Tension device for roller chain with chain wheel tension wheel

A roller and chain technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems affecting the service life of the chain transmission mechanism of the resistance rotary furnace and the wave vibration of the roller chain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

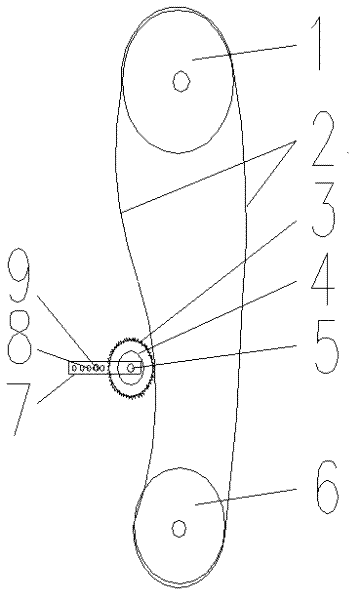

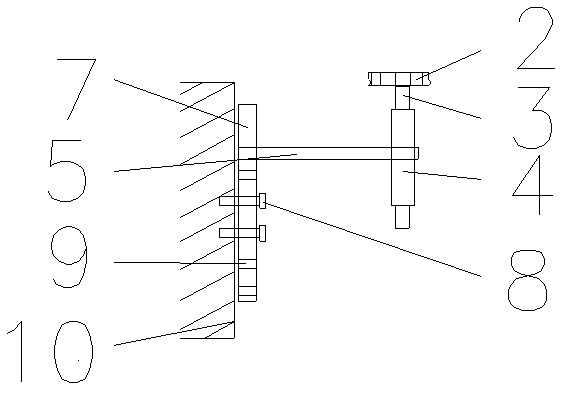

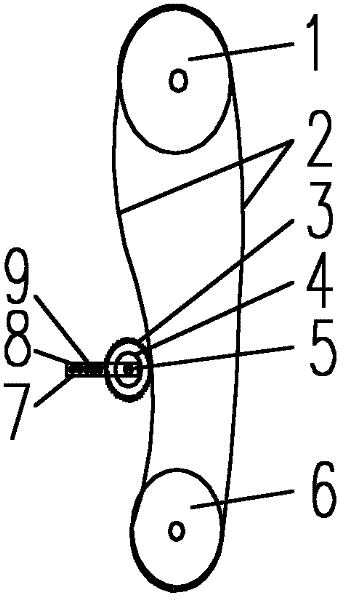

[0011] Such as figure 1 , figure 2 The illustrated embodiment is as follows: A tensioning device for a roller chain with a toothed tensioning pulley used on a simple tiltable electric resistance rotary kiln. The resistance rotary furnace sprocket 1 and the motor drive shaft sprocket 6 are connected by a roller chain 2 . Tensioning sprocket 3 is sheathed outside bearing 4, and tensioning sprocket 3 is close to roller chain 2 and tensions roller chain 2. The bearing 4 is sleeved on the bearing shaft 5 . The other end of the bearing shaft 5 is connected to the connecting plate 7 at right angles. A plurality of mounting holes 8 are opened on the connecting plate 7 . Screws 9 install the connecting plate 7 on the rotary kiln shell 10 through the mounting holes 8 . The position of the tensioning sprocket 3 that regulates the tension of the roller chain 2 can be realized by adjusting the position of the connecting plate 7 with a screw 9. Its characteristics are: the tensioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com