Pipe connecting connector

A connector and pipe connection technology, used in couplings, mechanical equipment, etc., can solve the problems of poor operability and large operating force, and achieve the effect of good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

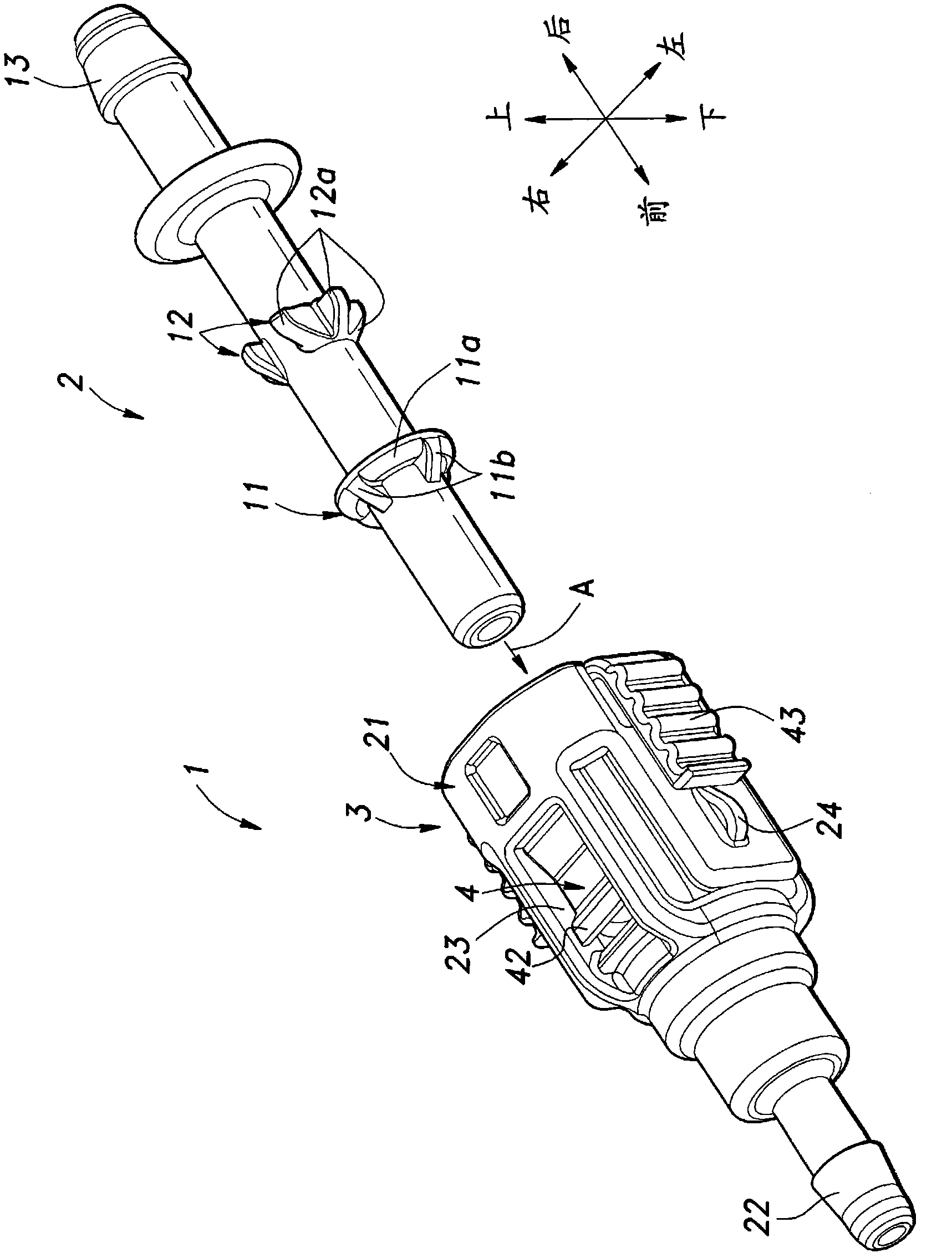

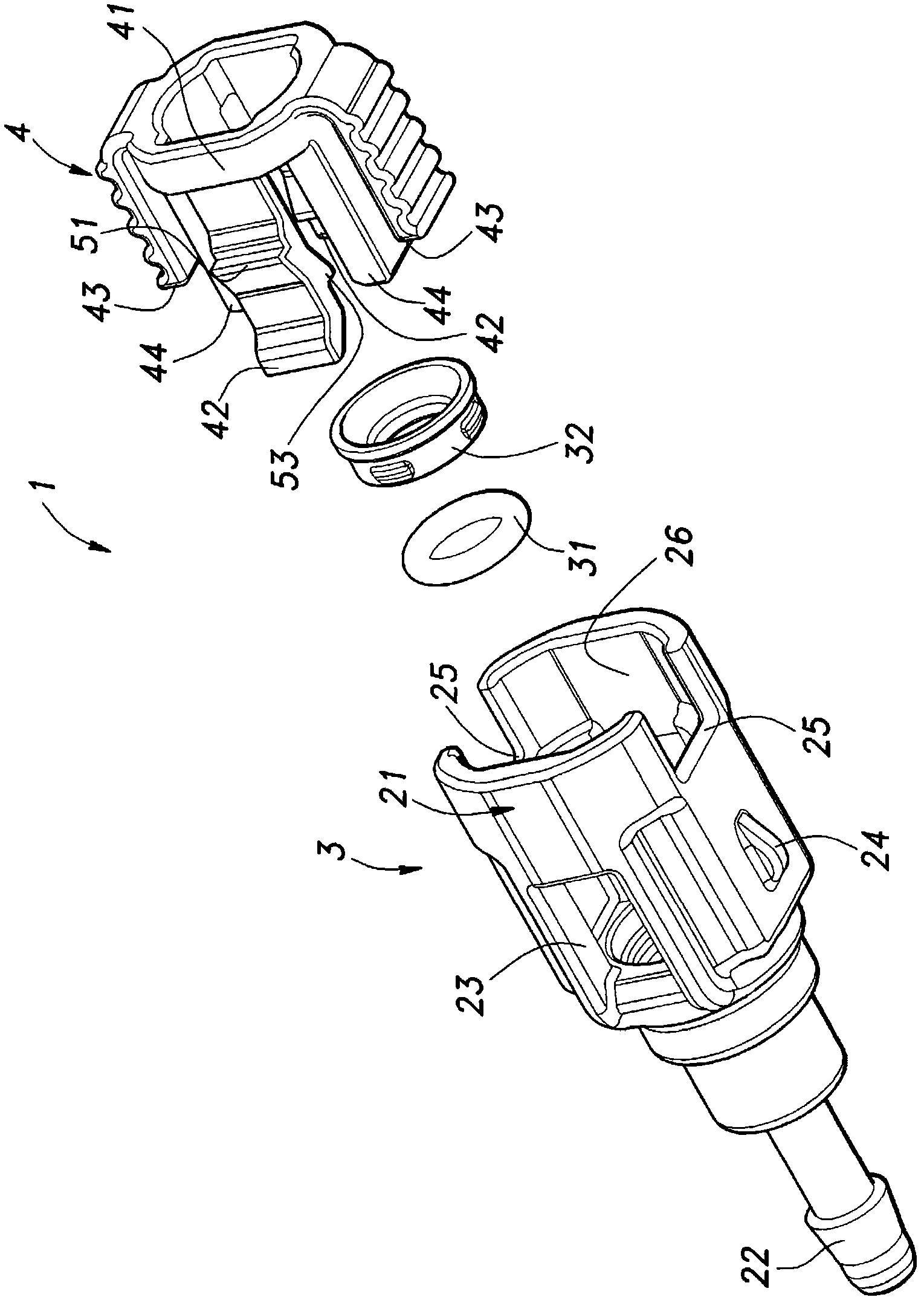

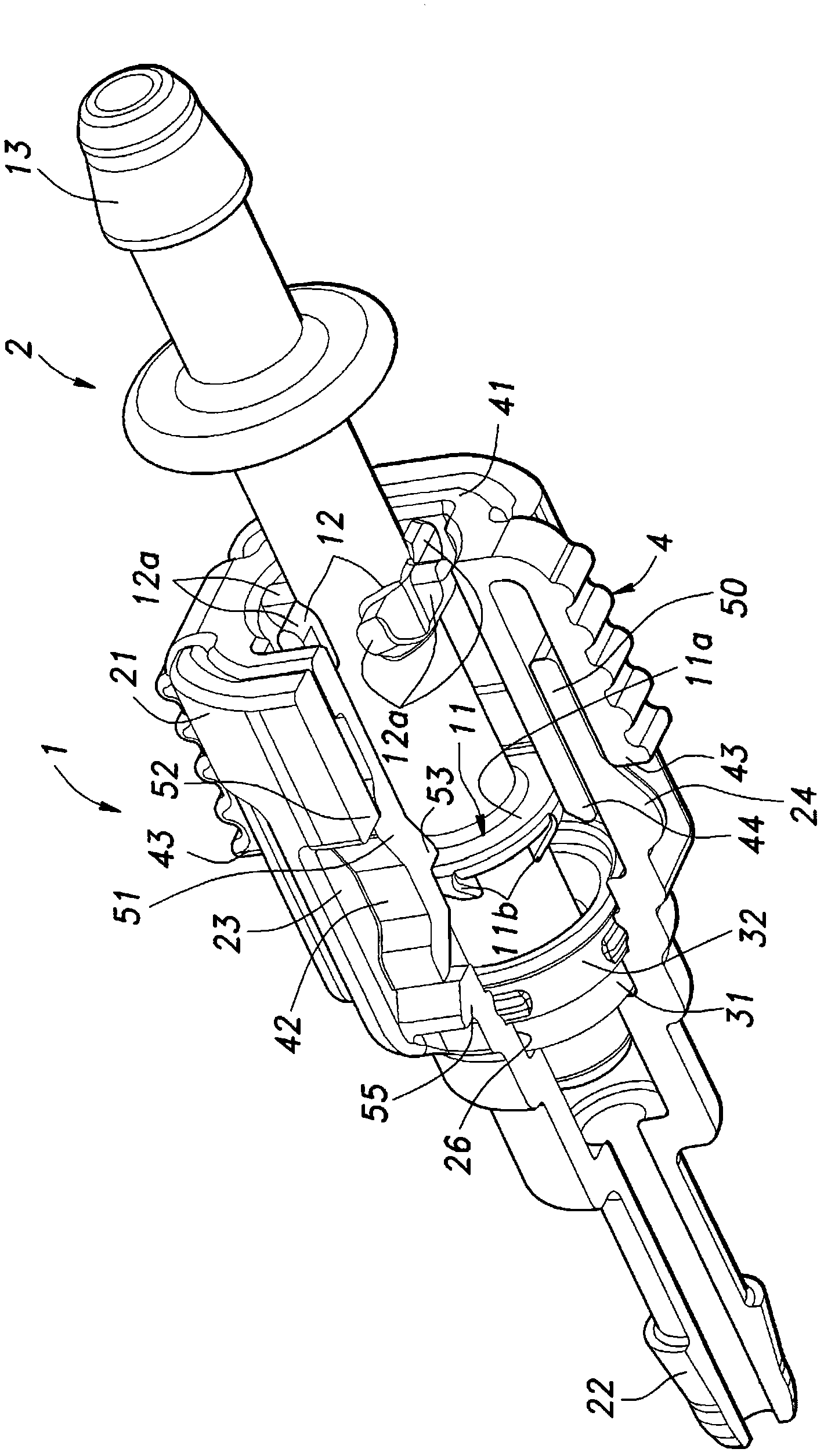

[0034] Refer below Figure 1 to Figure 10 The pipe connection connector according to the embodiment of the present invention will be described. In the following, the terms "upper", "lower", "front", "rear", "left" and "right" denoting direction are used according to figure 1 The direction shown is OK. For example, tube 2 relative to figure 1 The shown insertion direction (arrow A direction) of the connector 1 along the axis corresponds to "front", and the opposite direction corresponds to "rear".

[0035] like Figure 1 to Figure 4 As shown, the connector for pipe connection (hereinafter referred to as the connector) 1 is a component used to connect the pipe 2 for fluid delivery to the connection object (not shown), and the connector mainly includes: inserting the pipe 2 and a locking member 4 that is slidably held on the connector body 3 and that fixes the tube 2 according to the sliding action.

[0036] like figure 1 As shown, the tube 2 is equipped with: a front flang...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap