Injection valve

An injection valve and fluid injection technology, which is applied in the direction of fuel injection devices, special fuel injection devices, charging systems, etc., can solve the problems of reducing rebound, injection valve degradation, etc., and achieve the effect of ensuring manufacturing, ensuring simplicity and cost effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

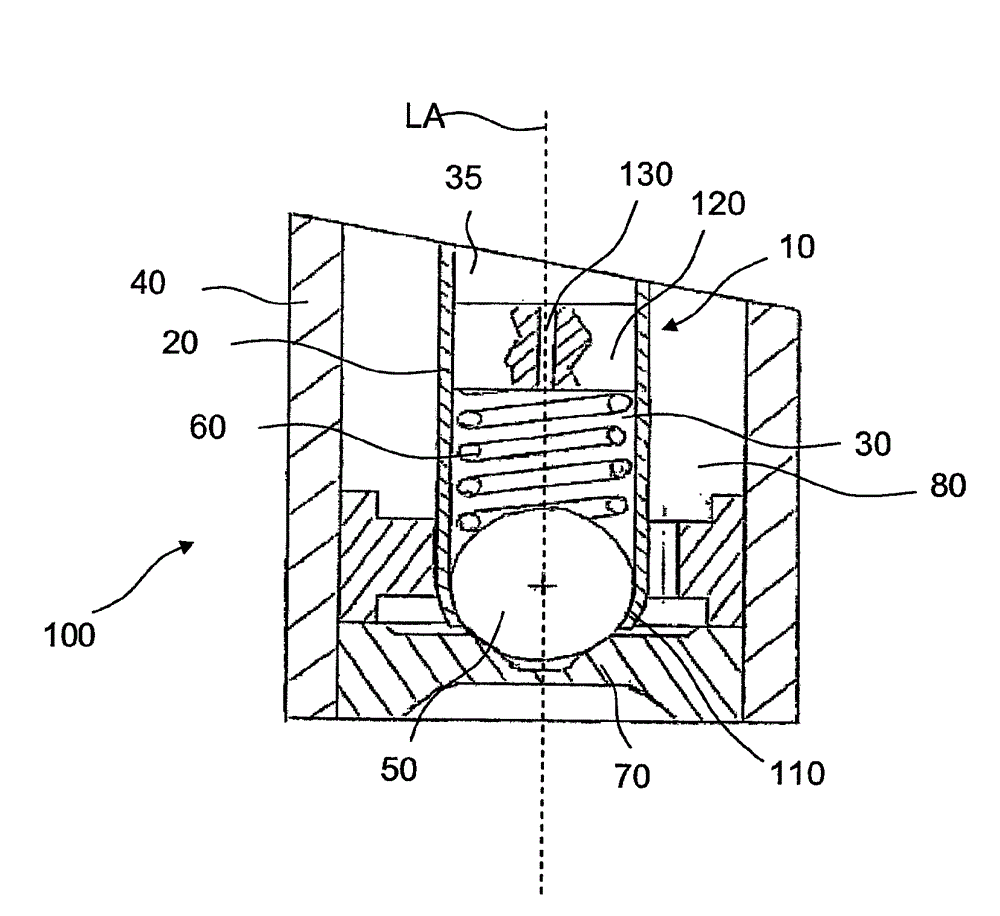

[0024] Injection valve 100 especially suitable for dosing fluid into an internal combustion engine ( figure 1 ) includes an injection valve housing 40 with a central longitudinal axis LA, an injection valve chamber 80 , a valve needle 10 and a valve needle seat 70 . The valve needle 10 comprises a valve needle body 20 , a partition element 120 , a sealing element 50 and a spring element 60 .

[0025] The needle body 20 preferably has a cylindrical shape and is actuated by an actuator of the injection valve 100 , for example an electromagnetic actuator or a piezoelectric actuator. When actuated, the needle body 20 moves axially within the injection valve chamber 80 . The needle body 20 comprises a needle chamber, wherein a partition element 120 is fixedly arranged dividing the needle chamber into a first fluid volume 30 and a second fluid volume 35 . Injection valve chamber 80 , first fluid volume 30 and second fluid volume 35 are designed to be filled with fluid (eg, fuel). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com