Automatic control method for small-sized bag type dust remover

A technology of bag filter and dust collector, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve problems such as low pressure of compressed air bag, a lot of dust accumulated in the ash hopper, and hidden dangers in the ash unloading process. Achieve optimal control, ensure rationality and safety, and realize the effect of undisturbed switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

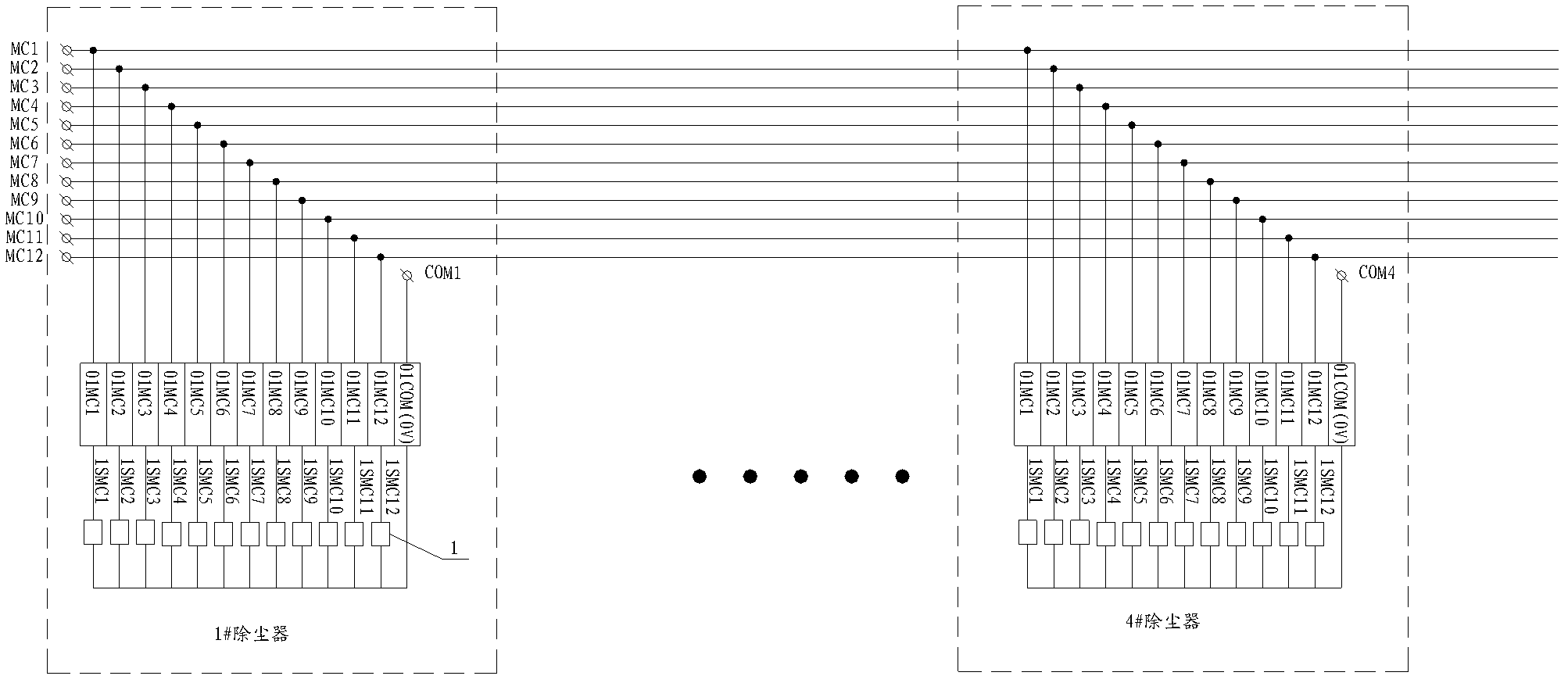

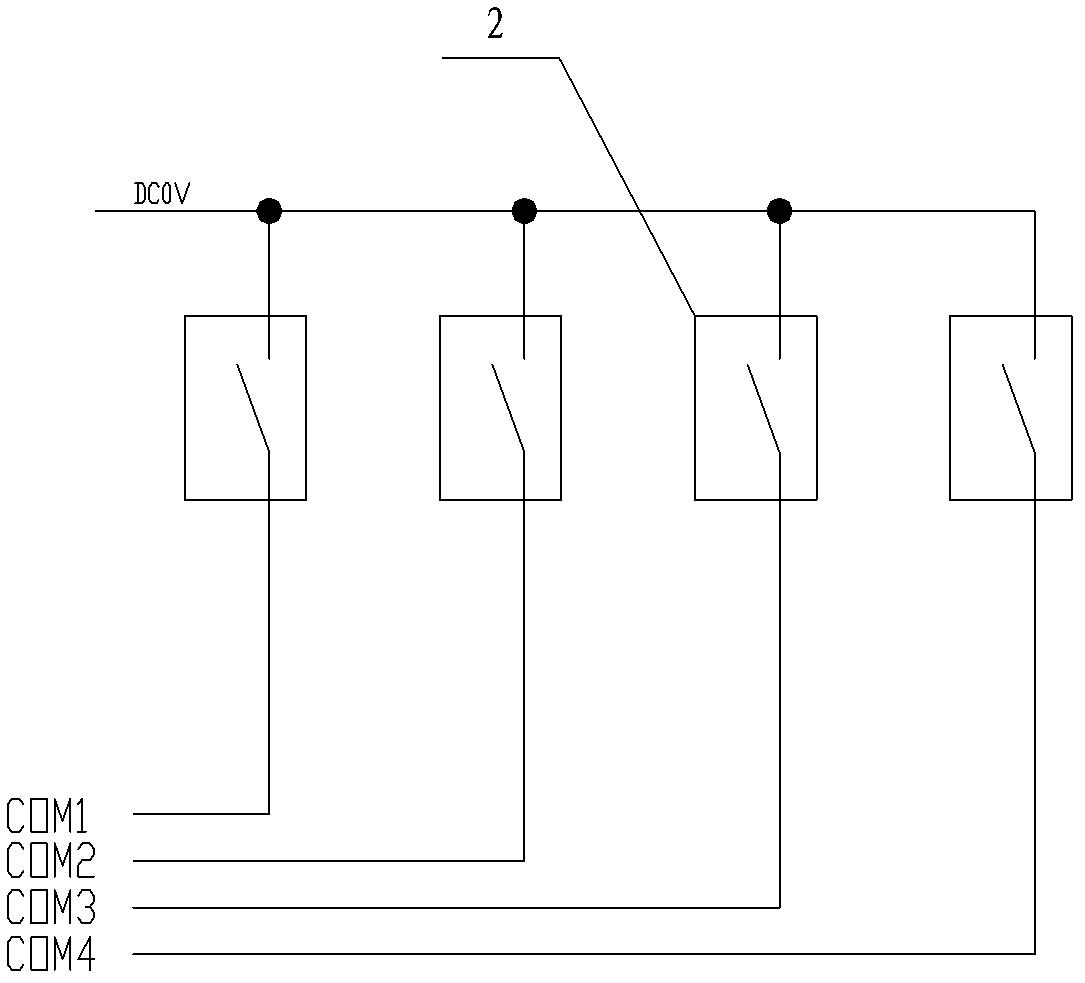

