Side-by-side distribution-typed oil tank system

A distributed and fuel tank technology, applied in the direction of the fuel tank of the power plant, can solve the problems of aircraft control and trim, the position of the center of gravity of the aircraft, insufficient problems, etc., and achieve the effect of uniform weight distribution of the lateral structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

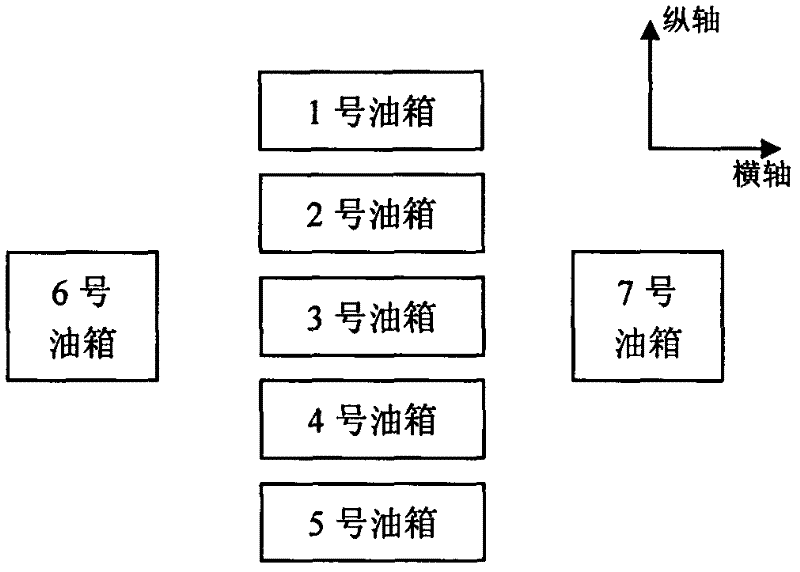

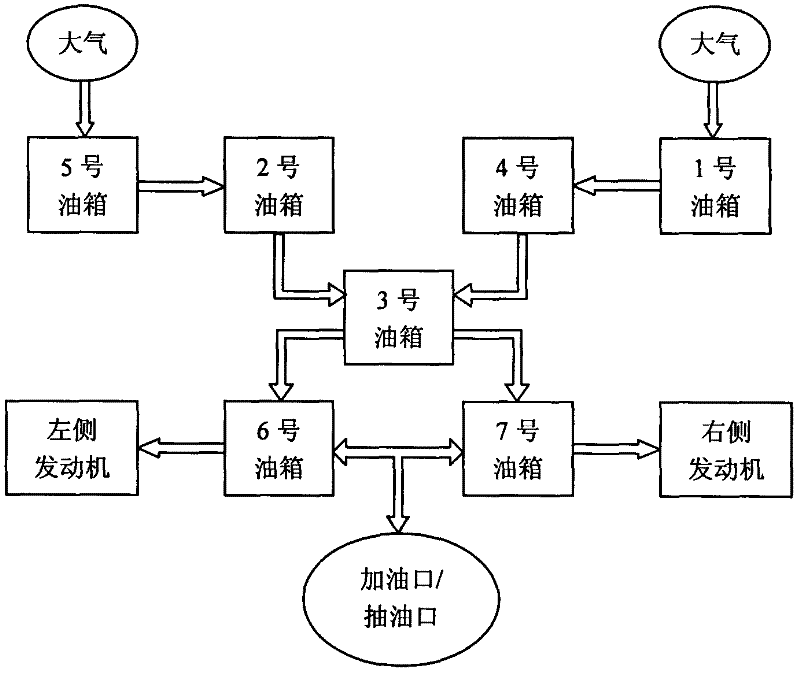

[0021] This embodiment is a fuel system for a small-sized twin-engine turbojet flying-wing unmanned aerial vehicle. The total take-off weight of the aircraft is about 45kg, and the total fuel weight is 11kg.

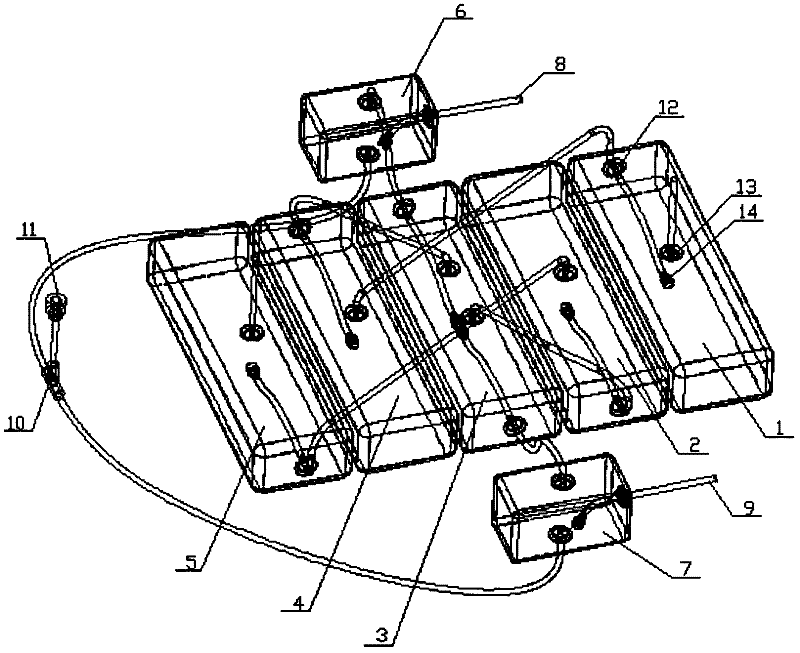

[0022] Such as image 3 Shown, the present invention comprises seven oil tanks altogether, is connected together in order to form oil supply system. All fuel tanks are made of fiberglass. Such as Figure 4 As shown, No. 1, 2, 4, and 5 fuel tanks all reserve one hole on the side and the center of the upper surface; No. 3 fuel tank has one hole on each side and two holes on the upper surface; Figure 5 As shown, one hole is left on the upper and lower surfaces of No. 6 and No. 7 anti-bubble fuel tanks, and one hole is left on the front side; the diameter of all holes is 16mm.

[0023] Such as Image 6 As shown, the connecting piece 1 is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com