Battery module

A technology of battery modules and single cells, which is applied in the direction of secondary batteries, battery pack components, battery temperature control, etc., can solve the problem of not being able to firmly maintain single cells, and achieve the effect of suppressing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

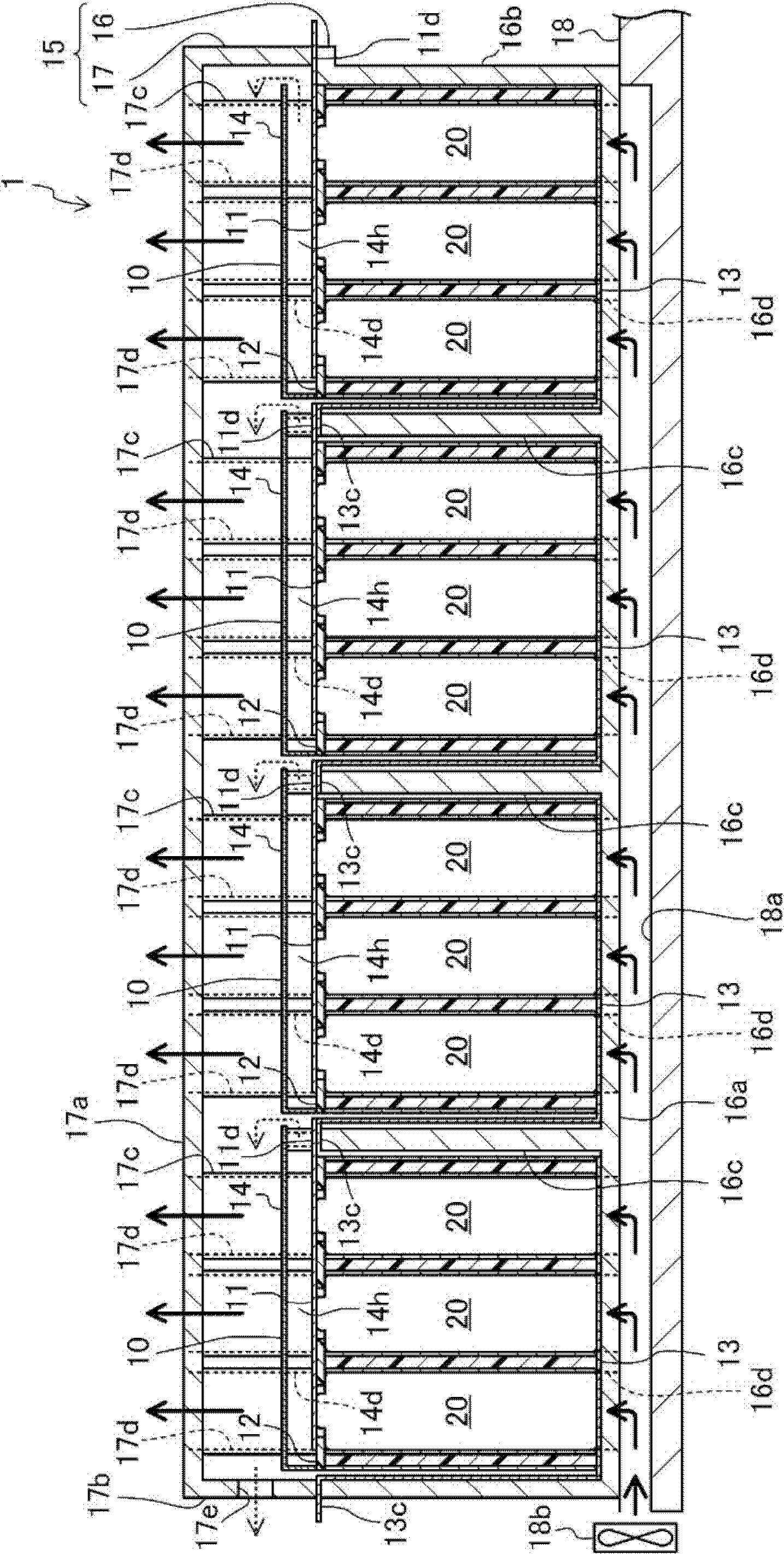

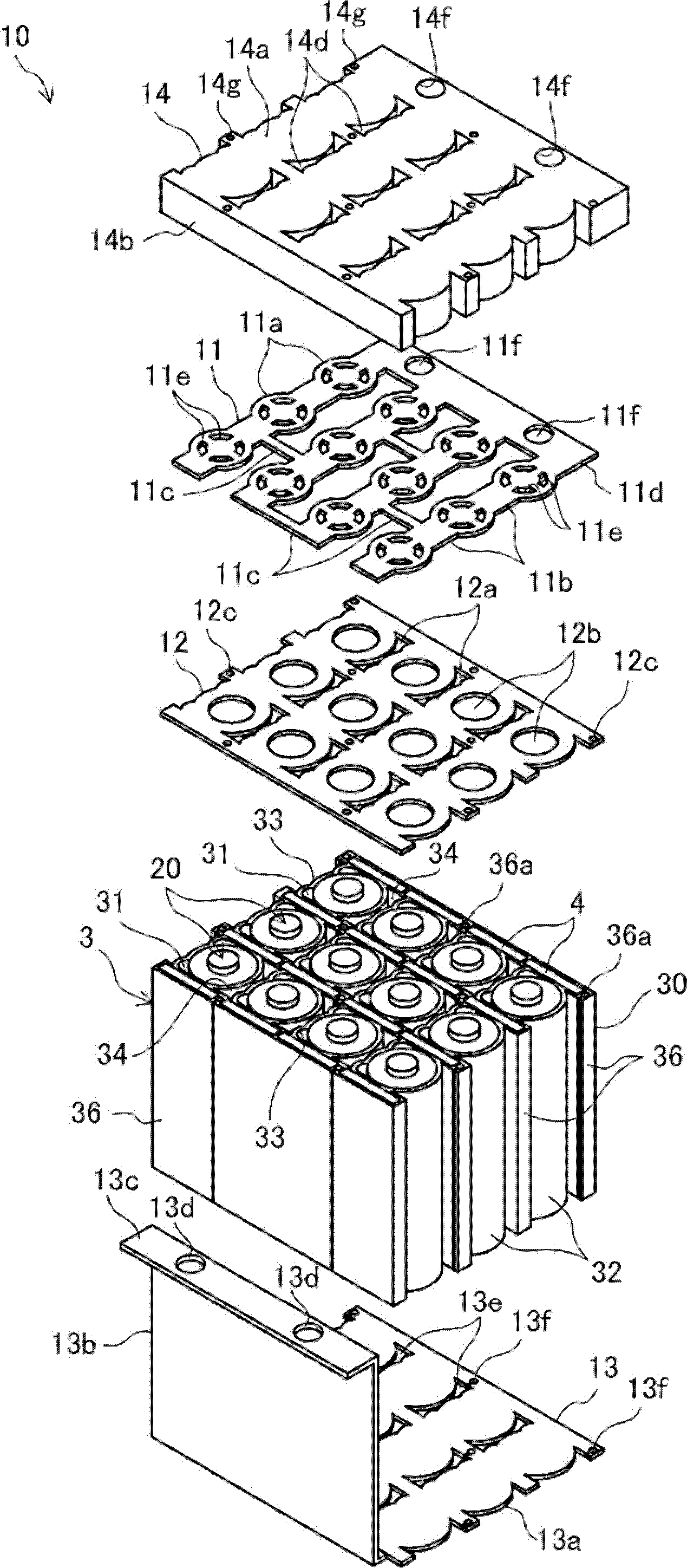

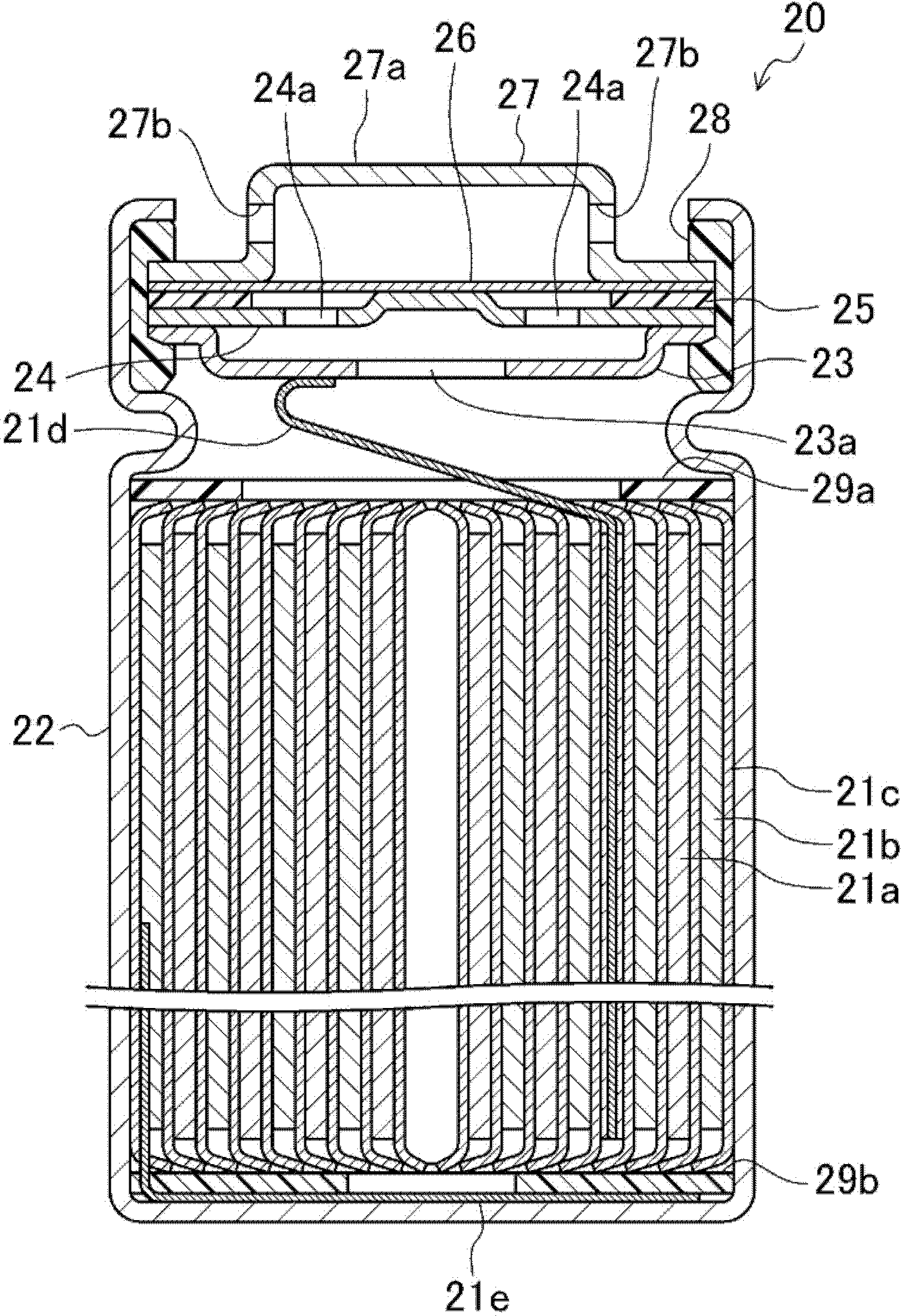

[0035] figure 1 A sectional view showing a battery module 1 according to an exemplary embodiment 1 of the present invention, figure 2 An exploded perspective view showing the battery unit. In addition, in figure 1 In , only the external shape of the unit cell 20 is shown.

