Mounting table structure and treatment device

A technology of processing device and mounting table, which is applied to electric heating device, gaseous chemical plating, coating, etc., can solve the problems of reduced surface uniformity of wafer temperature and inability to effectively correspond to it, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

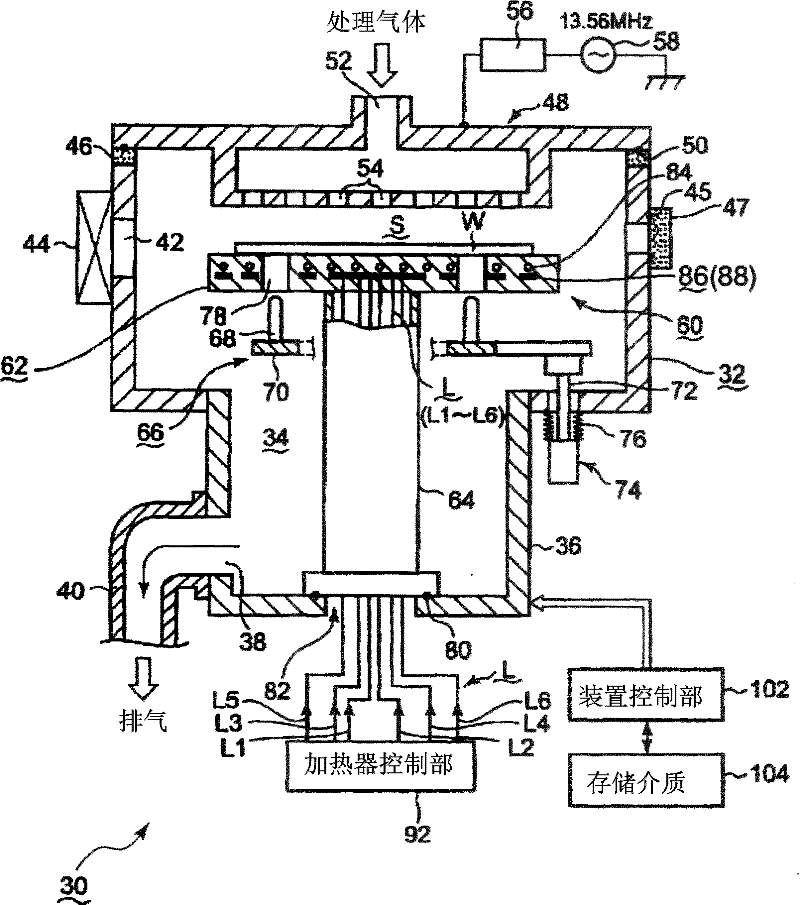

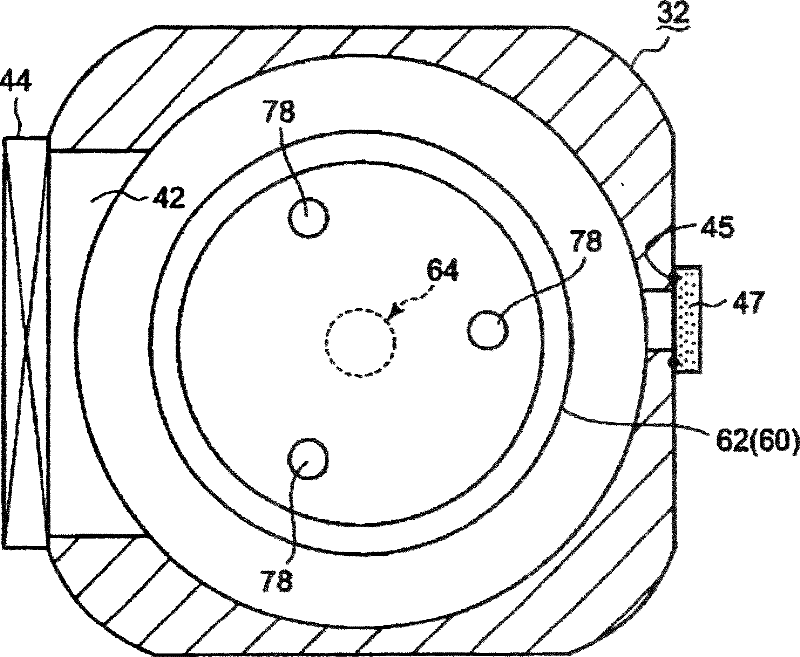

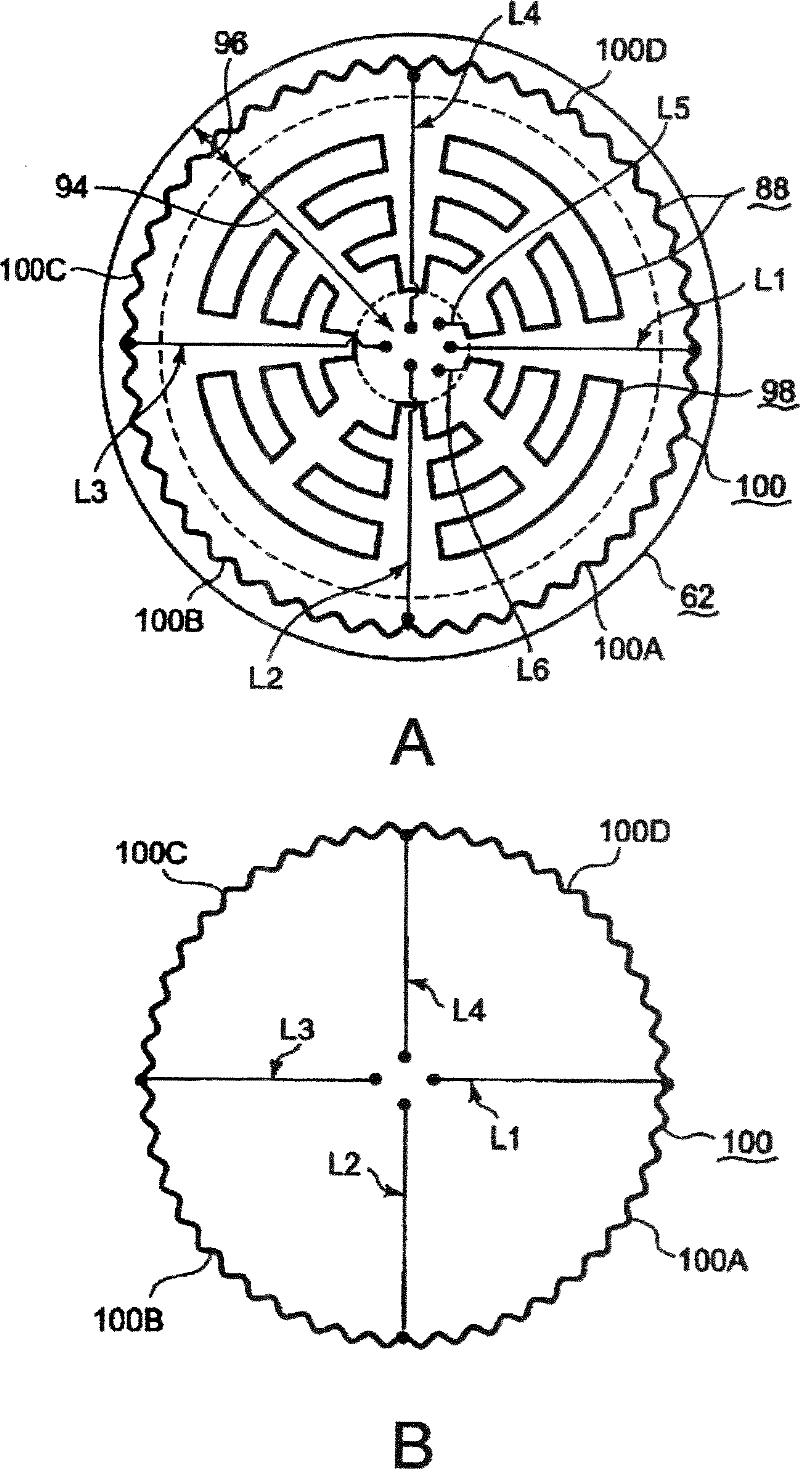

[0030] Hereinafter, one embodiment of the mounting table structure and processing apparatus of the present invention will be described in detail based on the drawings. figure 1 It is a block diagram showing a processing device having a mounting table structure of the present invention, figure 2 is a schematic cross-sectional view showing the inside of the processing container, image 3 It is a plan view showing the arrangement of resistance heaters of the heating mechanism.

[0031] Here, as the processing apparatus of the present invention, a parallel plate type plasma processing apparatus will be described as an example. like figure 1 As shown, a parallel plate type plasma processing apparatus 30 has a processing container 32 formed in a cylindrical shape, for example, from an aluminum alloy or the like. In the central part of the bottom of the processing container 32, an exhaust space 34 is further recessed downward and convexly formed by partitioning off a bottomed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com