Stirring device 3 is successively the long cutter 21 of longitudinal installation, and long cutter 21 below is provided with at least 1 pair of rotating blades 22, and below rotating blade 22 is provided with metal grid 23, and the distance between rotating blade 22 and metal grid 23 less than 4 cm. The compression device 4 is connected with a bag filling device 5 , and the capacity of the bag filling device 5 is consistent with that of the bag 8 . The cutting assembly 2 is a combination cutter. The compression device 4 is provided with a volume-limiting baffle 6, and the volume-limiting baffle has an inclination angle of 60 degrees. The bag filling device 5 is provided with a hook 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com