TA9 expansion joint manufacturing method

A manufacturing method and technology for expansion joints, which are applied to expansion compensation devices, manufacturing tools, and pipe components for pipelines to ensure quality, uniform stress distribution, and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

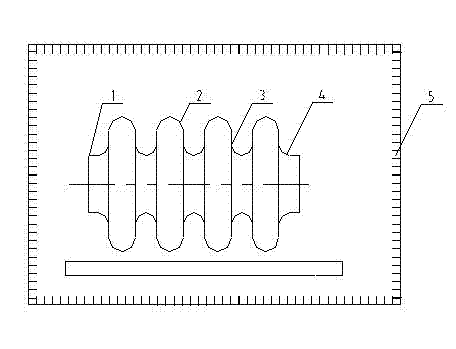

[0009] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0010] After the TA9 (titanium material) expansion joint meets the standard requirements after the re-inspection of the raw material, the blank is rolled into shape, the groove surface and both sides of the TA9 material are cleaned, and the tungsten argon arc welding process qualified for the welding process is adopted. In the state of sufficient protection, the tube blank is welded by means of low current and slow speed welding, and the surface 100% PT and 100% RT non-destructive testing method is adopted, and the non-destructive testing is qualified according to JB / T4730-2005 level I qualification inspection. The expansion joint tube billet is heat treated as a whole to eliminate the welding seam and plate rolling stress. The heat treatment furnace must be an electric furnace filled with inert gas and with good sealing performance. After being pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com