Self-riveting silicon steel sheet iron core

A silicon steel sheet, self-riveting technology, applied in the direction of transformer/inductor magnetic core, electrical components, transformer/inductor components, etc. Smooth surface and good electrical performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

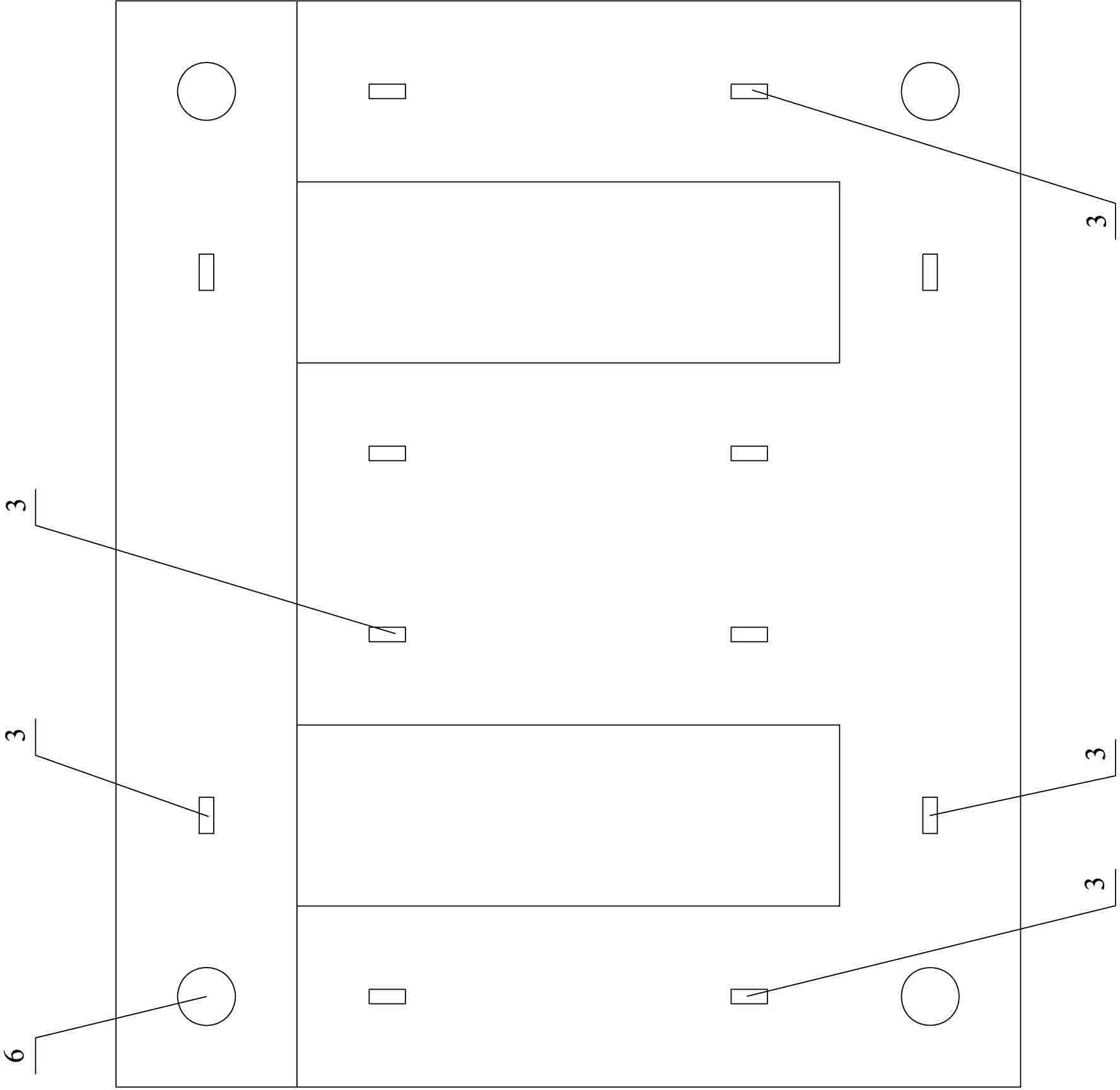

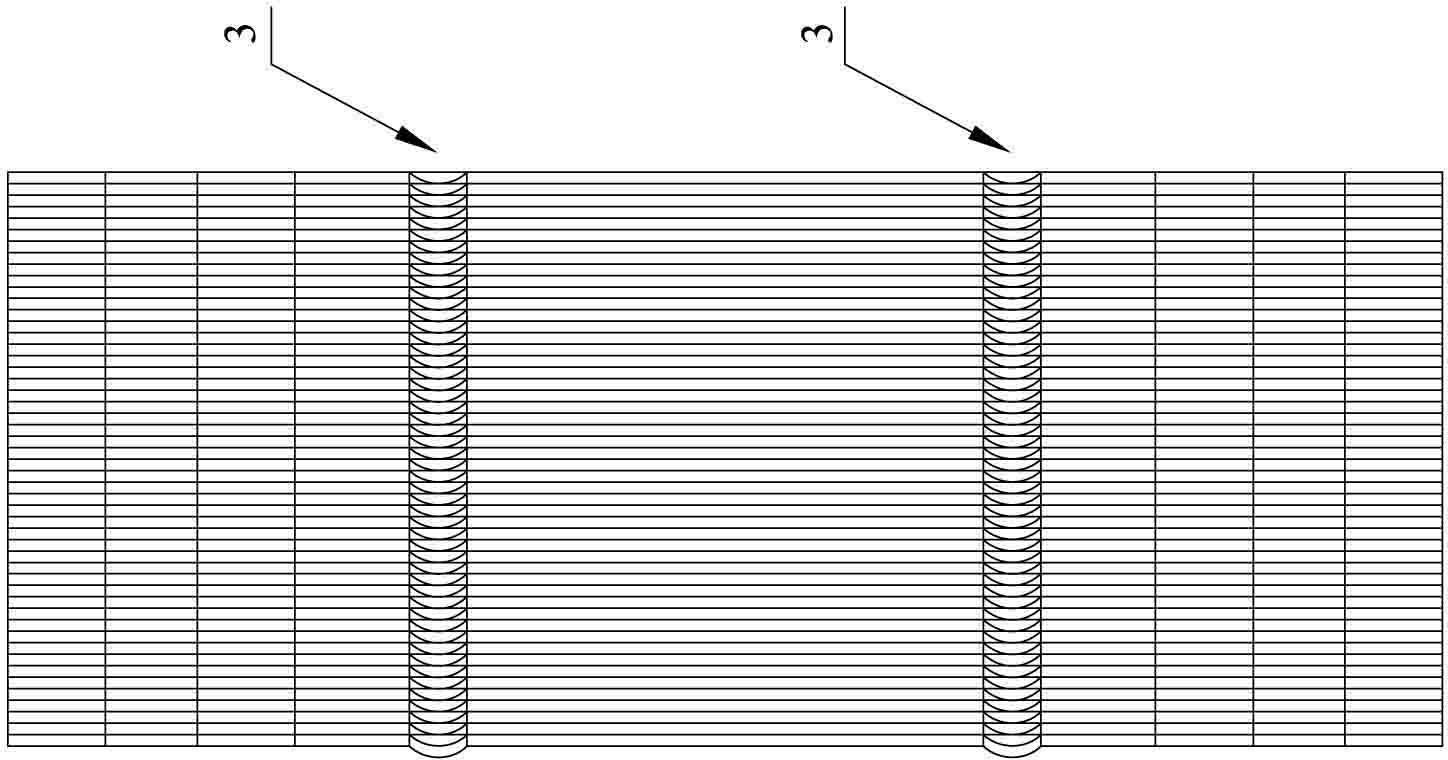

[0020] Embodiment one: see attached figure 1 To attach image 3 shown.

[0021] A self-riveting silicon steel sheet iron core is formed by overlapping and riveting several silicon steel sheets, and is used in electrical equipment such as transformers and reactors.

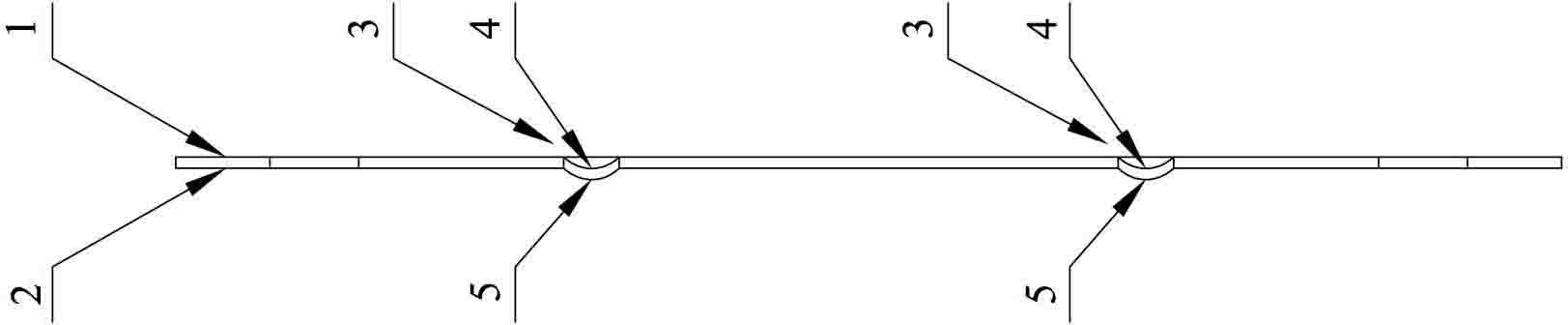

[0022] The self-riveting silicon steel sheet is in the shape of "day" and adopts the combination form of "EI". It includes a central pillar, two side pillars symmetrically arranged on both sides of the central pillar, a first connecting portion and a second connecting portion connecting the two ends of the central pillar and the side pillars. The self-riveting silicon steel sheet has opposite first surface 1 and second surface 2, and a plurality of riveting buckles 3 are symmetrically punched on the center column sheet, the side column sheet, the first connection part and the second connection part.

[0023] The riveting buckle 3 includes a first riveting surface 4 formed on the first surface 1 and concave in th...

Embodiment 2

[0026] Embodiment two: see attached image 3 And attached Figure 4 shown. The silicon steel sheet forming the self-riveting silicon steel sheet core adopts the combination form of "FF", on which a plurality of riveting buckles 3 are symmetrically punched, and a plurality of riveting holes 6 are opened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com