Turbine wheel with untuned blades comprising a damping device

A technology for turbine impellers and blades, which is applied in the directions of blade support elements, safety devices, mechanical equipment, etc., can solve problems such as expensive dampers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

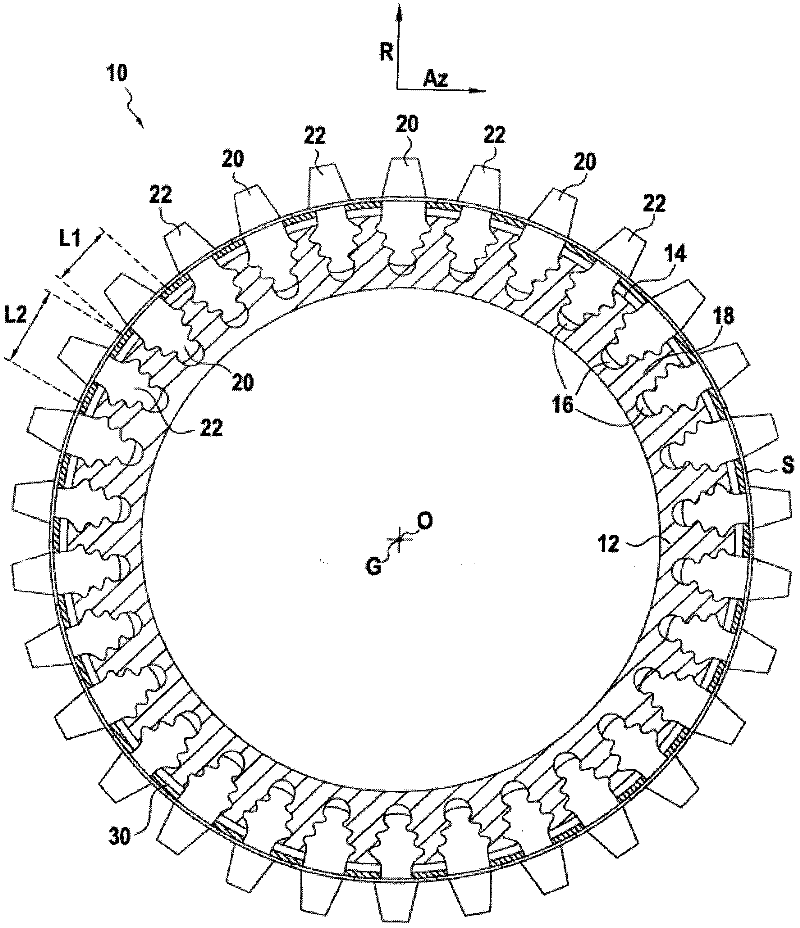

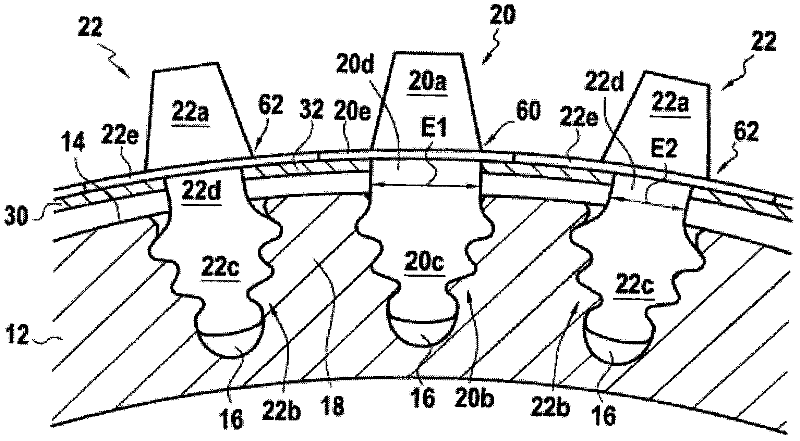

[0050] The embodiment of FIG. 1 represents a turbine wheel 10 as typically found in a turbomachine, such as a helicopter gas turbine 100 . Generally, a gas turbine, such as the gas turbine shown in FIG. 4 , includes a high pressure turbine 102 rotationally driven by a hot gas flow exiting a combustor 104 . High pressure turbine 102 drives rotation of compressor 106 to compress fresh air into gas turbine 100 and bring the fresh air into combustor 104 where it is mixed with fuel for combustion purposes.

[0051] The excess hot gas flow exiting the high pressure turbine 102 is used to drive the free turbine 108 in rotation. This turbine is specifically connected to the main rotor of the helicopter to drive it in rotation.

[0052] The inventive turbine wheel 10 can advantageously be applied in a high-pressure turbine 102 or indeed in a free turbine 108 .

[0053] Referring again to FIG. 1 , it can be seen that the turbine wheel 10 is comprised of a disk 12 having a center O and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com