Patents

Literature

30results about How to "Prevent fluid flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

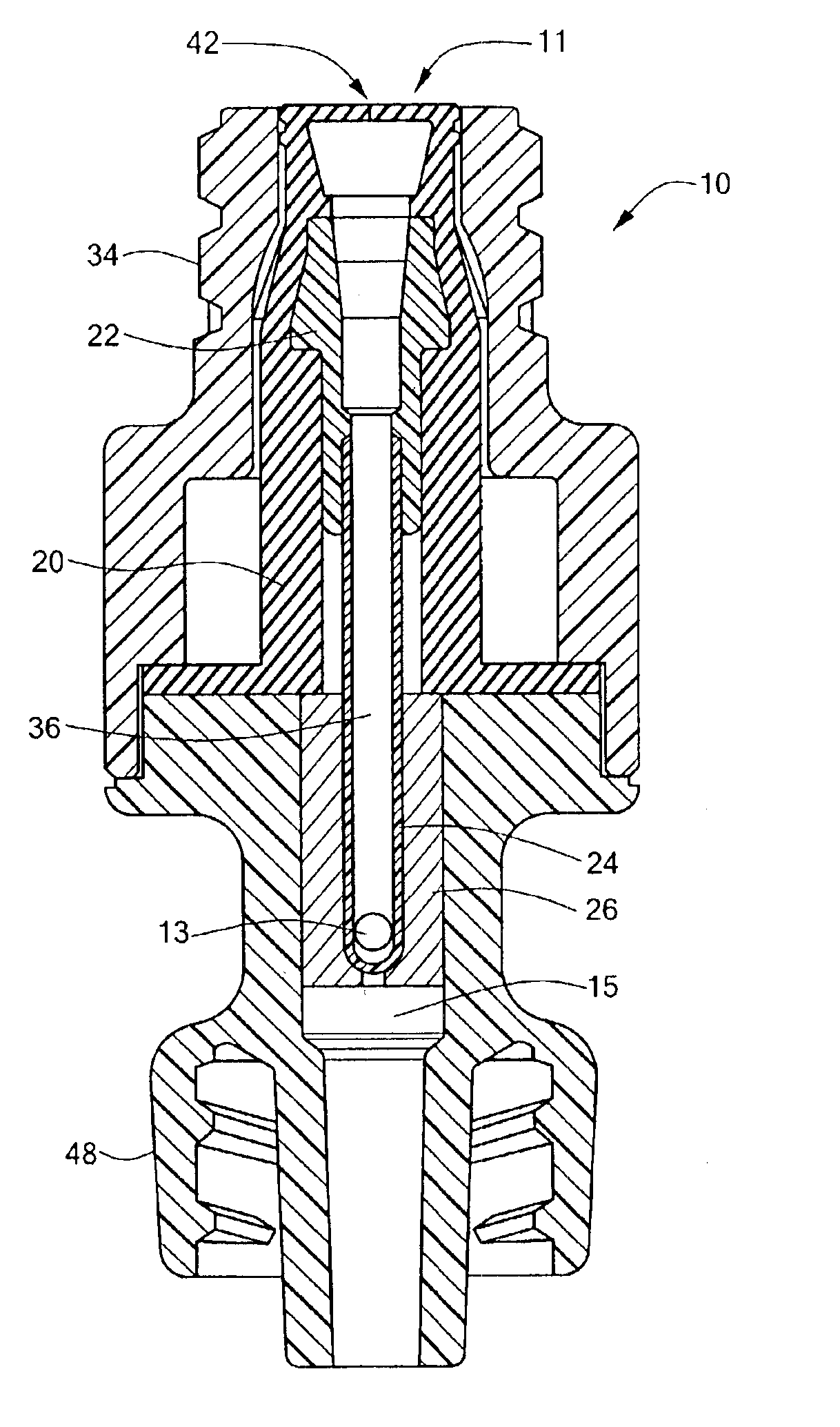

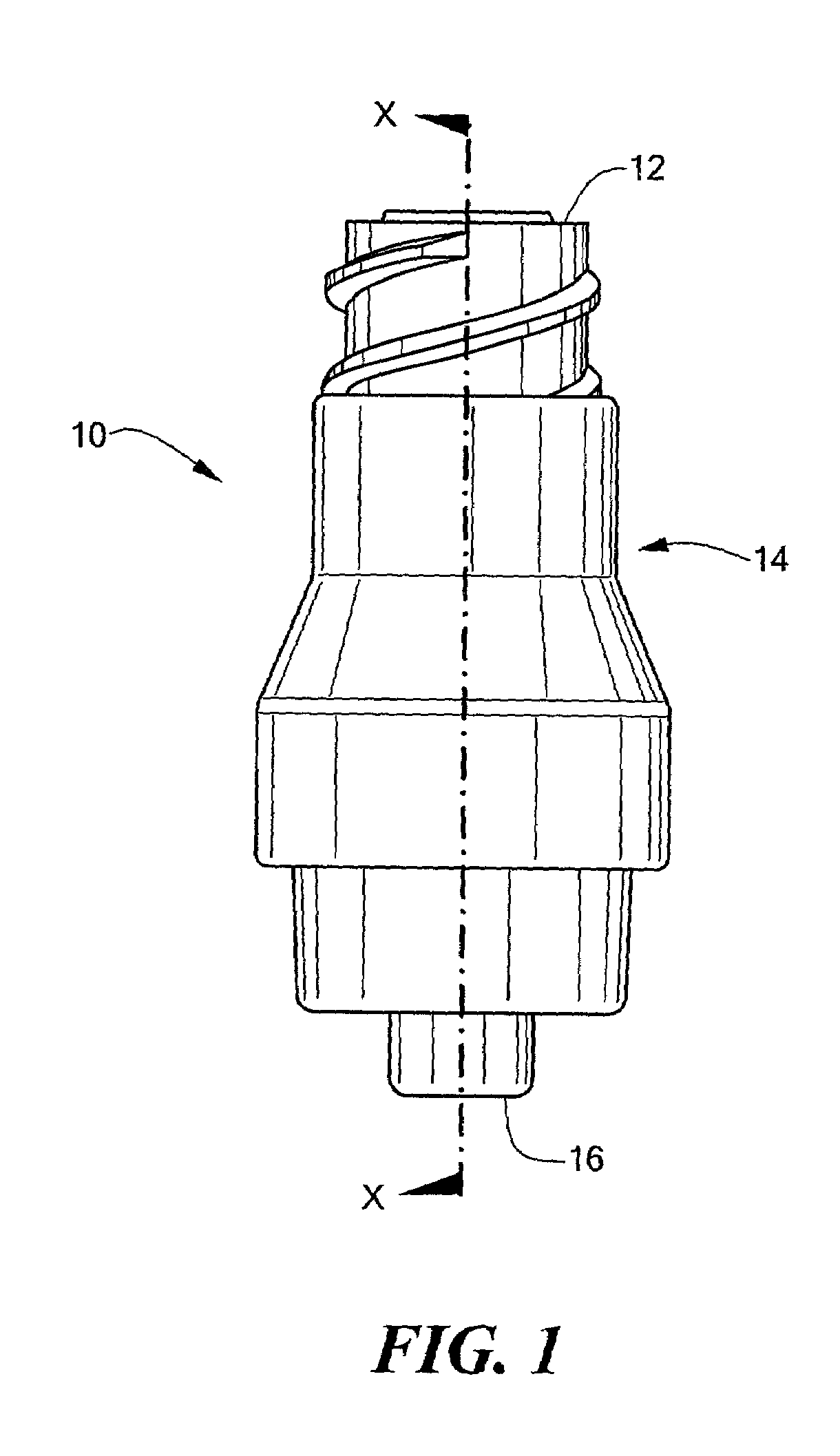

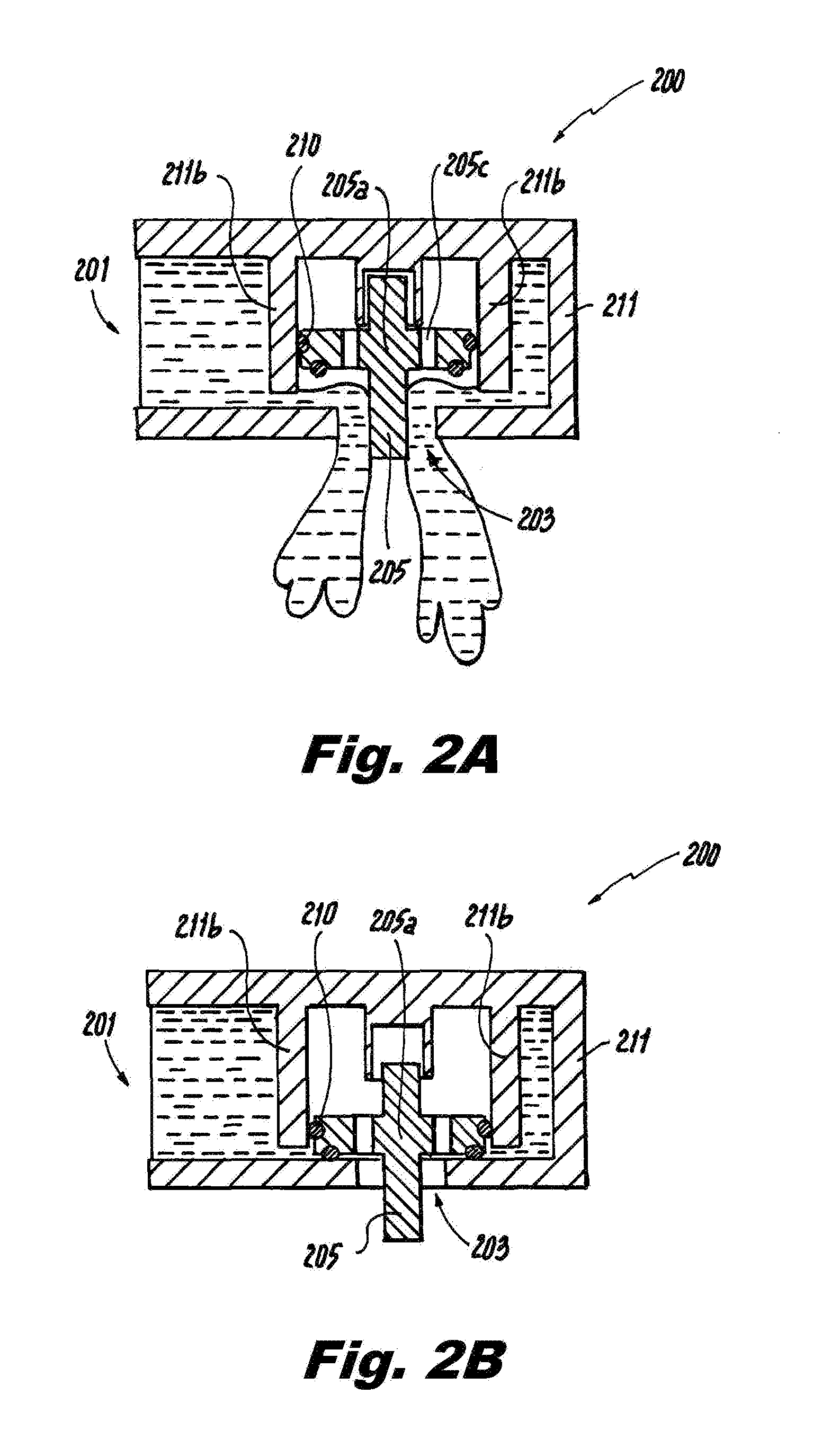

Anti-drawback medical valve

InactiveUS6869426B2Prevent fluid flowValve arrangementsSurgeryBiomedical engineeringMedical treatment

