Gas distribution group cover of pneumatic high pressure oil injector

A pneumatic high-pressure oiler technology, applied in the field of butter machines, can solve the problems of easy wear and tear of the reversing air distribution mechanism, high strength of the operator, and damage to other accessories, and achieves convenient and easy connection and disassembly, short disassembly time, and lightening The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

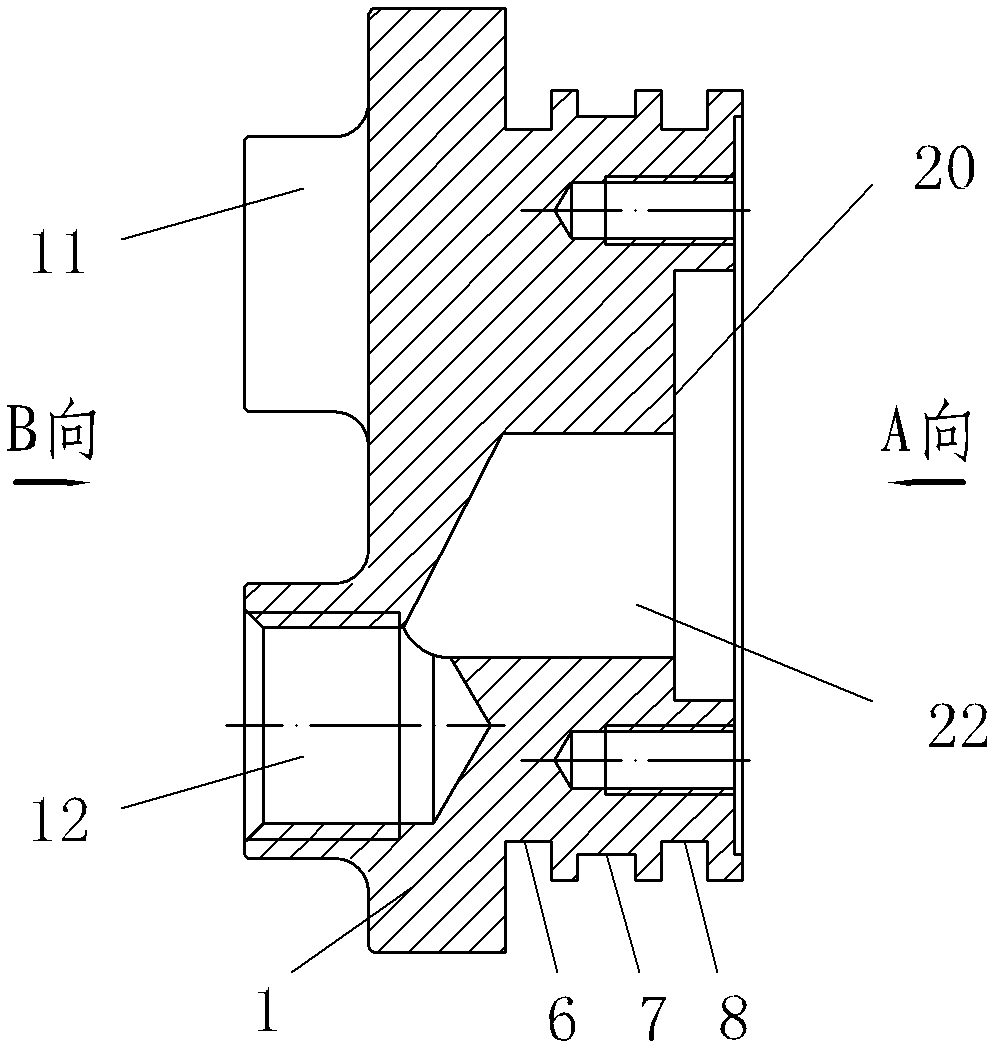

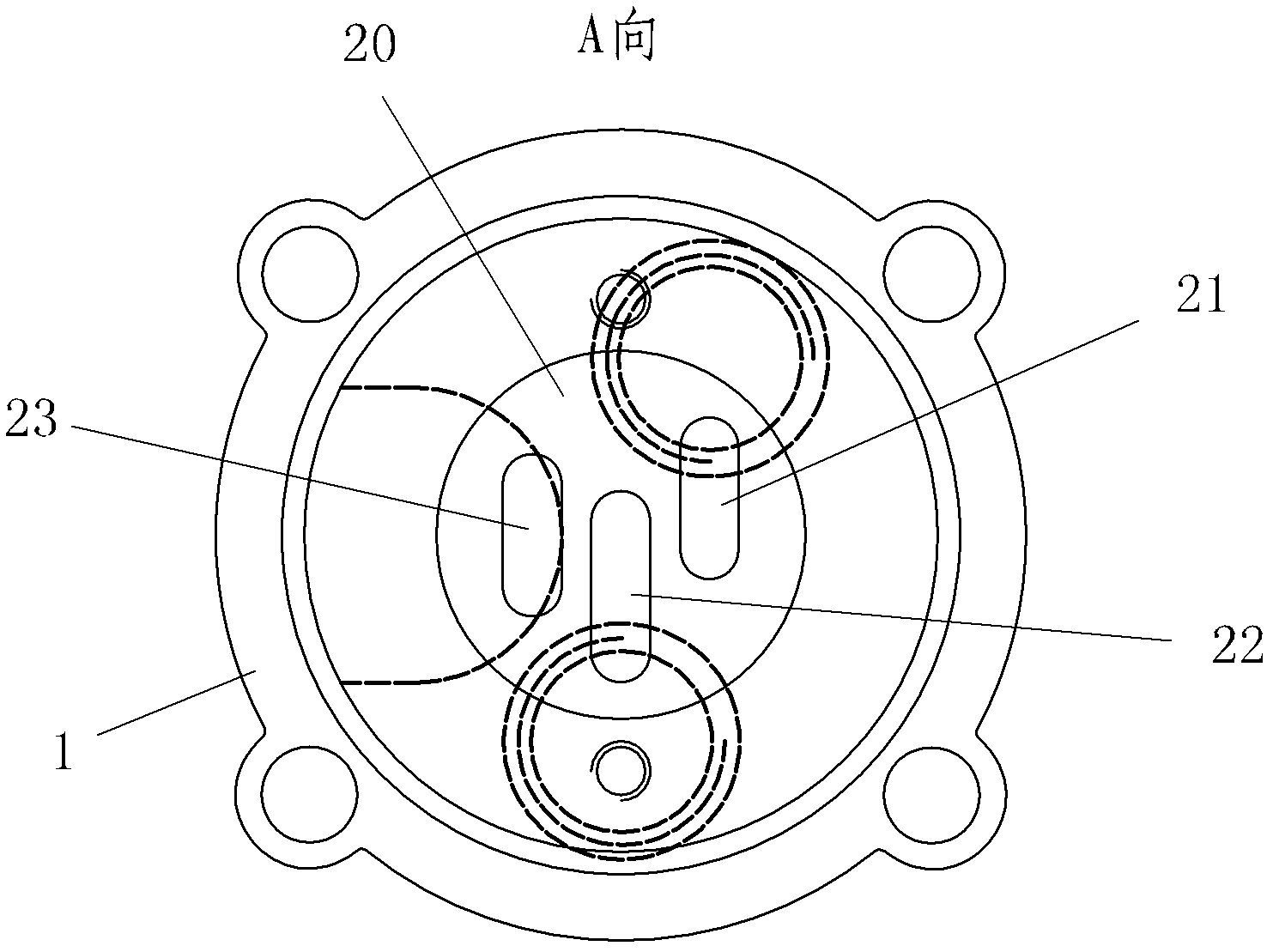