[0036] The battery module 1 has: a plurality of single cells 20, 20...; supports 3, 3... for holding the single cells 20, 20...; positive connection plates 11, 11... connected to the positive poles of the single cells 20, 20...; Separators 12, 12... between the end faces of the positive side of the cells 20, 20... Cover members 14 , 14 . . . form a discharge space 14 h described later on the outside of the positive electrode side of the battery cells 20 , 20 . The battery module 1 is installed in, for example, a hybrid vehicle or an electric vehicle as a power source. exist figure 1 In the present invention, the battery module 1 is arranged on the floor 18 of the hybrid vehicle.

[0037] In the batt...

Embodiment approach 2

[0091] Hereinafter, an exemplary embodiment 2 of the present invention will be described. Figure 8 A partial enlarged plan view of the battery cell 210 showing a state in which the positive electrode connection plate 11 , the separator 12 , and the lid member 14 are omitted.

[0092] In the battery unit 210 of the second embodiment, the structure of the bracket 203 is different from that of the first embodiment. Therefore, the same reference numerals are assigned to the same configurations as those in Embodiment 1, and description thereof will be omitted, and the description will focus on different configurations.

[0093] The holder 203 has: a holder main body 230 provided with housing portions 231, 231, . Refrigerant channels 234, 234... on the holder main body 230; and phase change members 4, 4... provided on the holder main body 230 and changing from a solid phase to a liquid phase at a predetermined melting point. The pressing plate 233 constitutes a pressing portion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com