Owner:NP MEDICAL

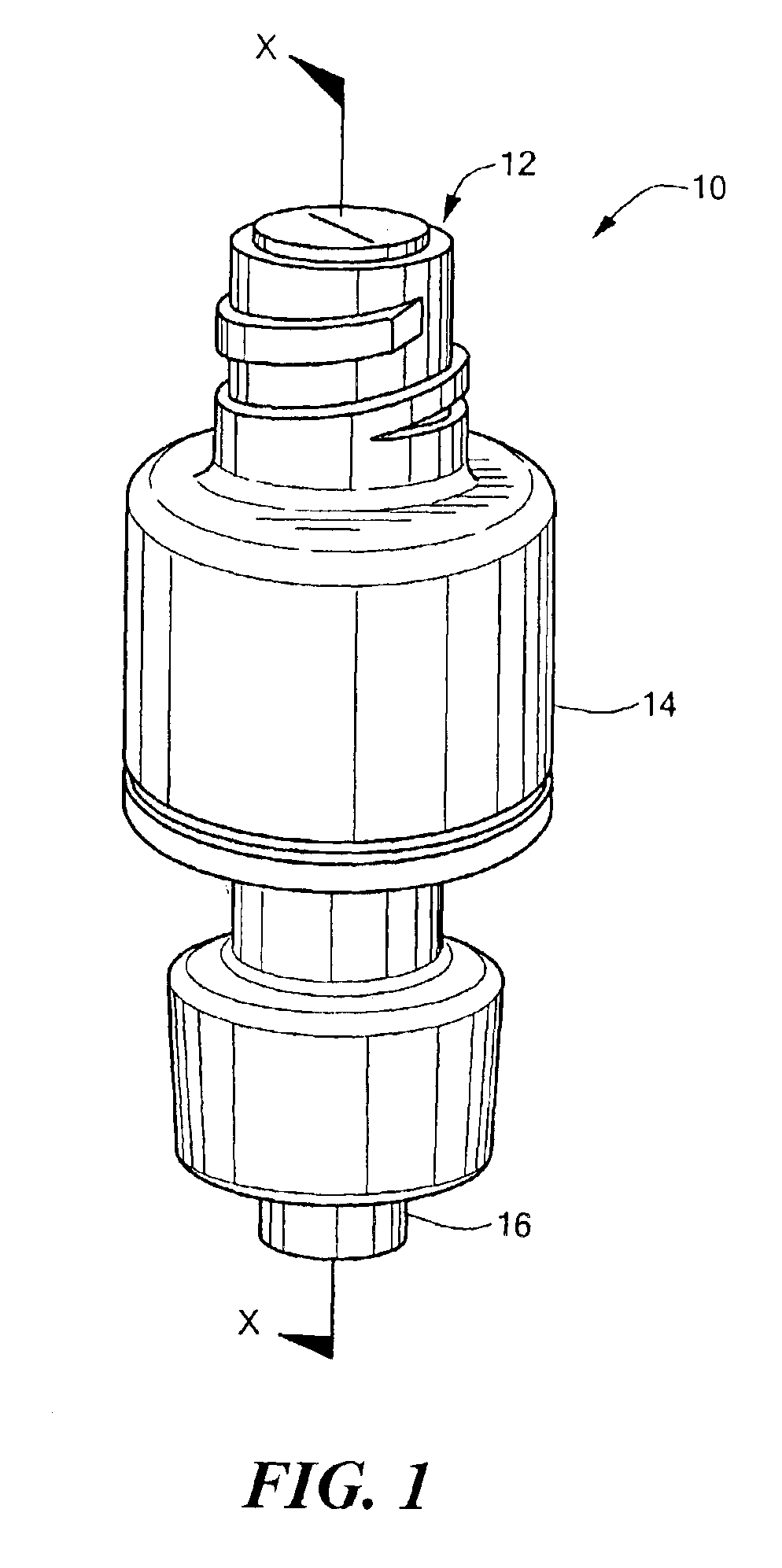

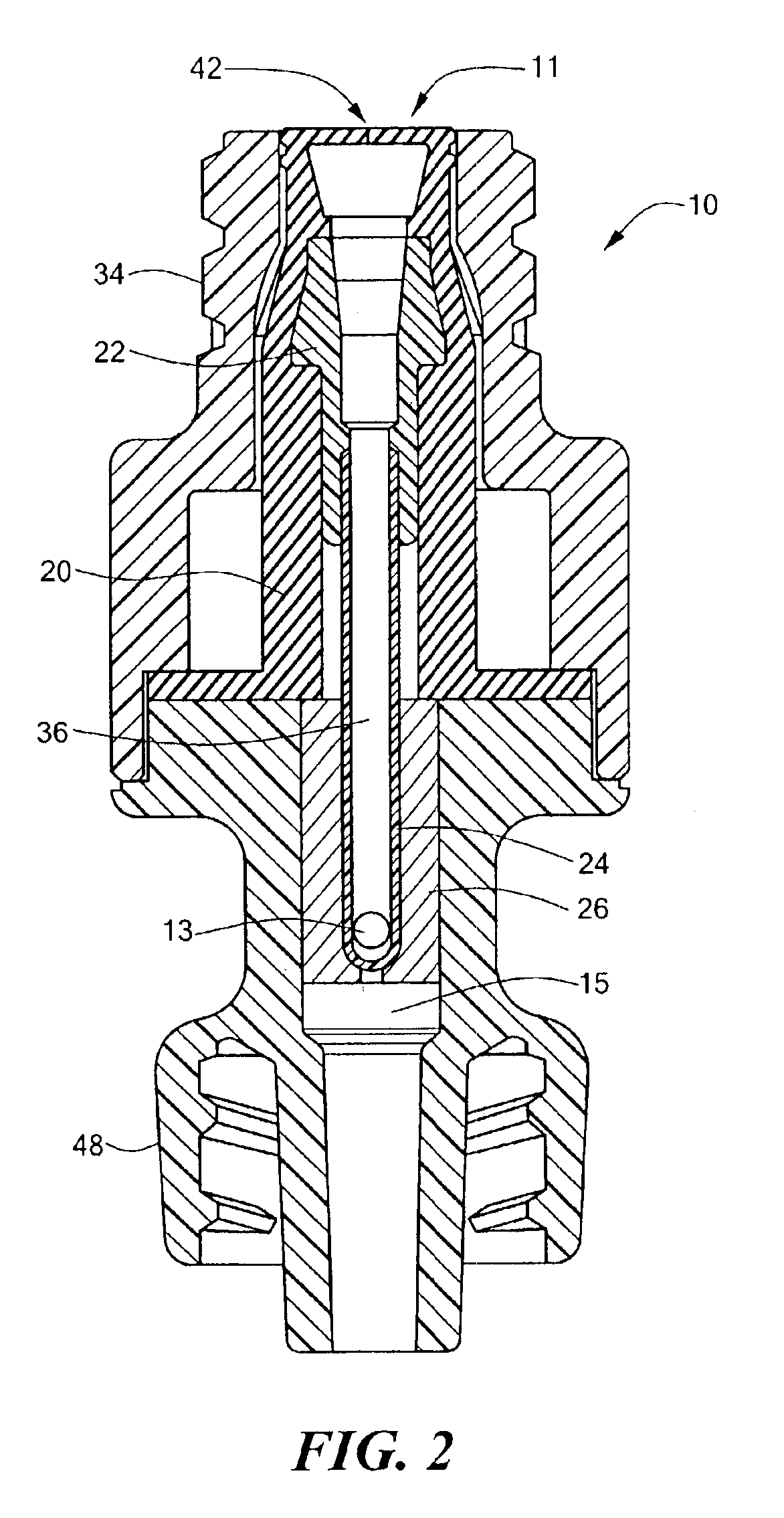

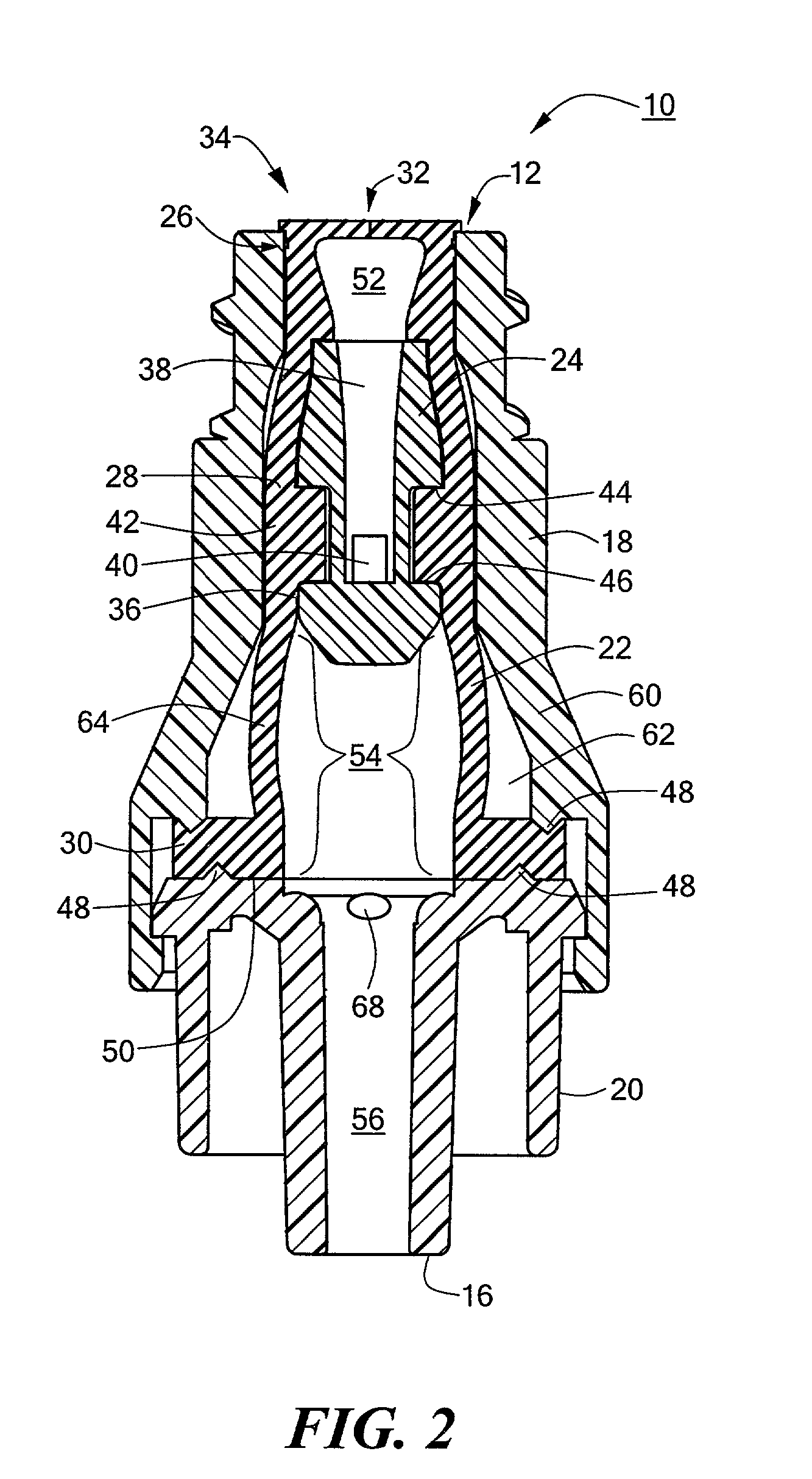

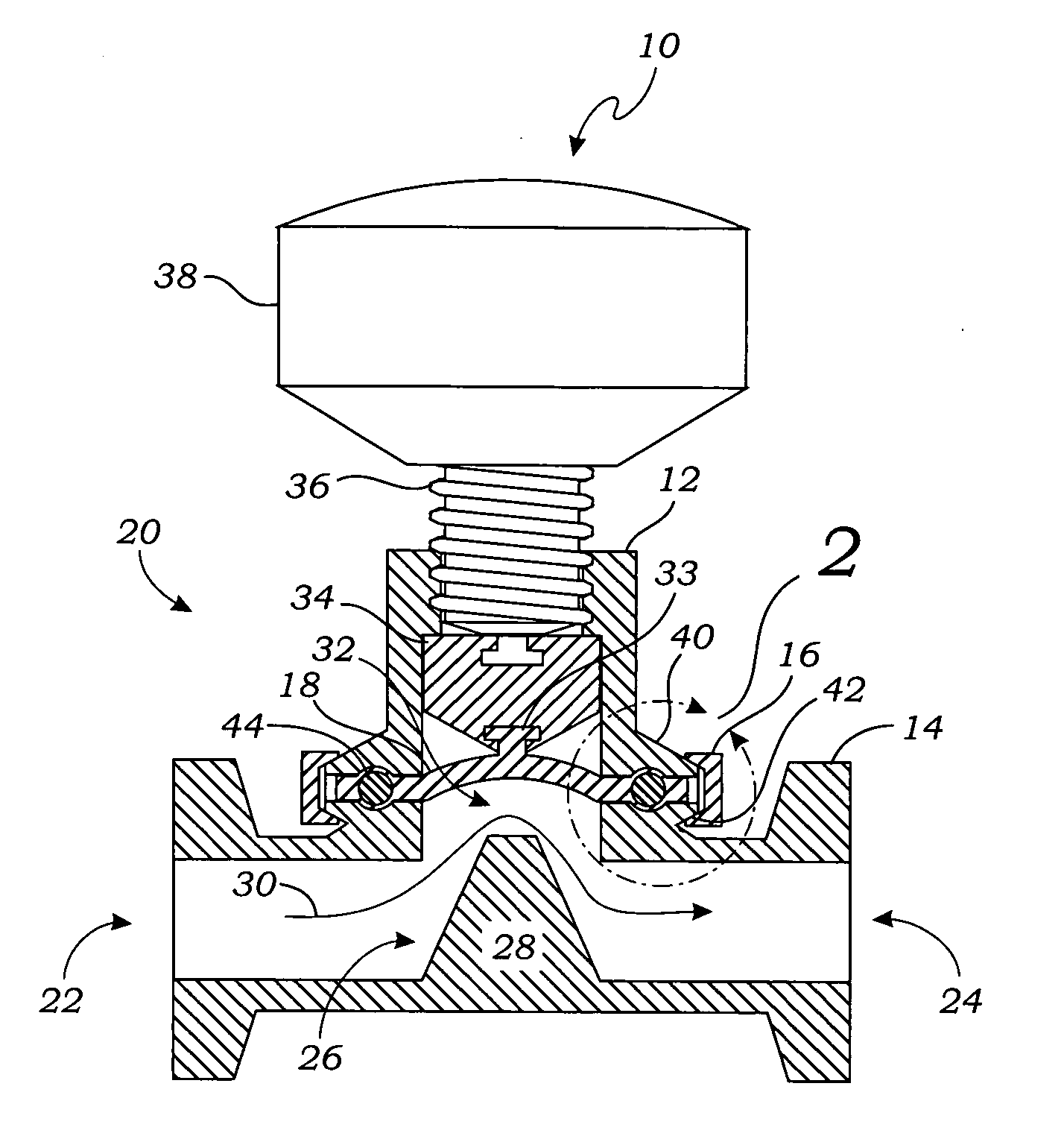

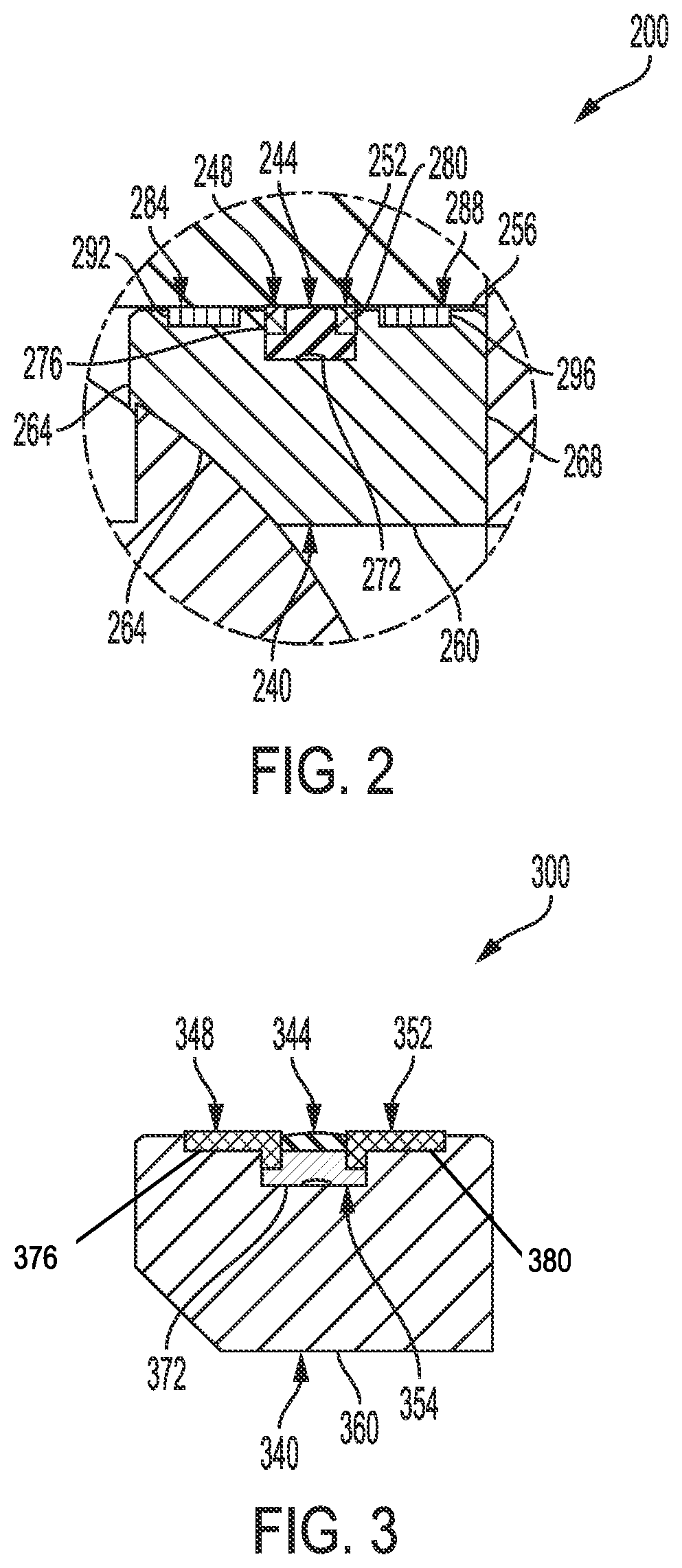

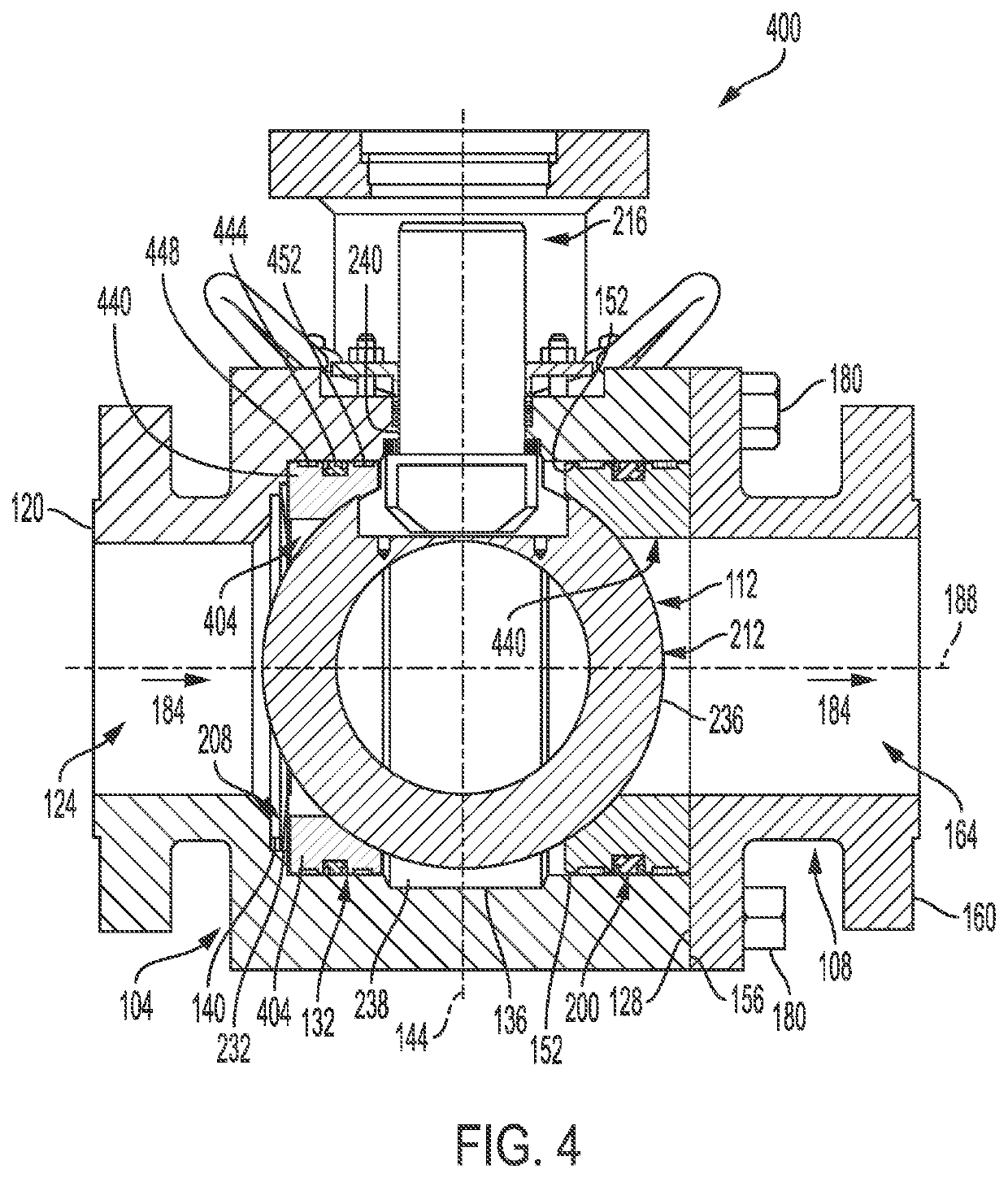

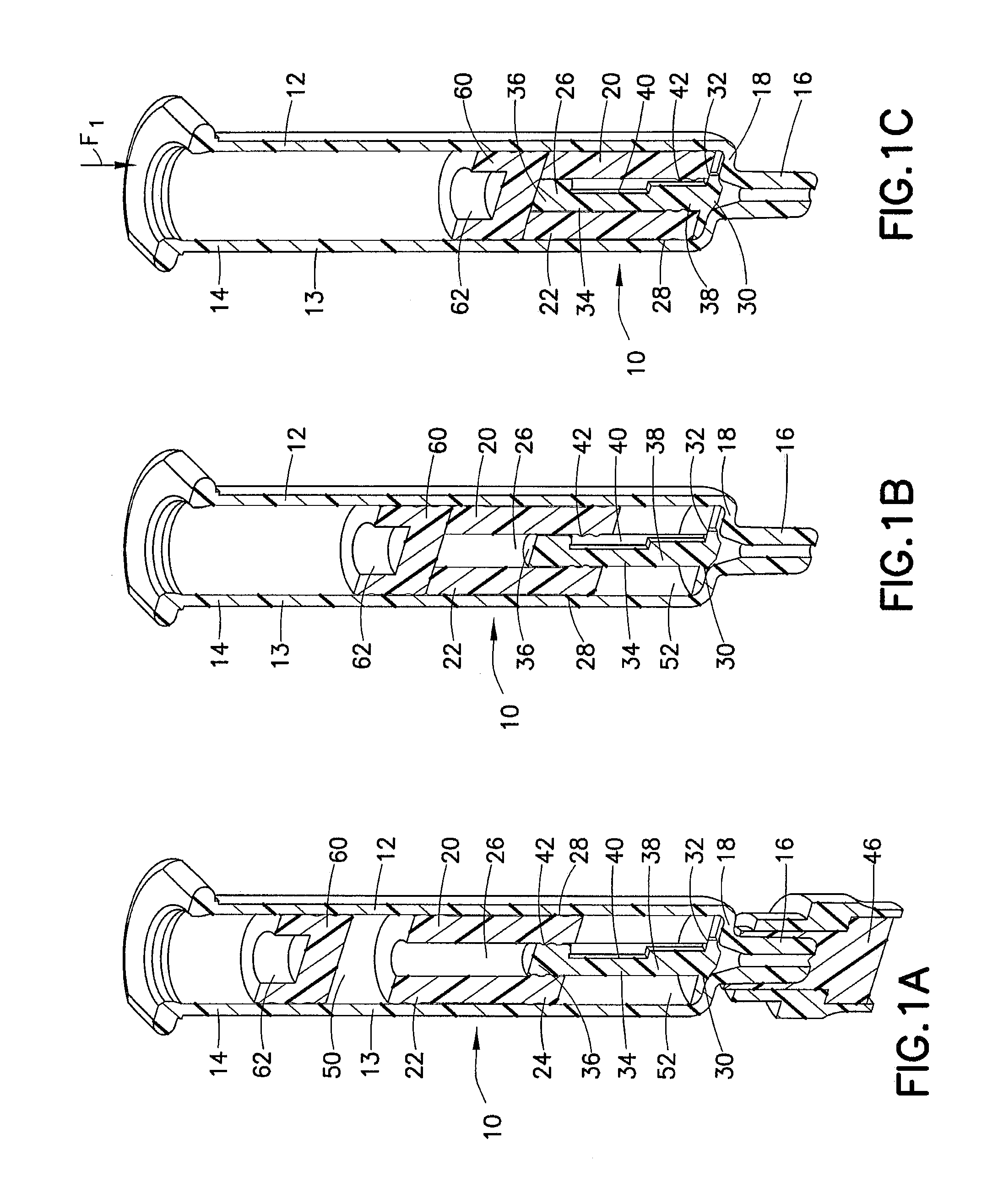

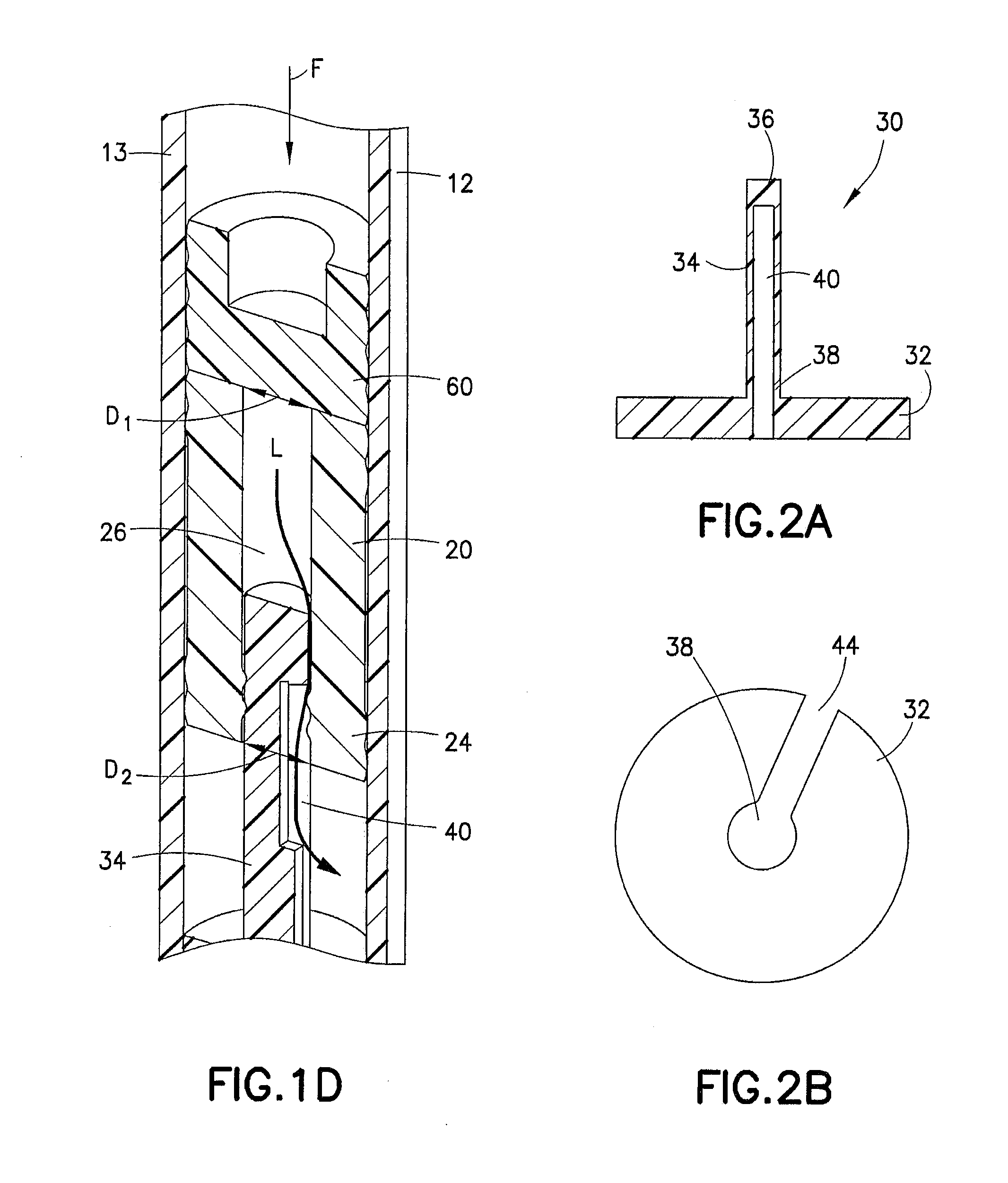

Medical valve with expandable member

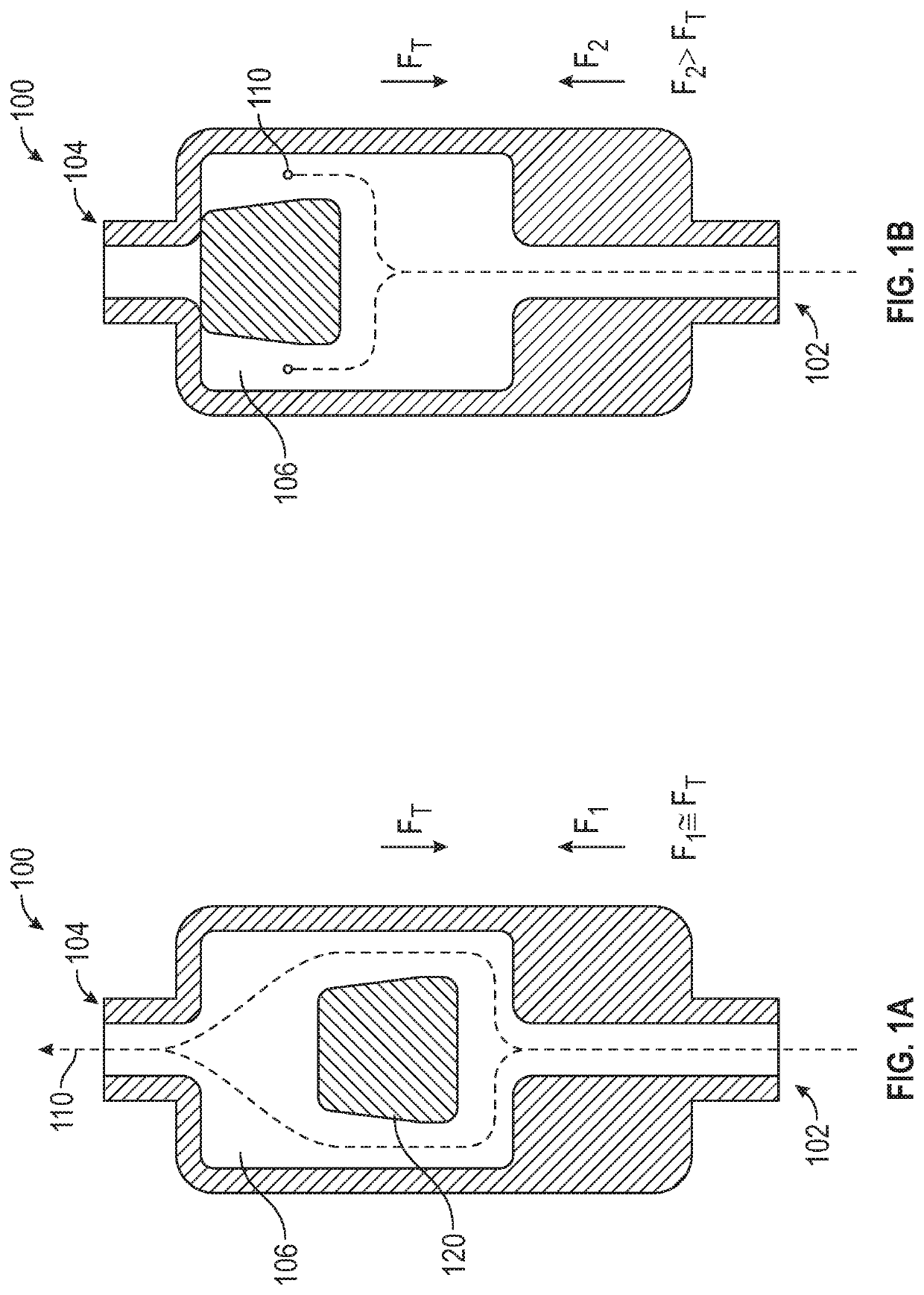

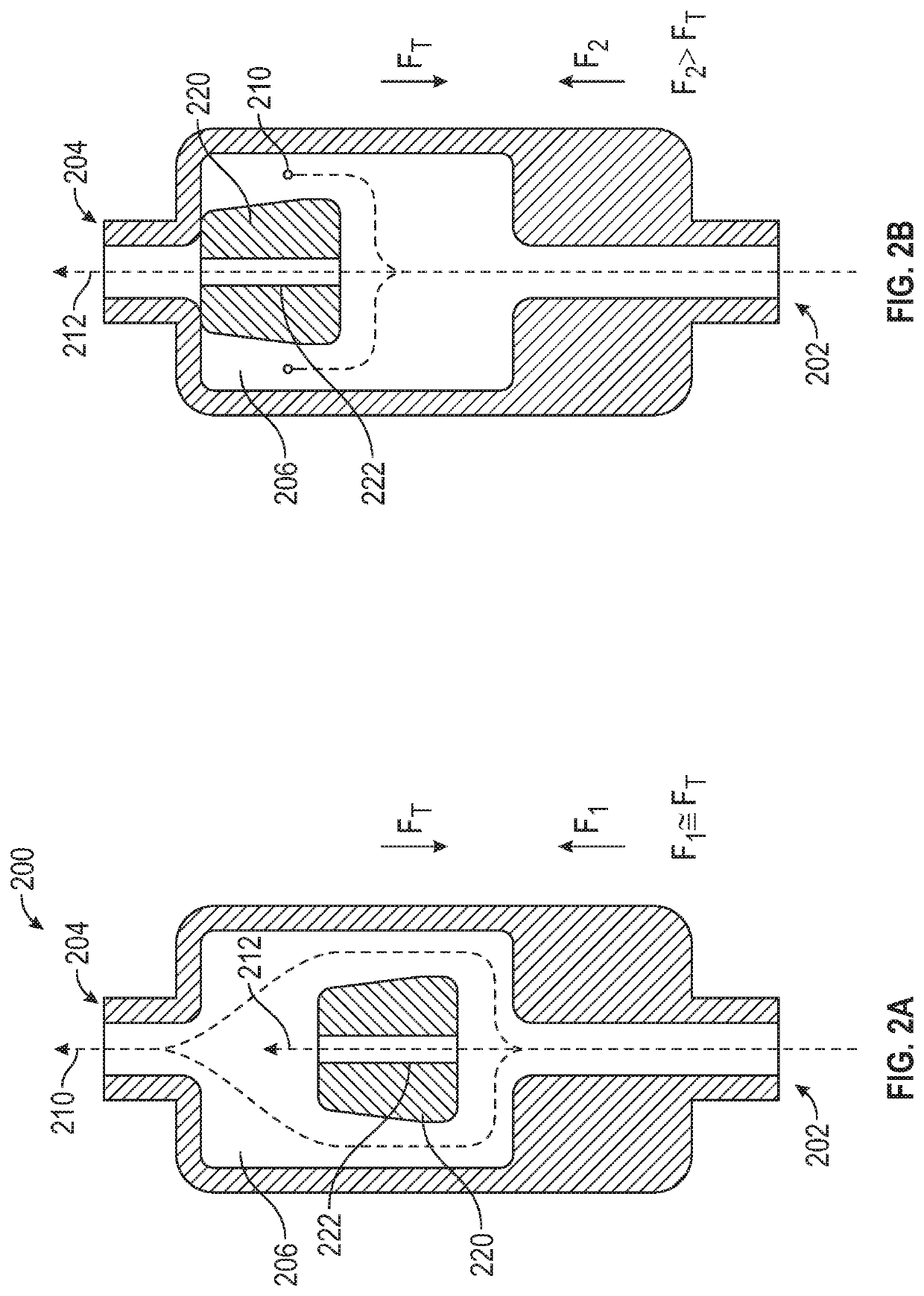

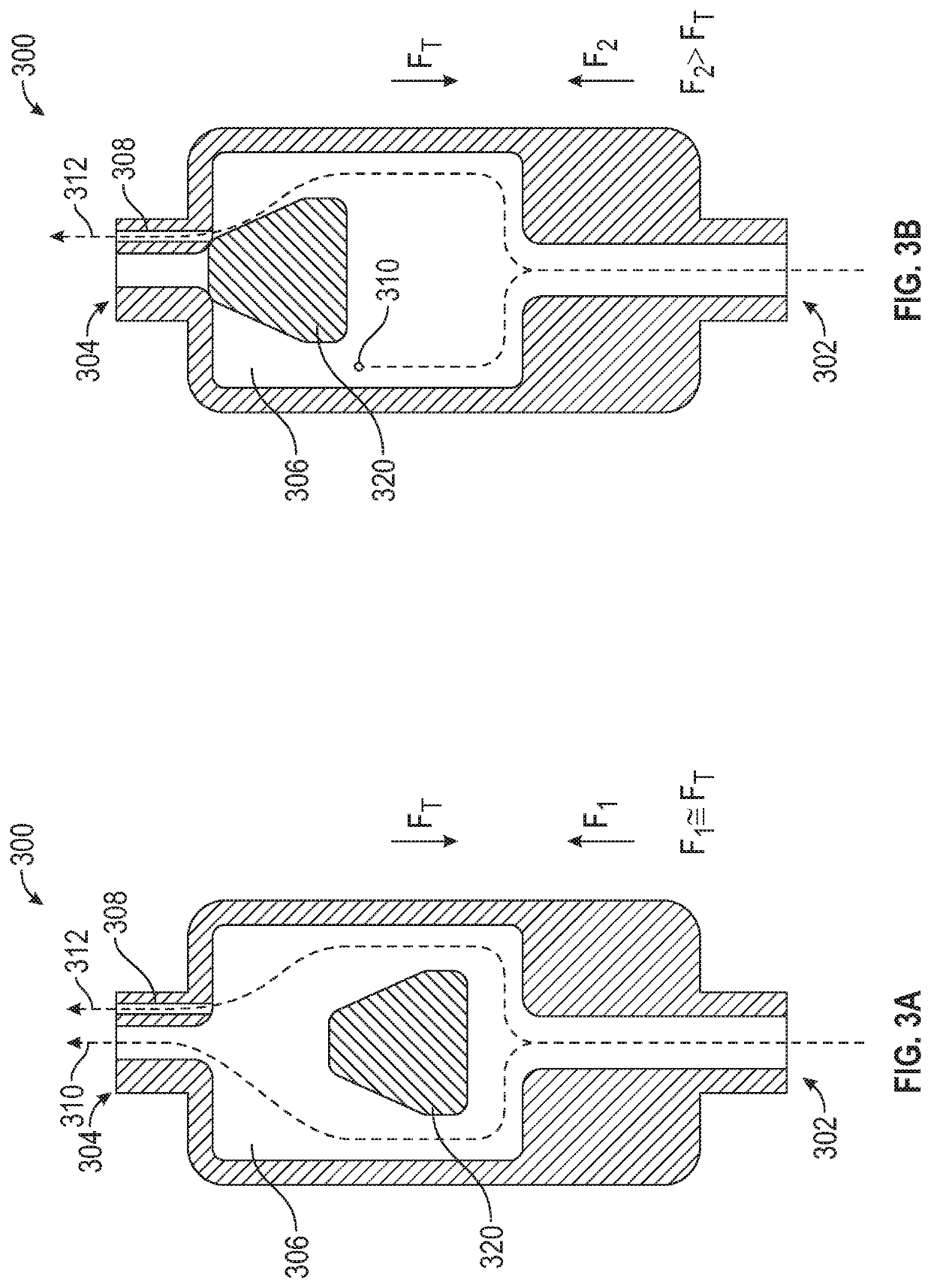

A medical valve has a resilient member that is forcibly expanded to an expanded volume from a normal volume. Specifically, the valve operates in a closed mode that prevents fluid flow, and an open mode that permits fluid flow. To these ends, the valve has a housing having an inlet and an outlet, and the noted resilient member within the housing. The resilient member and housing form a fluid channel between the inlet and the outlet. The fluid channel at least in part extends through the resilient member. The fluid channel has a given portion formed by a variable volume portion of the resilient member. The variable volume portion has a normal volume when in the closed mode, and an expanded volume when the open mode. The expanded volume is greater than the normal volume.

Owner:NP MEDICAL

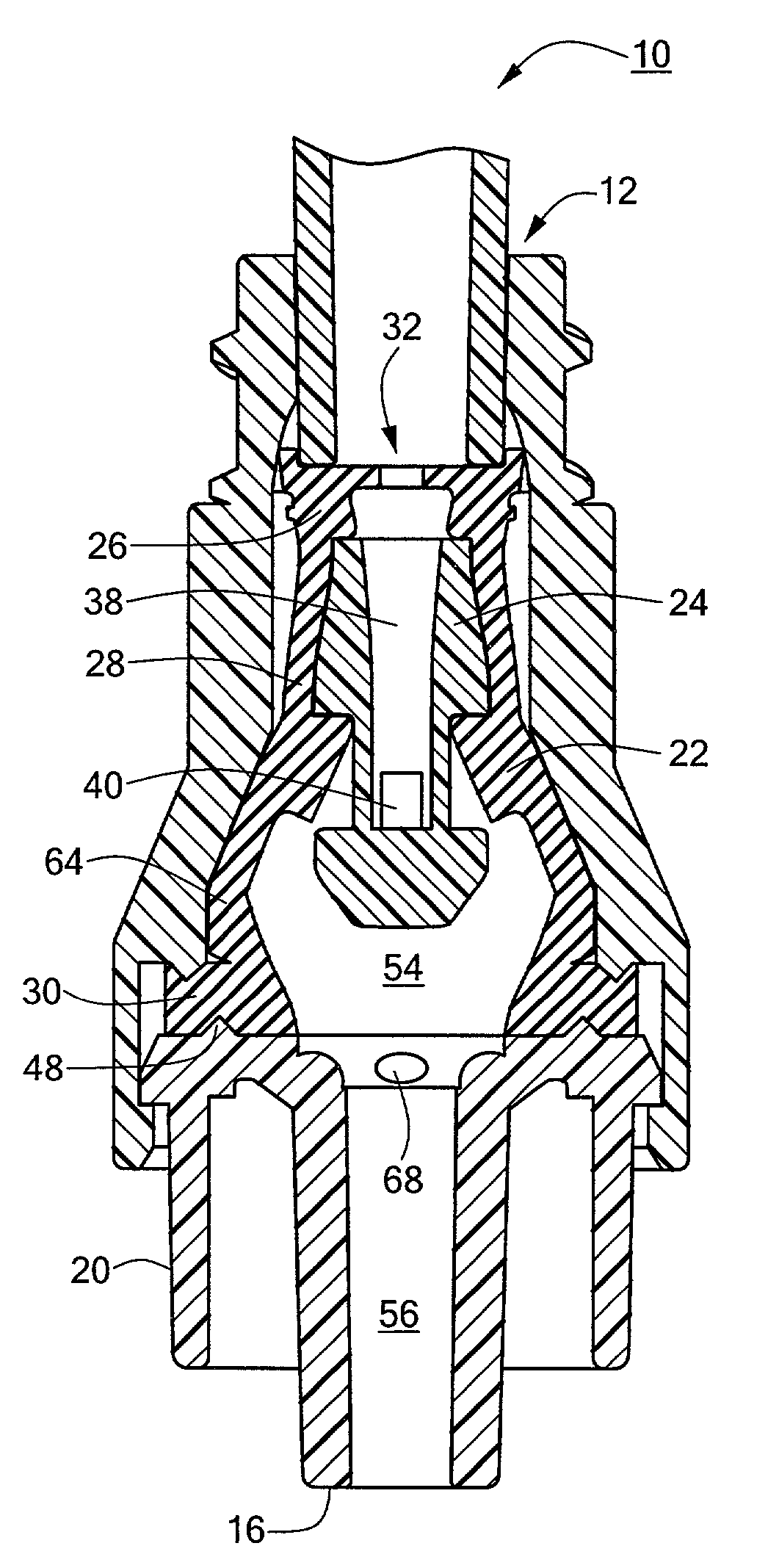

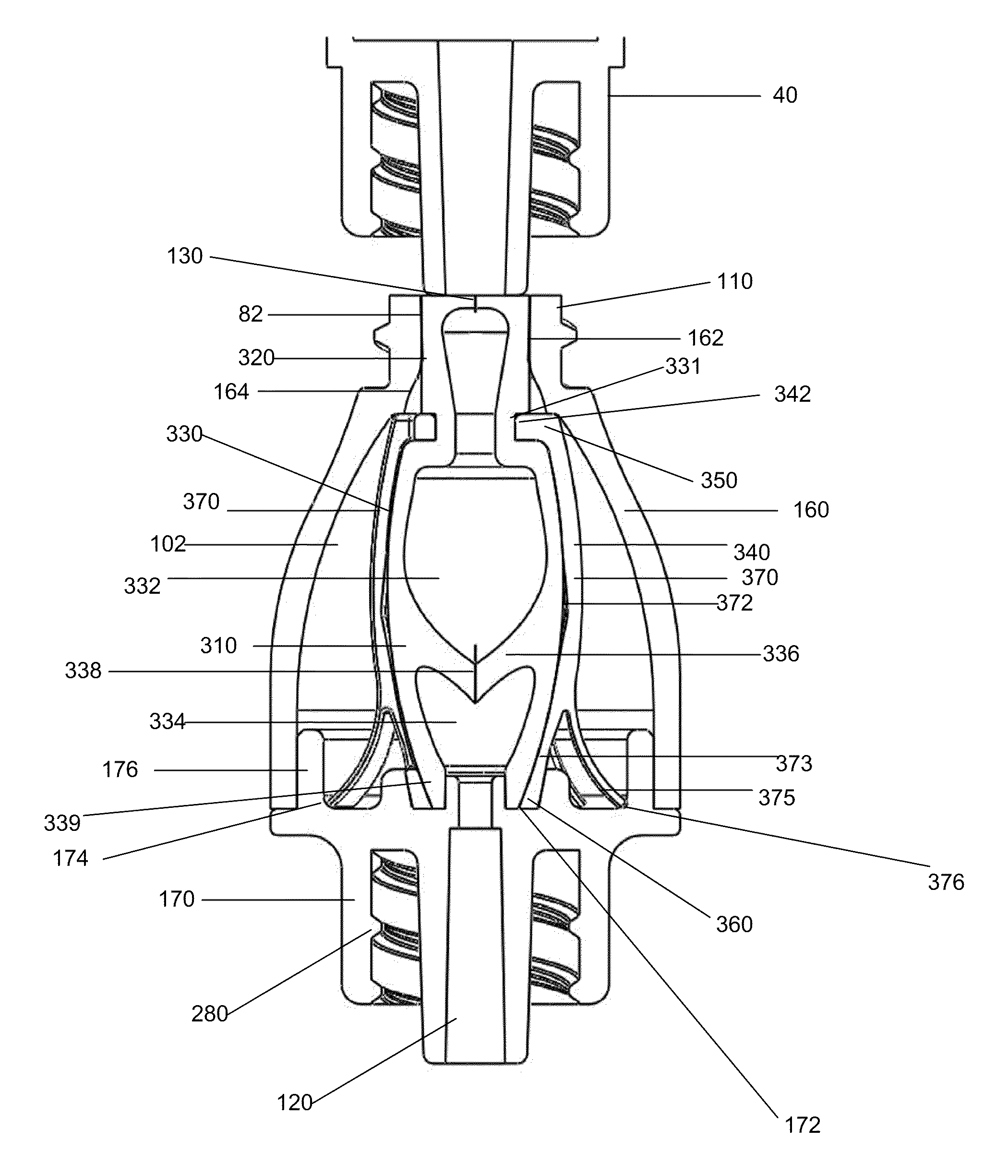

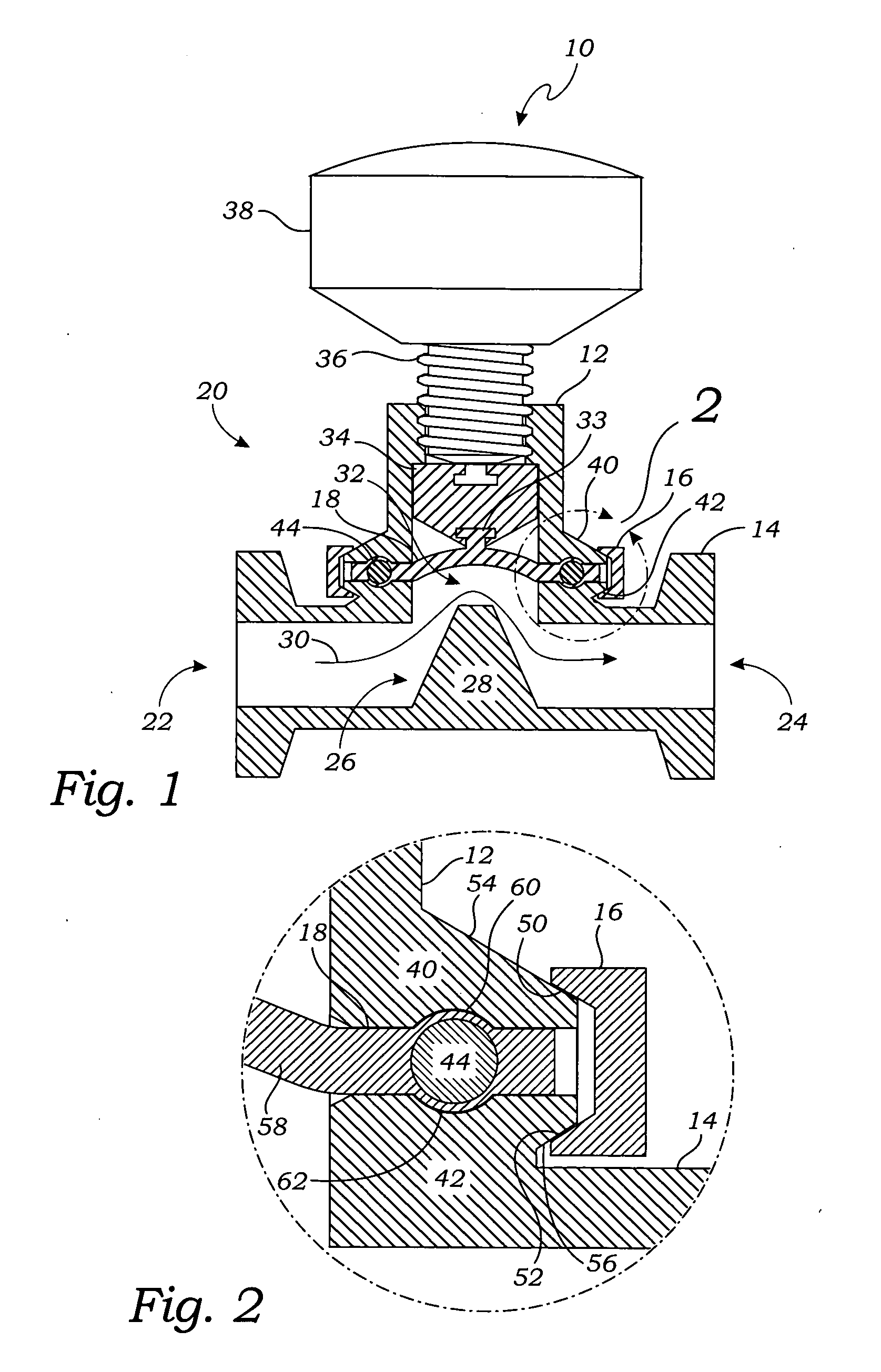

Medical Valve with Fluid Volume Alteration

ActiveUS20110319859A1Prevent fluid flowMedical devicesIntravenous devicesMechanical forceBiomedical engineering

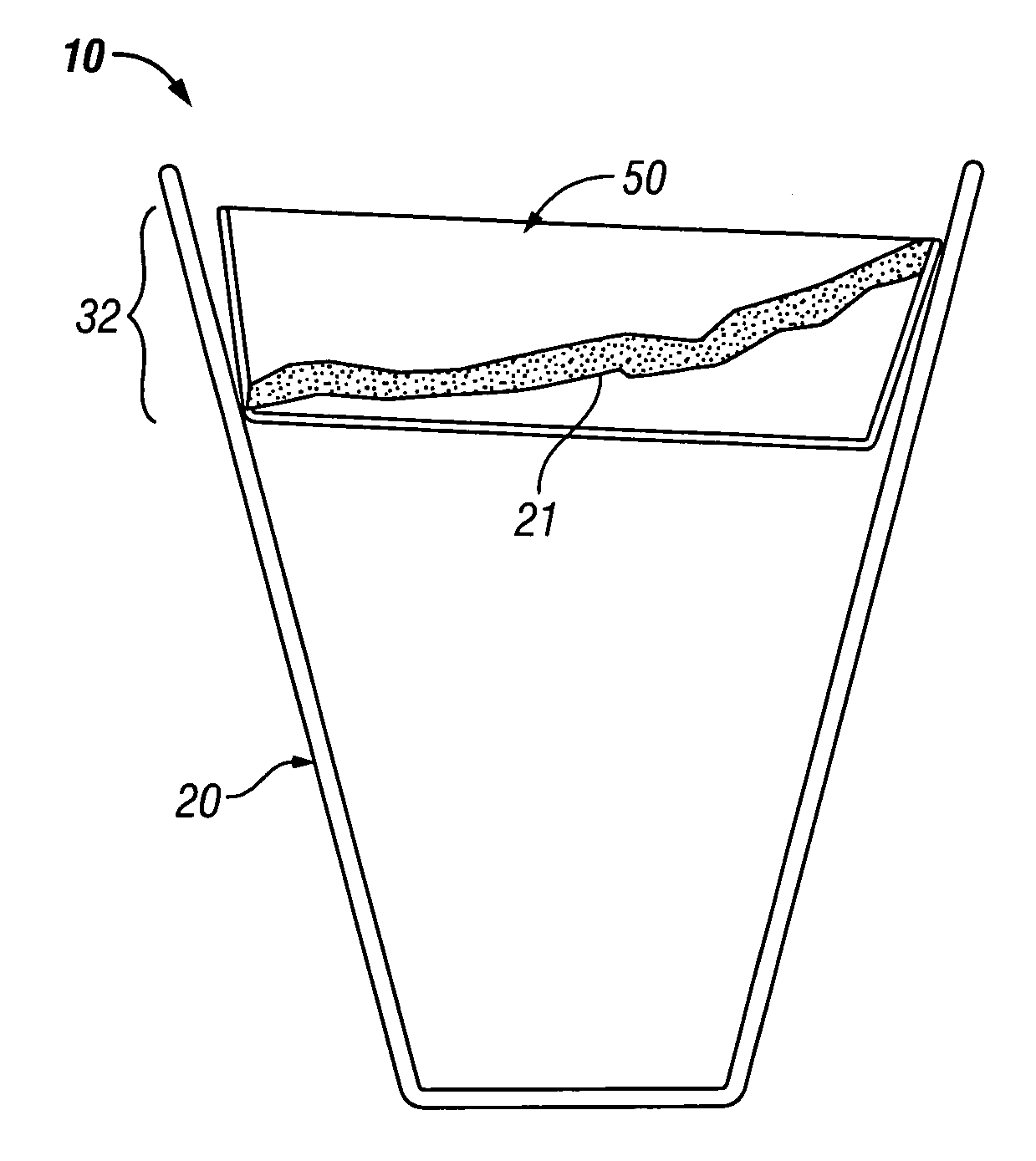

A medical valve has an open mode that permits fluid flow, and a closed mode that prevents fluid flow. To that end, the medical valve has a housing having an inlet and an outlet, and a resilient member within the housing. The resilient member has a body portion with a free state when undeformed by external mechanical forces and a deformed state when the valve is in the closed mode. The body portion is formed to return toward the free state as the valve transitions from the closed mode to the open mode and defining at least part of a fluid path through the valve.

Owner:NP MEDICAL

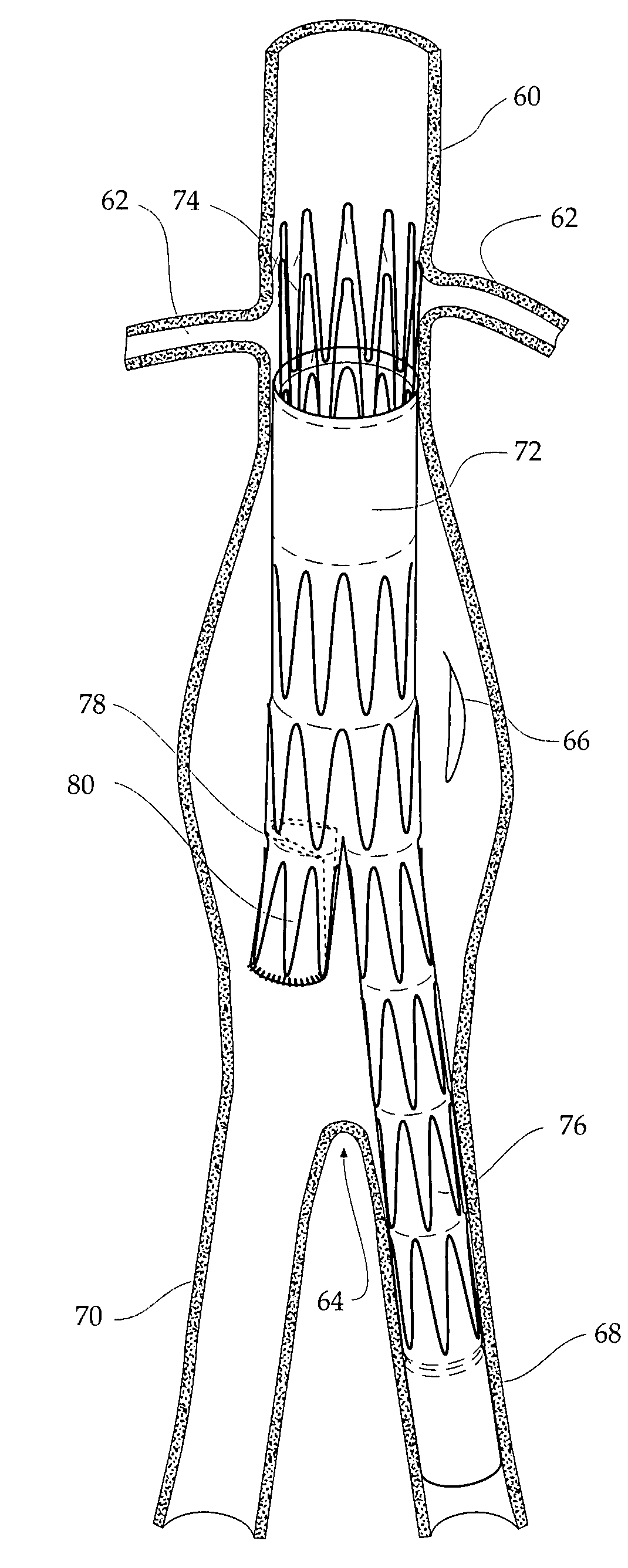

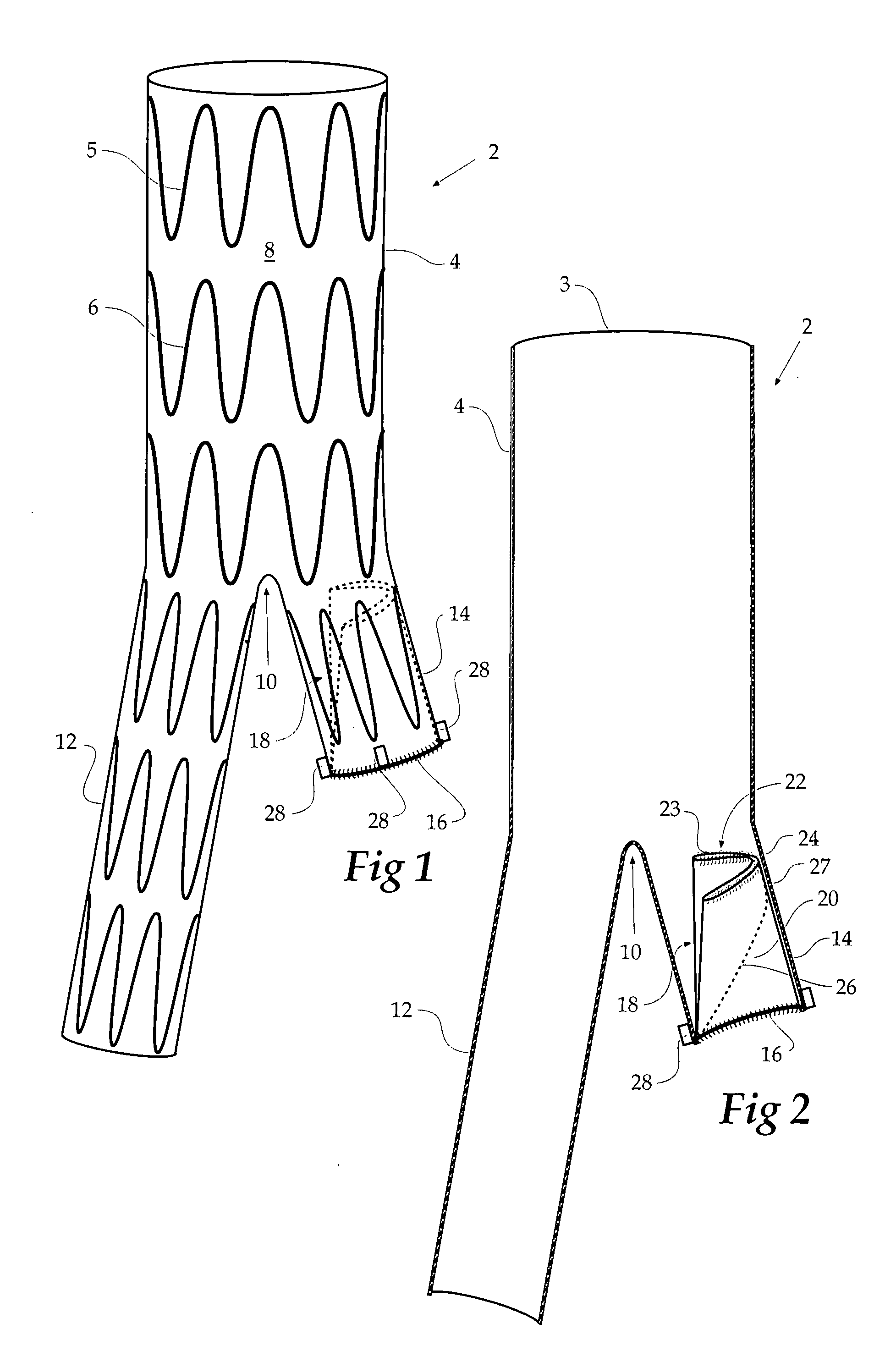

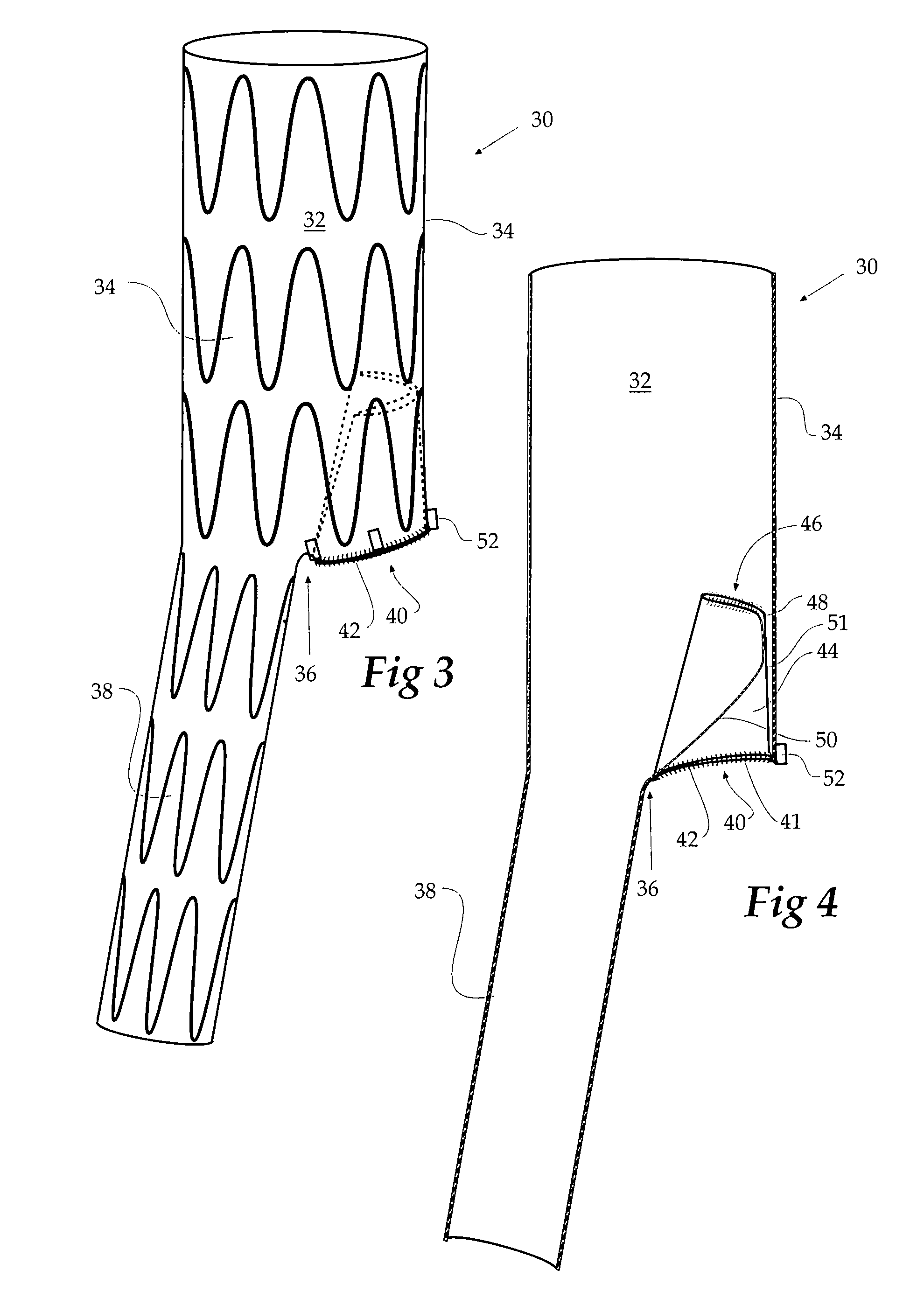

Stent graft for treatment of emergency rupture of a vessel

A stent graft (2) for treatment of an emergency rupture of, for instance, the aorta adjacent the aortic bifurcation. The stent graft comprising a tubular body (8) with a bifurcation (10) in the tubular body defining a first long leg (12) and a second short leg (14). The second leg has a valve arrangement (18) to prevent fluid flow through the second leg from the stent graft. The valve can be opened from external of the stent graft for the placement of a leg extension stent graft (90) therethrough.