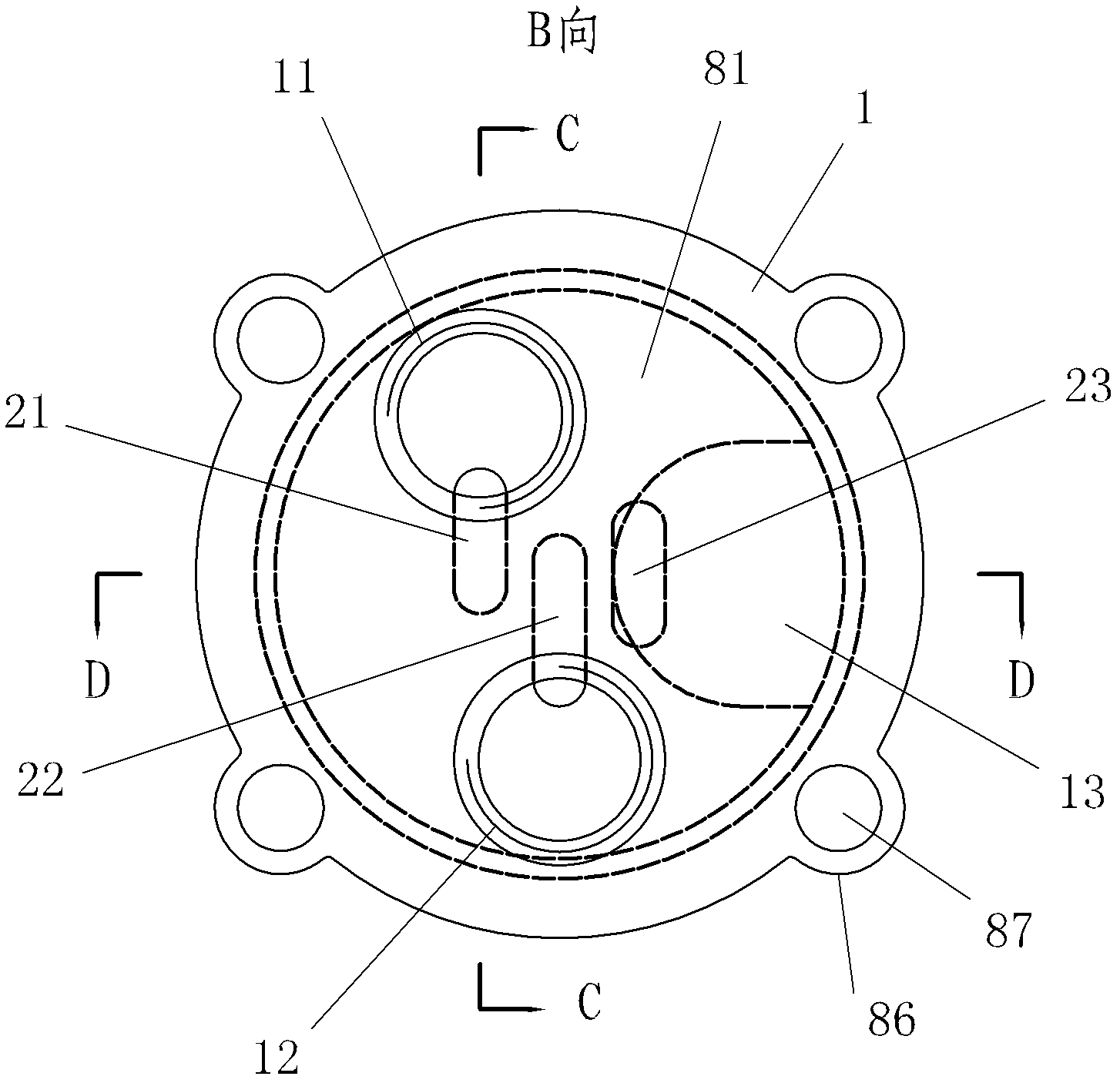

[0029] The present invention will be further described below with specific embodiments in conjunction with the drawings, see Figure 1-10 :

[0030] The gas distribution group cover of the pneumatic high-pressure oil injector is provided with a mounting part 1 in the middle of the main body of the gas distribution group cover, a pipe joint 11 and a muffler installation joint 12 are arranged side by side on one side, and a cylinder is arranged on the other side. The cylindrical surface is provided with three ring grooves (6, 7, 8), the circular surface 80 is provided with a cylindrical groove 20 in the center, and three strip holes (21, 22, 23) are axially provided in the groove 20 , The strip hole 22 in the middle communicates with the central hole of the muffler mounting joint 12, the strip hole 21 on one side communicates with the central hole of the pipe joint 11, and the strip hole 23 on the other side communicates with the annular groove in the middle of the cylindrical surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com