Sectional type guaranteed cost shape control method for cold-rolled steel strips

A technology for shape control and cold-rolled strip, applied in the field of cold-rolled strip, can solve the problem of not reflecting the control idea and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

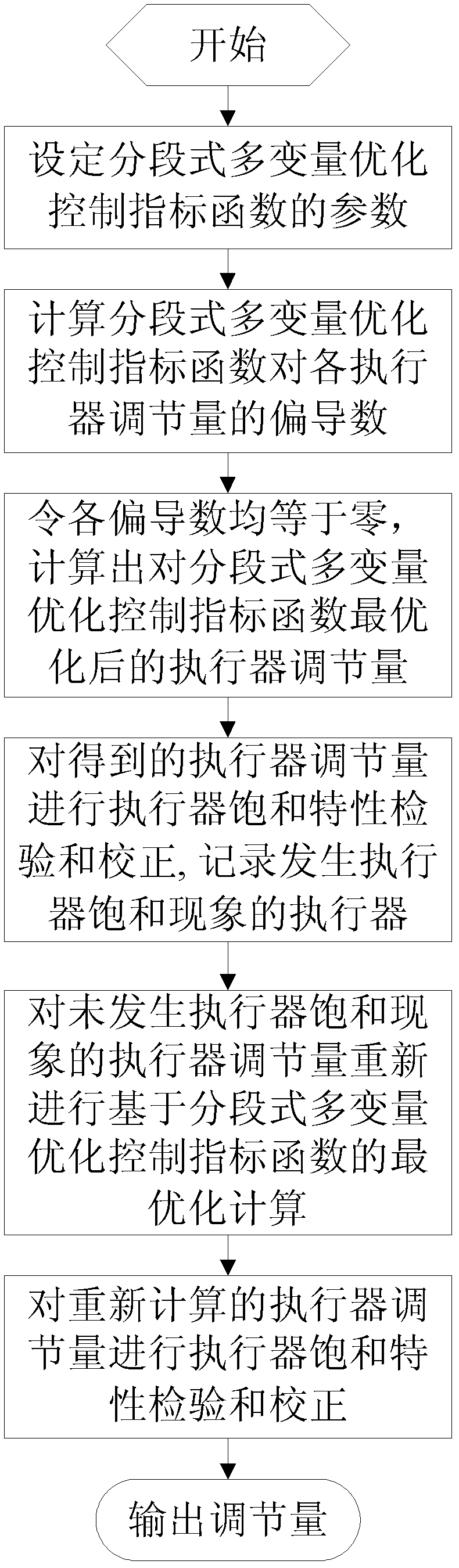

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

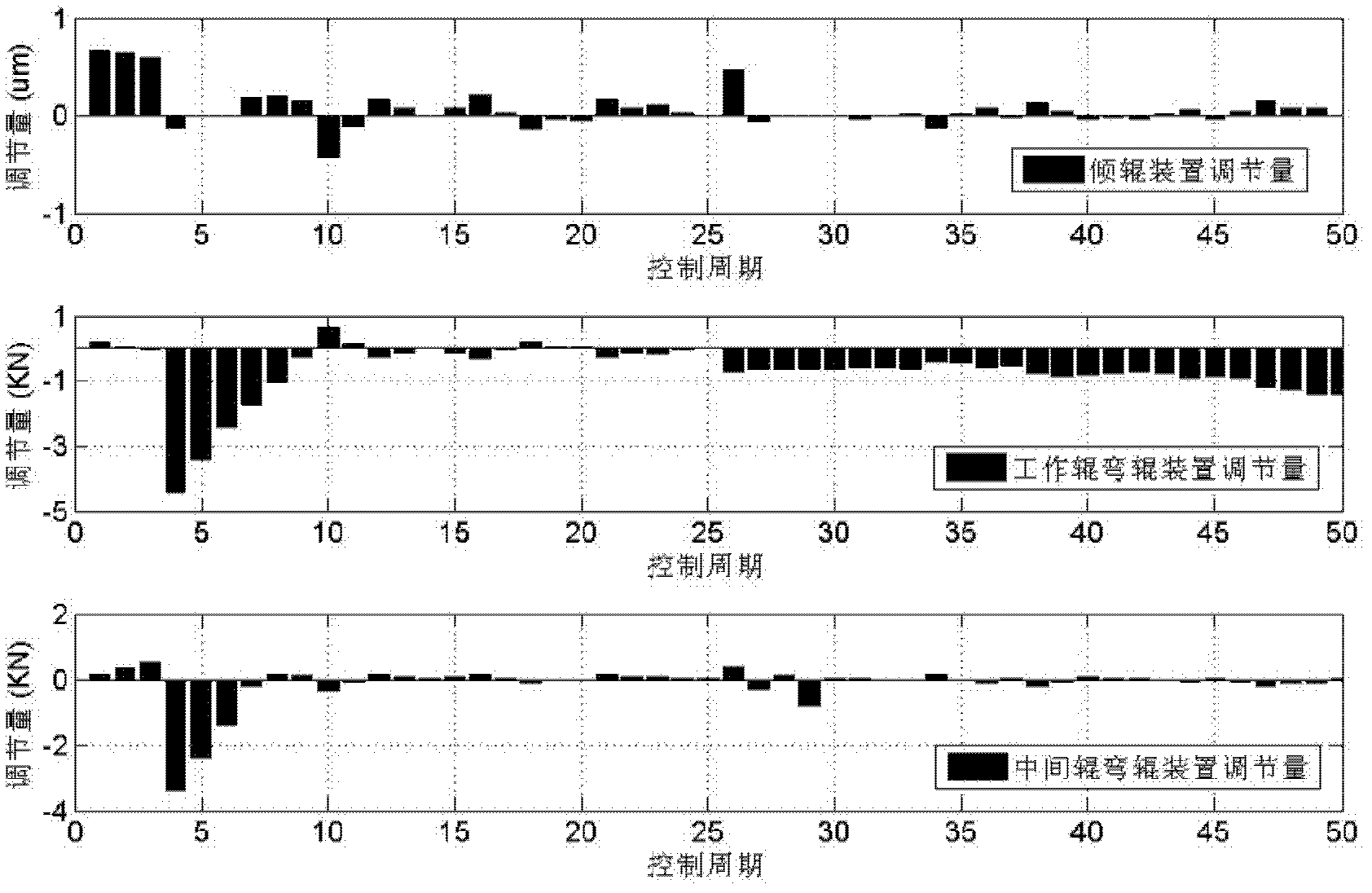

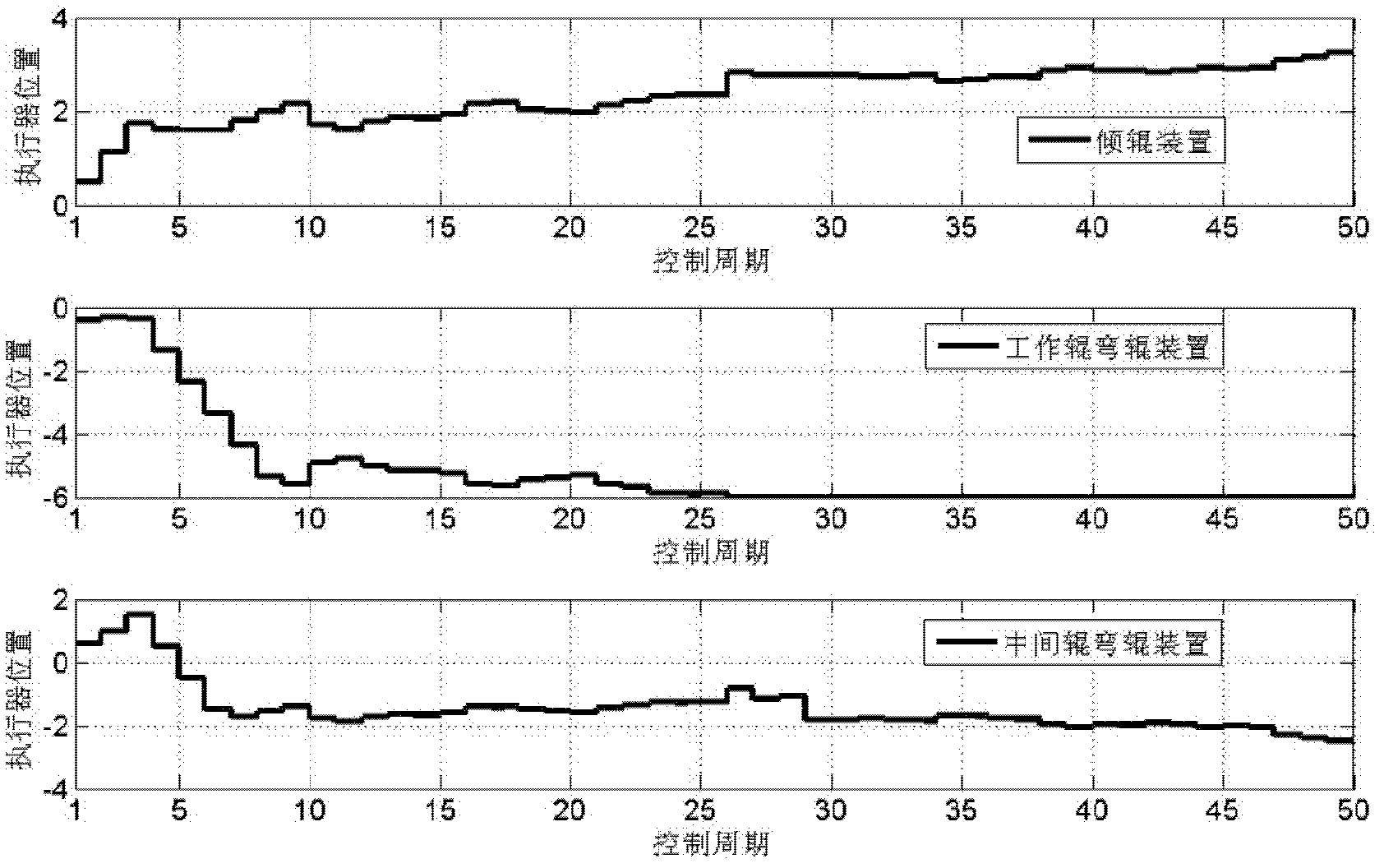

[0082]This embodiment discloses the design process of a segmented flat shape control method for a six-high cold rolling mill with horizontally movable work rolls in consideration of the saturation constraint characteristics of the actuator. Product specification (thickness×width): 0.35mm×1250mm, steel type: high-grade non-oriented HNGO, rolling speed: maximum 900m / min. At present, the shape control means of the six-high cold rolling mill in which the work rolls can move horizontally mainly include tilting rolls, positive and negative bending of the working rolls, positive and negative bending of the intermediate rolls, and roll shifting of the intermediate rolls. The shifting of the intermediate roll is preset according to the strip width. The adjustment principle is to align the edge of the intermediate roll bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com