Owner:COOK MEDICAL TECH LLC

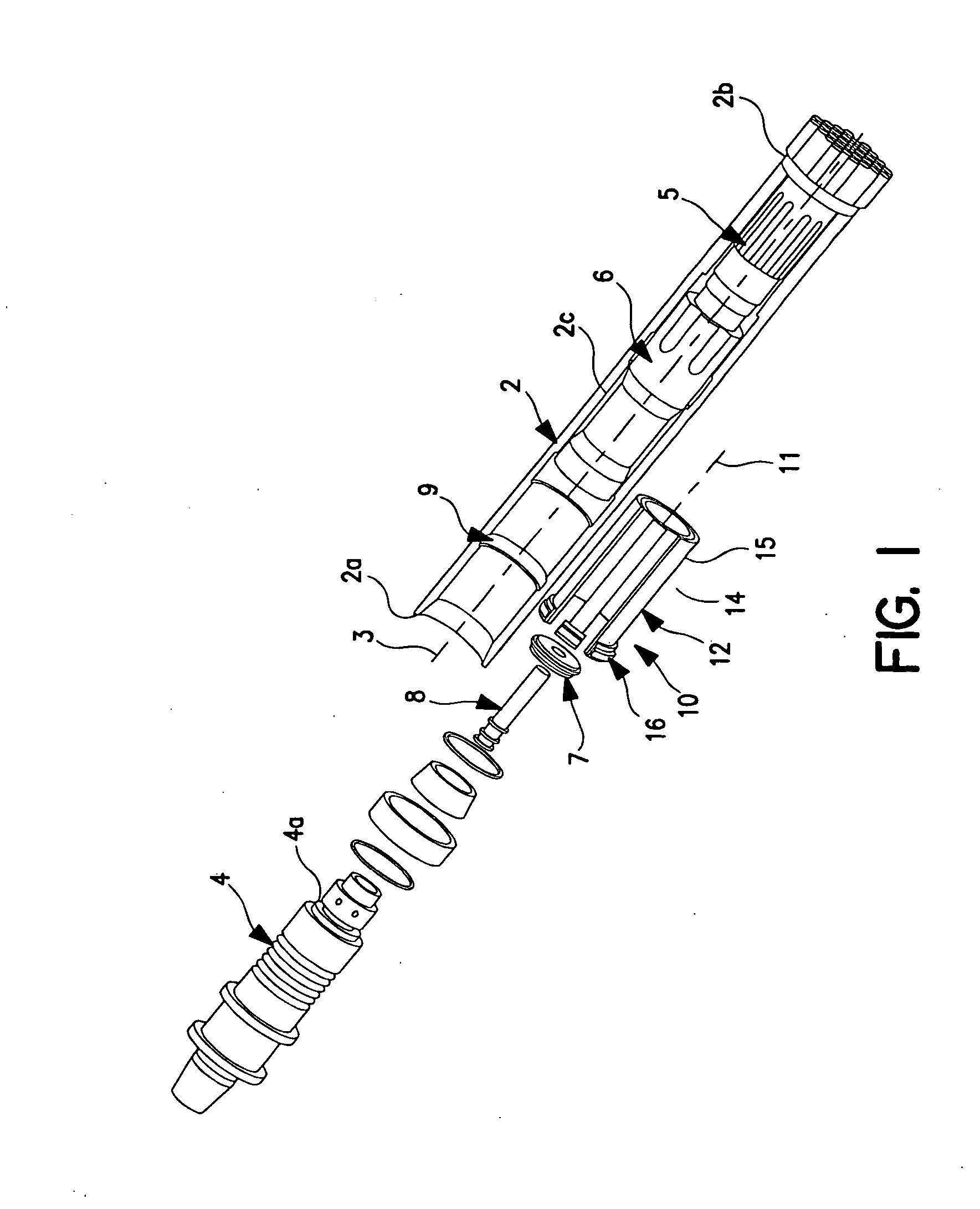

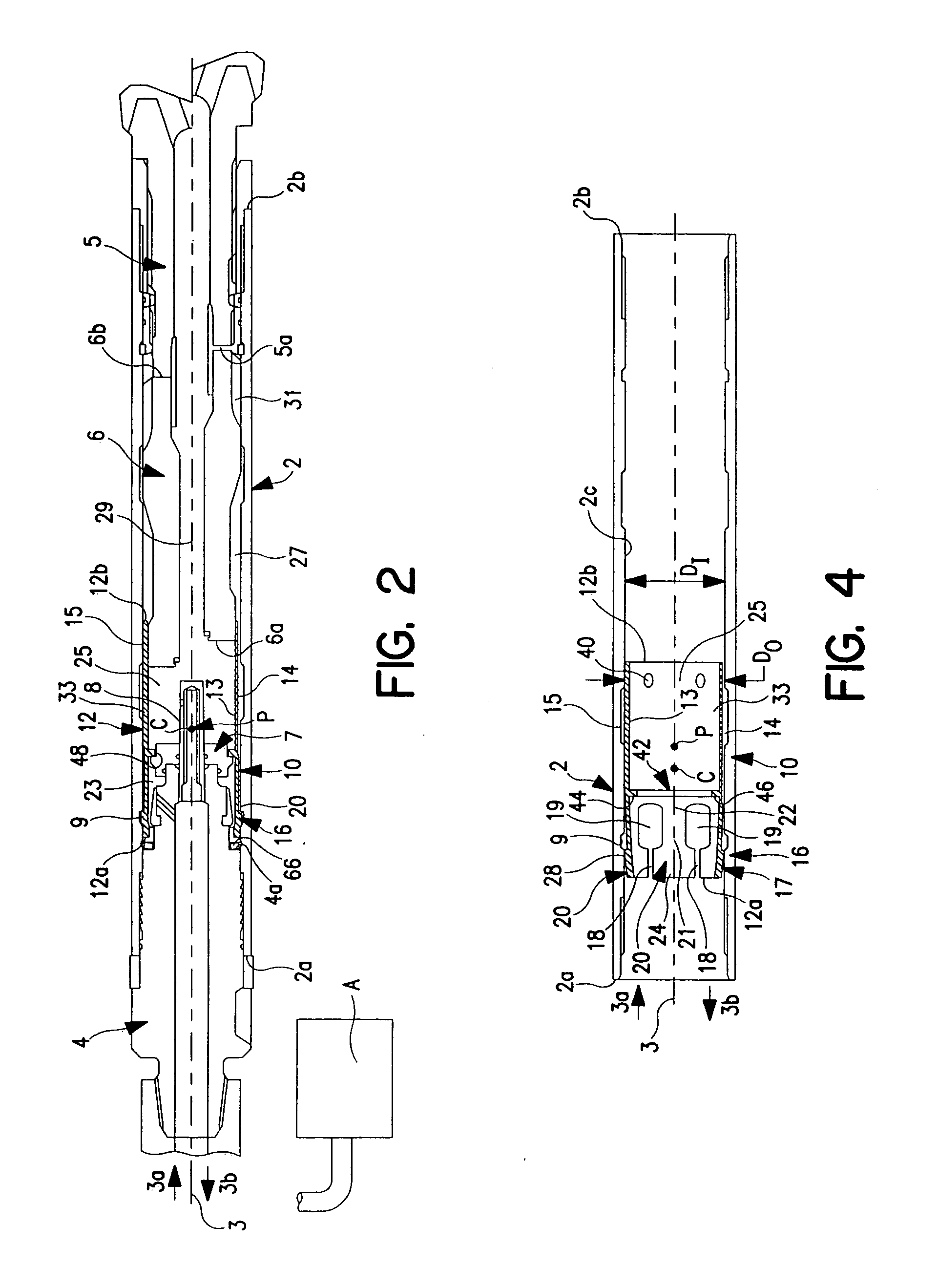

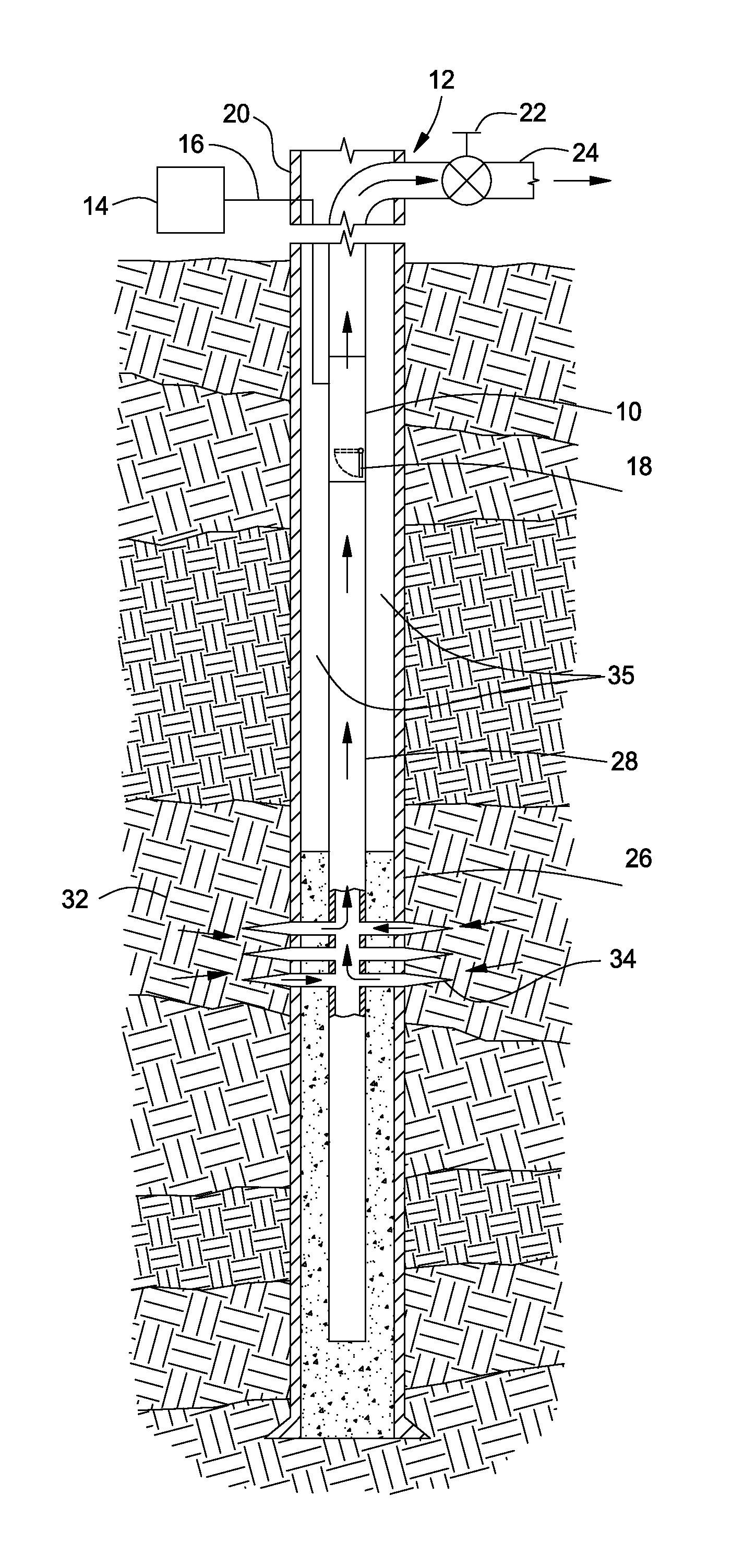

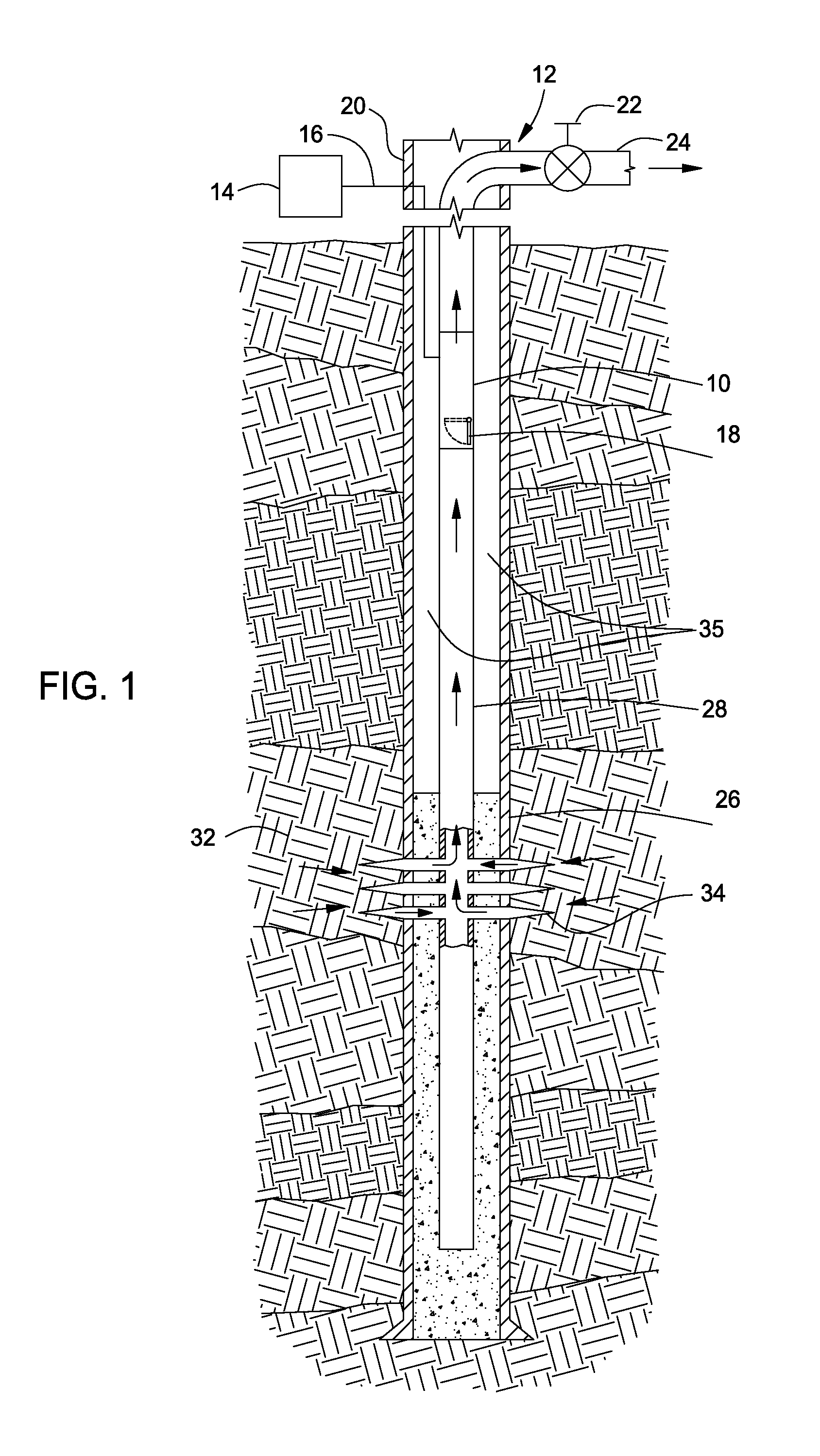

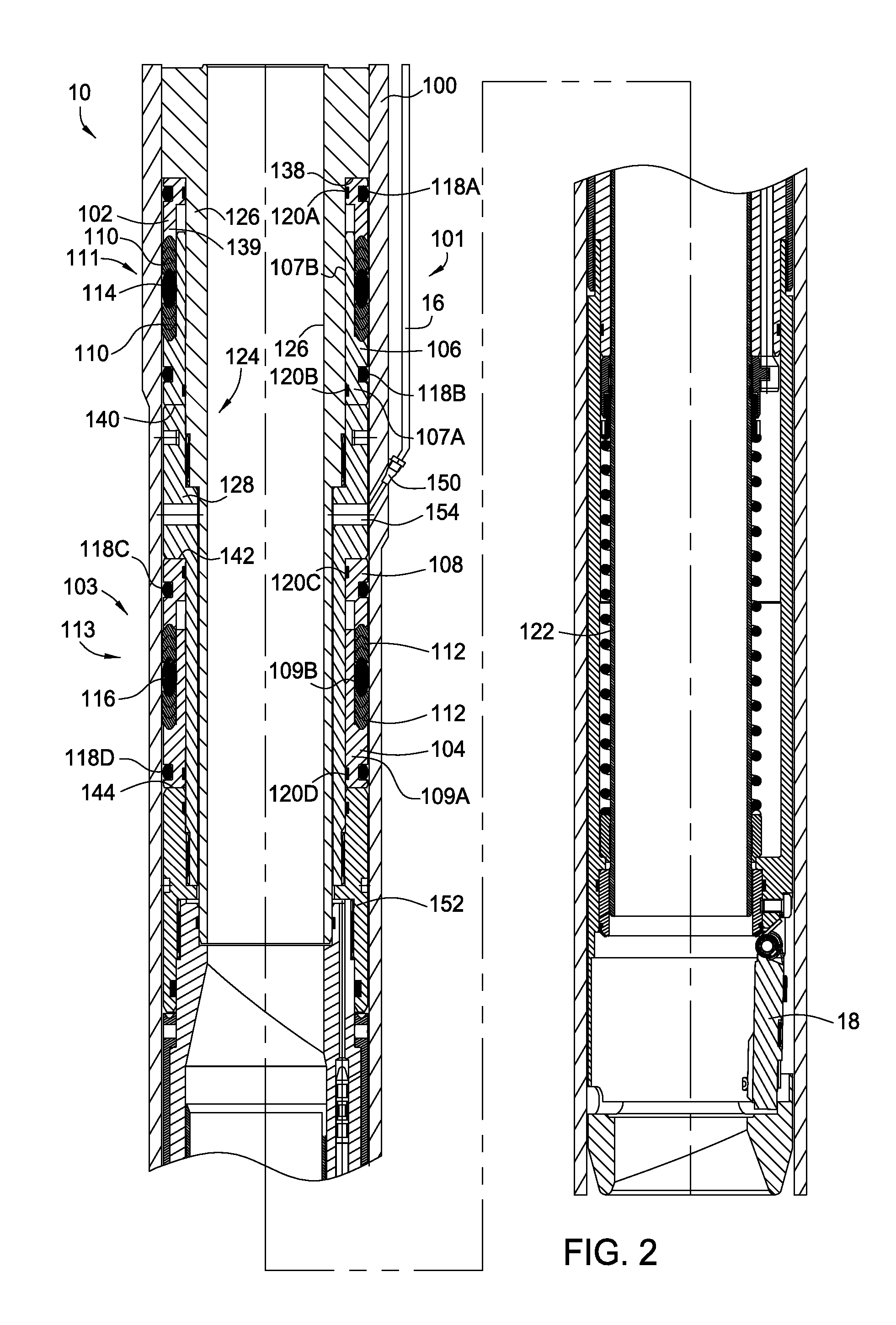

One-position fill-up and circulating tool

InactiveUS20060151181A1Prevent fluid flowDrilling rodsFluid removalStructural engineeringMechanical engineering

Embodiments of the present invention include methods and apparatus for circulating fluid through casing and filling the casing with fluid using a combination fill-up and circulating tool while maintaining the fill-up / circulating tool in substantially the same position relative to the casing. In one embodiment, the fill-up / circulating tool includes a mandrel insertable into casing and having a sealing element therearound, the sealing element capable of sealingly engaging with an outer diameter of the mandrel to permit circulating fluid through the casing. The fill-up / circulating tool is also capable of allowing air flow around the outer diameter of the mandrel for the operation of filling the casing with fluid without the need to move the mandrel within the casing.

Owner:WEATHERFORD TECH HLDG LLC

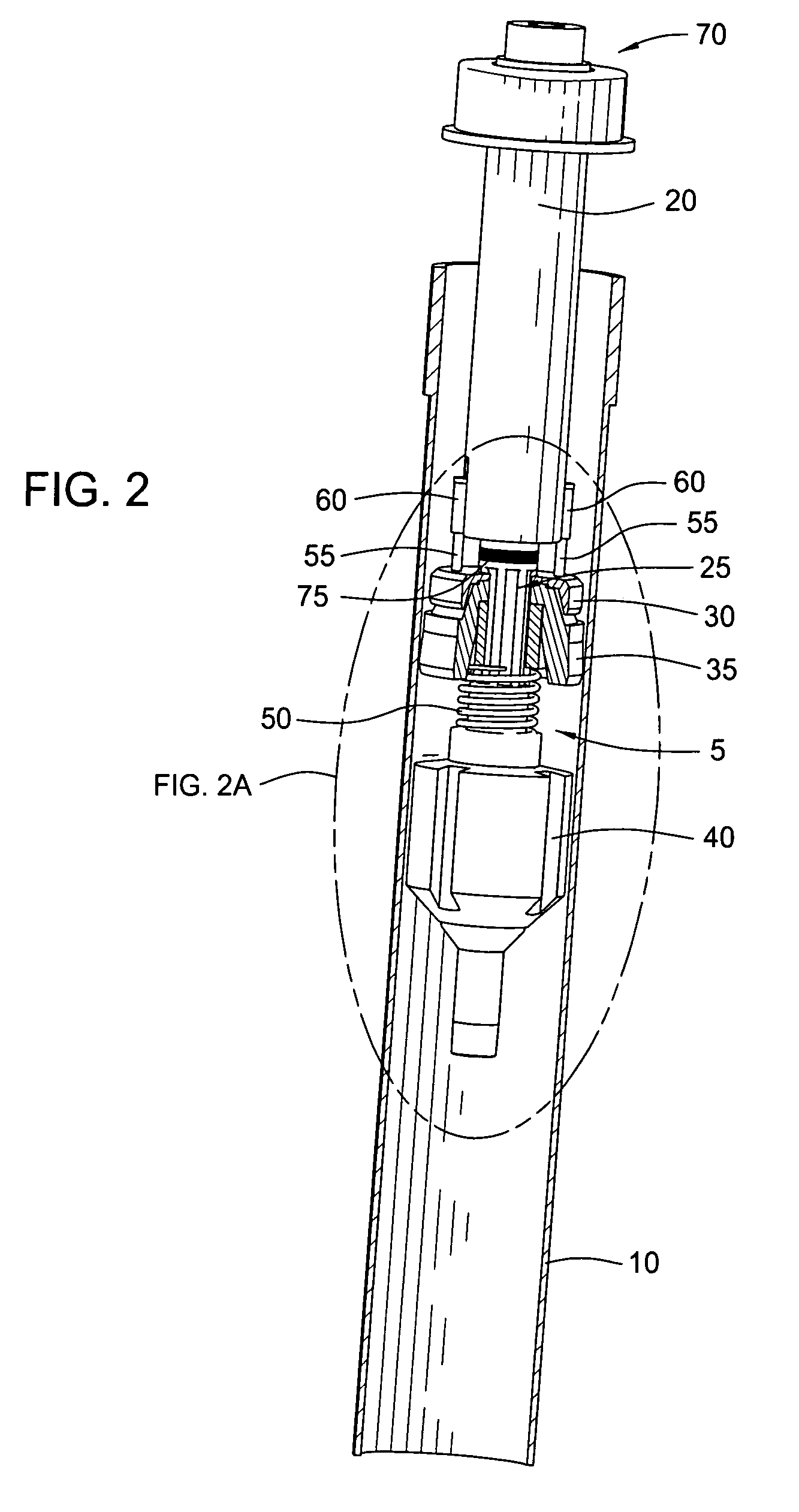

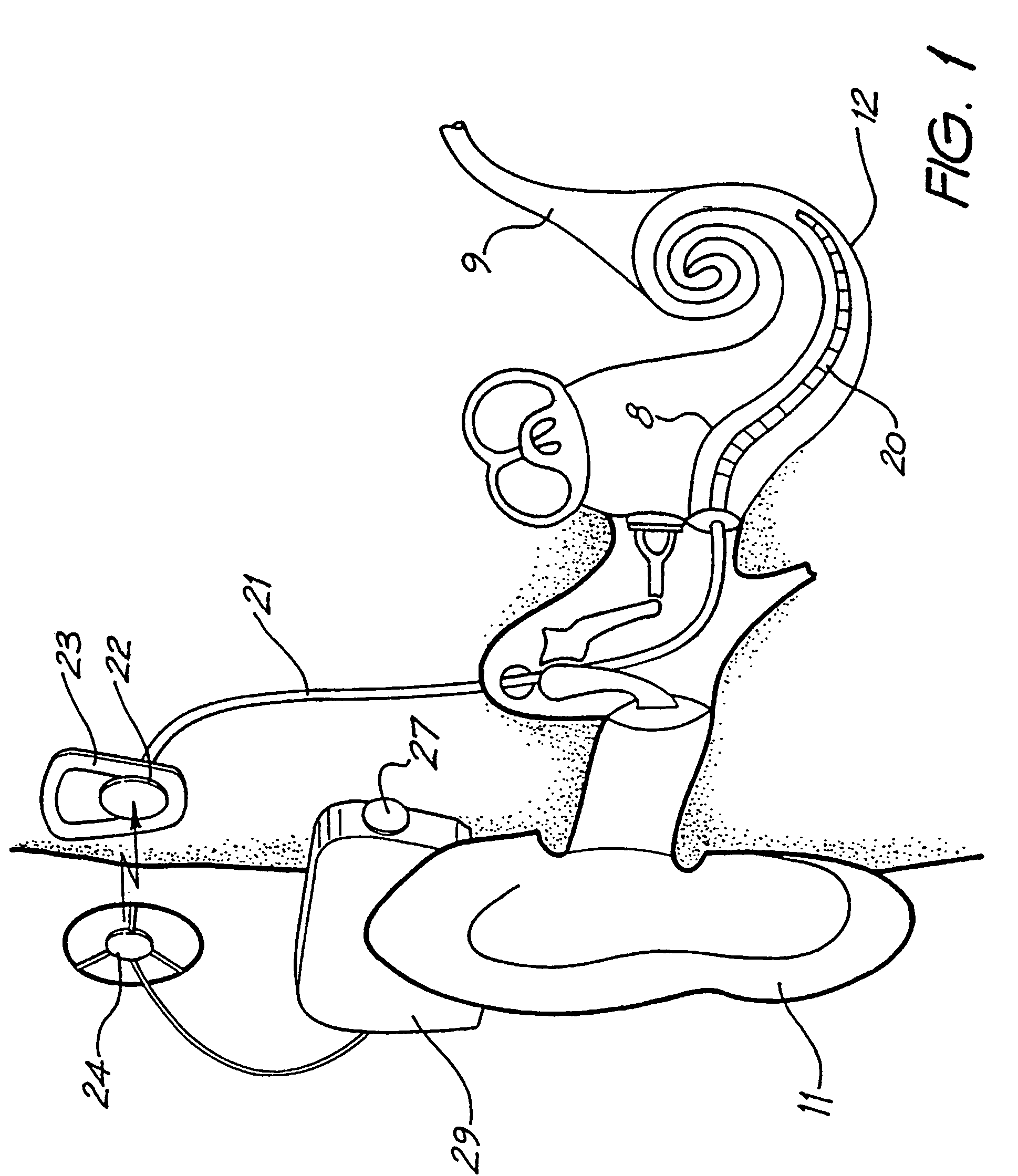

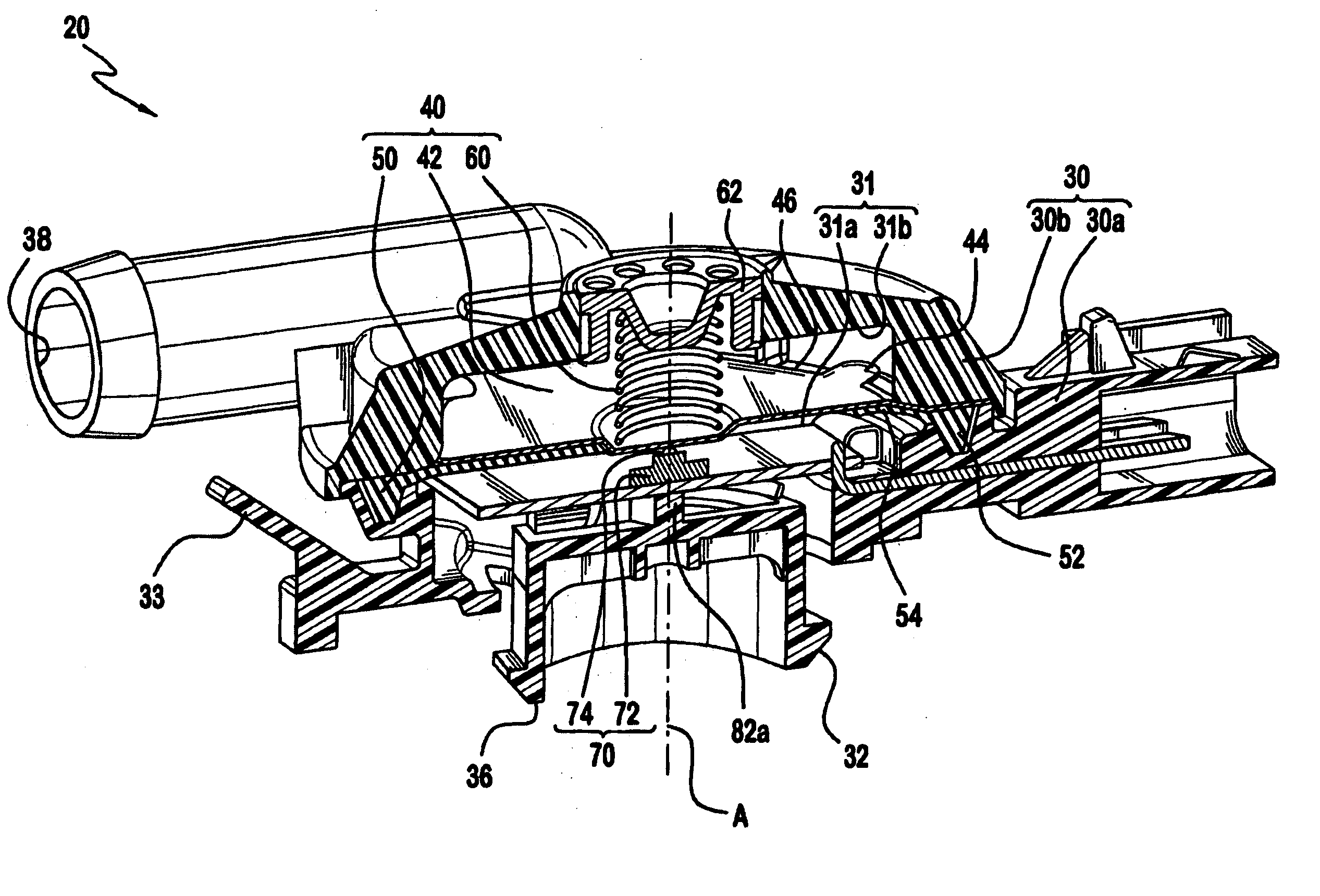

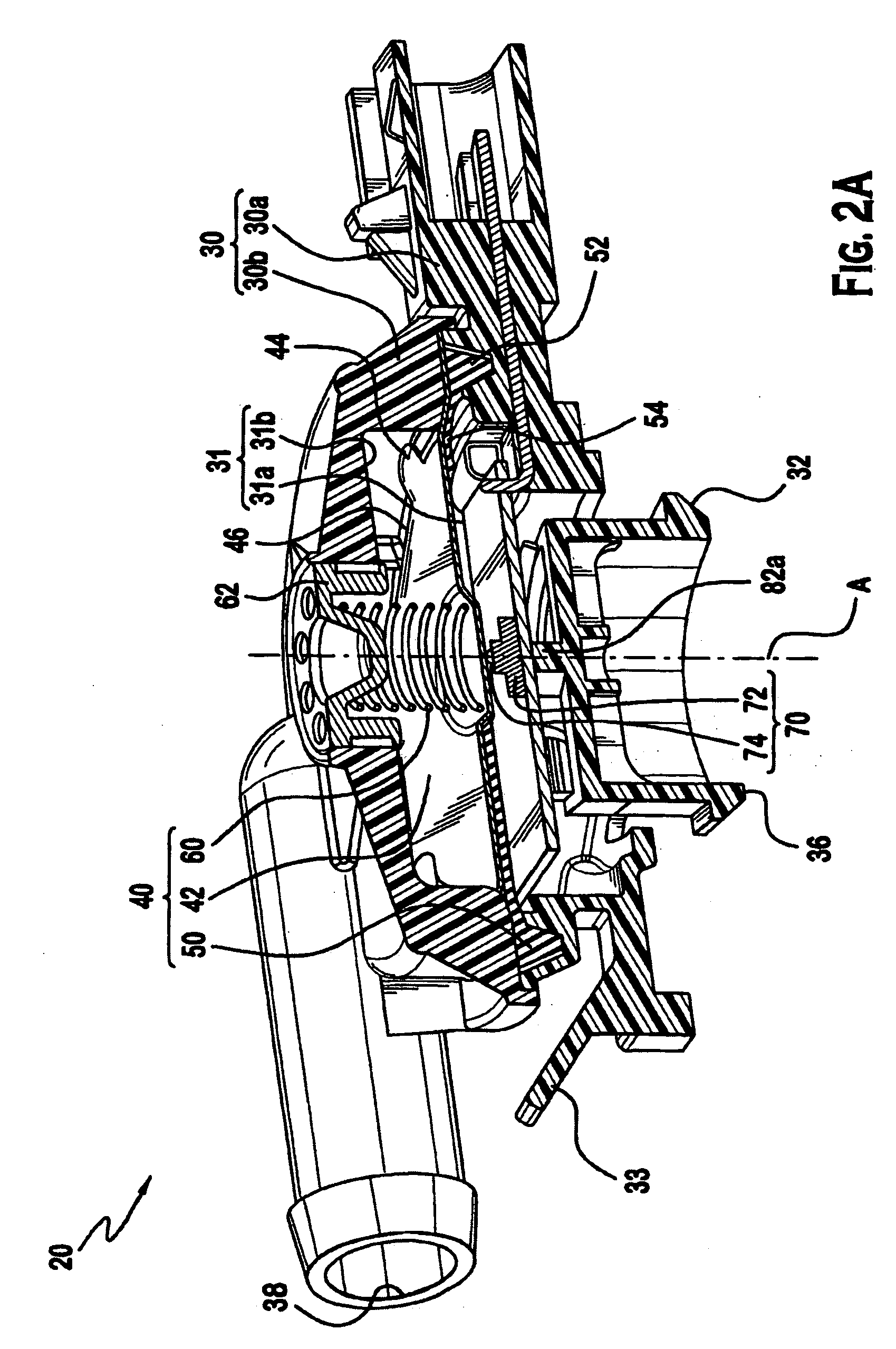

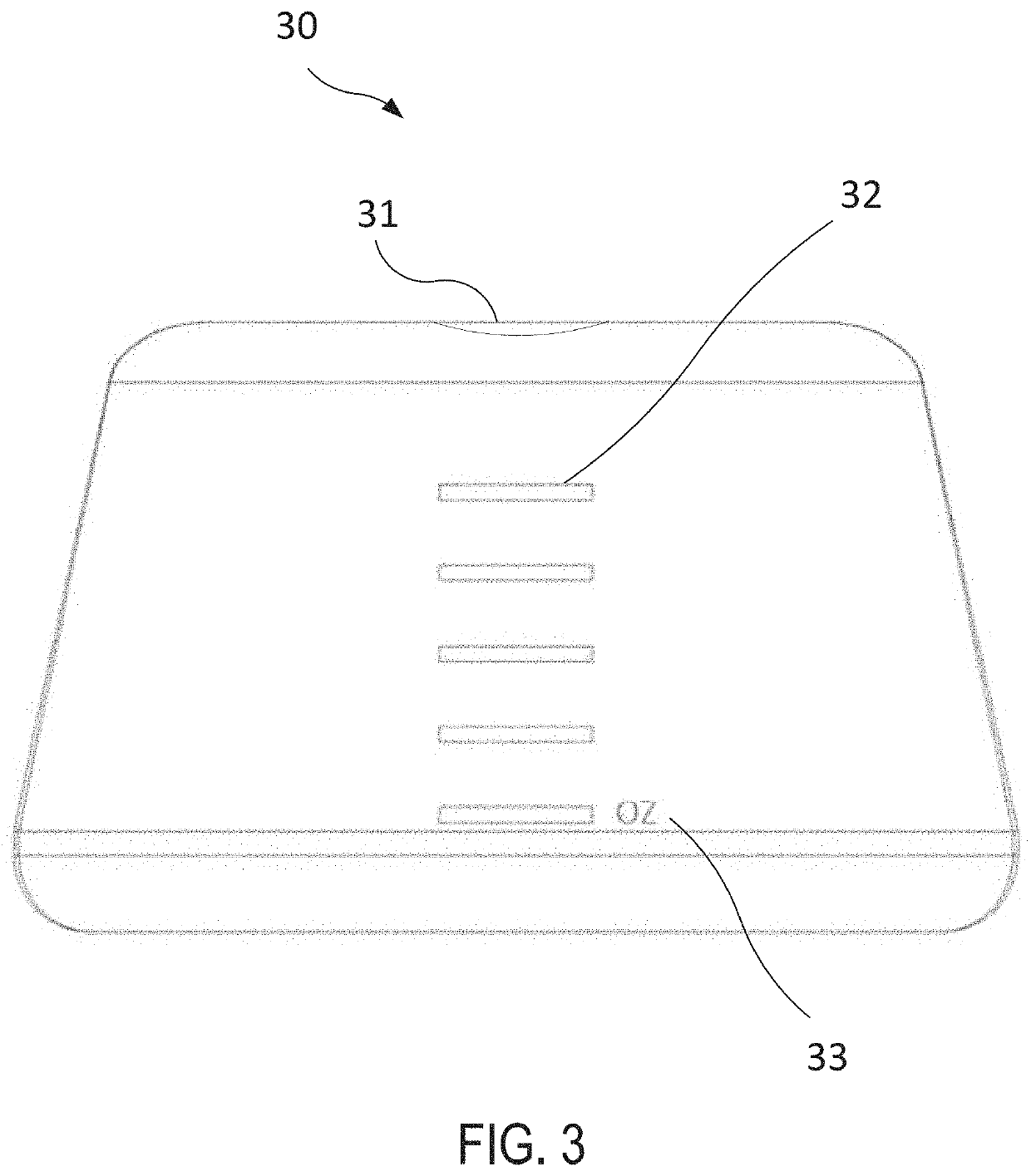

Laminated electrode for a cochlear implant

InactiveUS7406352B2Prevent fluid flowAvoid flowHead electrodesExternal electrodesCochlear implantationElectrode array

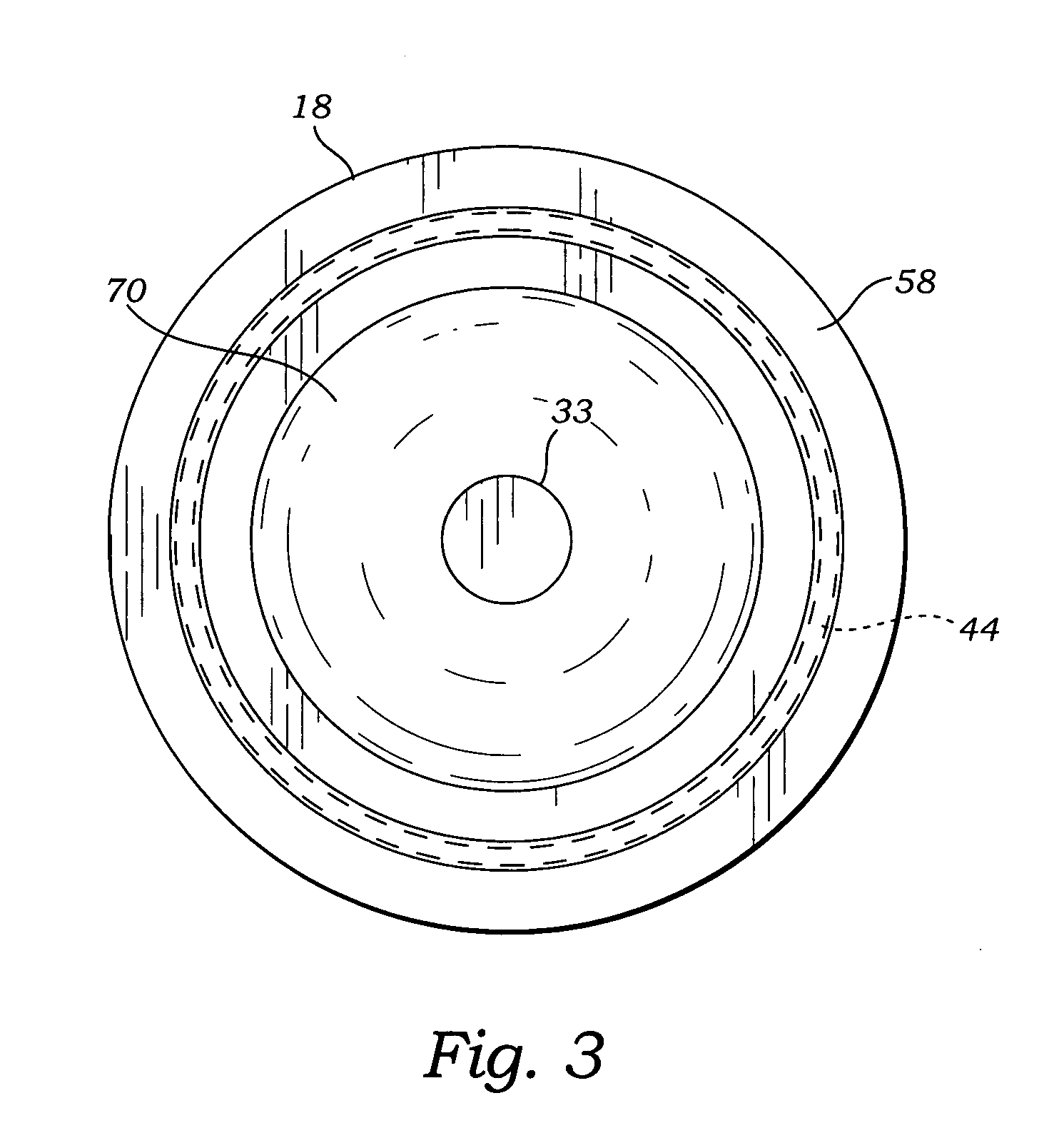

An implantable cochlear implant electrode array (30) that can adopt a first, preferably straight, configuration selected to allow the array to be inserted into the cochlea and at least a second, preferably, spirally curved, configuration wherein the electrode array (30) is adapted to apply tissue stimulation. The electrode array (30) comprises an elongate carrier (31) having a proximal end (37), a distal end (34), and a plurality of electrodes supported by the carrier (31) at respective spaced locations thereon, the carrier (31) is formed, preferably moulded, to preferentially adopt the second configuration or another configuration different to said first configuration. The outer layer (33) is releasably connected to the elongate carrier (31) by an adhesive layer (32) and is formed so as to bias the carrier (31) into the first configuration when connected thereto. A method of forming the electrode array (30) is also disclosed.

