Car-mounted roadbed compactness rapid determinator

A technology for rapid measurement and compaction, applied in the direction of applying stable tension/pressure to test material strength, instruments, measuring devices, etc., can solve the problems of limited applicability, lack of universal adaptability, one-sidedness, etc., and achieve convenient and fast The effect of low cost of mobile and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

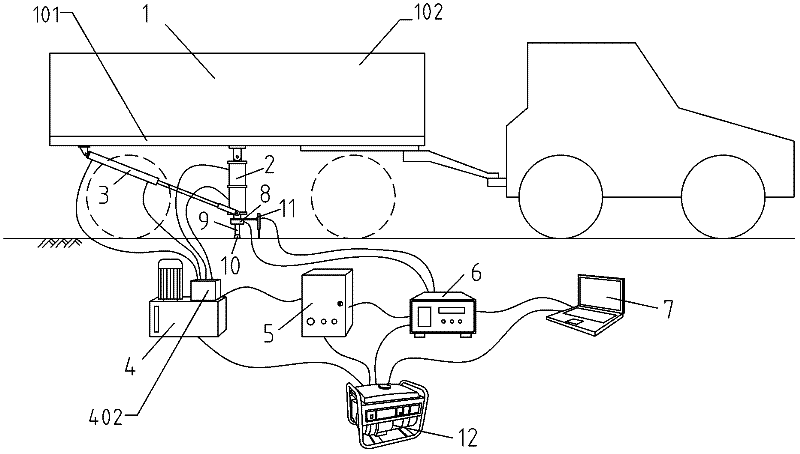

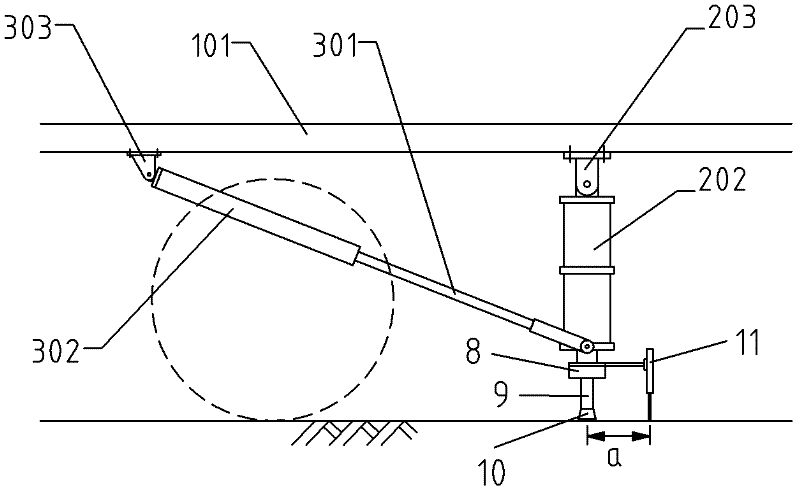

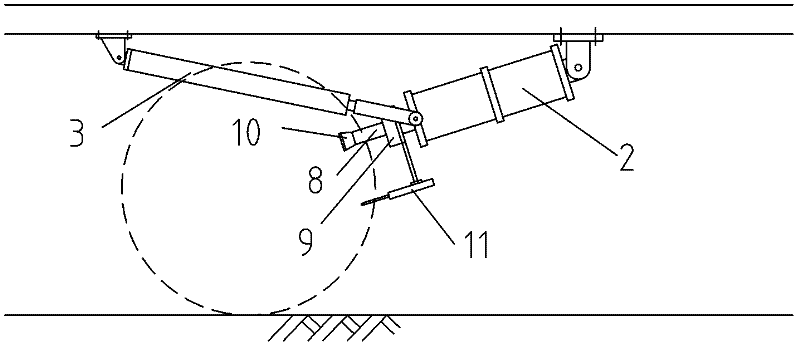

[0028] exist Figure 1 to Figure 3In the illustrated embodiment of the vehicle-mounted subgrade compactness rapid tester of the present invention, the vehicle-mounted rapid compaction test includes a trailer 1, a loading oil cylinder 2, a retractable oil cylinder 3, an oil source 4, a control box 5, a measurement and control Instrument 6, notebook computer 7, pressure sensor 8, connecting rod 9, probe 10, displacement sensor 11, generator 12. The loading oil cylinder 2, the retractable oil cylinder 3, the oil source 4, the control box 5, the measuring and controlling instrument 6, and the generator 12 are installed on the trailer 1. The oil source 4 is connected to the loading oil cylinder 2 and the retracting oil cylinder 3 through the oil pipe, the pressure sensor 8 is installed on the lower end of the piston rod 201 of the loading oil cylinder 2 through an internal screw, the lower end of the pressure sensor 8 is connected with the connecting rod 9 in a screw connection, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com