A kind of aluminum-lithium alloy material and its preparation method with improved vacuum melting process

A technology for aluminum-lithium alloys and alloy materials, which is applied in the field of preparation of aluminum-lithium alloy materials and their improved vacuum melting process, can solve the problems of low plasticity of aluminum-lithium alloys, achieve high alloy plasticity and toughness, prevent hydrogen absorption, and increase content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 Preparation of aluminum-lithium alloy material of the present invention

[0031] Batching smelting: The raw materials are according to the mass ratio: lithium 2.0wt%, copper 0.03wt%, magnesium 5.0wt%, zirconium 0.1wt%, titanium 0.01wt%, iron 0.1wt%, silicon 0.05wt%, the balance is aluminum The ratio is put into the melting furnace, and the temperature of the melting furnace is controlled at 800° C. for 1.5 hours.

[0032] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

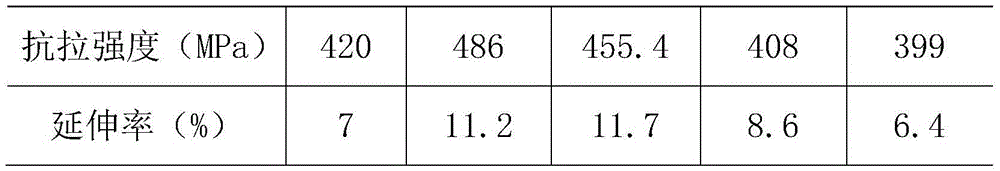

[0033] Vacuum smelting: heat the alloy liquid to 700°C and place it in a vacuum melting furnace for remelting. Under the conditions of 700°C and 300Pa vacuum, vacuum smelt for 20 minutes.

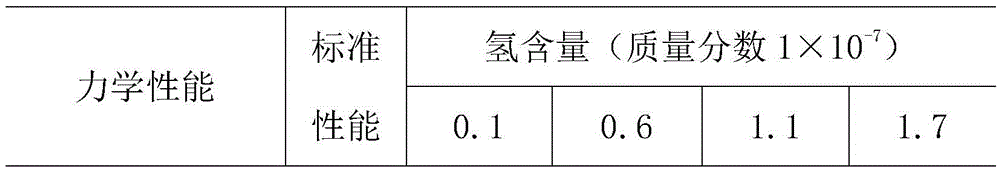

[0034] Hydrogen absorption detection: through volumetric method, gravimetric method and other chemical methods to detect the hydrogen absorption of the alloy to be less than or equal to the mass fraction of 1×10 -7 .

[0...

Embodiment 2

[0042] Embodiment 2 Preparation of aluminum-lithium alloy material of the present invention

[0043] Batching smelting: the raw materials are according to the mass ratio: lithium 3.5wt%, copper 0.01wt%, magnesium 6.8wt%, zirconium 0.35wt%, titanium 0.1wt%, iron 0.2wt%, silicon 0.15wt%, the balance is aluminum The proportion is put into the smelting furnace, and the temperature of the smelting furnace is controlled at 850° C. for 1 hour.

[0044] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0045] Vacuum smelting: heat the alloy liquid to 700°C and place it in a vacuum melting furnace for remelting. Under the conditions of 700°C and 500Pa vacuum, vacuum smelt for 20 minutes.

[0046] Hydrogen absorption detection: through volumetric method, gravimetric method and other chemical methods to detect the hydrogen absorption of the alloy to be less than or equal to the mass fraction of 1×10 -7 . ...

Embodiment 3

[0054] Embodiment 3 Preparation of aluminum-lithium alloy material of the present invention

[0055] Ingredients smelting: The raw materials are according to the mass ratio: lithium 2.75wt%, copper 0.02wt%, magnesium 7.5wt%, zirconium 0.275wt%, titanium 0.05wt%, iron 0.15wt%, silicon 0.1wt%, the balance is aluminum The ratio is put into the melting furnace, and the temperature of the melting furnace is controlled at 850° C. for 1.5 hours.

[0056] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0057]Vacuum melting: heat the alloy liquid to 700°C and put it in a vacuum melting furnace for melting again. Under the conditions of 700°C temperature and 1000Pa vacuum degree, vacuum melting is carried out for 20 minutes.

[0058] Hydrogen absorption detection: through volumetric method, gravimetric method and other chemical methods to detect the hydrogen absorption of the alloy to be less than or equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com