Owner:COCHLEAR LIMITED

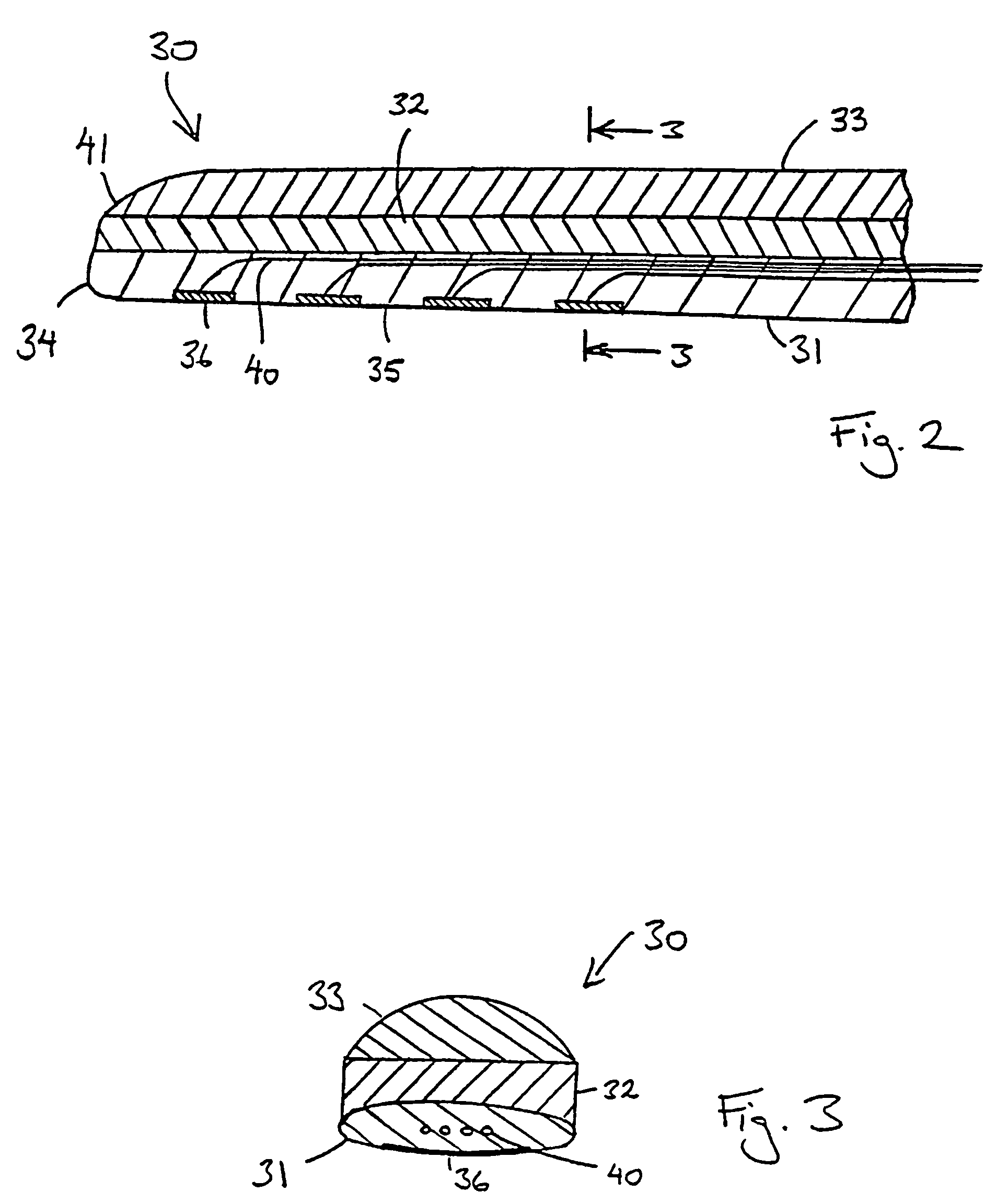

Valve diaphragm with a compression restraining ring, and valve including same

A valve is disclosed including a body, a bonnet, a flexible diaphragm adapted to be positioned between the bonnet and the body, and an actuator mechanism. The flexible diaphragm has a central portion and a peripheral portion surrounding the central portion, wherein the peripheral portion includes a substantially rigid ring extending continuously through or on the peripheral portion. The body has an input port, a central portion, and an output port. The actuator mechanism is operatively coupled to the diaphragm for moving the diaphragm between an open configuration wherein the input port and output port are in fluid communication with each other, and a closed configuration wherein the diaphragm blocks the central portion and prevents fluid flow between the input port and the output port. The bonnet is adapted to house the actuator mechanism, and the actuator mechanism is positioned in the bonnet.

Owner:WINCEK CHRISTOPHER P

Lid for cup

InactiveUS20100288827A1Reduce thermal transferPrevent fluid flowRemovable lids/coversLidsMechanical engineeringClassical mechanics

Owner:BOOTH MICHAEL LYLE

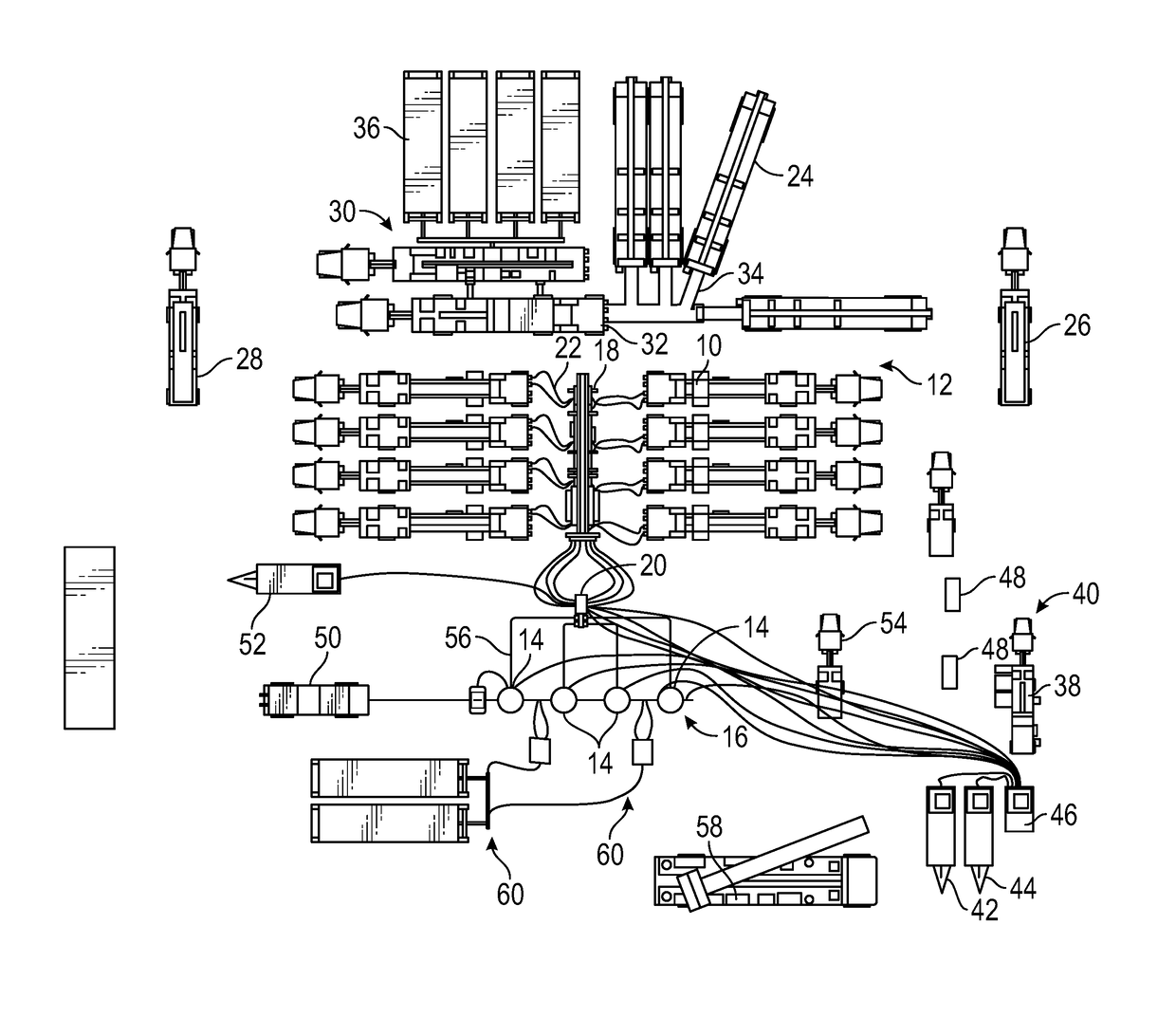

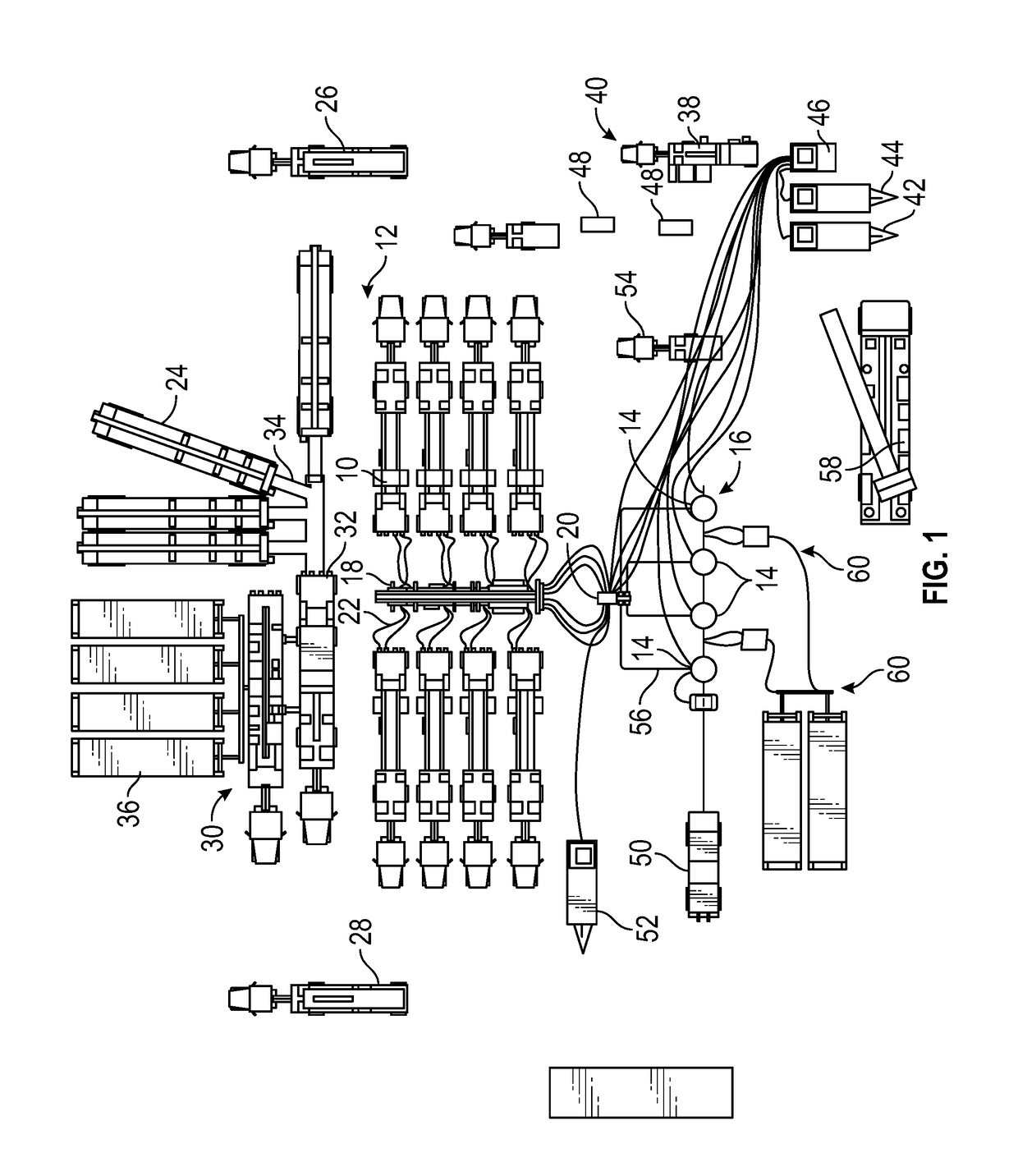

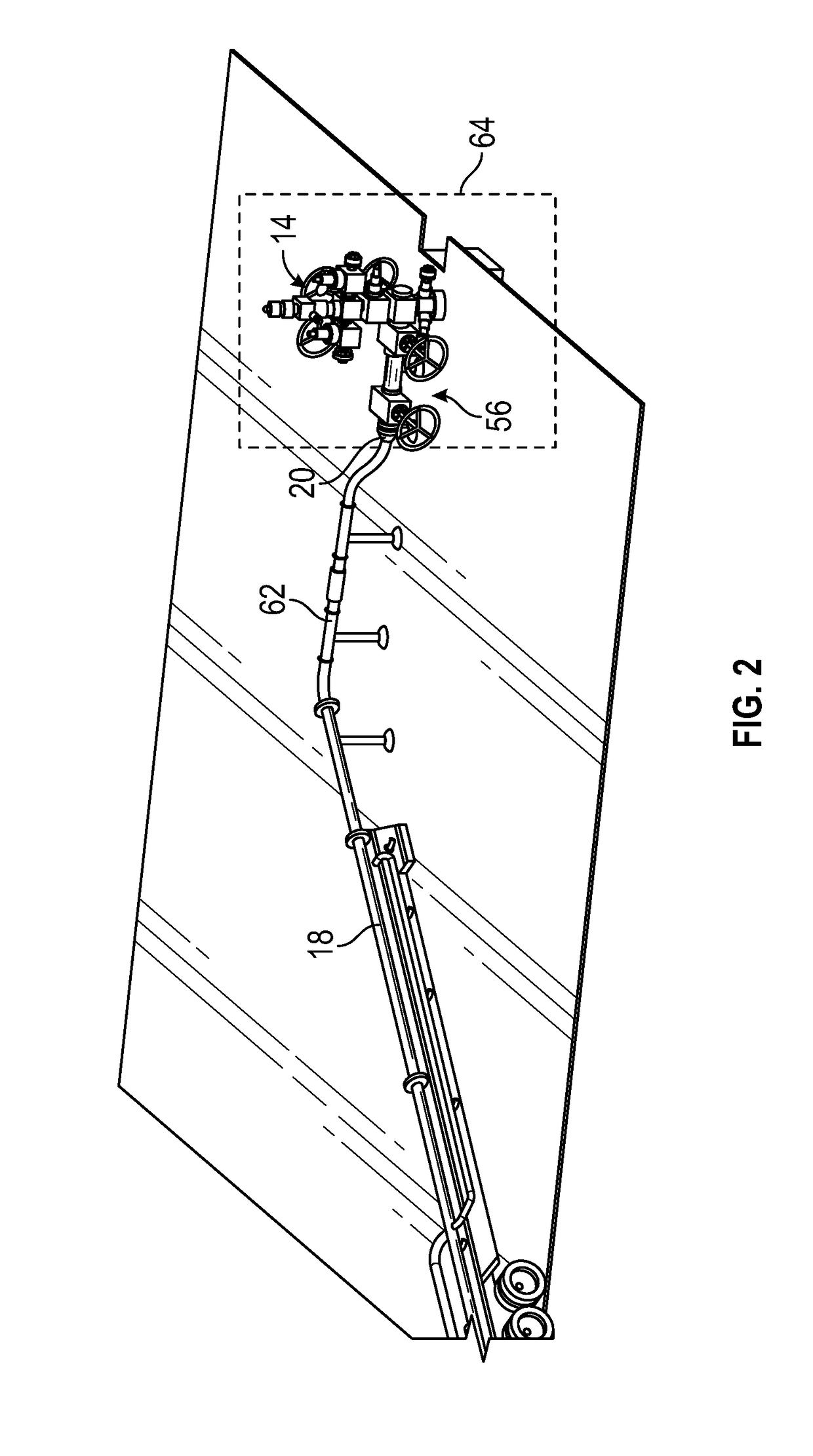

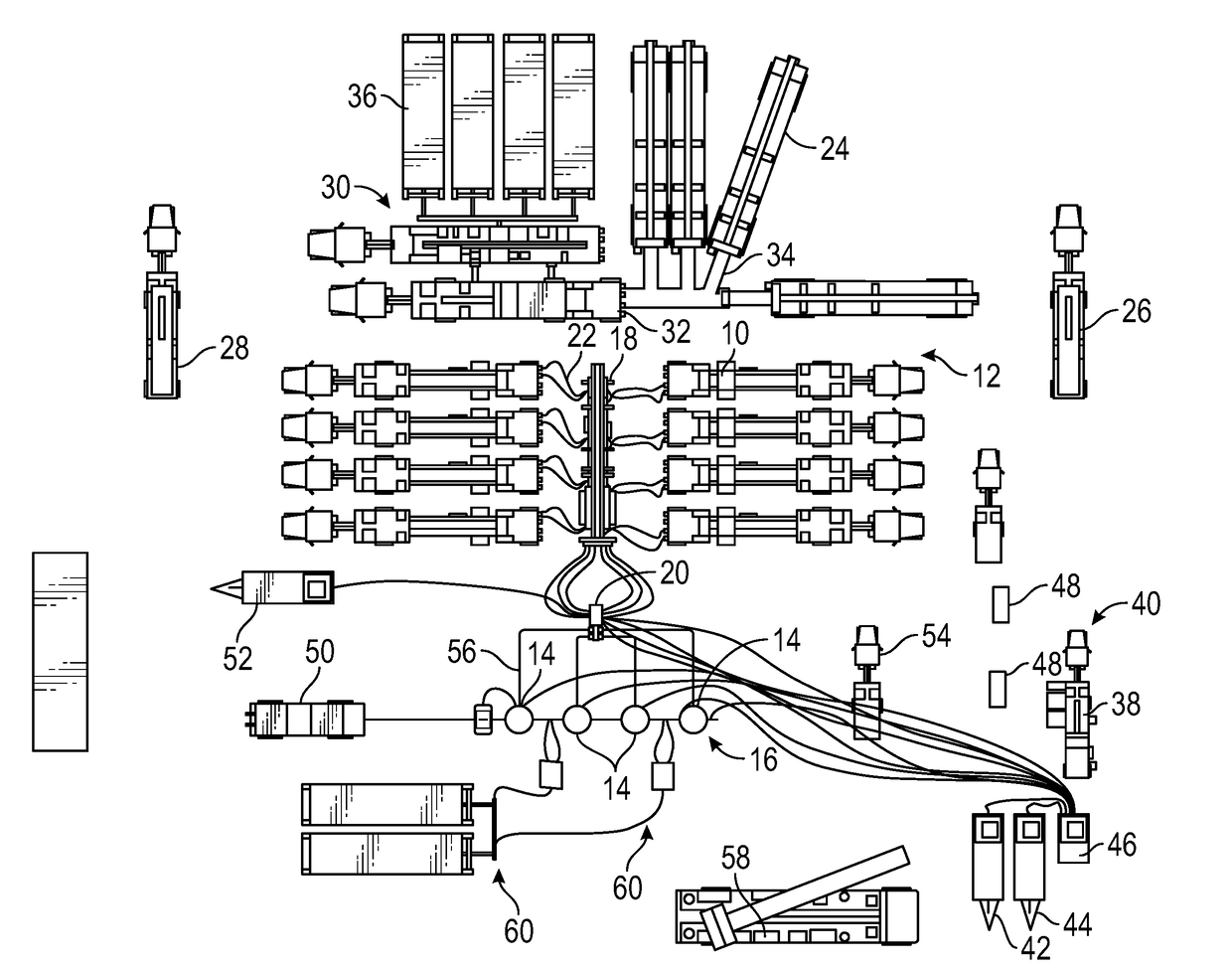

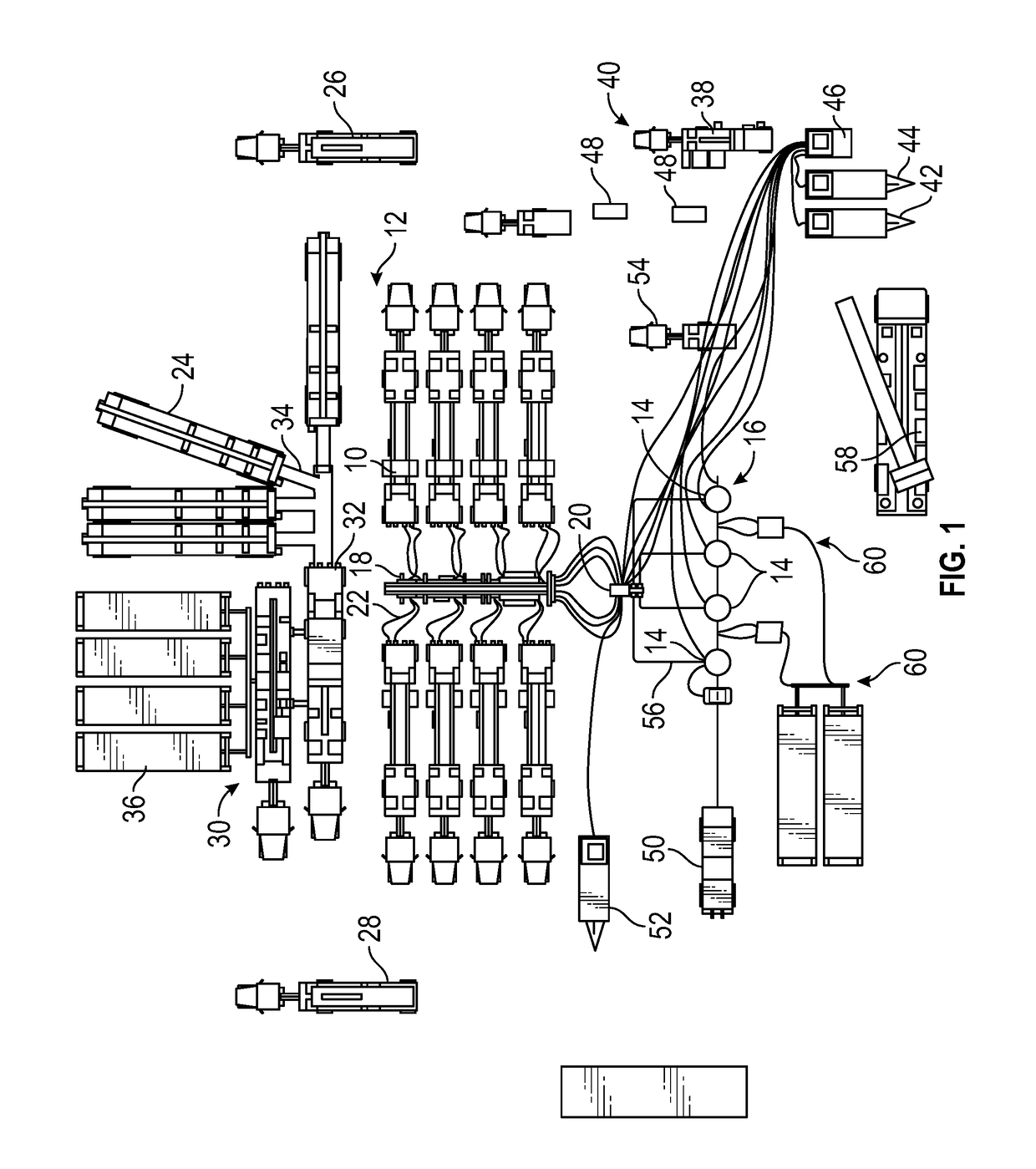

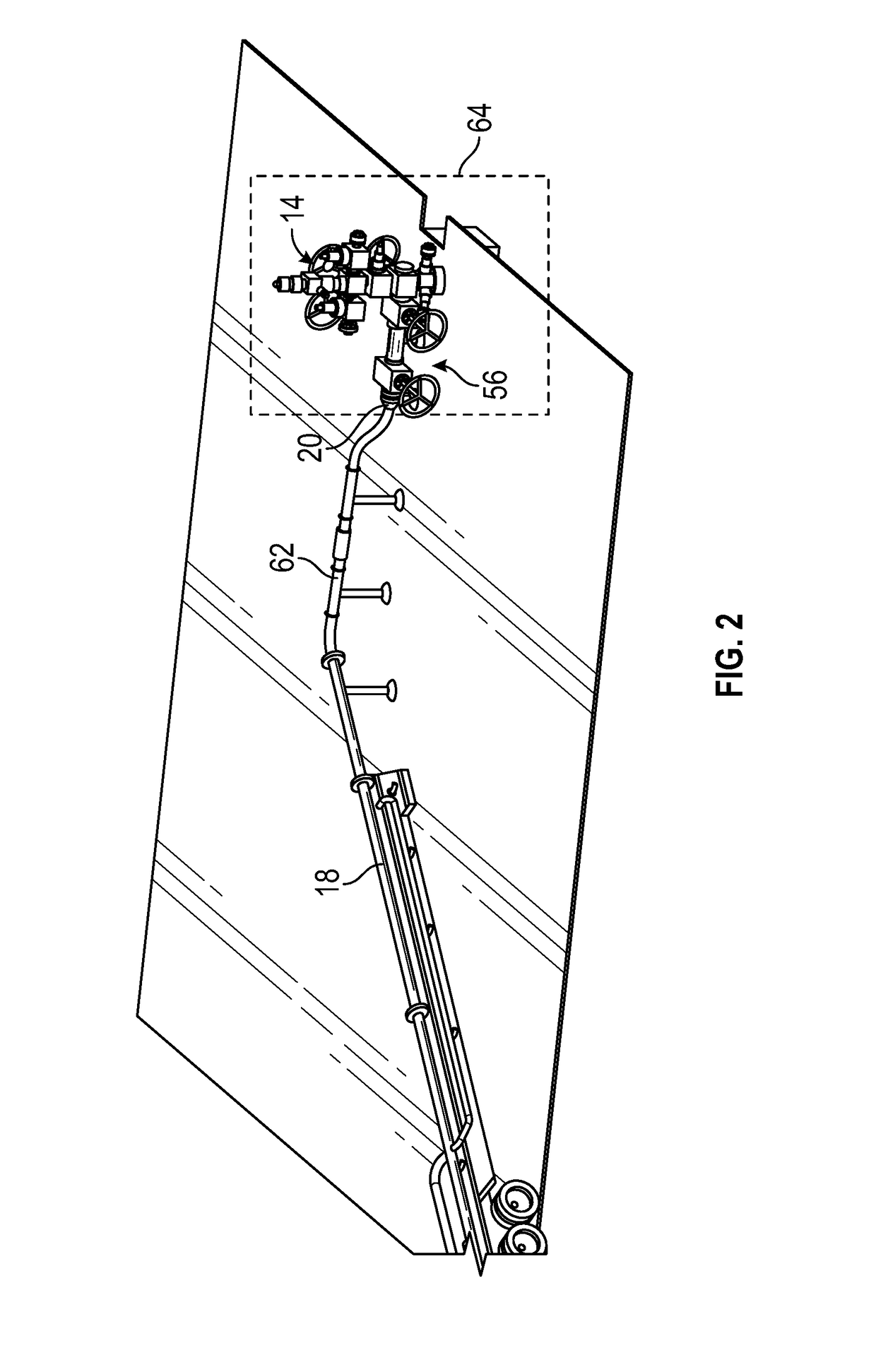

Systems and methods for fracturing a multiple well pad

A flow system for use at a hydraulic fracturing well site, including a tree attached to a wellhead, an inlet head in fluid communication with at least one hydraulic fracturing pump at the well site, and an adjustable fluid conduit providing fluid communication between the inlet head and the tree. The flow system further includes a valve in the fluid conduit and having an open position and a closed position, the valve permitting fluid flow through the fluid conduit when in the open position, and preventing fluid flow through the fluid conduit when in the closed position, at least a portion of the fluid conduit positioned between the valve and the tree.

Owner:VAULT PRESSURE CONTROL LLC

Fluid distributor device for down-hole-drills

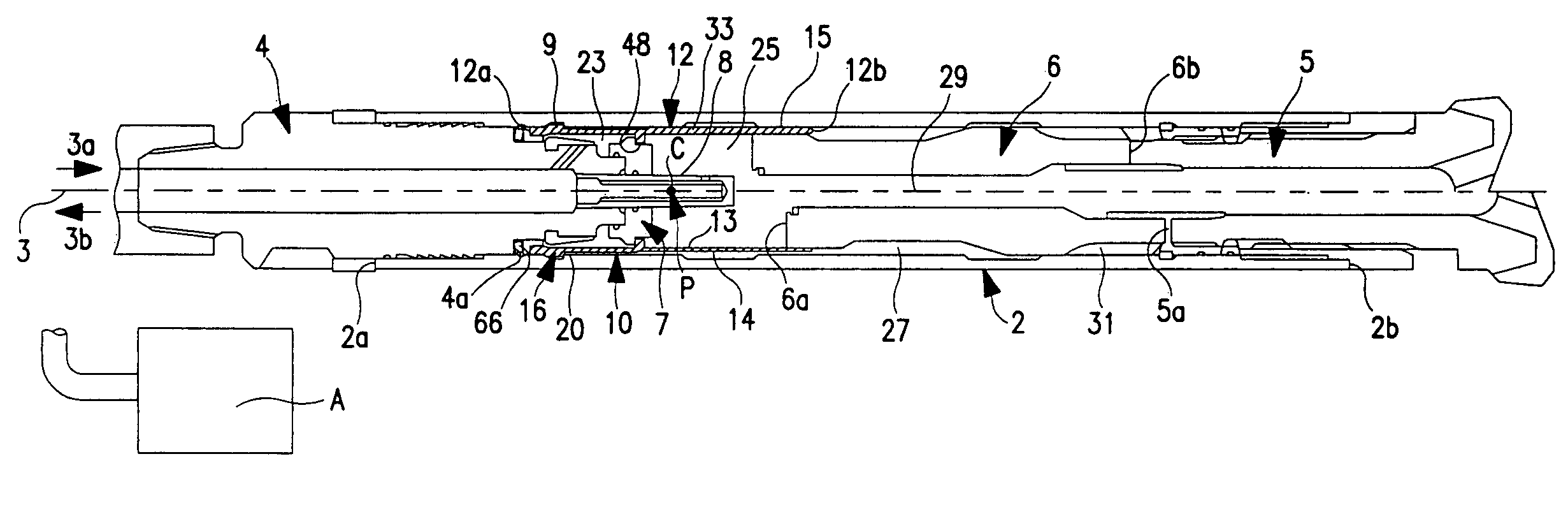

A fluid distributor device is for a percussive drill assembly including a generally tubular casing (2) having a longitudinal centerline and a piston (6) disposed within the casing so as to define a reservoir chamber (27) in the casing. The distributor device comprises a generally cylindrical body (12) disposed within the casing and including a central axis, two opposing ends spaced apart along the axis, first and second interior chambers and a port fluidly connecting the two chambers. The body further has a plurality of fluid passages extending between the two ends and fluidly connecting the first chamber with the reservoir chamber and a deflectable retainer portion (16) releasably engaged with the casing so as to retain the body at a desired position with respect to the casing centerline. A valve (7) is disposed within the body and is configured to permit fluid flow through the port and to alternatively prevent fluid flow through the port.

Owner:ATLAS COPCO SECOROC AB

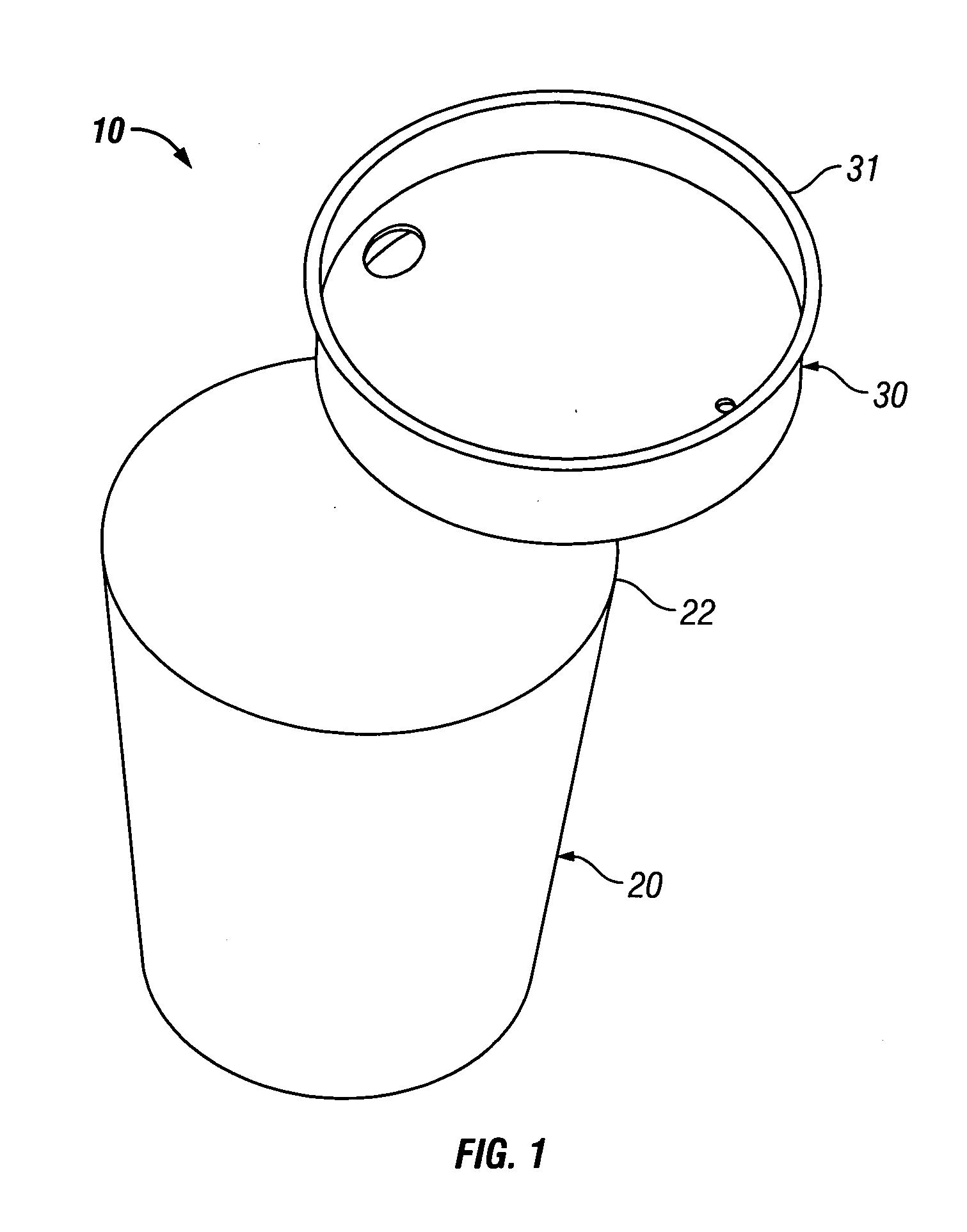

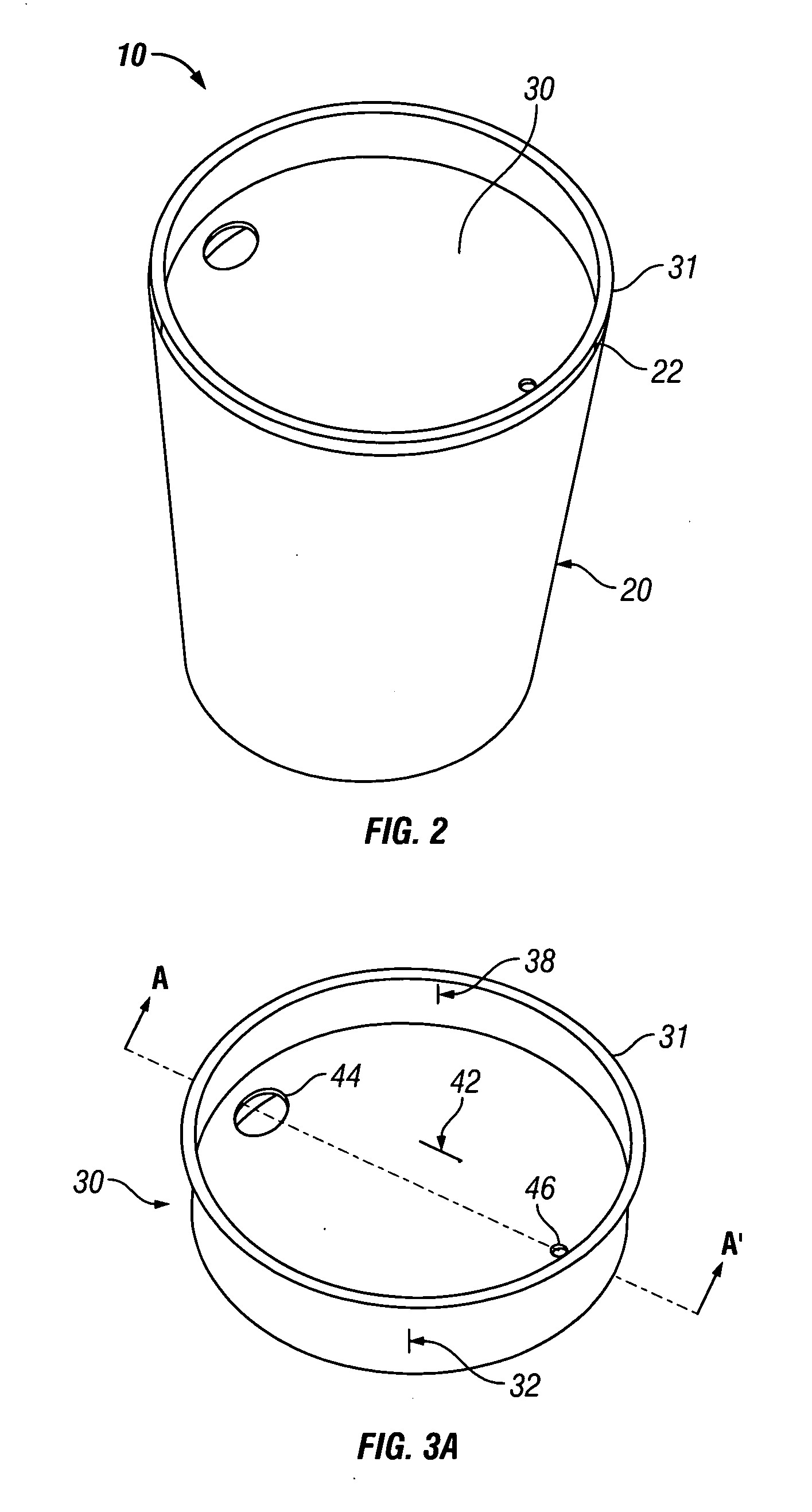

Pour Cap For Fluid Containers

InactiveUS20090250469A1Prevent fluid flowAvoid flowCapsPower operated devicesEngineeringBiomedical engineering

A pour cap for a fluid container includes a cap body, a gasket mounted to the cap body, and a threaded ring attached to the cap body. The cap can be positioned on the container in a closed position wherein the container is hydraulically sealed with a high pressure seal, or in an open position wherein fluid flow occurs through flow passages on the gasket and the cap body with first and second low pressure seals preventing unwanted leakage between joining parts on the cap. A method for sealing and pouring a fluid from a container includes the steps of providing the pour cap with the cap body, the gasket and the threaded ring; tightening the cap body to a closed position wherein deformation of the gasket seals the container with a high pressure seal; and then rotating the cap body to an open position wherein the gasket returns to an essentially undeformed state to form a fluid flow passage, while providing first and second low pressure seals for preventing unwanted fluid flow through the cap body and the threaded ring.

