Dual-lateral surface supported bearing pedestal installation structure

A technology for supporting bearing housings and installation structures, applied in the testing of machine gears/transmission mechanisms, etc., can solve unsatisfactory problems, and achieve the effects of easy control, small space occupation, and simplified counterweight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

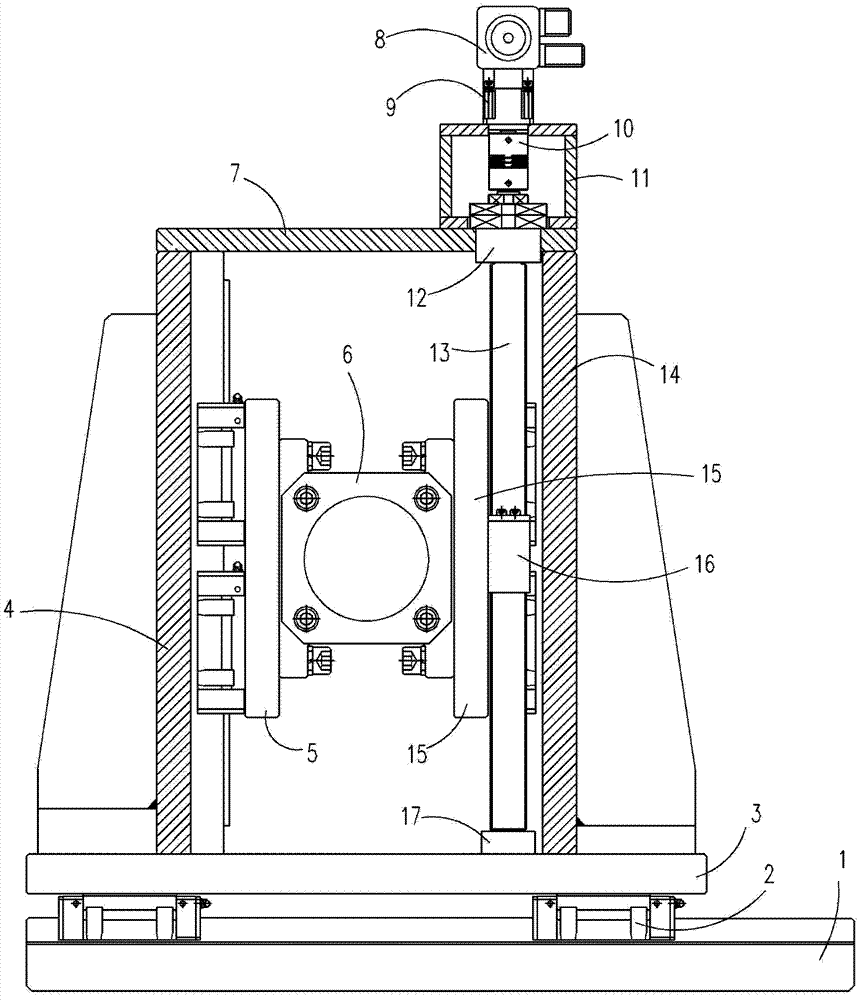

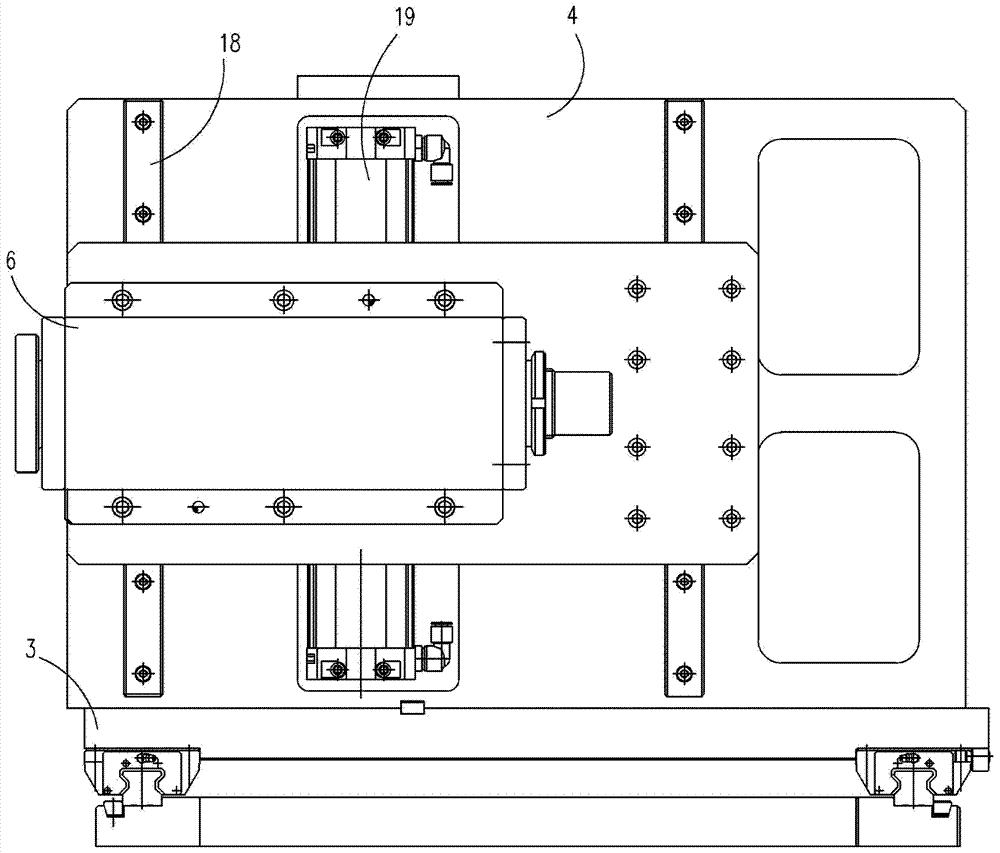

[0021] see figure 1 , figure 2 , the installation structure of the double-side support bearing seat in this embodiment is:

[0022] A pair of support plates are arranged vertically and parallelly on the bottom plate 3, and the pair of support plates are respectively the cylinder side support plate 4 and the screw side support plate 14; the bearing seat 6 is clamped between the pair of support plates to form an "H" shape Structure; on the inner side of the support plate, a longitudinal linear guide rail 18 is vertically arranged;

[0023] figure 1 As shown, the bearing seat 6 is an "H"-shaped bearing seat composed of a center seat and vertical plates on both sides, and the cylinder side bearing seat mounting plate 5 and the screw side bearing seat mounting plate 5 are fixedly installed on the outer sides of the vertical plates on both sides. Plate 15; the cylinder side bearing seat mounting plate 5 and the screw rod side bearing seat mounting plate 15 are slidingly supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com