Sealing mechanism for gap between impeller and volute

A technology of sealing mechanism and impeller, which is applied to components, mechanical equipment, machines/engines, etc. of elastic fluid pumping devices, which can solve the problems of increasing pump energy loss, reducing water supply of water pumps, leakage, etc., and achieve volume reduction loss, simplification of installation process, and reduction of secondary flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

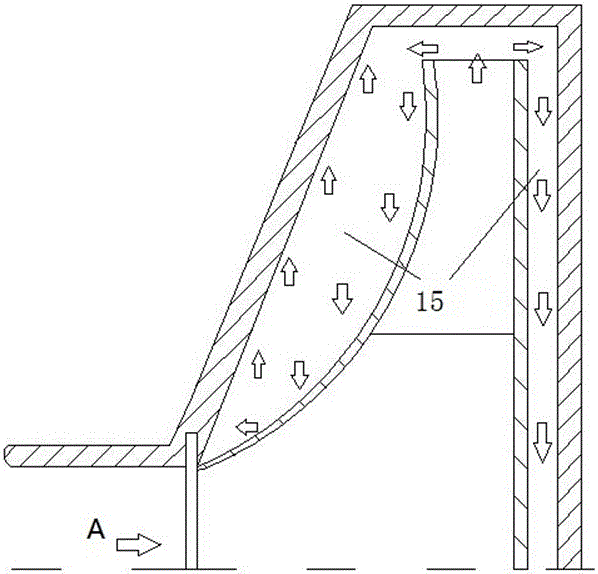

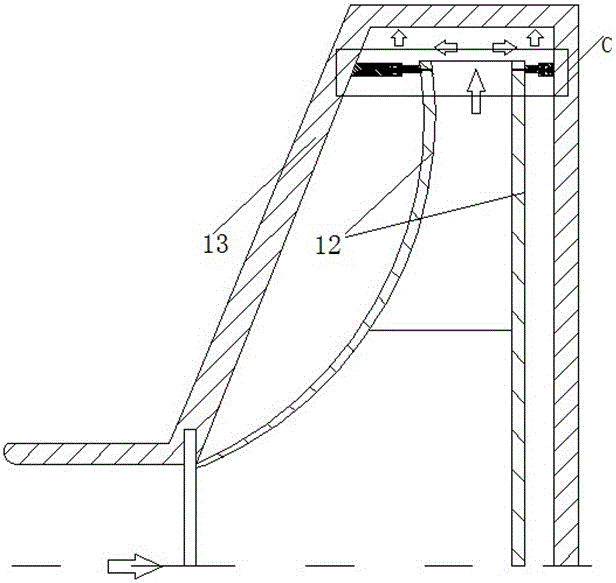

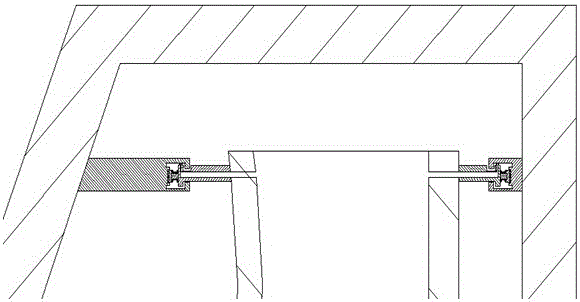

[0033] figure 1 It is a simplified schematic diagram of a pump section in the prior art. The impeller inflow A flows between the cover plate 12 on both sides of the impeller and the inner wall of the volute 13 to form a leakage flow 15 . The present invention as figure 2 and image 3 As shown, the sealing mechanism is installed between the cover plate 12 on both sides of the water outlet of the impeller and the corresponding inner wall of the volute 13, and is installed between the cover plate 12 on both sides of the water outlet of the impeller and the corresponding inner wall of the volute 13. Have the same sealing mechanism, the sealing mechanism includes pressure water ring seal block 2, elastic seal and static ring 1, pressure water ring seal block 2 such as Figure 6 and Figure 7 As shown, the cover plates 12 on both sides are symmetrically opened with a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com