Owner:HYDRAPAK LLC

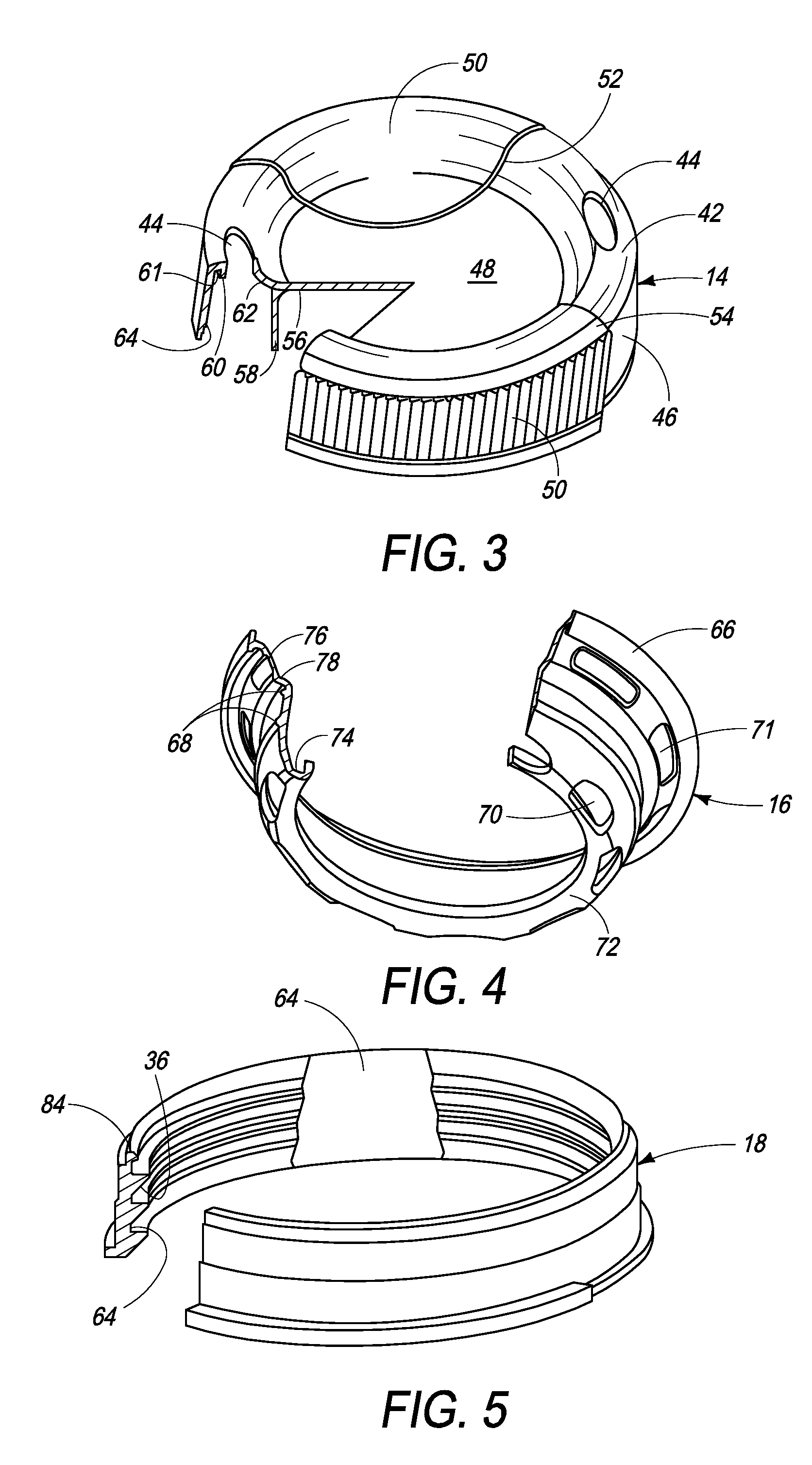

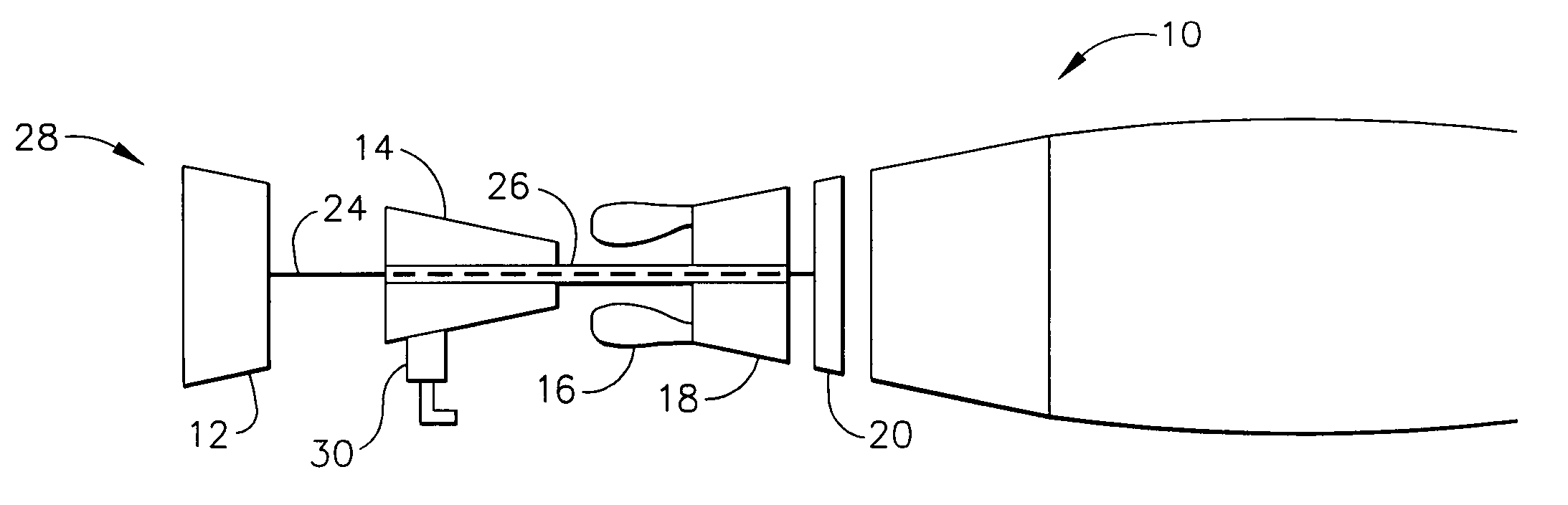

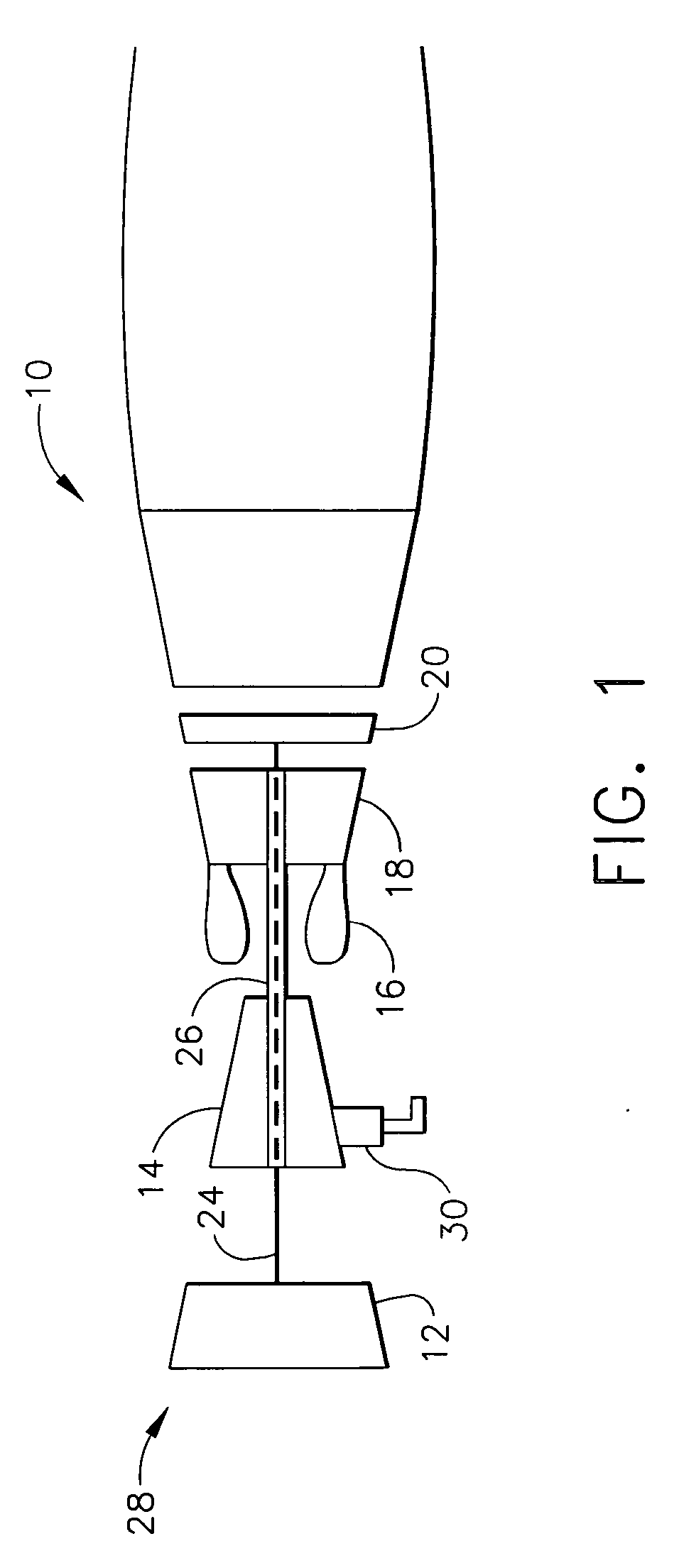

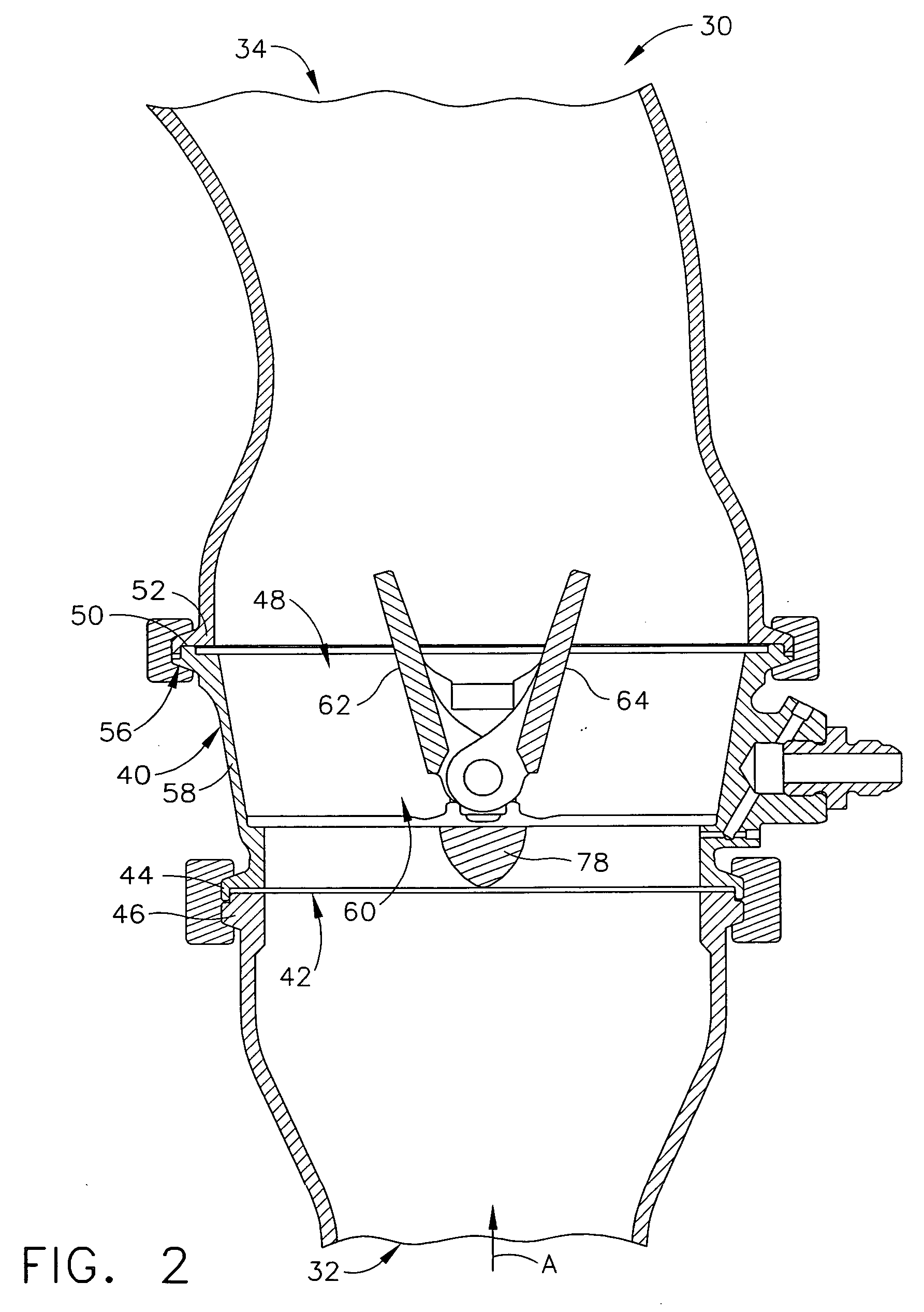

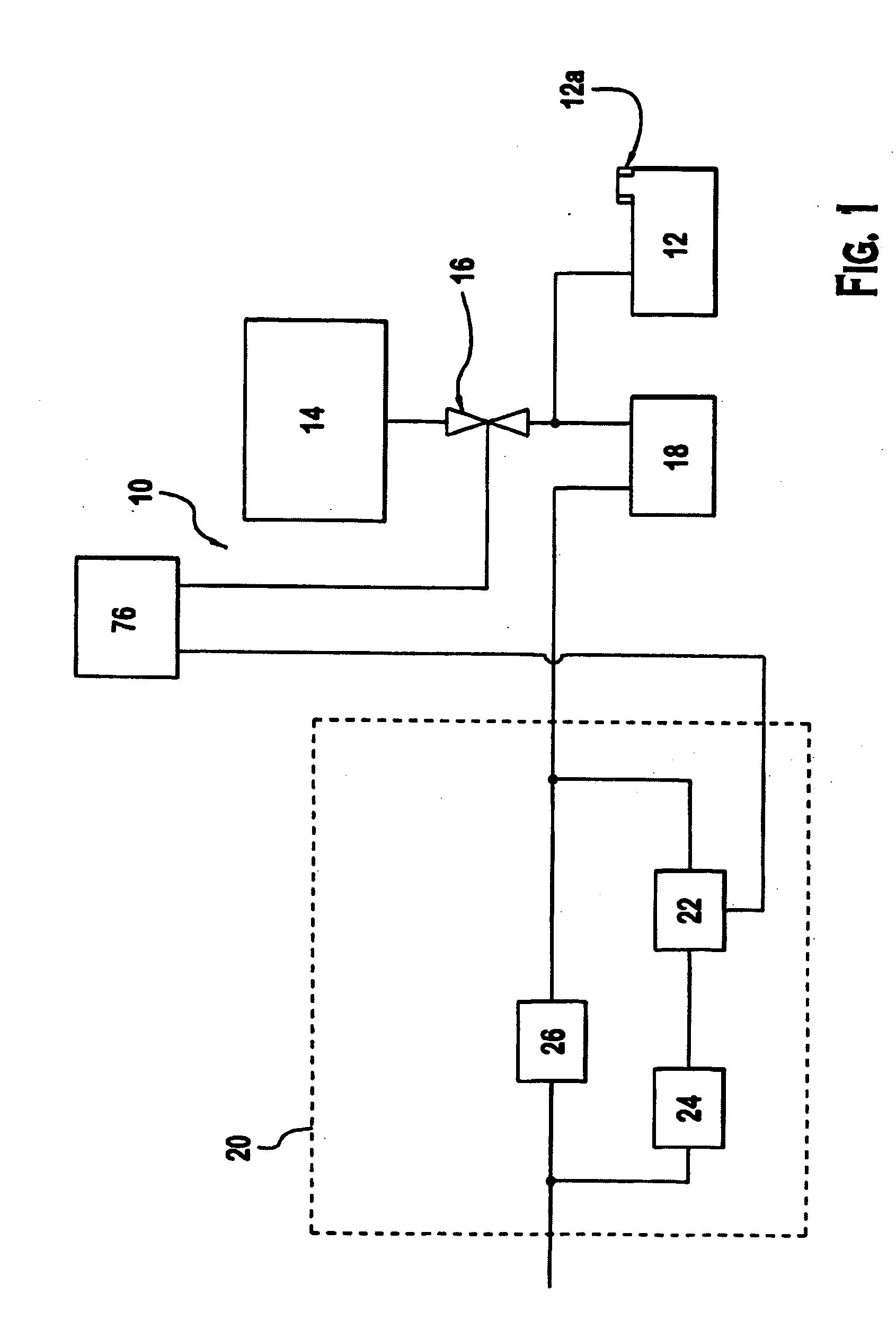

Methods and apparatus for regulating airflow supply systems

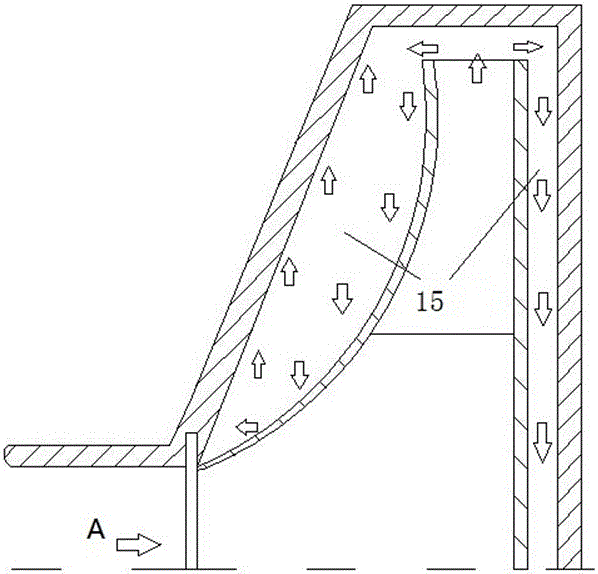

ActiveUS20060026965A1Prohibit some movementPrevent fluid flowCheck valvesGas turbine plantsAirflowCheck valve

A check valve is provided that includes a valve housing that has a side wall and a flow path therethrough, the side wall defining the flow path. The flow path includes an inlet, an outlet, and a centerline extending between the inlet and the outlet. At least one control member is positioned in the flow path and movable between a first position, wherein fluid flow through the valve housing is substantially prohibited and a second position wherein fluid flow is permitted. The side wall includes a stop configured to limit movement of the at least one control member at a pre-determined stop angle relative to the flow path centerline.

Owner:UNISON INDUSTRIES

Systems and methods for fracturing a multiple well pad

A flow system for use at a hydraulic fracturing well site, including a tree attached to a wellhead, an inlet head in fluid communication with at least one hydraulic fracturing pump at the well site, and an adjustable fluid conduit providing fluid communication between the inlet head and the tree. The flow system further includes a valve in the fluid conduit and having an open position and a closed position, the valve permitting fluid flow through the fluid conduit when in the open position, and preventing fluid flow through the fluid conduit when in the closed position, at least a portion of the fluid conduit positioned between the valve and the tree.

Owner:VAULT PRESSURE CONTROL LLC

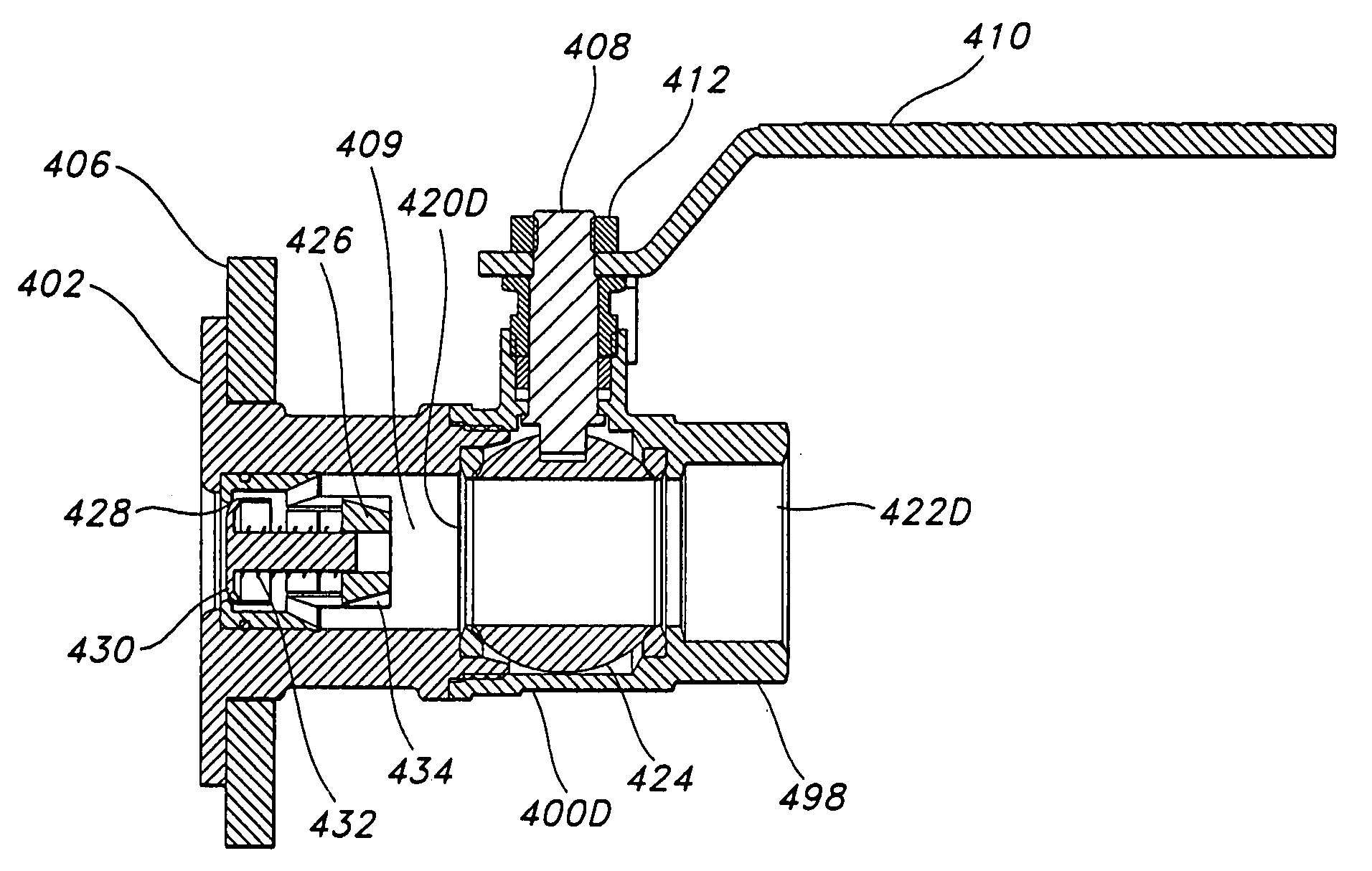

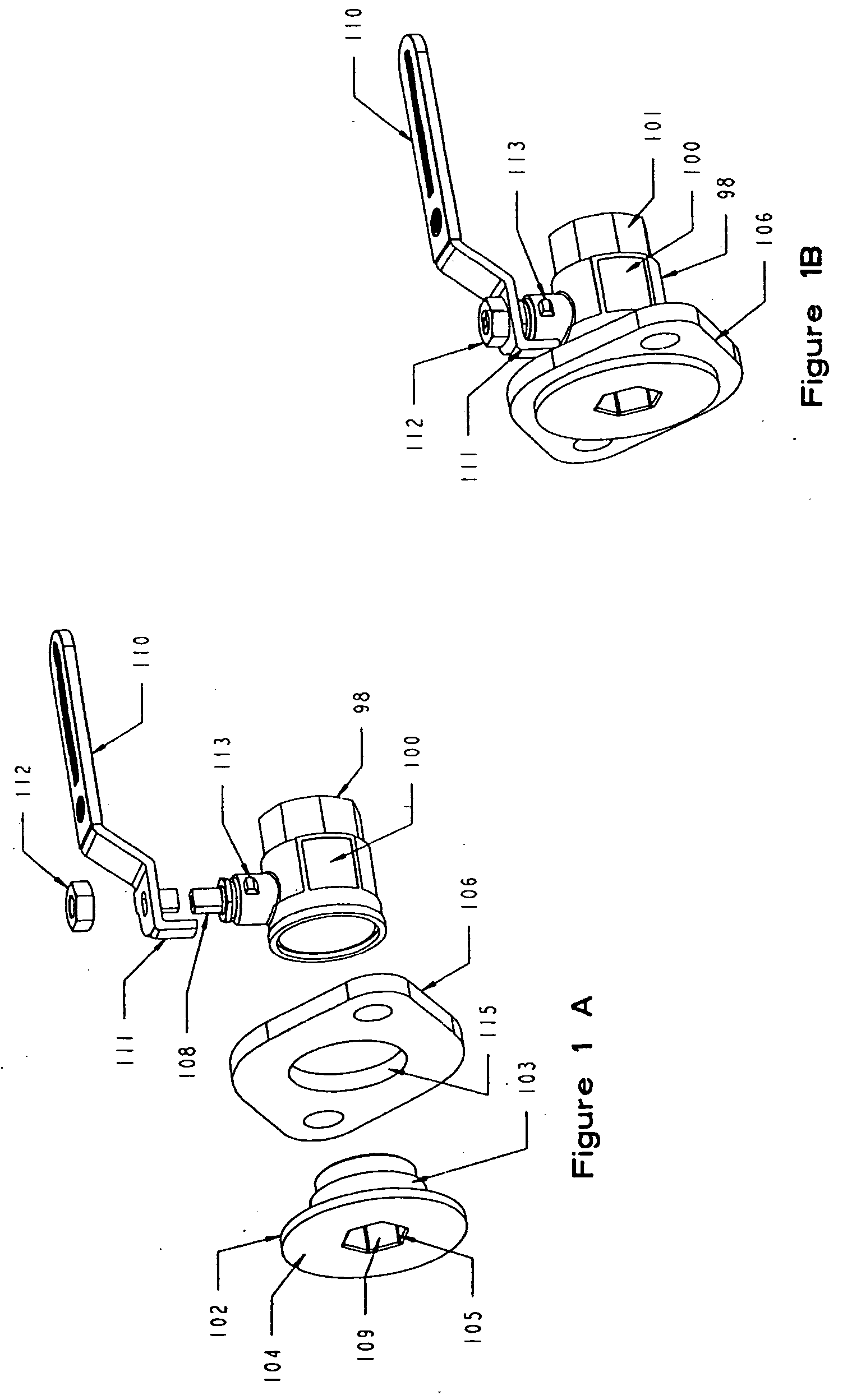

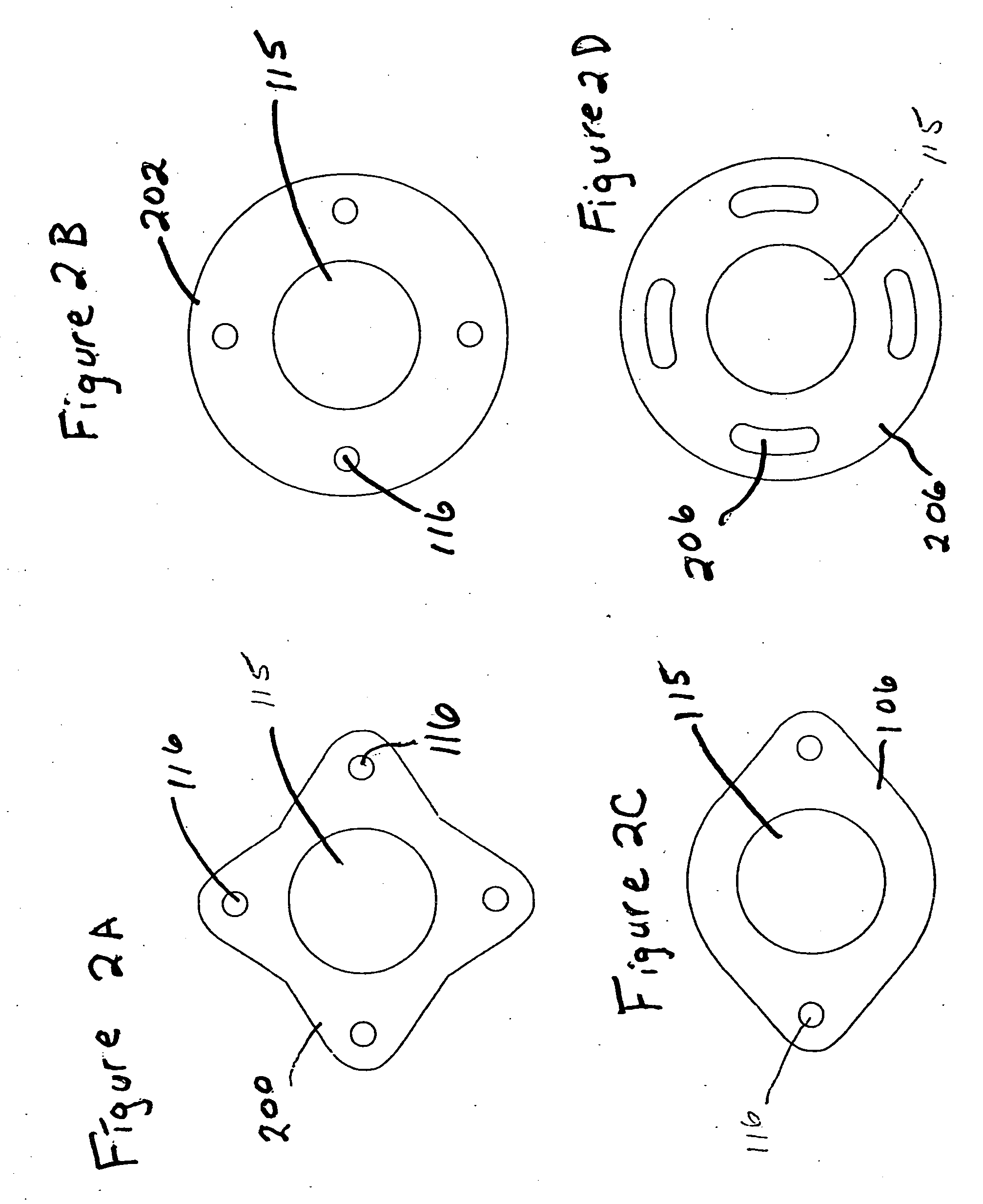

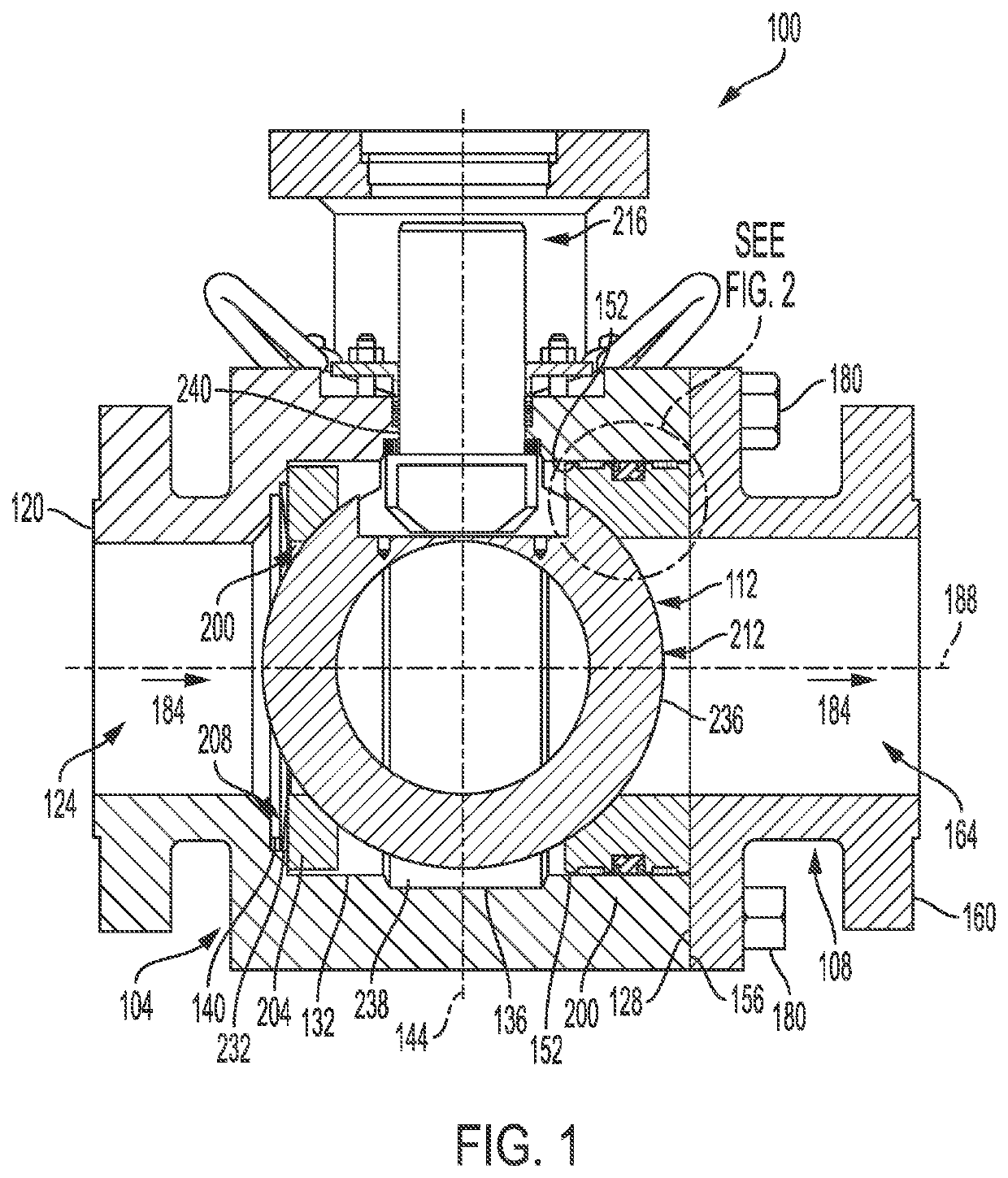

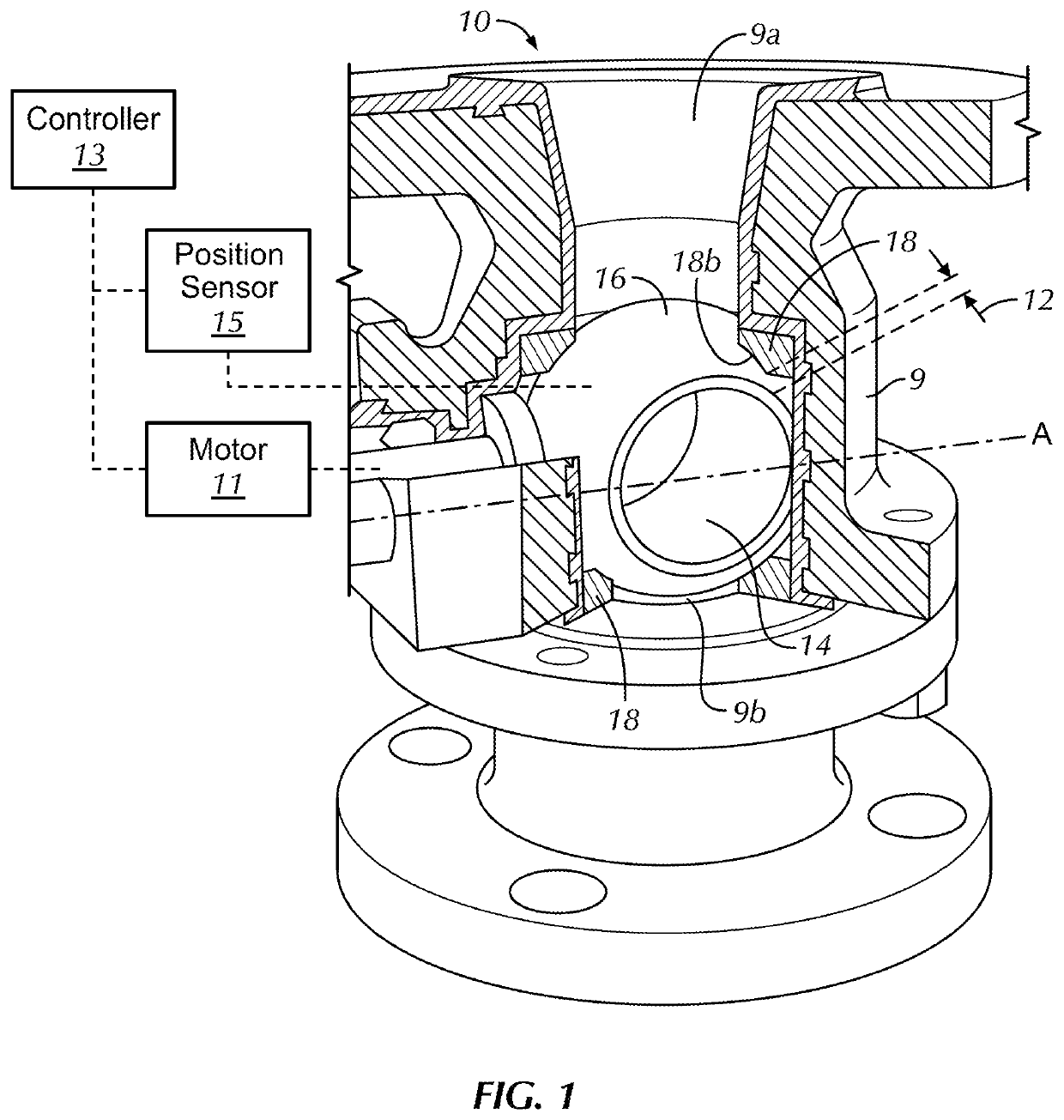

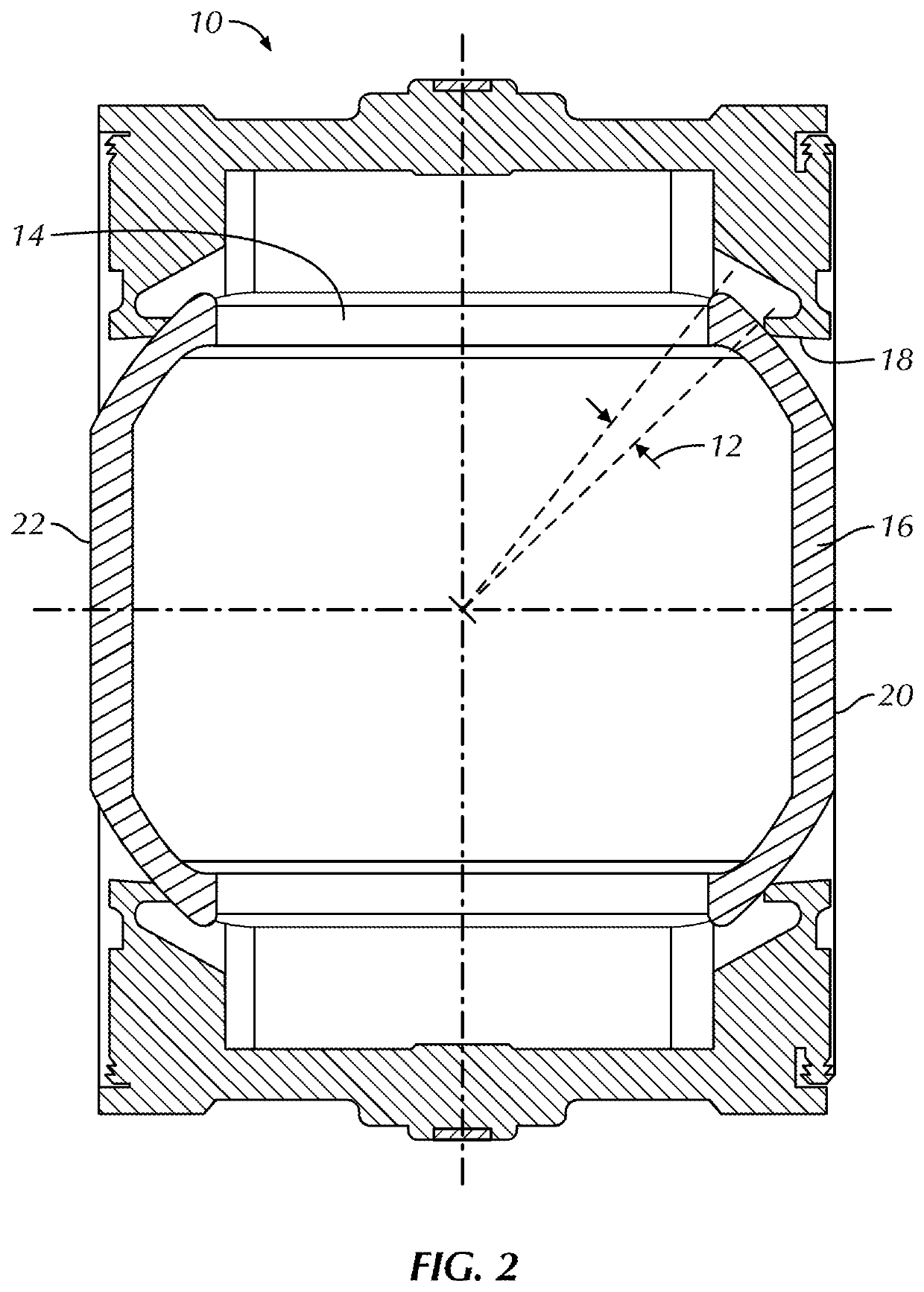

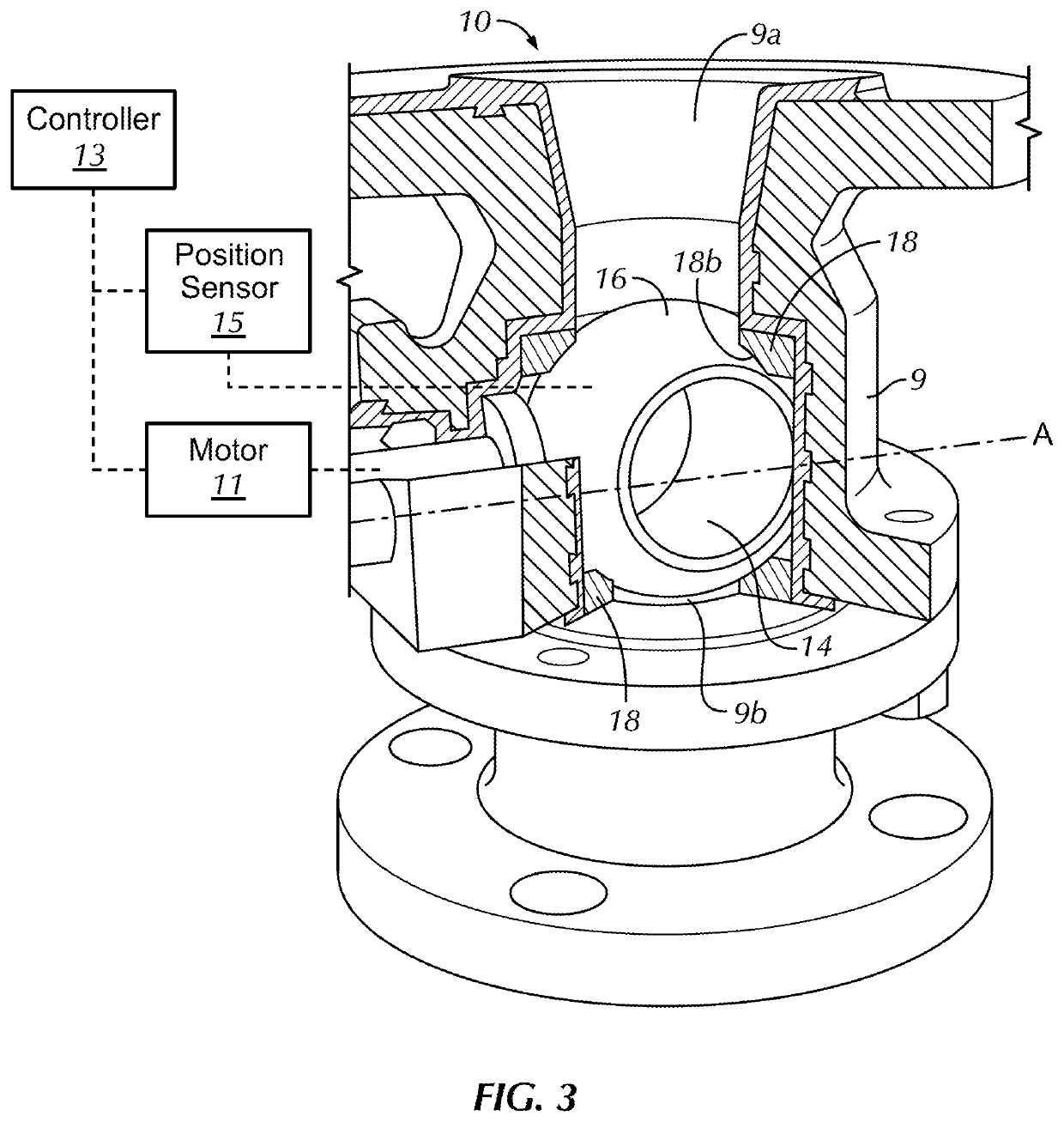

Isolation valve with rotatable flange

A valve assembly, including a quarter turn ball valve, an insert carried by the valve housing, and a flange, rotatably carried on the insert. The flange is used to secure the valve assembly in a fluid system and the assembly and disassembly of the valve assembly is facilitated by the adjustable position of the flange.