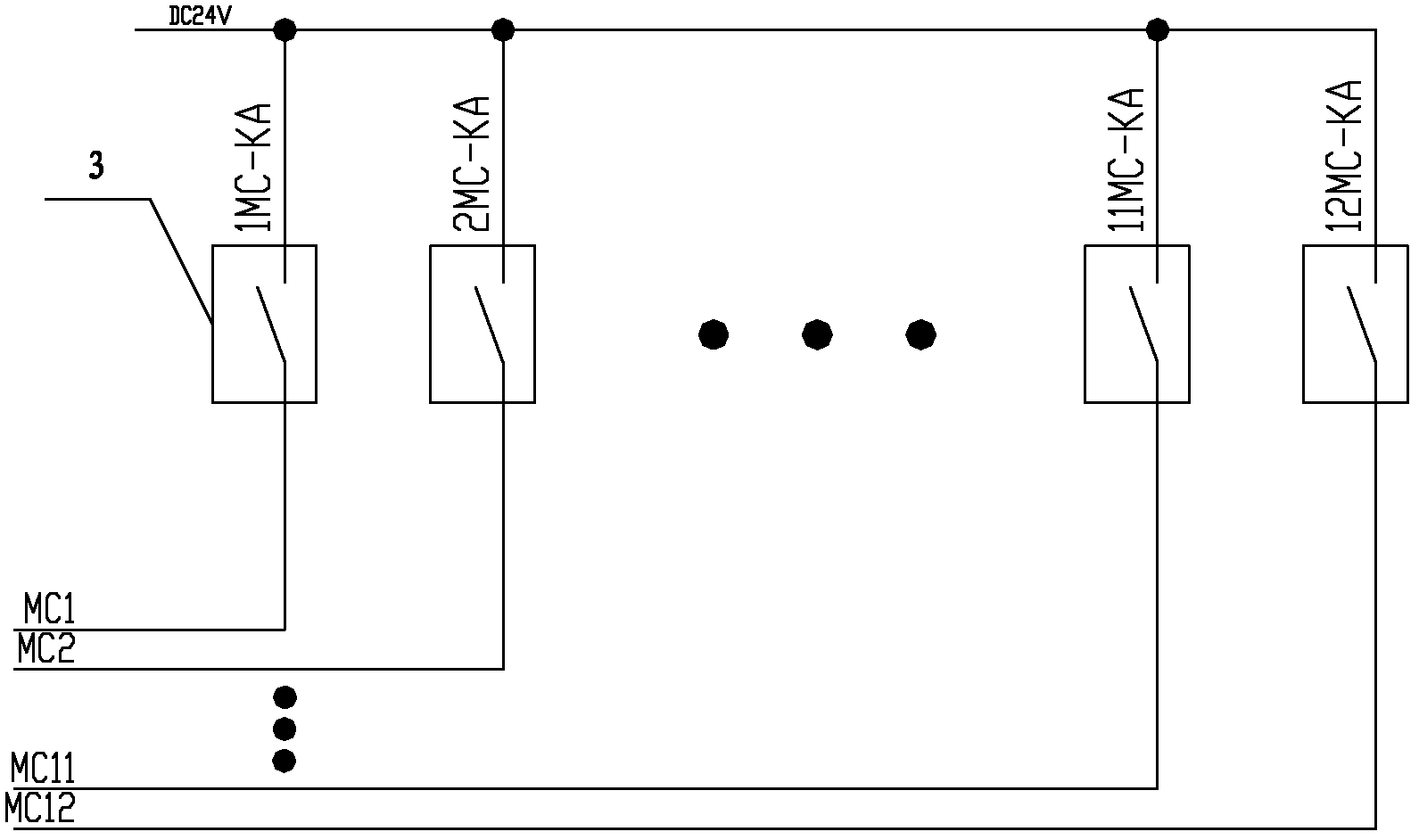

[0046] Small bag-type dust collectors are generally online dust removal. In the dust removal strategy, first of all, establish the concept of pulse valve numbering, and number the pulse valves of all boxes from the beginning to the end. The number is recorded as num, and num is from 1 to m* The number of n (m, the number of pulse valves in each box; n, the number of boxes); then, set the number of interval pulse valves Δnum (0<=Δnum<num); finally, the cleaning strategy is based on the two values of num and Δnum data to realize jump cleaning. In the ash conveying and unloading strategy, first, when receiving the ash conveying and unloading start command for the first time, start the dust-free ash unloading device or bucket elevator in sequence, and start the scraper machine after a delay; then, open the No. 1 ash hopper to unload Ash valve, after the ash discharge valve of No. 1 ash hopper is closed, open the ash discharge valve of No. 2 ash hopper in a delayed manner. If th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com