Shaft bearings, compressor with same, and methods

A support, support technology, applied in the direction of bearing components, bearings, combustion methods, etc., can solve problems such as extra costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

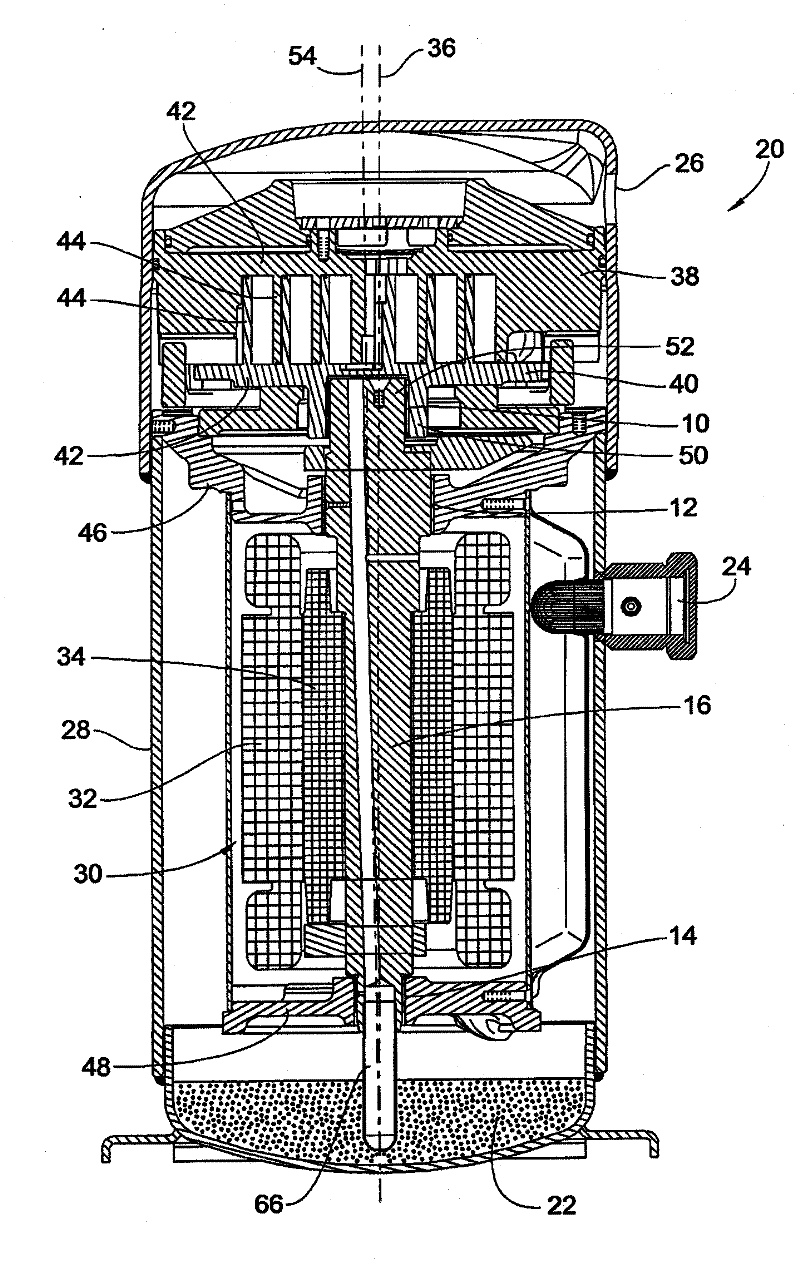

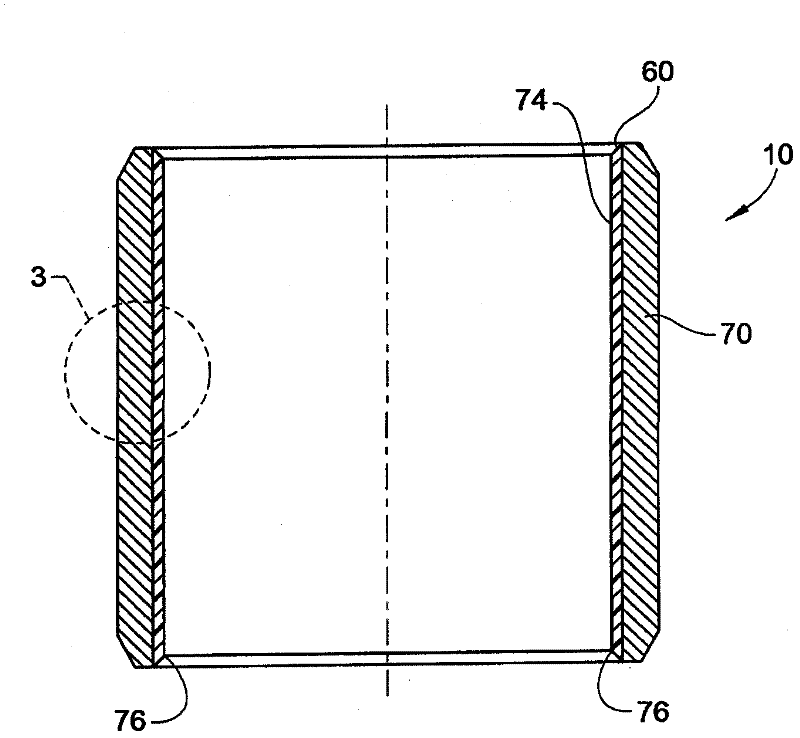

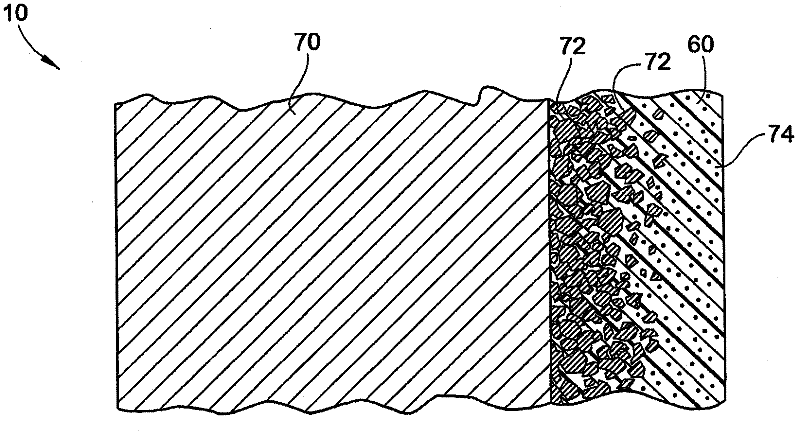

[0021] One embodiment of the present invention has been shown as one or more bearing sleeves 10 , 12 and 14 that are rotatably mounted relative to the drive shaft 16 in the context and application of the scroll compressor assembly 20 . Scroll compressor assembly 20 operates in lubricating oil 22 and is adapted to compress refrigerant entering through inlet 24 . Within scroll compressor assembly 20, refrigerant is compressed and exits outlet 26 in a compressed state.

[0022] Before turning to details of the one or more bearing sleeves 10, 12, 14, some background on the illustrated scroll compressor assembly 20 will be given for orientation purposes, although it should be understood that the present invention can also Applicable to other compressor structures for refrigerants, etc. Scroll compressor assembly 20 generally includes an outer housing 28 that includes an inlet 24 and an outlet 26 . Shell 28 may typically comprise one or more stamped and formed sheet steel shell se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com