Owner:ARENTSEN ROBERT P +4

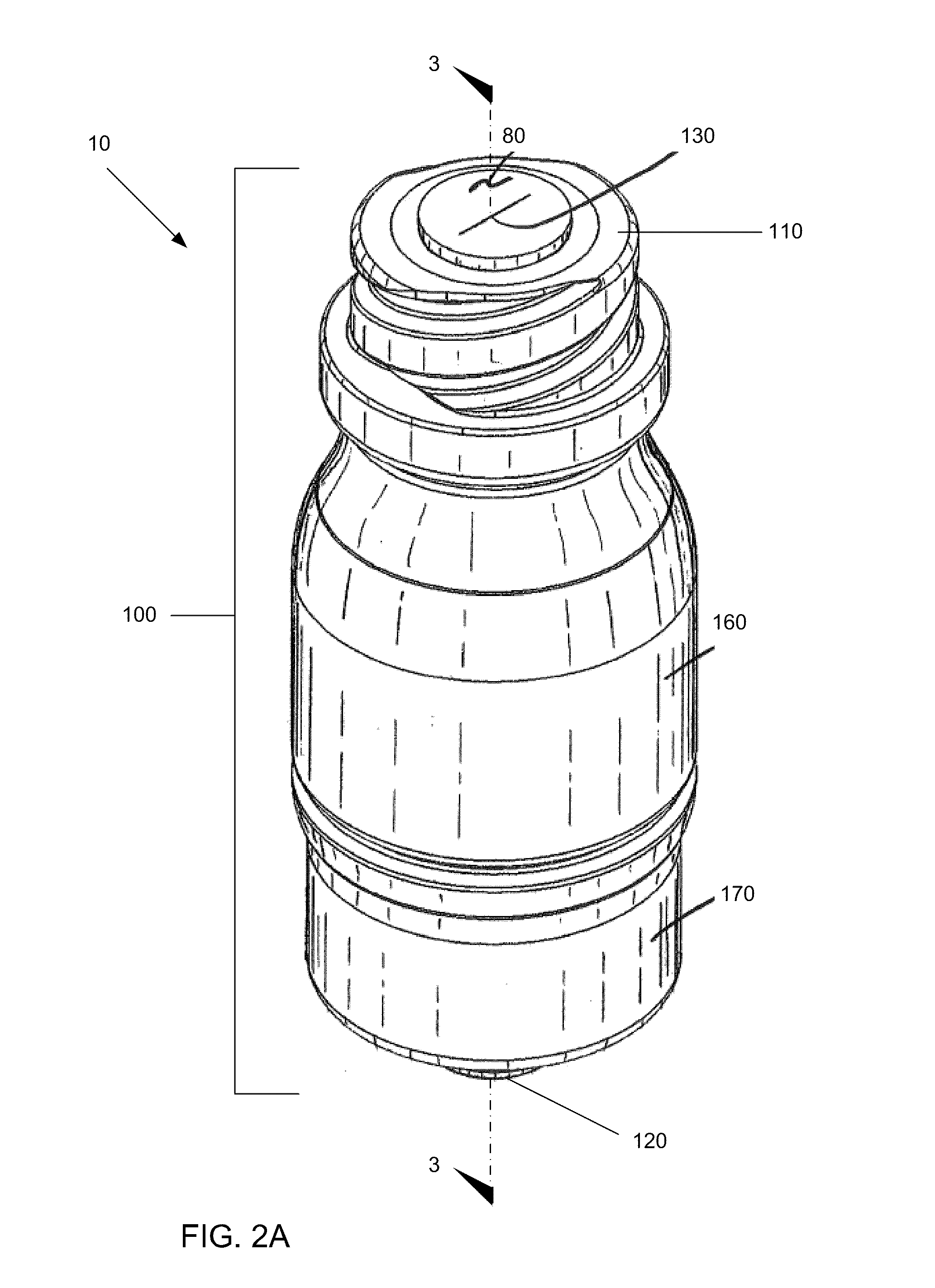

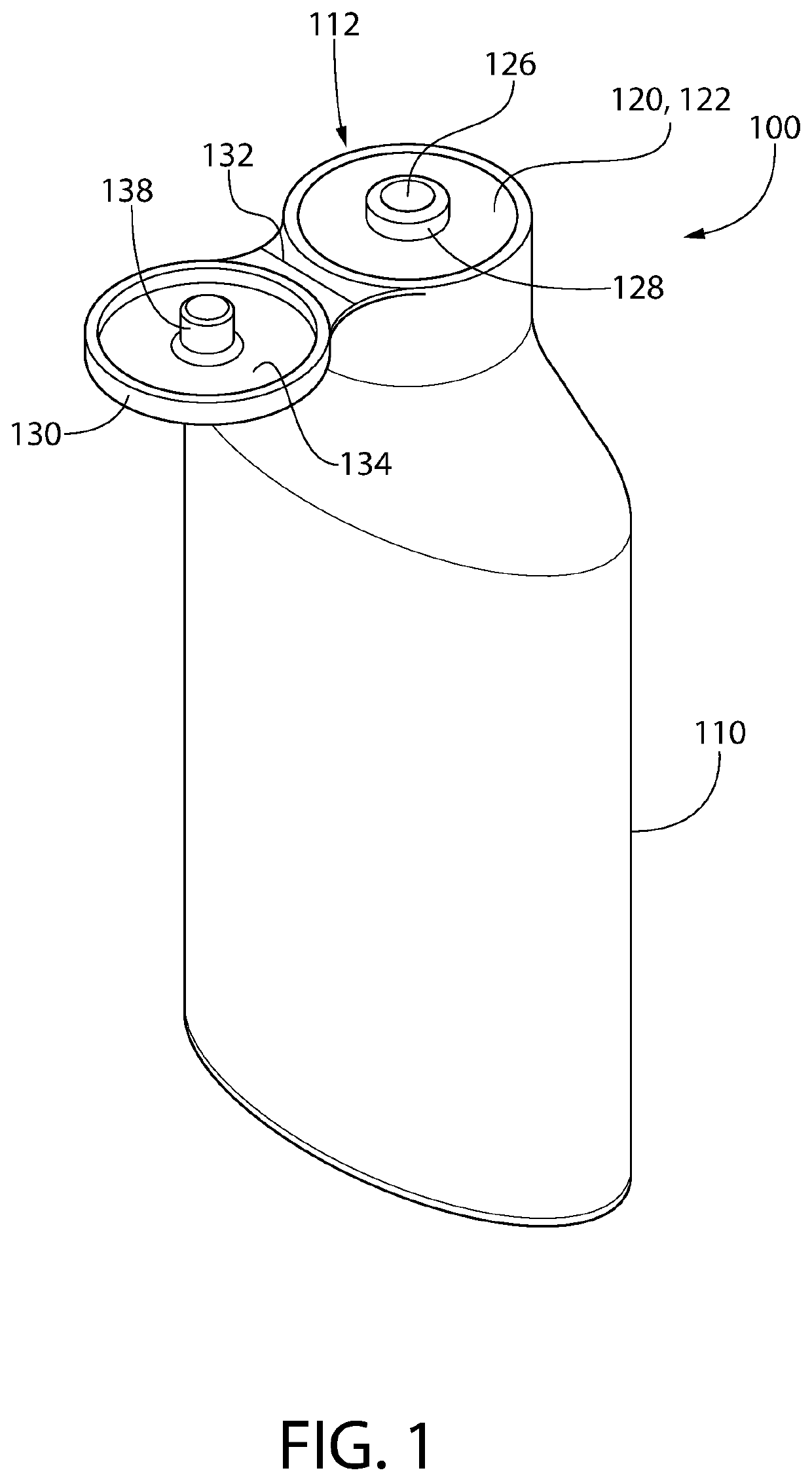

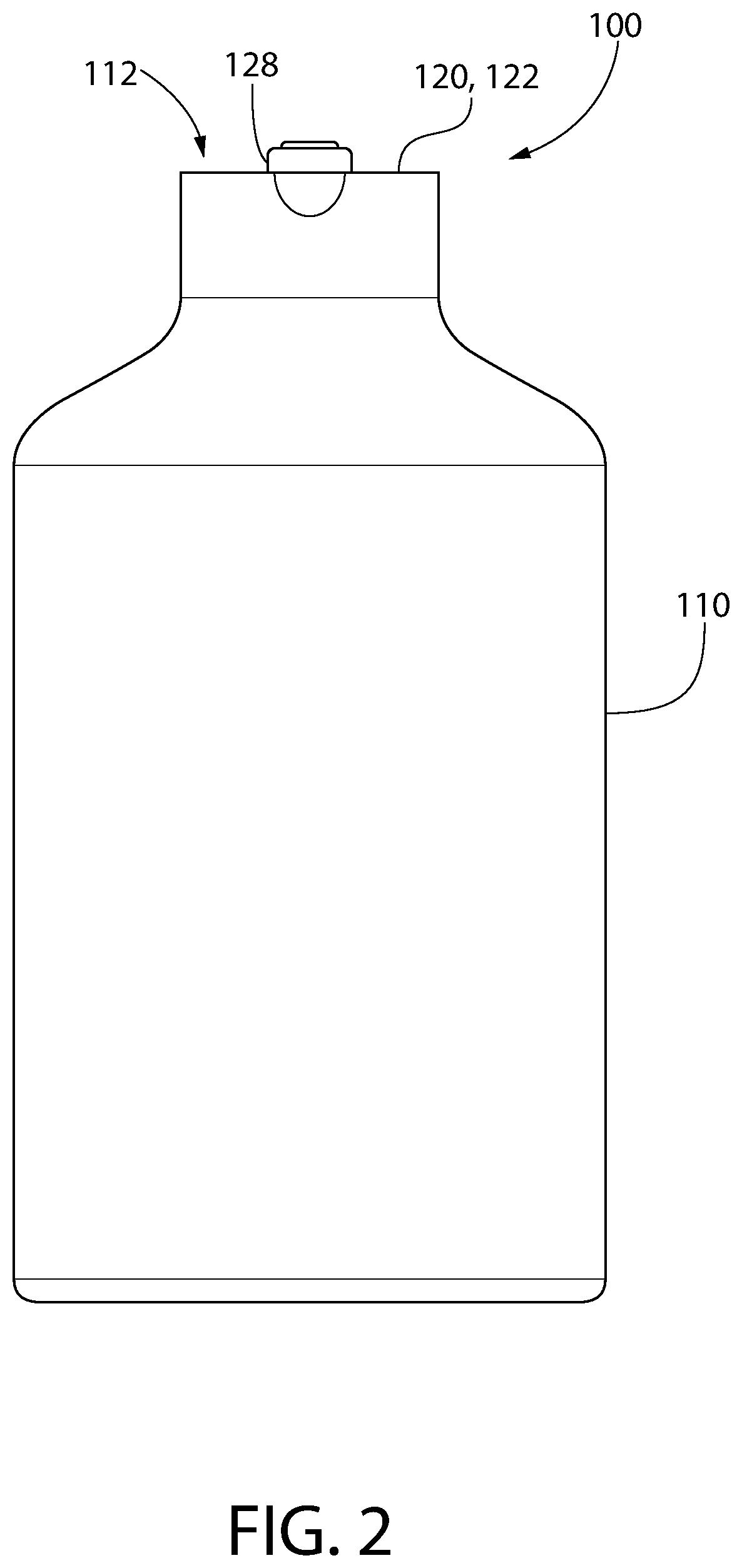

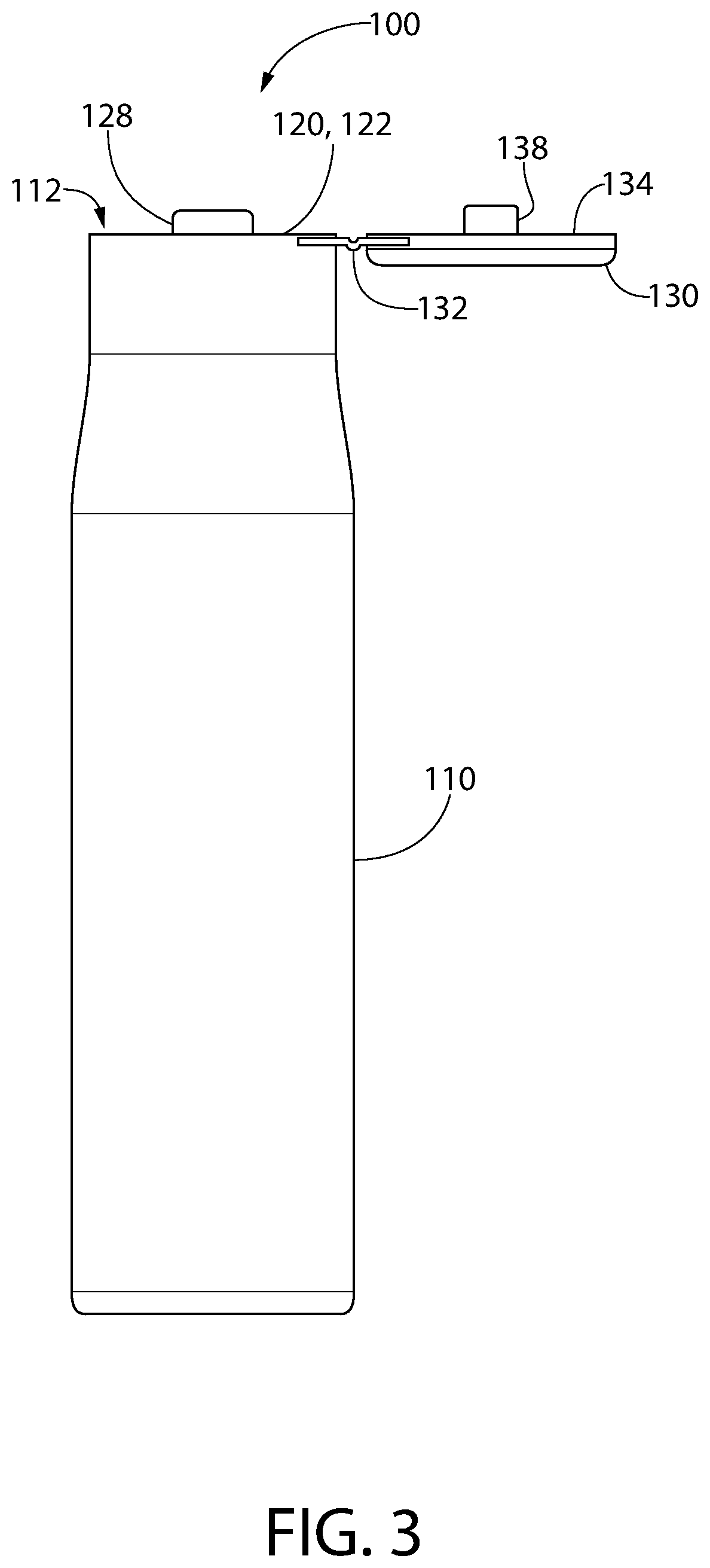

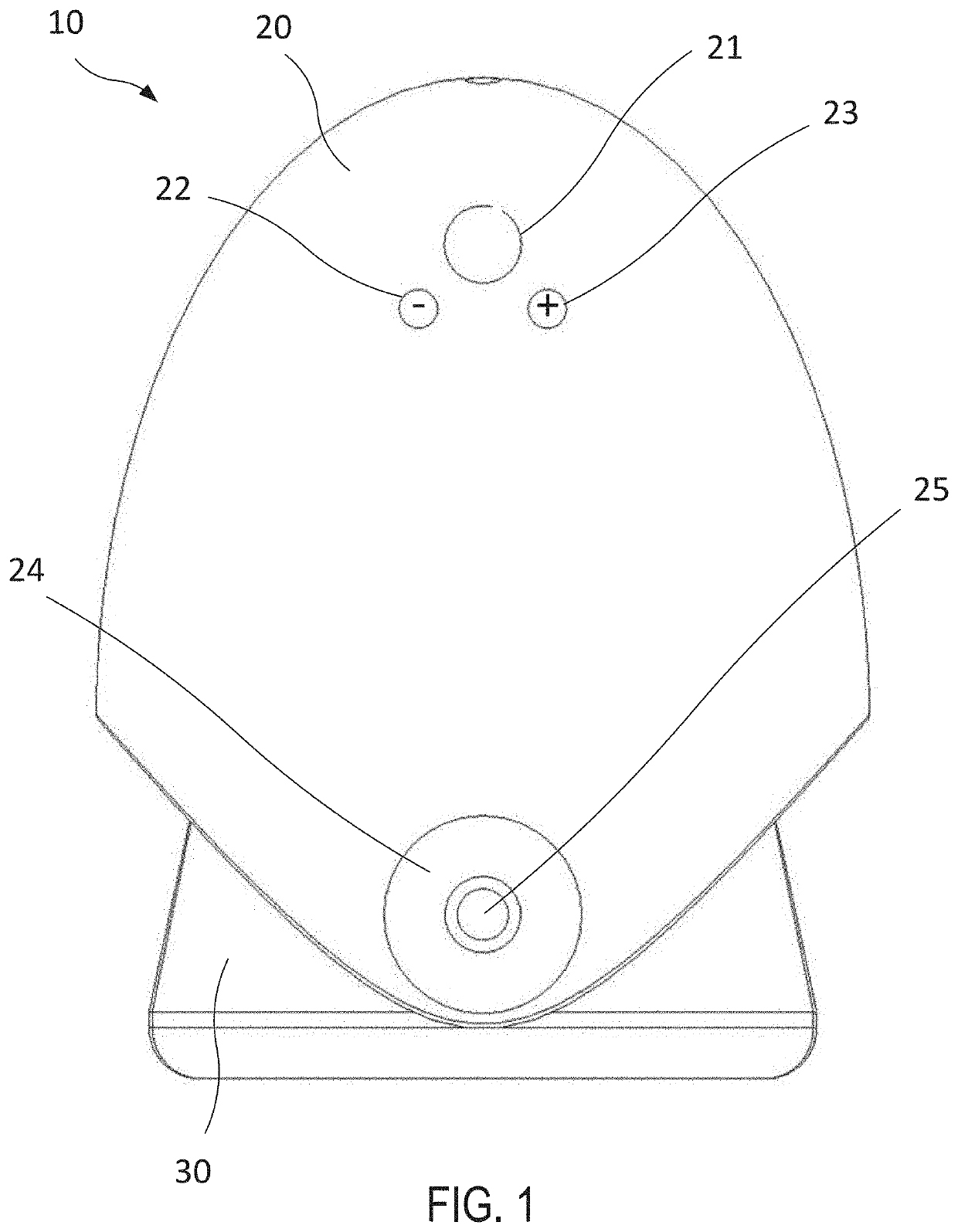

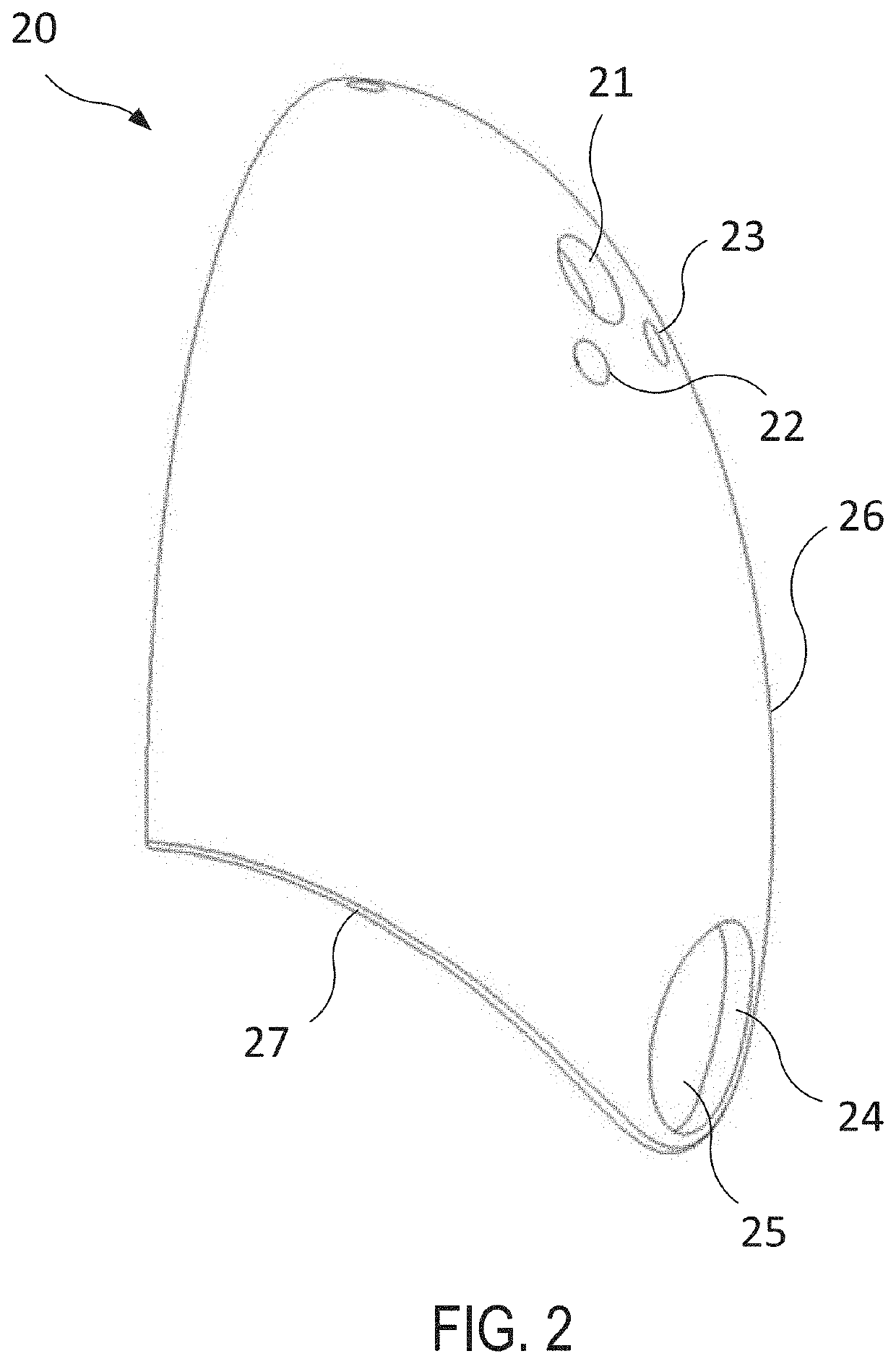

Container

A container (100) includes a body (110) defining an internal volume and a first opening (112) that provides a path of fluid communication between the internal volume and an exterior of the body. A nozzle piece (120) is positioned at least partially within the opening in the body. The nozzle piece defines a second opening (126) that is smaller than the first opening in the body. A cap piece (130) is integral with the body. The cap piece is configured to pivot between an open position and a closed position via a hinge (132) that is positioned between the body and the cap piece. Fluid flow is permitted through the second opening in the nozzle piece when the cap piece is in the open position, and the cap piece prevents fluid flow through the second opening in the nozzle piece when the cap piece is in the closed position.

Owner:COLGATE PALMOLIVE CO

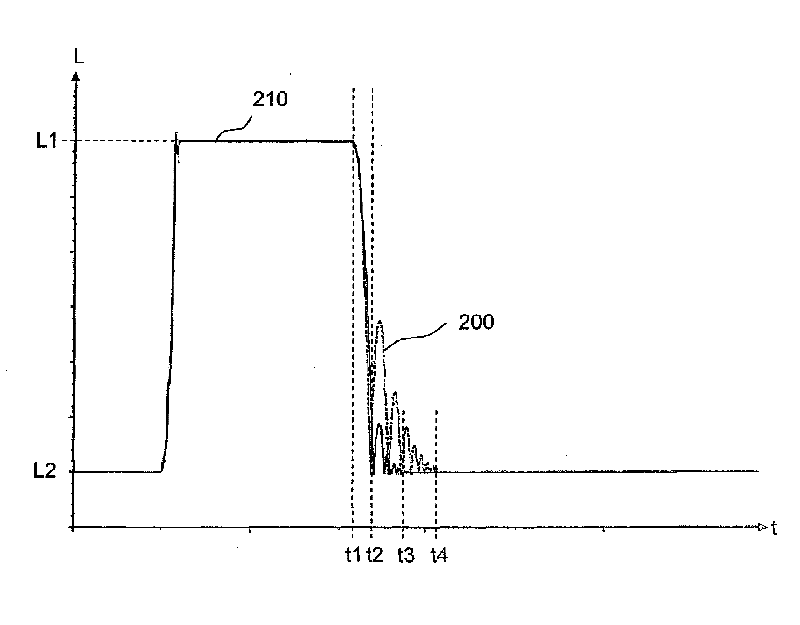

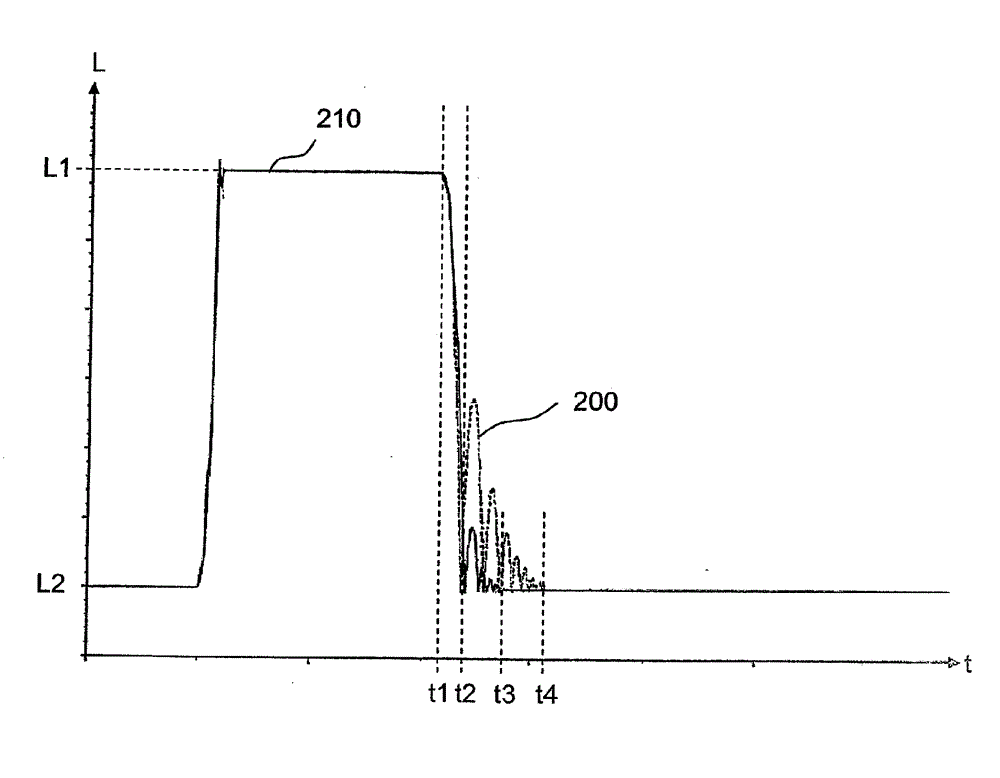

Low power consumption latch circuit including a time delay for a fuel vapor pressure management apparatus

InactiveUS20060076063A1Prevent fluid flowDetection of fluid at leakage pointNon-fuel substance addition to fuelTime delaysPressure management

A fuel vapor pressure management apparatus for an internal combustion engine includes a housing, a pressure operable device, and a printed circuit board. The pressure operable device moves between first and second configurations with respect to the housing. The printed circuit board is supported by the housing and includes a delay and a sensor. The delay commences upon internal combustion engine shutdown and concludes after a preset period. And the sensor indicates movement of the pressure operable device in the first configuration after the conclusion of the preset period.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

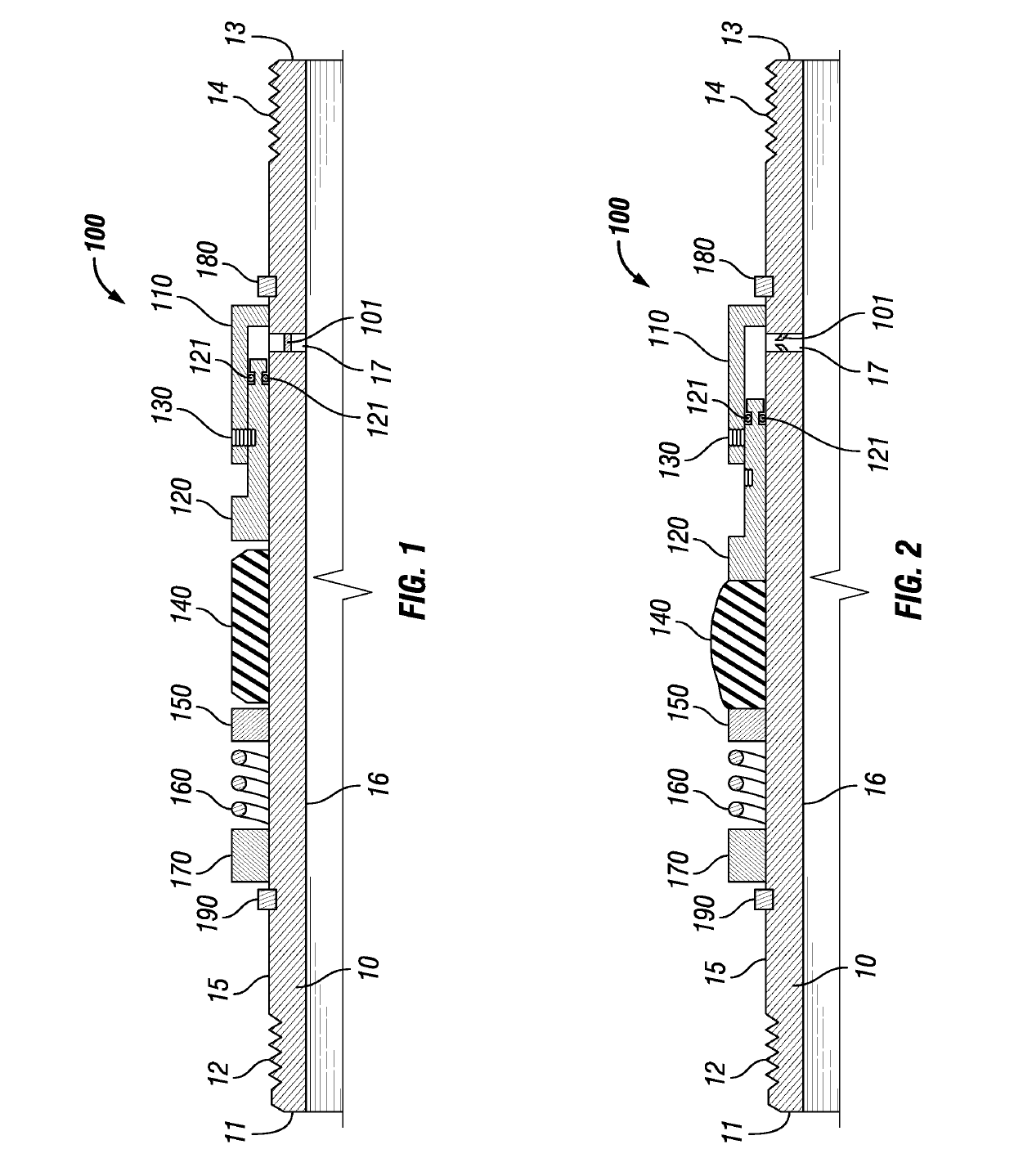

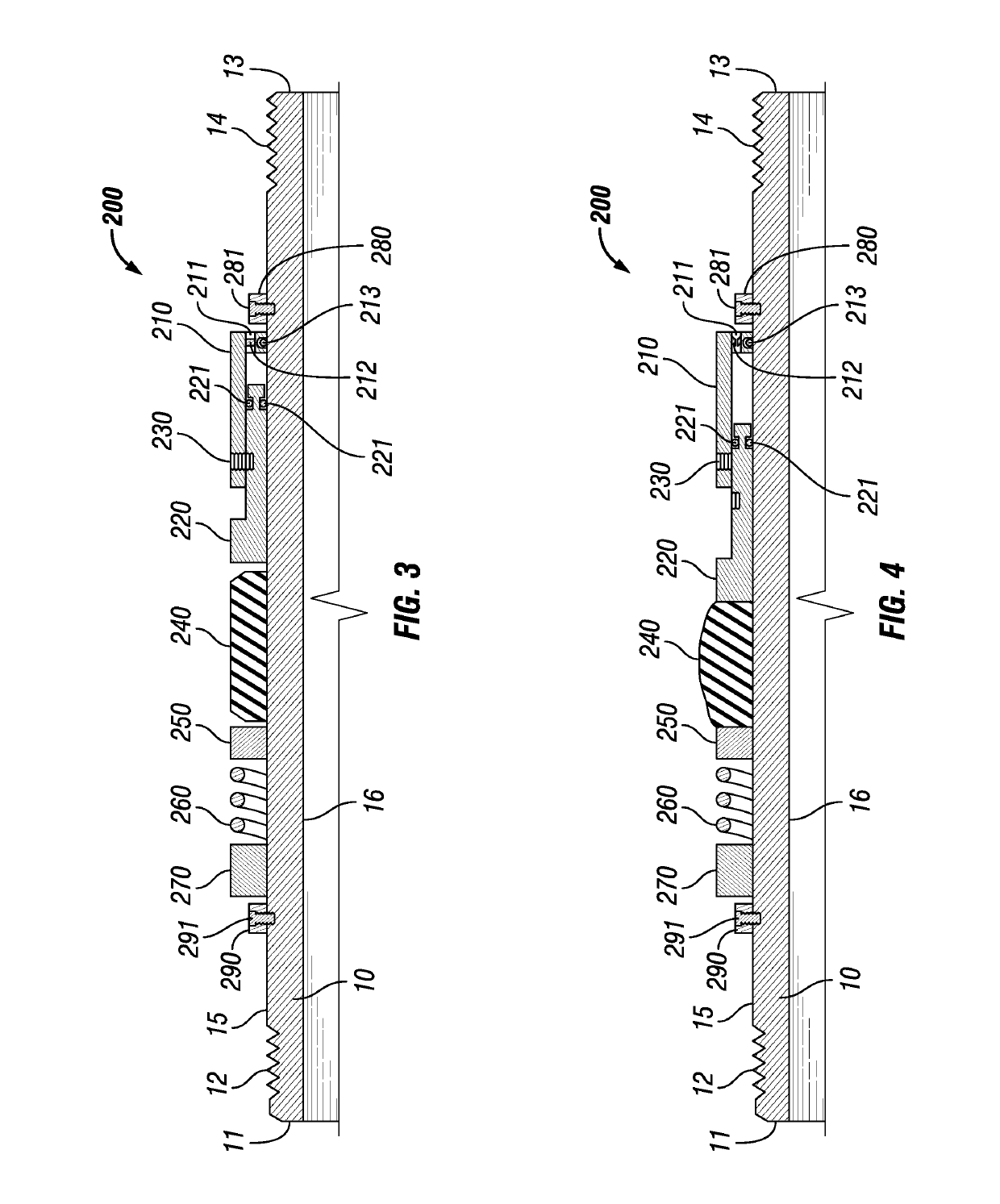

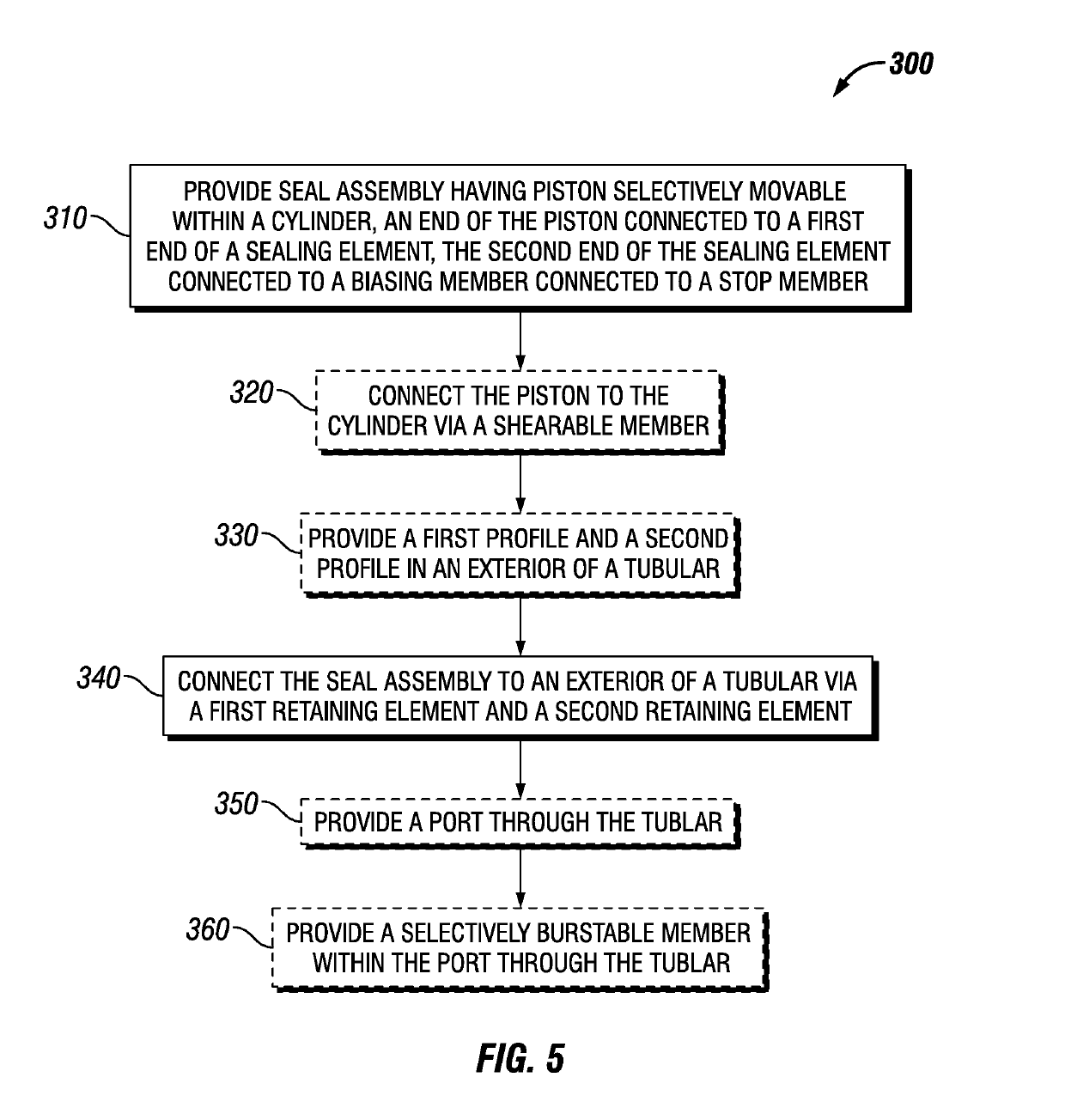

Slip on Hydraulic Packer

A slip on hydraulic packer system and method. The packer system includes a tubular, a packer assembly that includes a piston moveable within a cylinder, a sealing element connected to the piston, and a biasing member connected between a stop member and the piston. Retaining elements selectively connect the packer system to an exterior surface of the tubular. A predetermined amount of hydraulic pressure may be applied to move the piston moving the sealing element from an unset position to a set position. The retaining elements may be snap rings and / or set screws that engage a profile on the tubular. Hydraulic pressure may be applied from an interior of the tubular through a port in the tubular or from an exterior of the tubular through a port in the cylinder. The predetermined amount of hydraulic pressure may shear an element or burst a member before moving the piston.

