Line-marking tool for numerical control milling machine and line-marking method thereof

A CNC milling machine and engraving technology, which is applied to the engraving tool and its engraving field for CNC milling machines, can solve the problems of lack of CNC milling machine engraving accuracy, low processing efficiency, etc., achieve uniform force, improve processing efficiency, Avoid the effect of overstressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

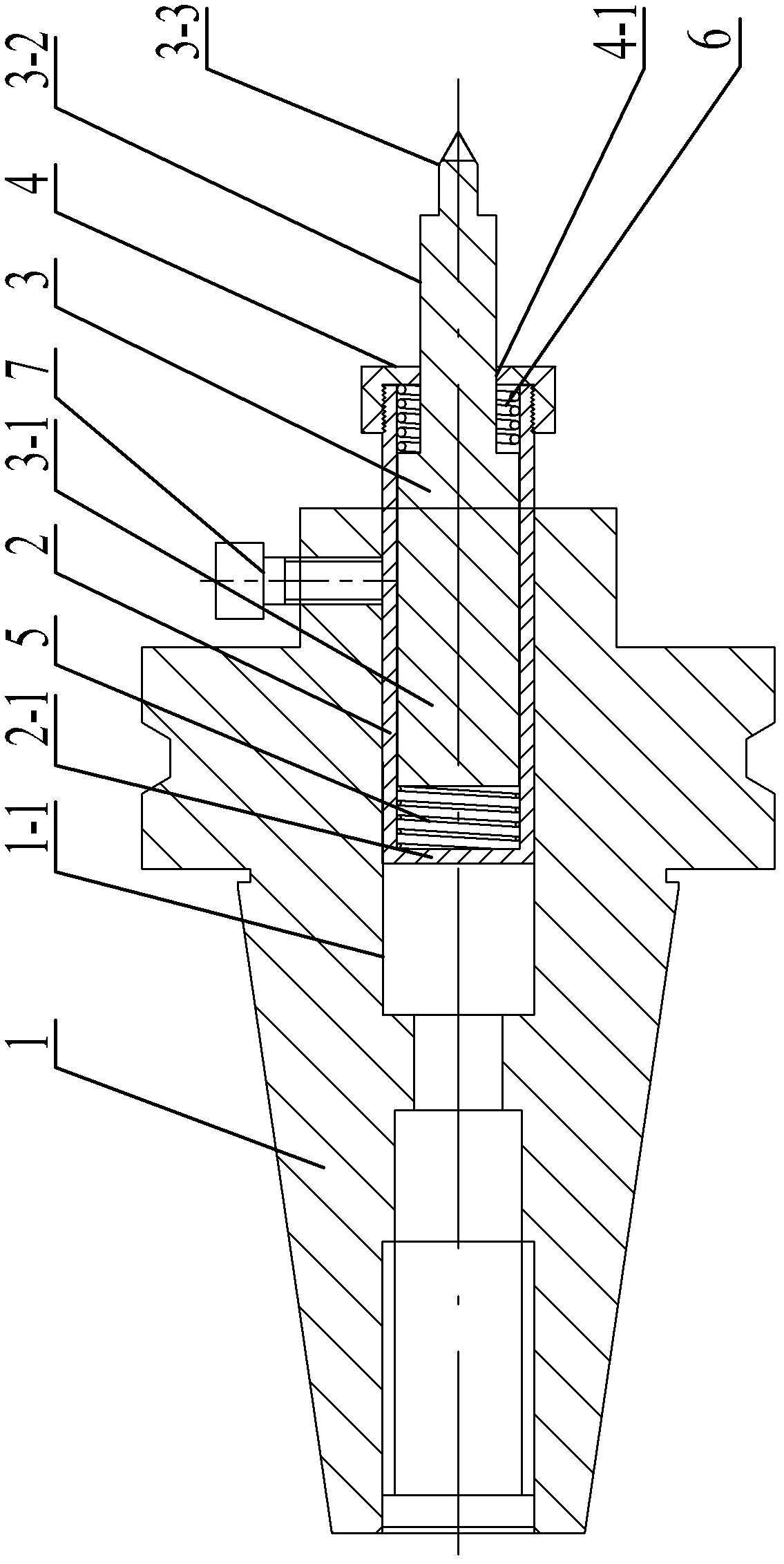

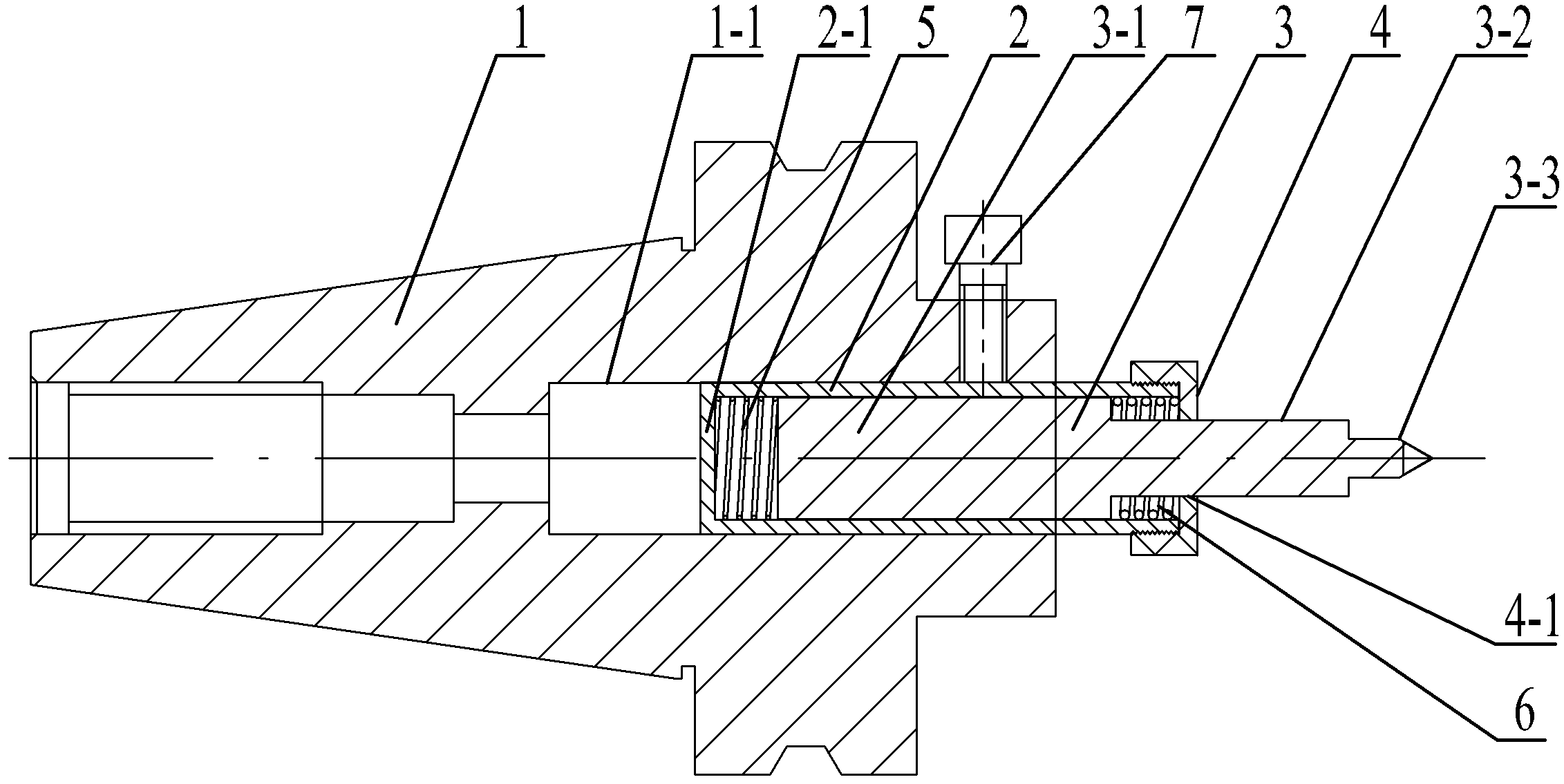

[0018] Specific implementation mode one: as figure 1 As shown, the marking tool for the CNC milling machine of the present embodiment includes a cutter bar 1, a sleeve 2, a marking needle 3, an end cover 4, a first spring 5, a second spring 6 and a locking screw 7, the The tool bar 1 is processed with a stepped through hole 1-1 along the axial direction, and one end of the sleeve 2 is provided with a bottom 2-1, and the bottom end of the sleeve 2 is inserted into the stepped through hole 1-1, and the sleeve 2 passes through the The locking screw 7 is affixed to the cutter bar 1, the first spring 5 is located in the sleeve 2 and one end of the first spring 5 is in contact with the bottom of the cylinder 2-1, and the engraving needle 3 is formed by a large cylindrical section 3-1 , small cylindrical section 3-2 and engraved line head 3-3, the large cylindrical section 3-1, small cylindrical section 3-2 and engraved line head 3-3 are fixed in sequence as one, and the large cylind...

specific Embodiment approach 2

[0019] Specific implementation mode two: as figure 1 As shown, the end cap 4 in this embodiment is screwed to the open end of the sleeve 2 . Designed in this way, it is connected by thread, so it is easy to disassemble. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific Embodiment Three: The engraving head 3-3 in this embodiment is a cemented carbide engraving head. With such a design, the cemented carbide engraving head has high hardness and wear resistance, and has a long service life. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com