Owner:BAKER HUGHES INC

Floating Valve Seat For A Rotary Control Valve For Use In Severe Service Applications

A valve seat is provided for use in a rotary valve for use in highly corrosive and abrasive applications. The valve seat includes a seat body adapted to selectively engage a portion of the floating ball element. The valve seat also includes a sealing element disposed in a first groove formed in the seat body and adapted to prevent fluid flow between the seat body and the valve body. The valve seat further includes a first bearing disposed in a second groove formed in the seat body, and a second bearing disposed in a third groove formed in the seat body, wherein the second and third grooves are formed immediately adjacent the first groove such that the first and second bearings are disposed immediately adjacent the sealing element.

Owner:FISHER CONTROLS INT LLC

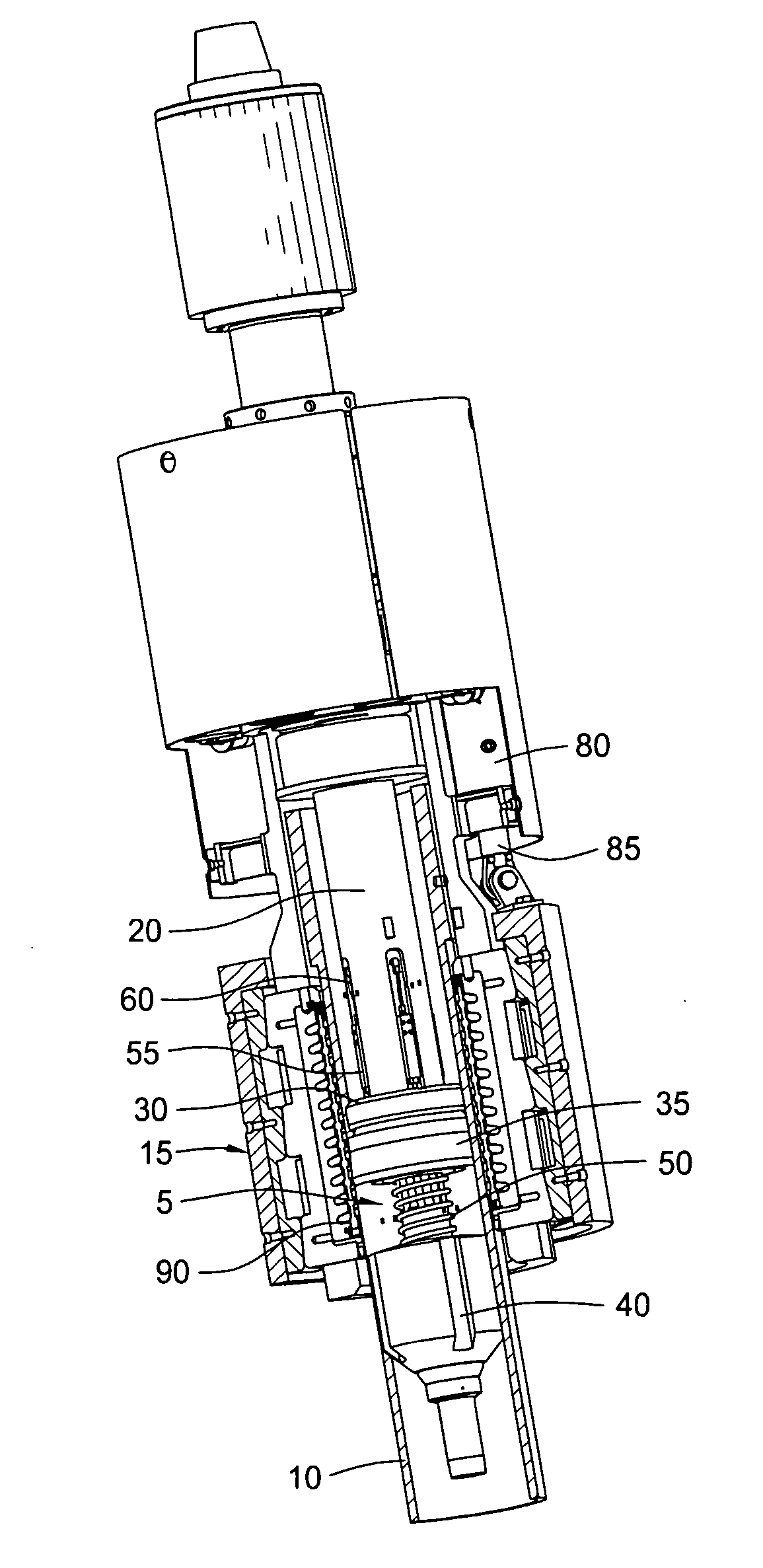

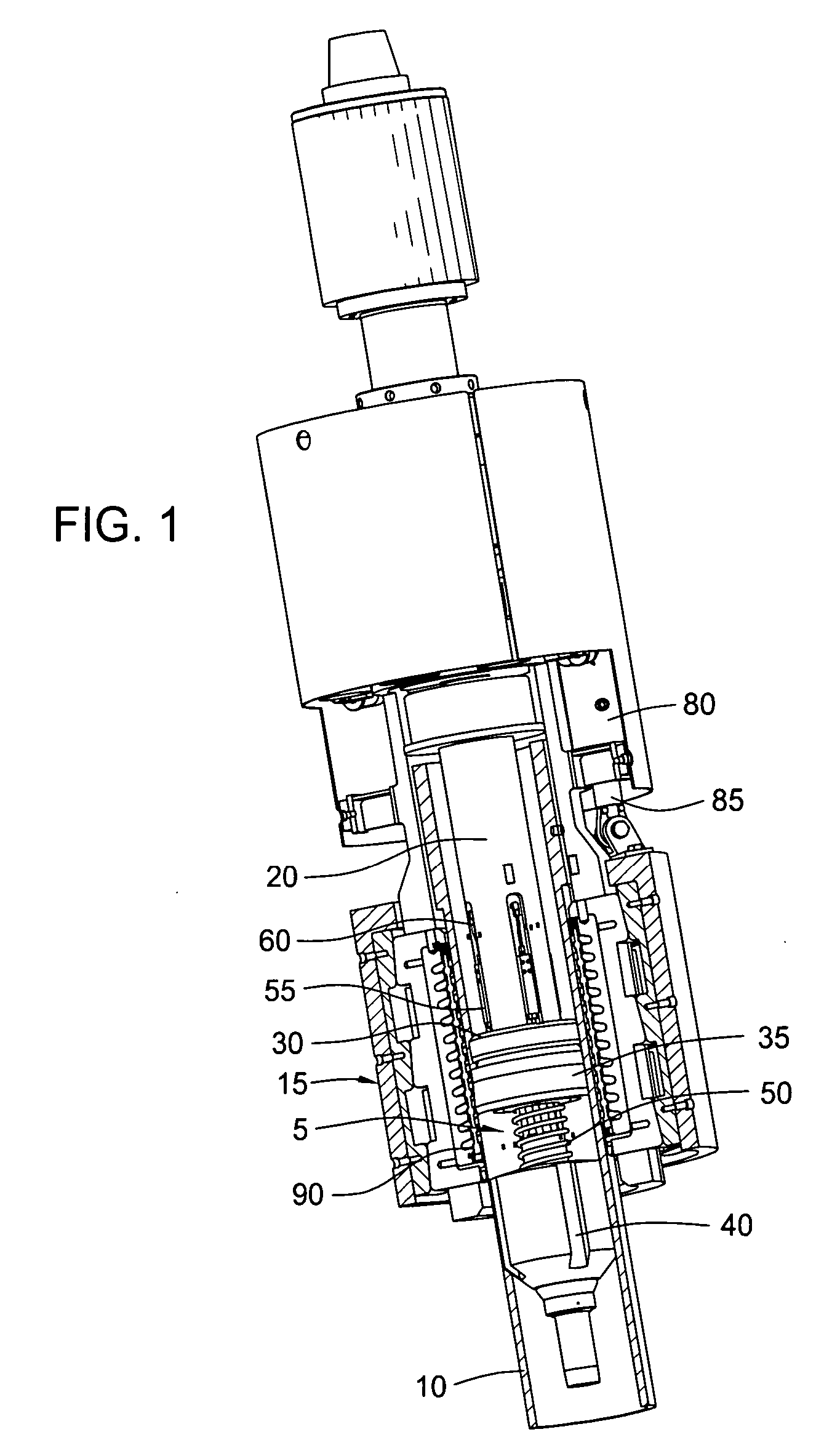

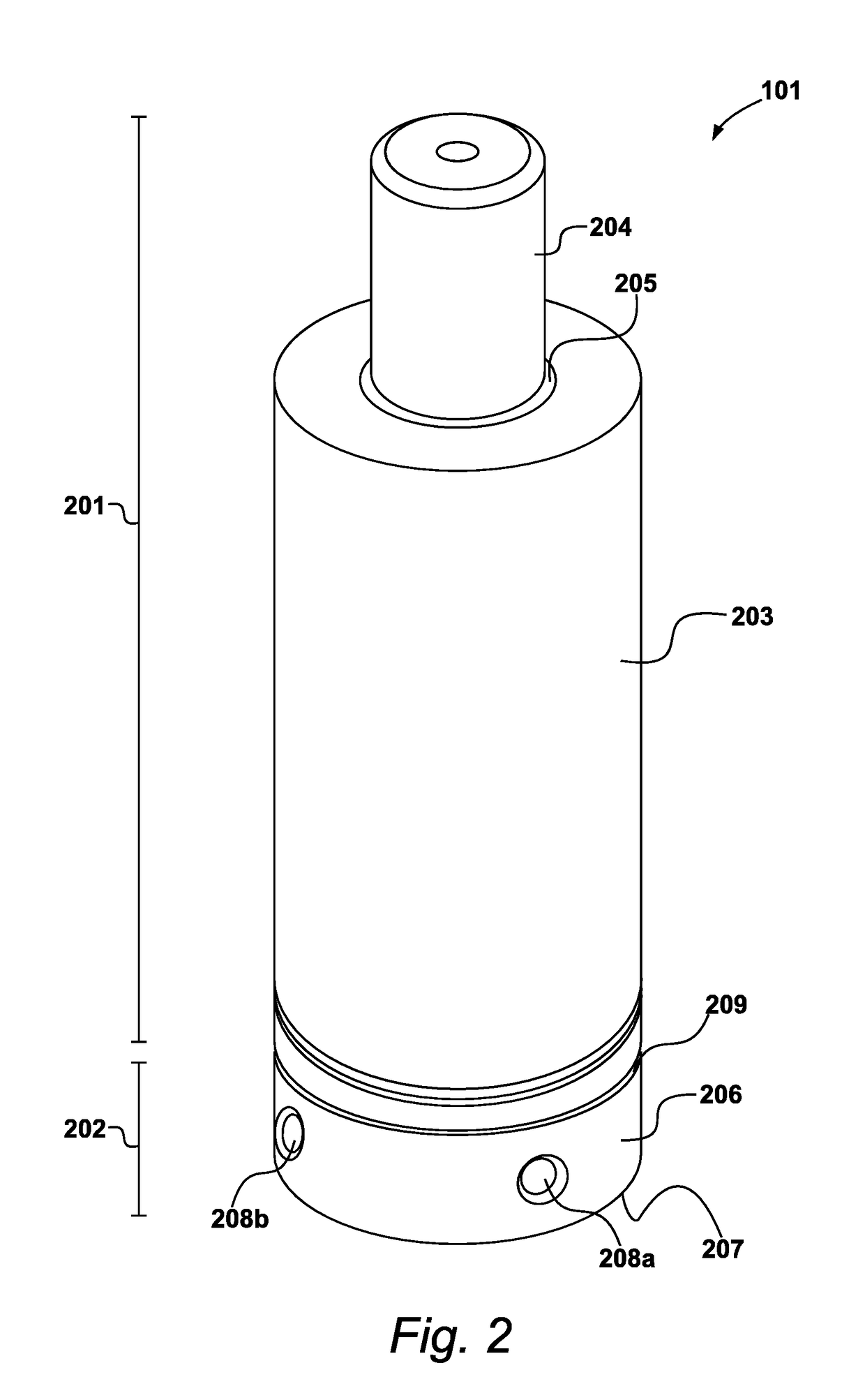

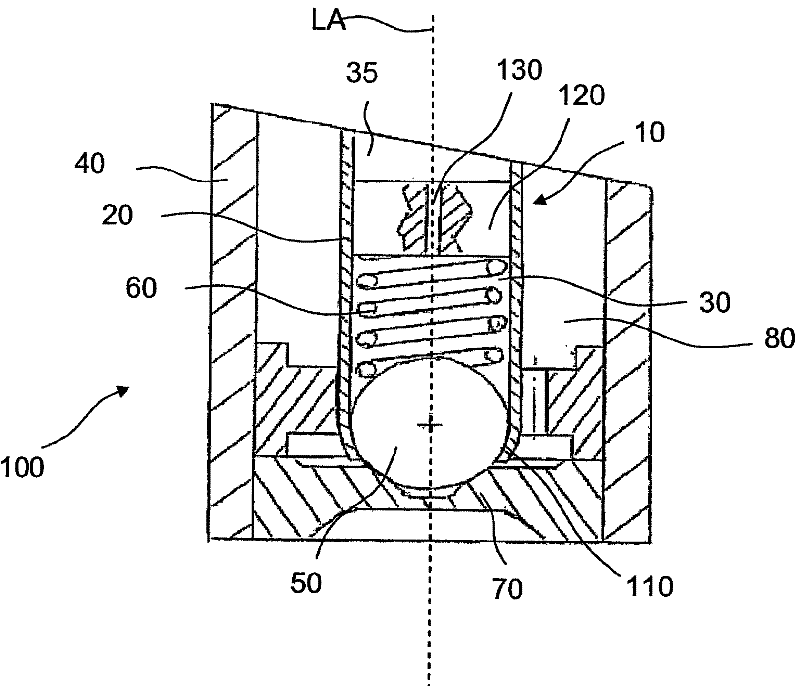

Linear actuator

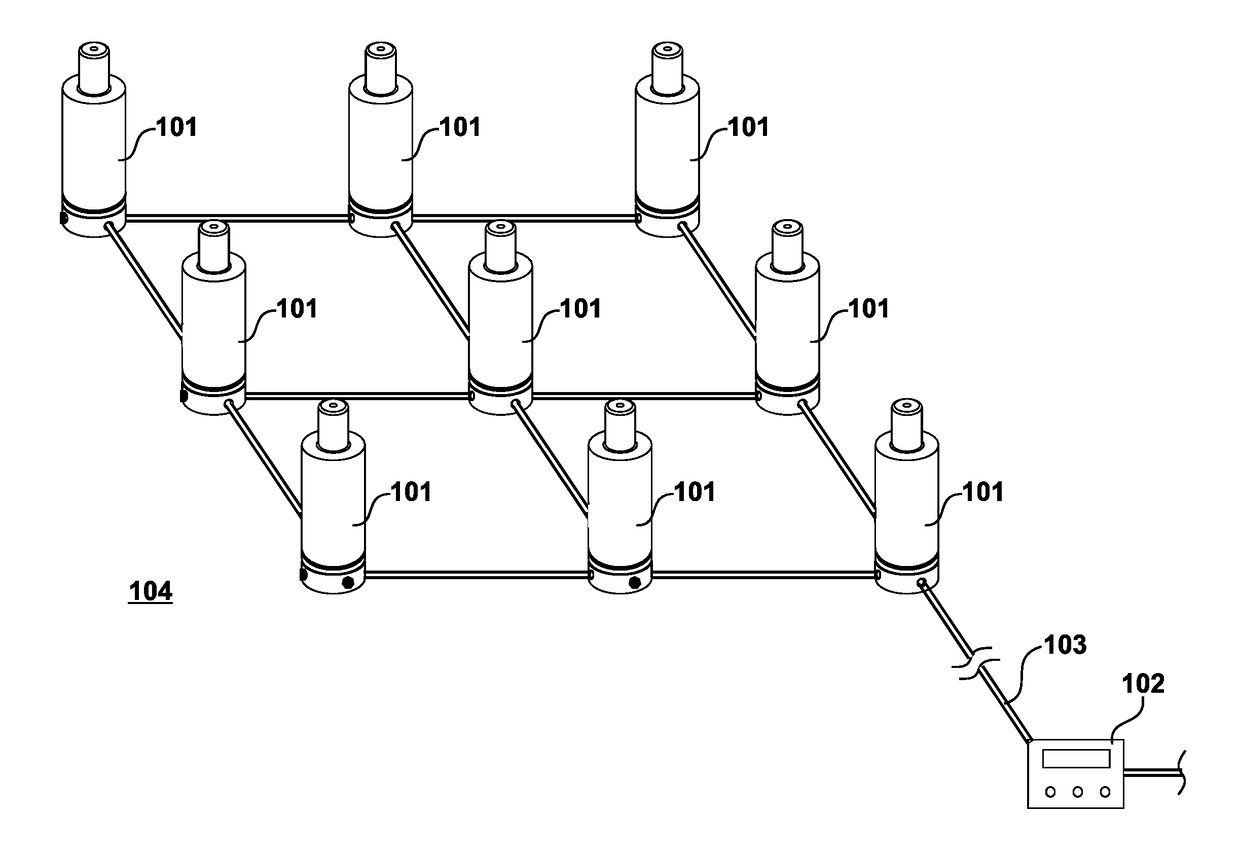

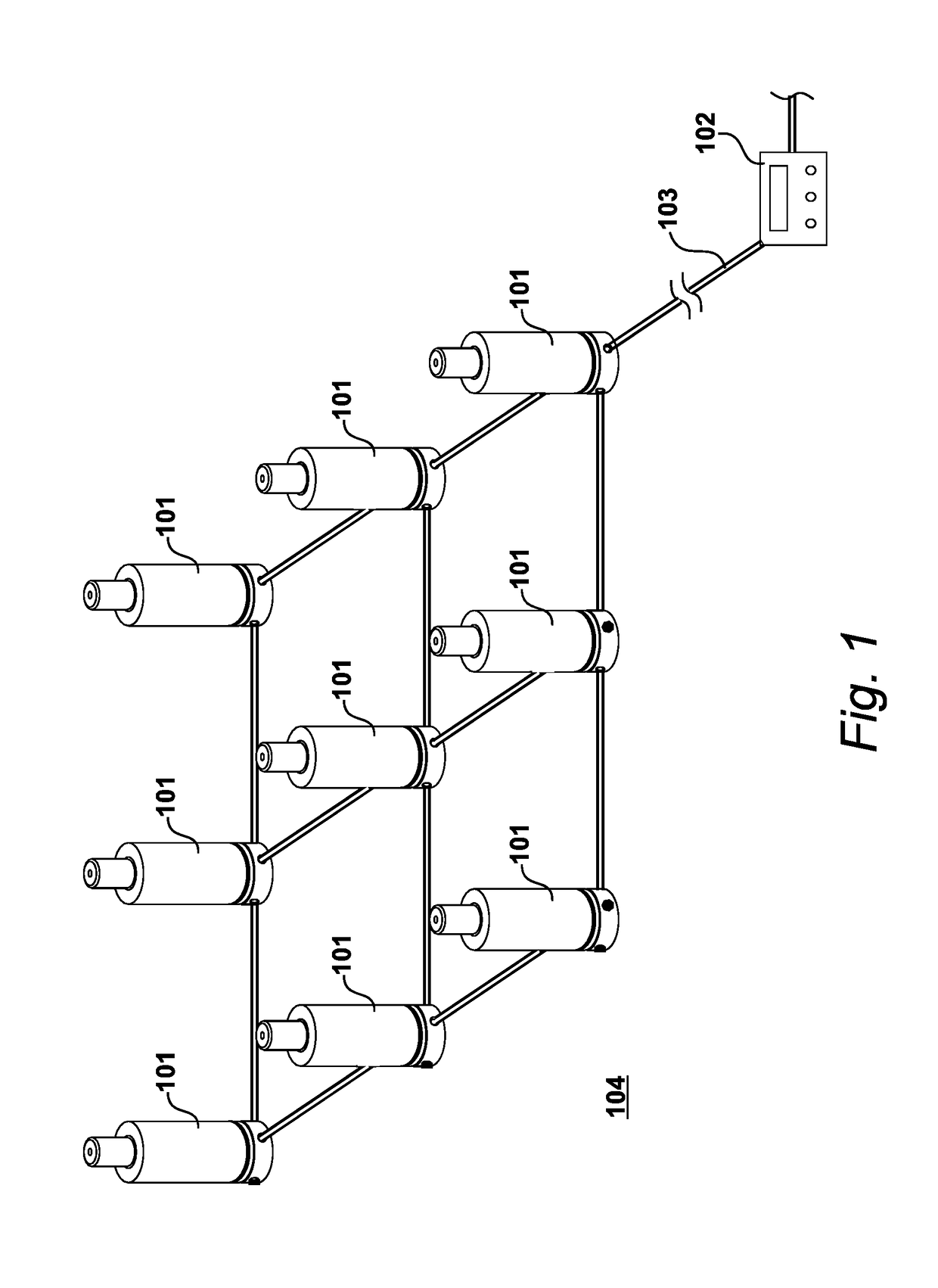

ActiveUS20180195535A1Prevent fluid flowPrevent from flowSpringsFluid-pressure actuatorsPistonLinear actuator

A linear actuator is disclosed. The linear actuator comprises a cylinder portion and a base portion. The cylinder portion comprises a housing defining internally a compression chamber for containing a fluid and comprising a piston assembly that can reciprocate within the compression chamber. The housing further defines a cylinder port in fluid communication with said compression chamber. The base portion defines a first base port and a second base port and a passage extending therebetween fluidly communicating the first base port with the second base port, and comprises valve means operable to control the flow of fluid through the second base port, in which the valve means is actuatable between an open condition in which the flow of fluid through the second base port is permitted, and a closed condition in which the flow of fluid through the second base port is substantially prevented. The cylinder portion is releasably engageable with the base portion such that the cylinder portion and the base portion may be arranged in an engaged condition in which engaged condition the cylinder port and the second base port are in fluid communication.

Owner:METROL SPRINGS

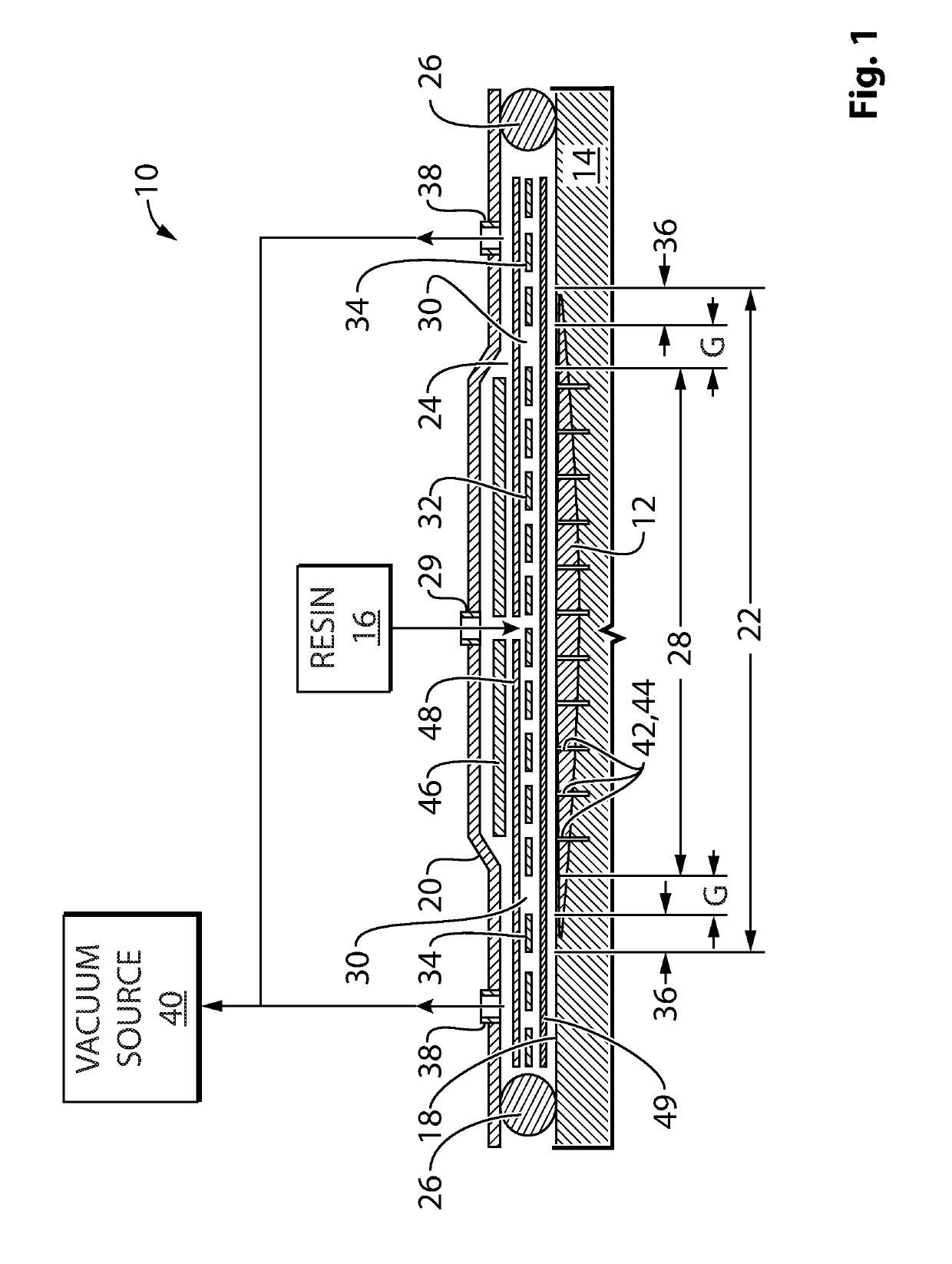

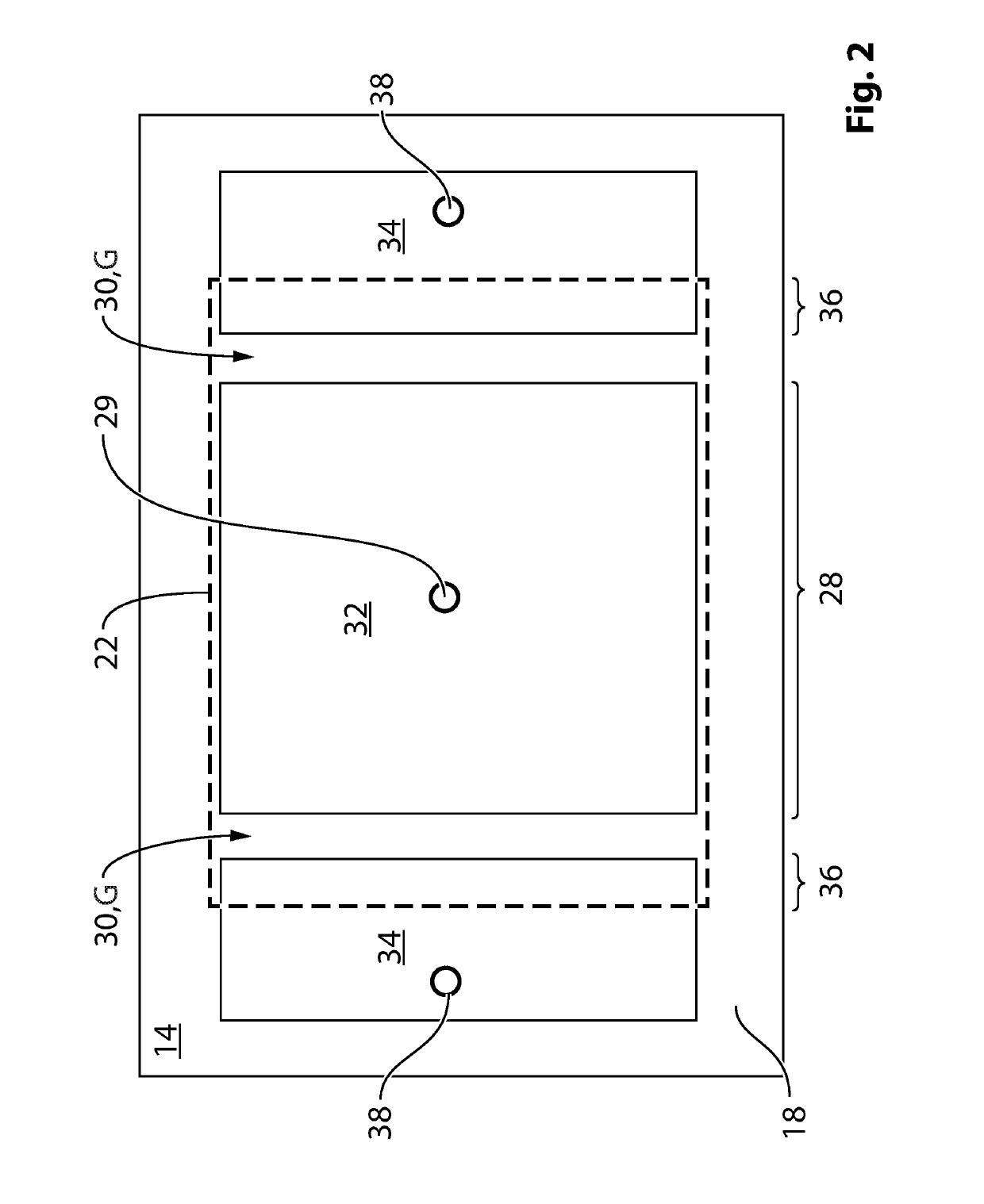

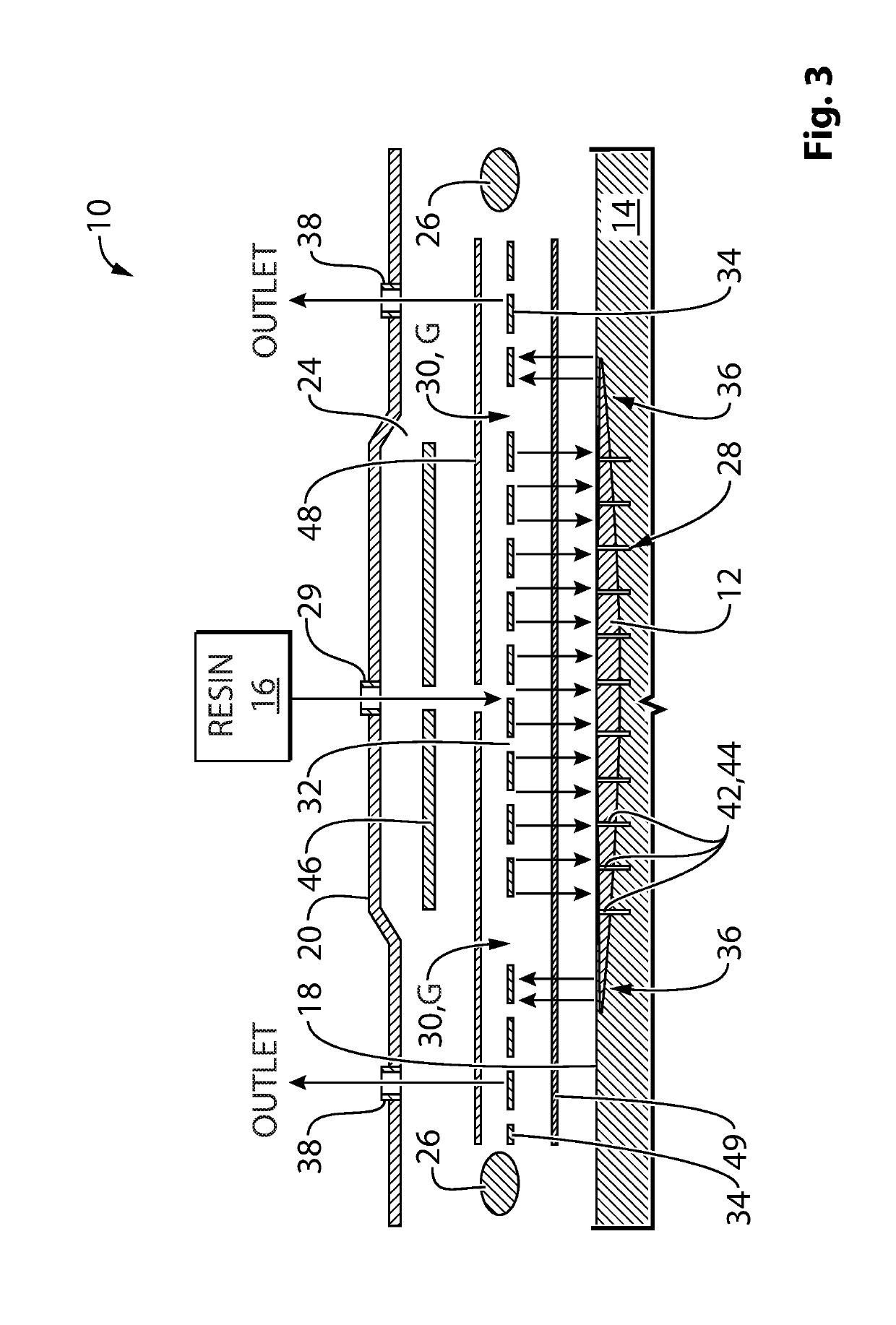

Apparatus and methods for repairing composite laminates

ActiveUS20190111637A1Prevent fluid flowAvoid flowWeight reductionMechanical engineeringComposite laminates

Owner:SHORT BROTHERS

Seal assembly

ActiveUS20140102725A1Prevent fluid flowFluid removalWell/borehole valve arrangementsEngineeringPiston

A seal assembly for use in a tubular includes a mandrel, a compressible seal member disposed around the mandrel, a first piston assembly in contact with a first end of the seal member, and a second piston assembly in contact with a second end of the seal member. The first piston assembly includes a piston head, and a piston extension sealing member integrally formed with the piston head, and extending at least partially between the mandrel and the compressible seal member. The compressible seal member forms a seal with the tubular when at least one of the piston assemblies is urged toward the compressible seal member.

Owner:WEATHERFORD TECH HLDG LLC

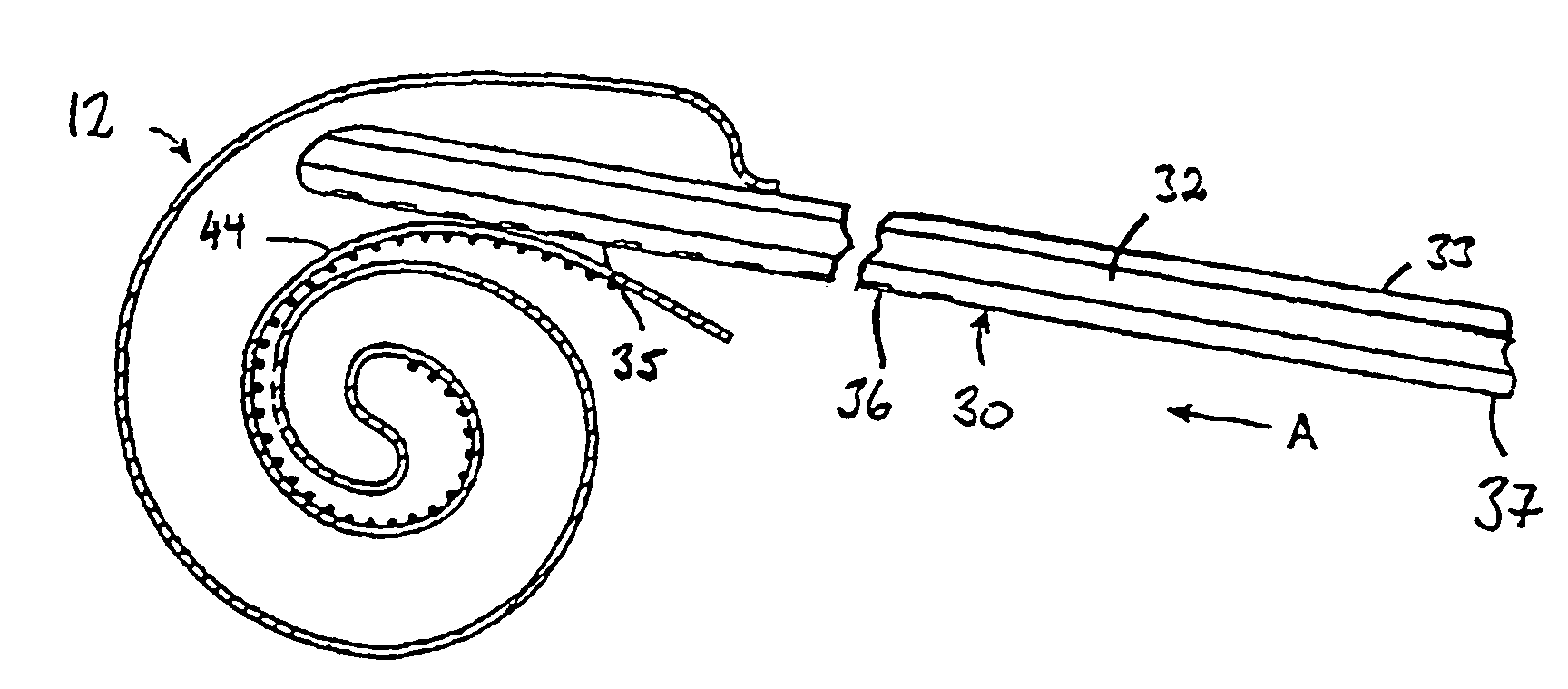

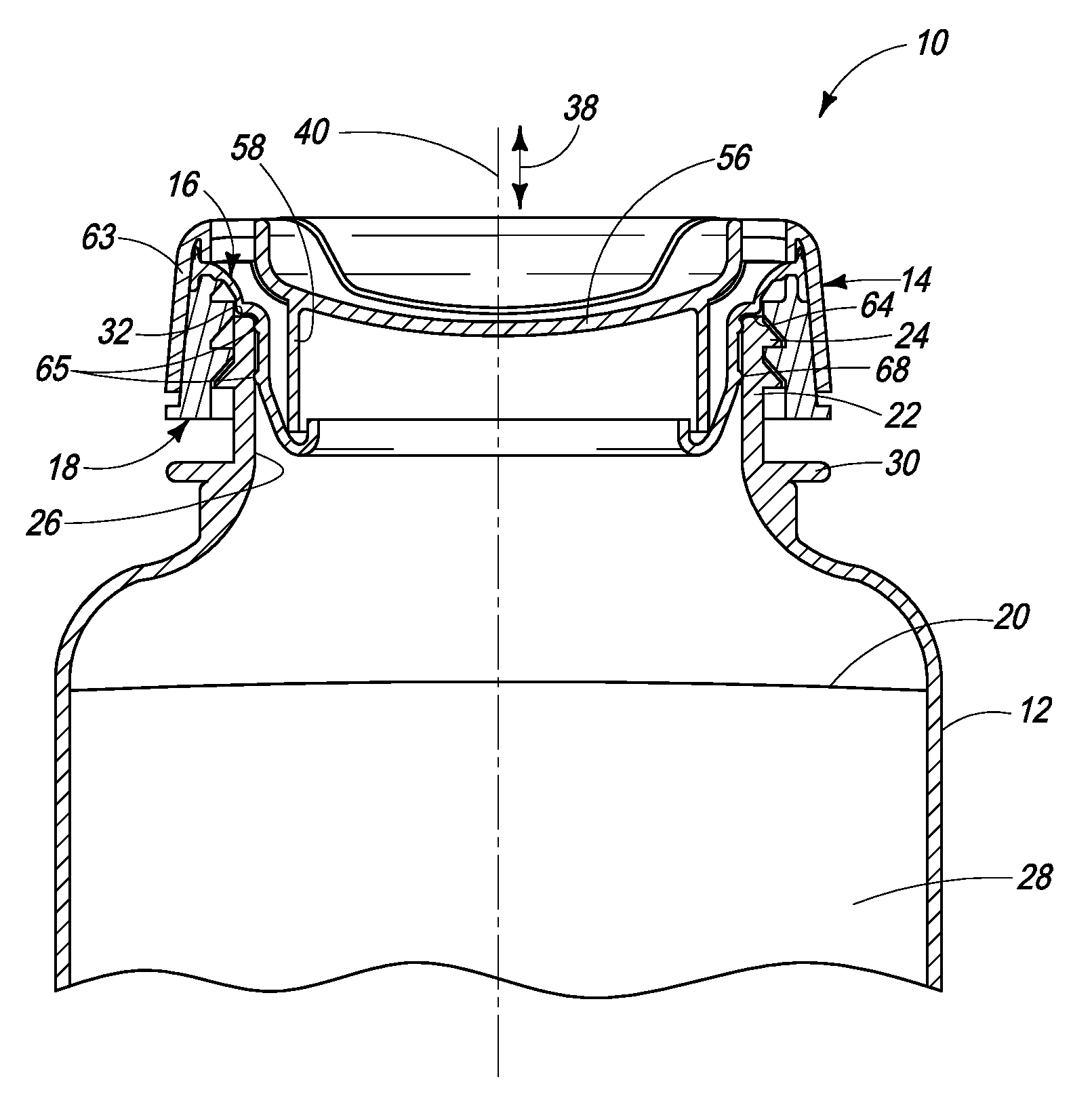

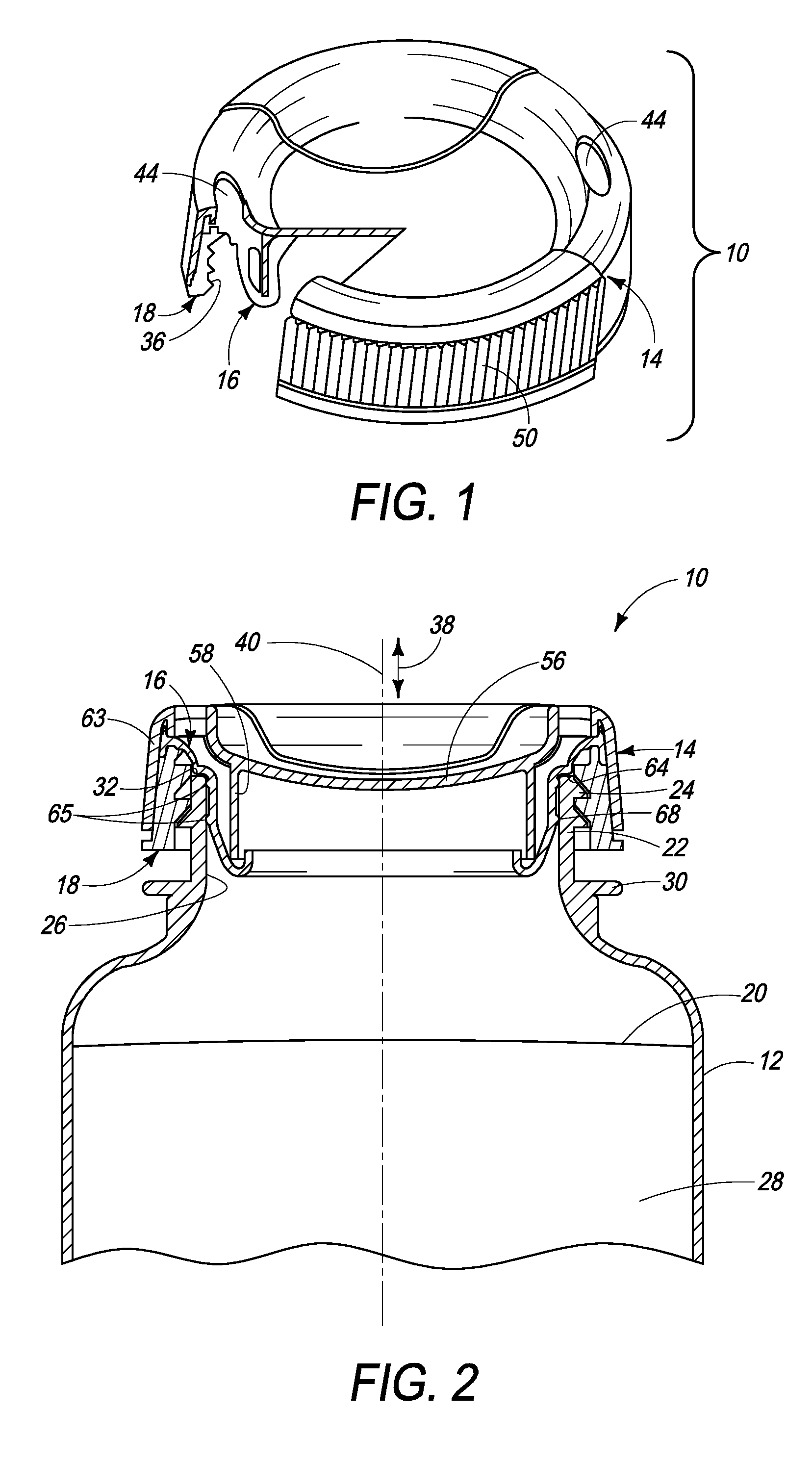

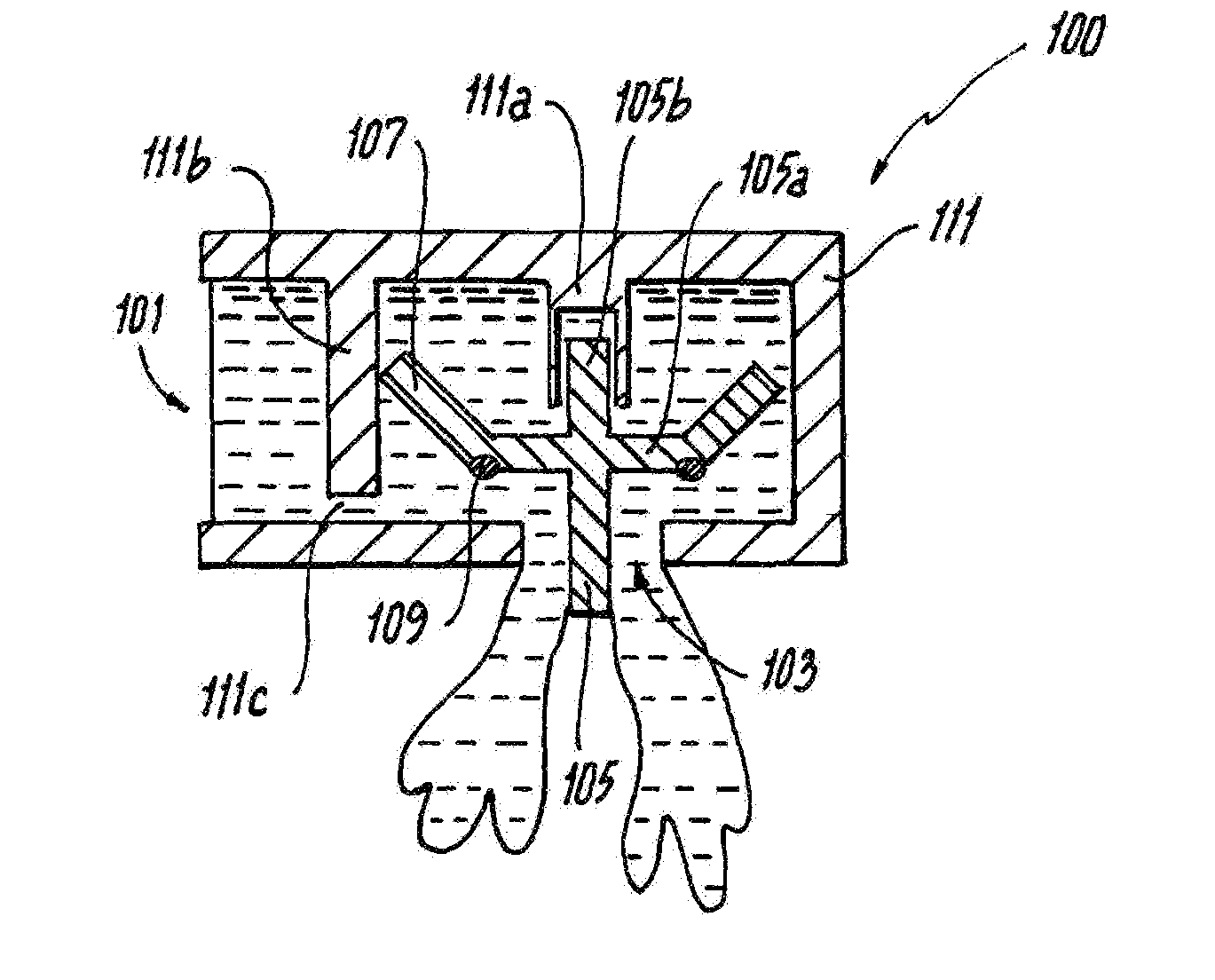

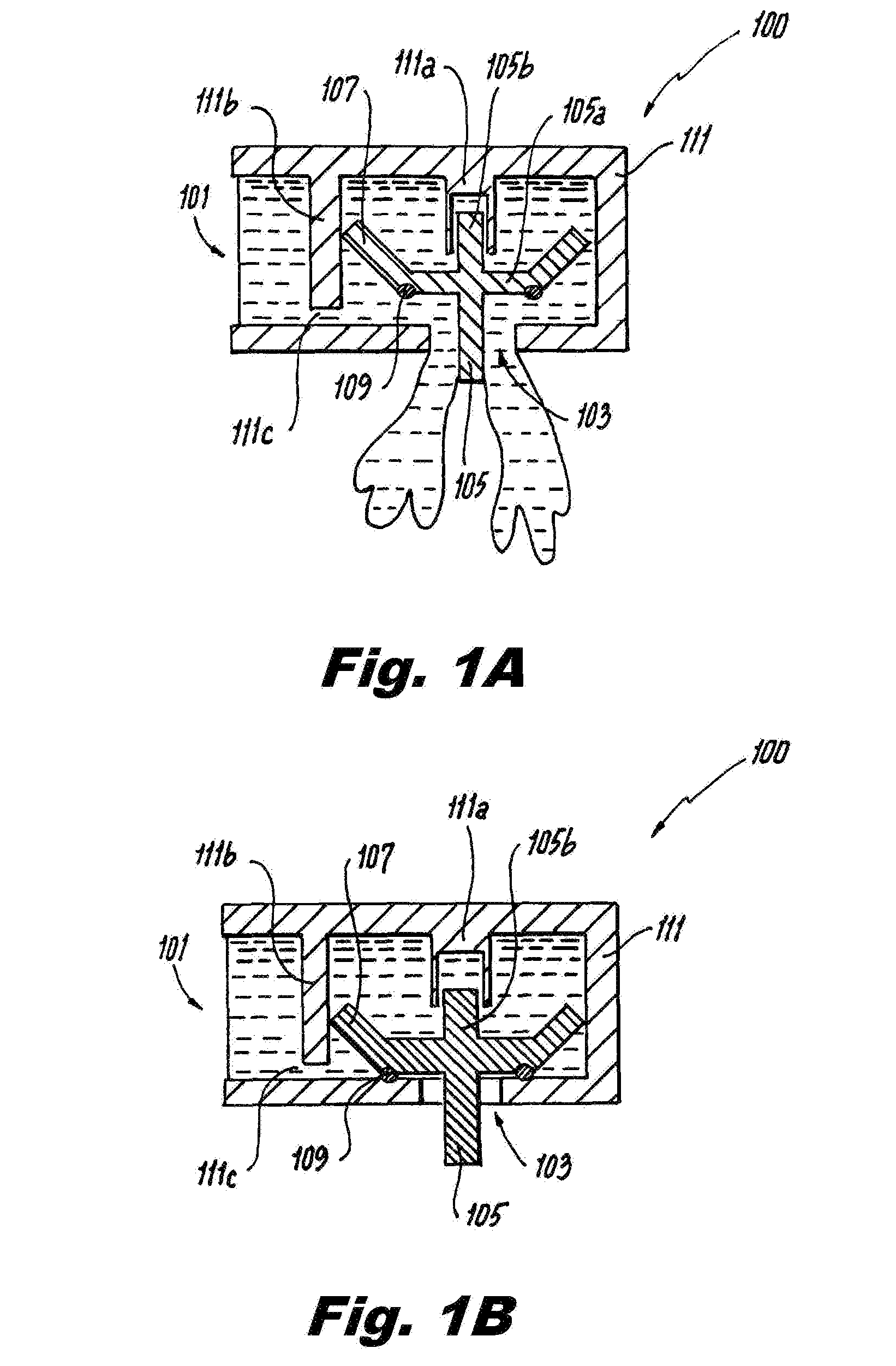

Valve Permitting Mixing in a Drug Delivery Device

ActiveUS20150314071A1Prevent fluid flowEasy to separateAmpoule syringesMedical devicesDrugDrug delivery

A valve (10) for permitting mixing of at least two components within a barrel (12) is provided including a stopper (20) configured for slidable liquid-tight engagement with an inner surface (13) of the barrel. The stopper is moveable between a first position and a second position and includes a proximal end (22), a distal end (24), and a channel (26) extending therebetween. The valve further includes a stationary body (30) comprising a base (32) and a stem (34), the stem being disposed within the channel of the stopper when the stopper is in the second position. When the stopper is in the first position, there is a liquid-tight seal in the channel, such that fluid flow through the channel is prevented. Movement of the stopper to the second position terminates the liquid-tight seal, thereby establishing fluid communication through the channel. A drug containing device and assembly for delivering a reconstituted drug are also provided herein.

Owner:BECTON DICKINSON & CO

Shut off valves and components thereof for ecology fuel return systems

ActiveUS20160305328A1Prevent fluid flowOperating means/releasing devices for valvesPressure relieving devices on sealing facesEngineeringGlobe valve

In at least one aspect of this disclosure, a shut off valve for an ecology fuel return system can include an inlet for receiving a fluid, an outlet for effusing the fluid, and a valve member configured to move between an open position such that the valve member allows fluid to effuse from the outlet and a closed position such that the valve member prevents fluid from effusing from the outlet. The valve member can include a pressure deflector configured to prevent fluid flow from biasing the valve member toward the closed position.

Owner:HAMILTON SUNDSTRAND CORP

Fire truck valve checker system and method

PendingUS20210394002A1Prevent fluid flowAvoid static frictionOperating means/releasing devices for valvesFire rescuePhysicsTruck

A valve checker system includes a valve having a valve housing with an inlet side, an outlet side, and a valve element therebetween. The valve element is selectively and repeatably rotatable between a first closed position, wherein a seal is formed between the valve element and the valve housing, thereby substantially preventing fluid flow between the inlet and outlet sides, and an open position, wherein the seal is broken such that fluid flow is permissible between the inlet and outlet sides. The valve element is also selectively and repeatably rotatable within a discrete angle in a direction toward the open position, from the first closed position into a second closed position in which the seal is maintained between the valve element and the valve housing. A controller is operatively coupled to the valve element and configured to rotate the valve element between the first and second closed positions.

Owner:HALE PRODUCTS INC

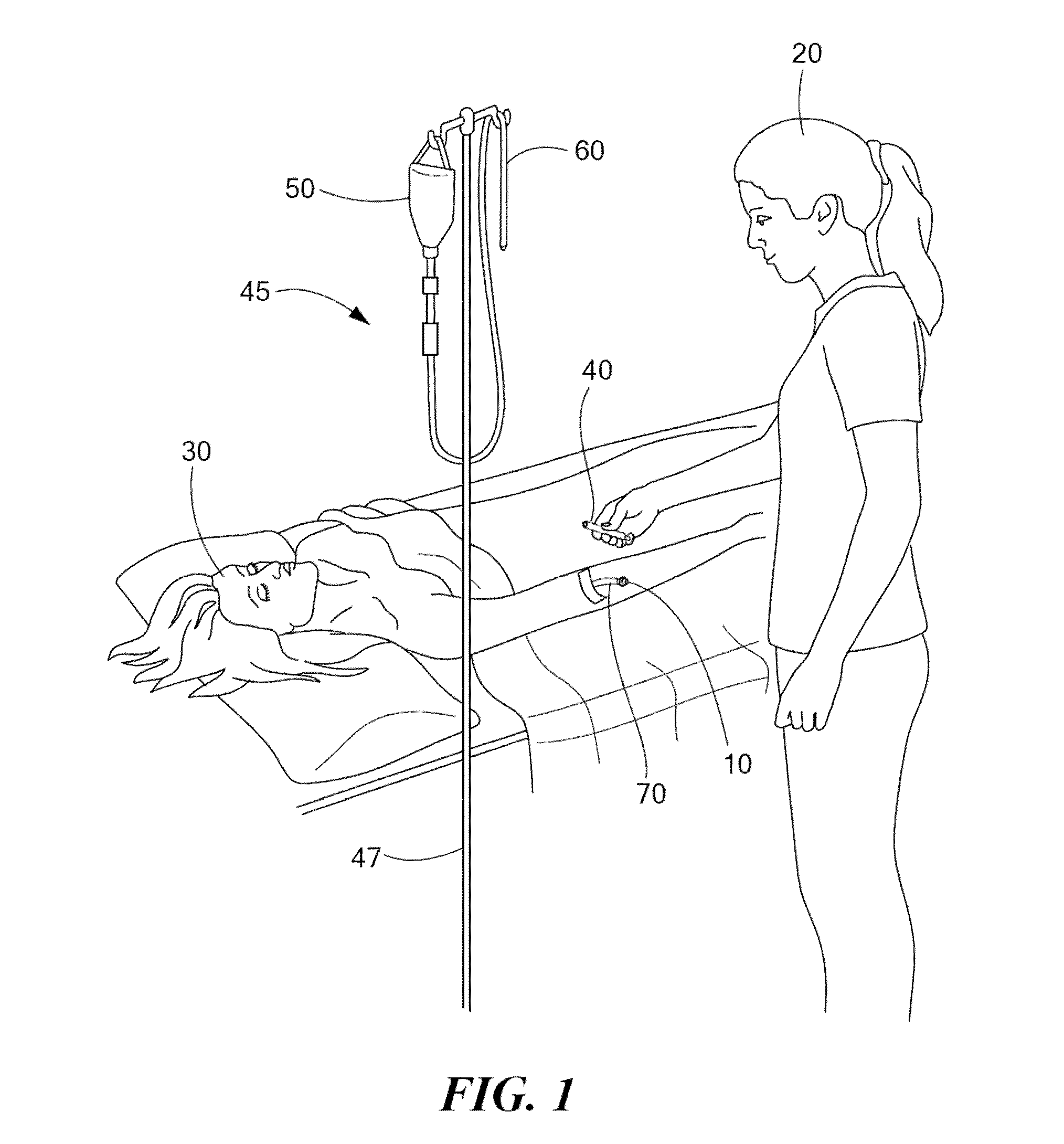

Breastmilk Pumping And Feeding Systems And Methods

ActiveUS20220193313A1Prevent fluid flowDecrease in numberFluid parameterMechanical/radiation/invasive therapiesNipple shieldEngineering

Methods and breast pump devices for simultaneous pumping and feeding breastmilk in the nursing position and quantification of breastmilk consumption are provided. A breast pump device includes a nipple shield for receiving a nipple, a housing having a throughput aperture and a fluid path, the fluid path extending from the nipple shield to the throughput aperture, and a negative pressure source. In some embodiments, the housing further includes a gate to control the quantity of breastmilk displaced to a baby. In some embodiments, the gate operates to respond to the amount of breastmilk displaced to the baby, and thereby allows for quantification. In some embodiments, the quantity of breastmilk displaced is also recorded.

Owner:AVIRA HEALTH INC

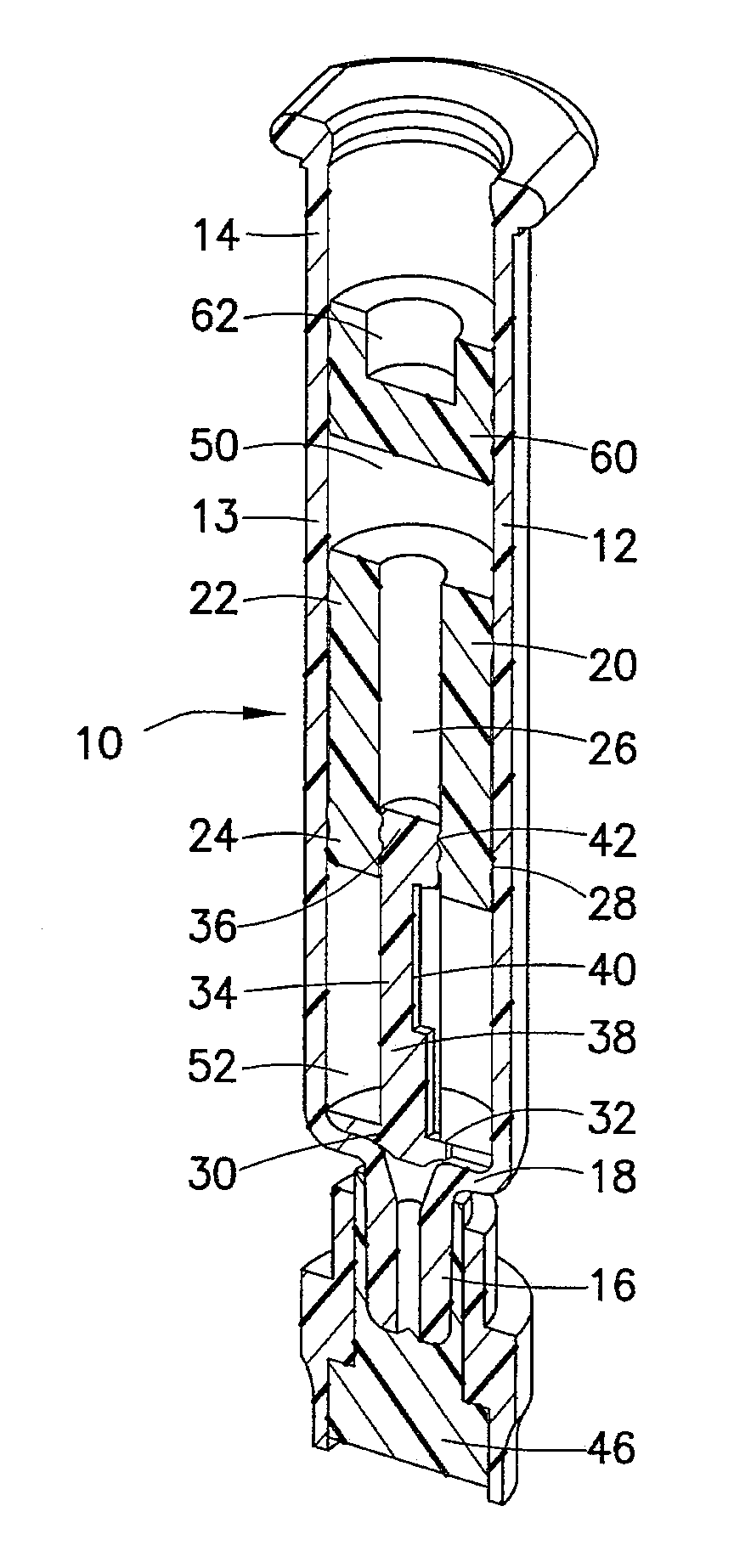

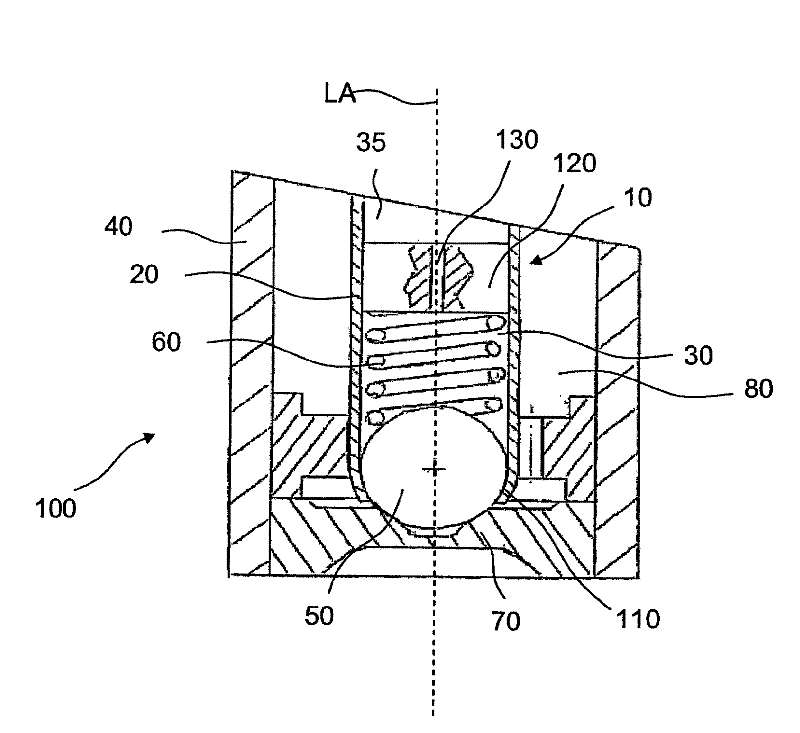

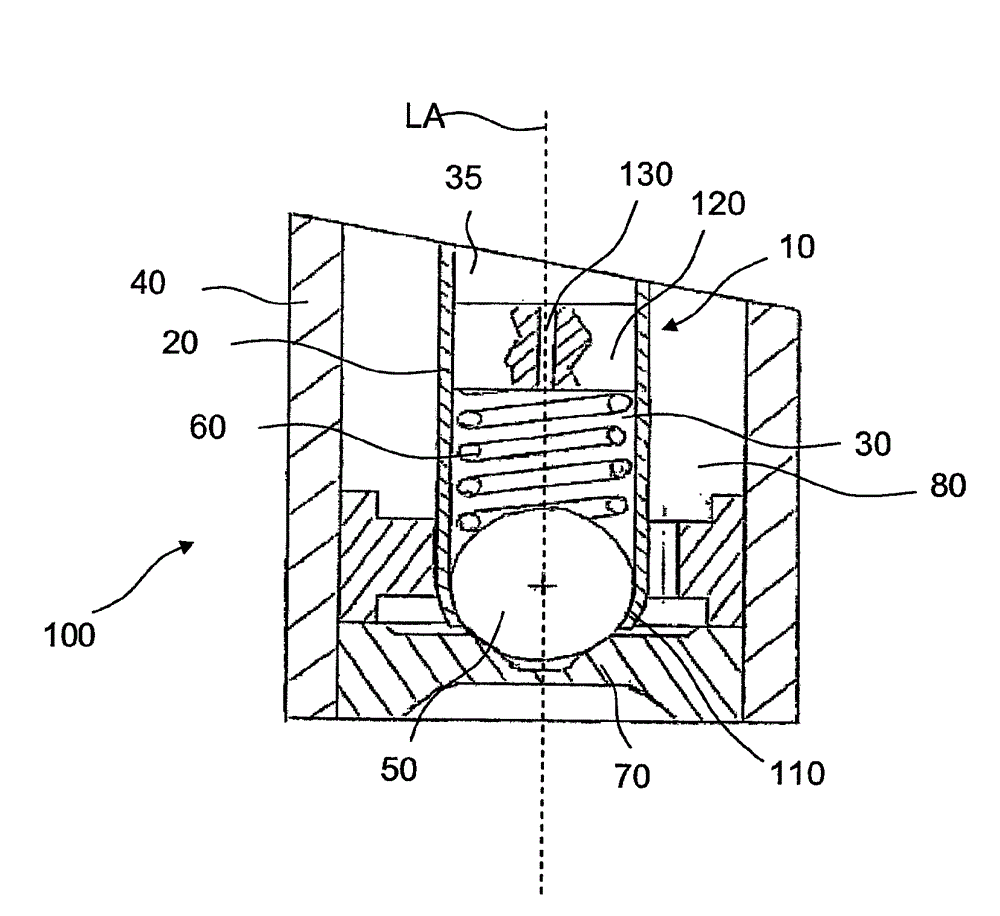

Injection valve

InactiveCN102362060APrevent fluid flowEfficient manufacturingMachines/enginesSpecial fuel injection apparatusBiomedical engineeringFluid injection

Injection valve (100) for injecting fluid, comprising an injection valve housing (40) with an injection valve cavity (80). The injection valve (100) comprises a valve needle (10] being axially moveable within the injection valve cavity (80). The valve needle (10) comprises a valve needle body (20) with a valve needle cavity and a separation element (120) being fixedly arranged within the valve needle cavity and being adopted to divide the valve needle cavity into a first and second fluid volume (30, 90). The separation element comprises at least one fluid passage (130) with a predetermined passage opening to hydraulically connect the first fluid volume (30) with the second fluid volume (90). The valve needle (10) comprises a sealing element (50) being arranged to predetermine the first fluid volume (30) and preventing a fluid injection in a closing position and permitting the fluid injection in further positions. In addition, the valve needle (10) comprises at least one spring element(60) being preloaded and acting on the sealing element (50) towards a maximum axial expansion of the valve needle (10).

Owner:CONTINENTAL AUTOMOTIVE GMBH

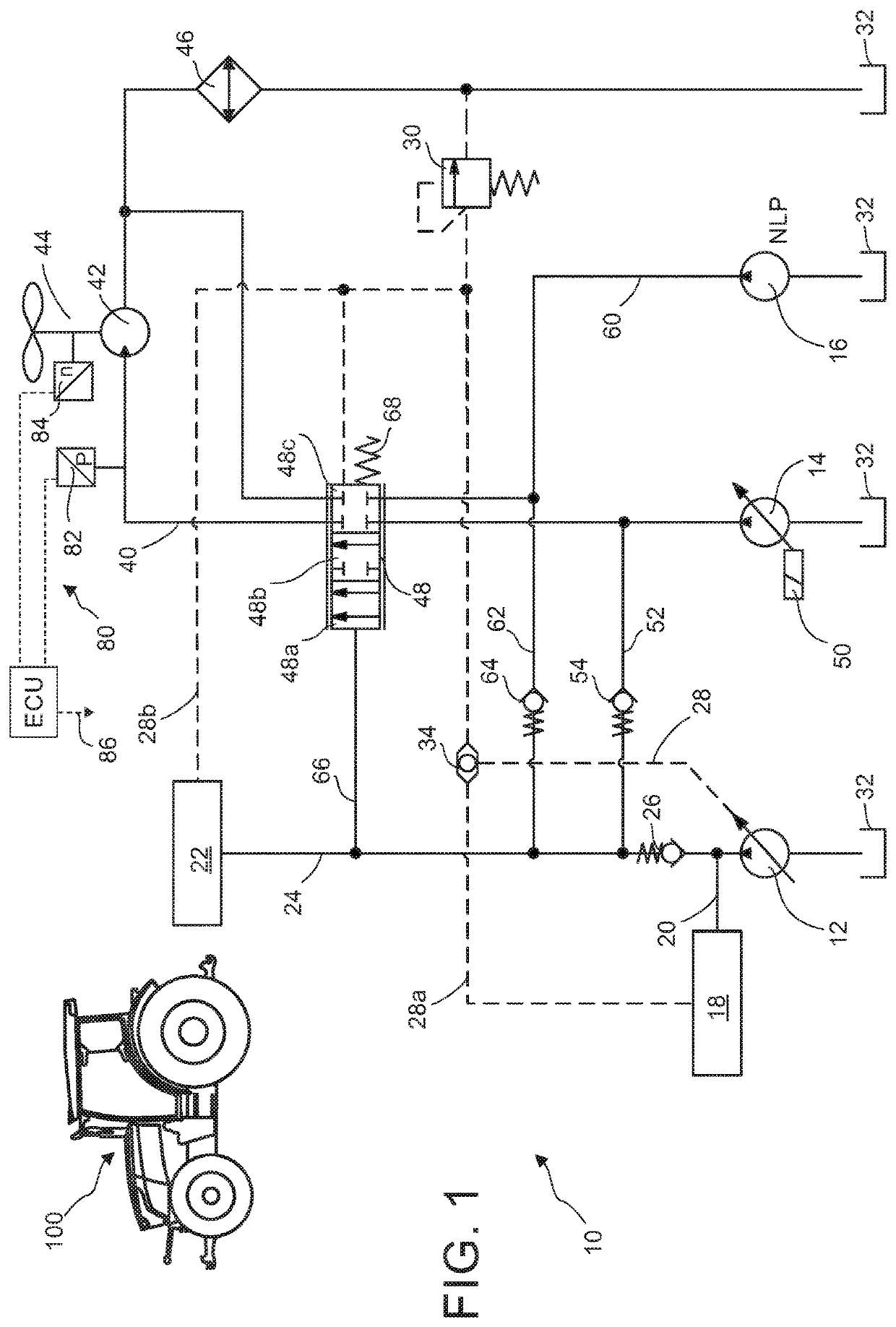

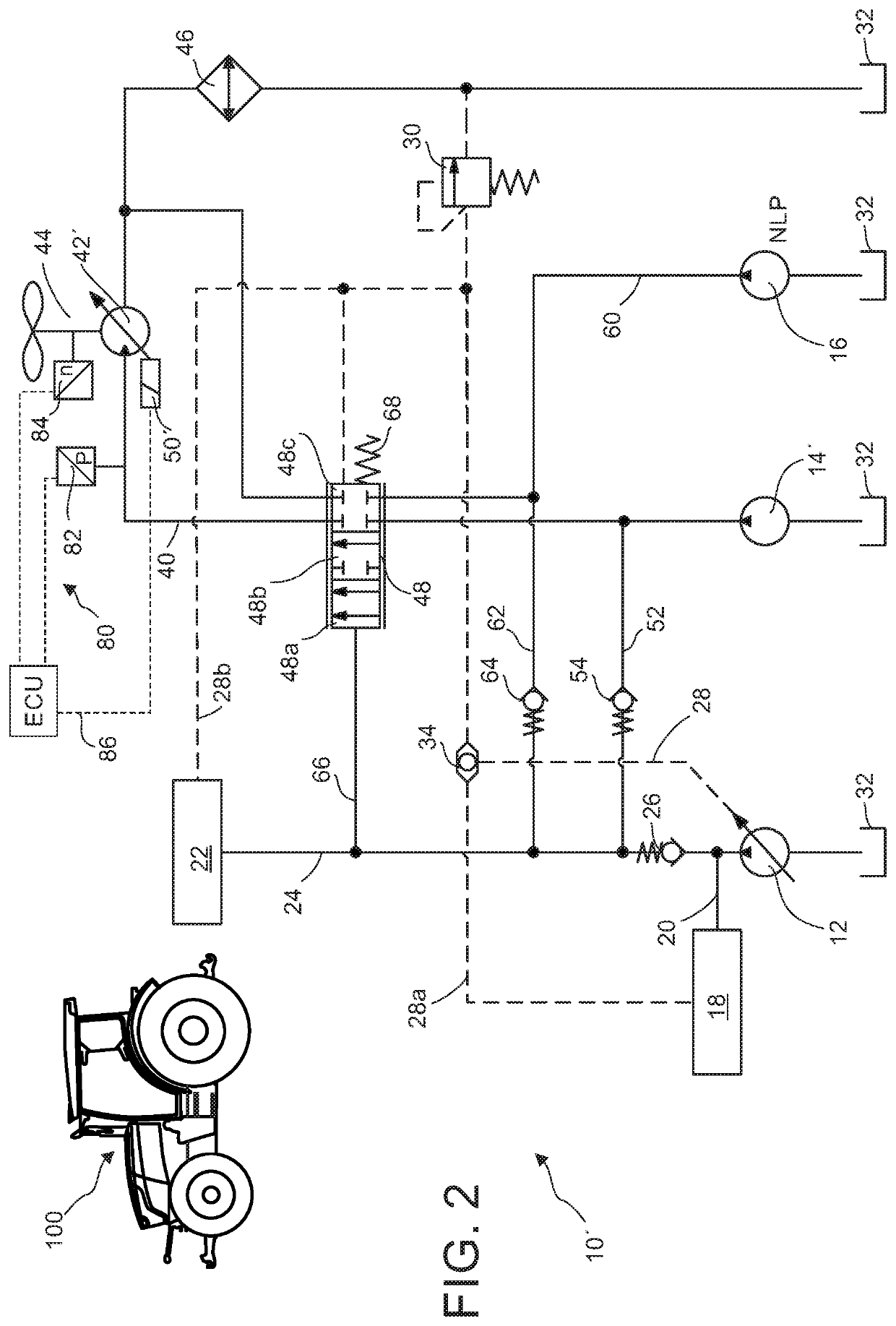

Pressurized fluid supply system for an agricultural vehicle

ActiveUS20220186753A1Prevent fluid flowImprove system efficiencyServomotorsServometer circuitsEngineeringTractor

In a hydraulic system, such as for a tractor or other agricultural vehicle, a main supply pump supplies fluid to a steering system through a steering circuit and a second pump supplies fluid to a cooling fan motor. The second pump is connected with the steering circuit to provide a second a source of fluid to the steering system when the main supply pump is unable to meet demand. A prioritization valve regulates the flow of fluid from the second pump to the motor. The second pump acts as a secondary pump for the steering system and drives a cooling fan.

Owner:AGCO INT GMBH

Pressure-driven flow rate control valves

ActiveUS20210140550A1Prevent fluid flowReduce flowCheck valvesEqualizing valvesPressure-driven flowElectrical and Electronics engineering

Owner:BECTON DICKINSON & CO

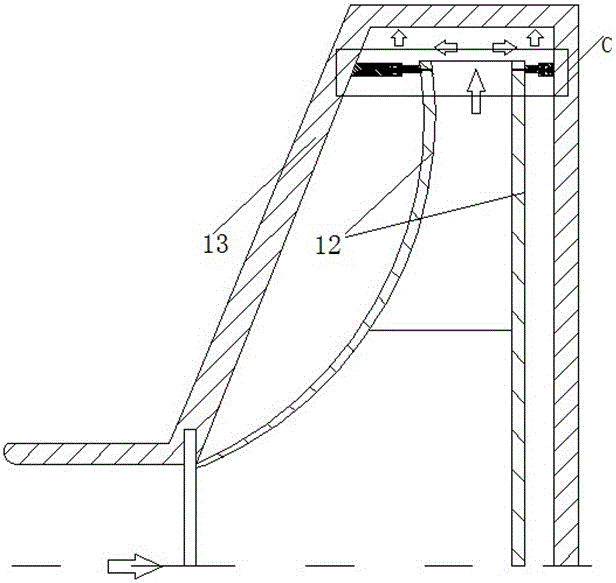

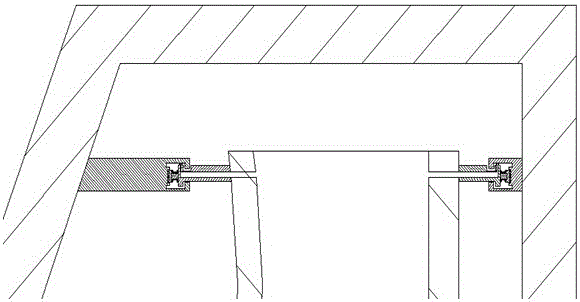

Sealing mechanism for gap between impeller and volute

The invention discloses a sealing mechanism for a gap between an impeller and a volute. The sealing mechanism is installed between cover plates installed at the both sides of the water outlet of the impeller and the inner sidewall of the corresponding volute, and comprises pressure water annular sealing blocks and static rings; the cover plates at the both sides are symmetrically provided with pressure water annular through grooves close to the water outlet of the impeller; one end of each pressure water annular sealing block is connected to one pressure water annular through groove; the other end of each pressure water annular sealing block is installed in an open groove in one end surface of one static ring through an elastic sealing element; the other end surface of each static ring is hermetically fixed on the inner sidewall of the volute. The sealing mechanism is used for realizing sealing for the gap between the impeller and the volute, capable of effectively preventing fluid flowing from the outlet of the impeller to gaps between the front and rear cover plates, and the volute, and greatly reducing capacity losses and the generations of secondary flows and vortexes; meanwhile, with the adoption of the double matching of two types of sealing, the reliability and the error-tolerant rate of the sealing mechanism are improved.

Owner:ZHEJIANG TIANDE PUMPS

Injection valve

InactiveCN102362060BPrevent sprayingJetting is reliable and preciseMachines/enginesSpecial fuel injection apparatusBiomedical engineeringFluid injection

Injection valve (100) for injecting fluid, comprising an injection valve housing (40) with an injection valve cavity (80). The injection valve (100) comprises a valve needle (10) being axially moveable within the injection valve cavity (80). The valve needle (10) comprises a valve needle body (20) with a valve needle cavity and a separation element (120) being fixedly arranged within the valve needle cavity and being adopted to divide the valve needle cavity into a first and second fluid volume (30, 90). The separation element comprises at least one fluid passage (130) with a predetermined passage opening to hydraulically connect the first fluid volume (30) with the second fluid volume (90). The valve needle (10) comprises a sealing element (50) being arranged to predetermine the first fluid volume (30) and preventing a fluid injection in a closing position and permitting the fluid injection in further positions. In addition, the valve needle (10) comprises at least one spring element (60) being preloaded and acting on the sealing element (50) towards a maximum axial expansion of the valve needle (10).

Owner:CONTINENTAL AUTOMOTIVE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com