Cutter moving device in gear cutting machine

A mobile device and processing machine technology, which is applied in the field of machinery, can solve problems such as manufacturing difficulties, poor mechanical stability, and insufficient rigidity, and achieve the effects of stable, safe and reliable work, improved processing accuracy, and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

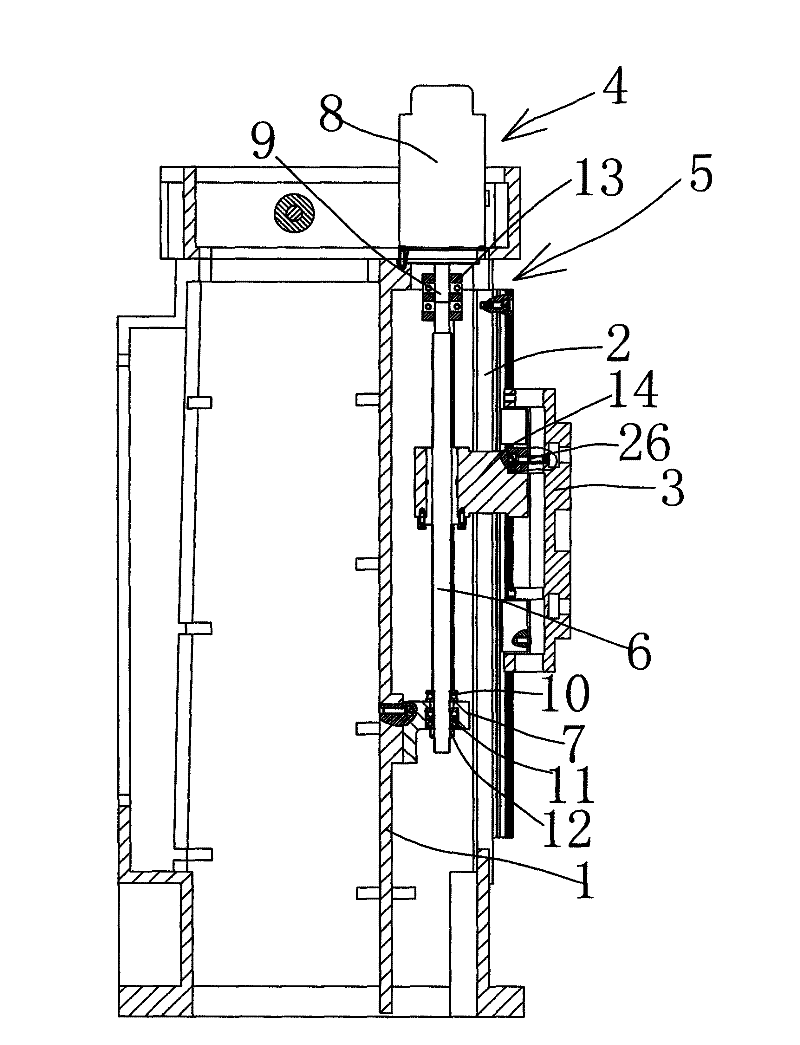

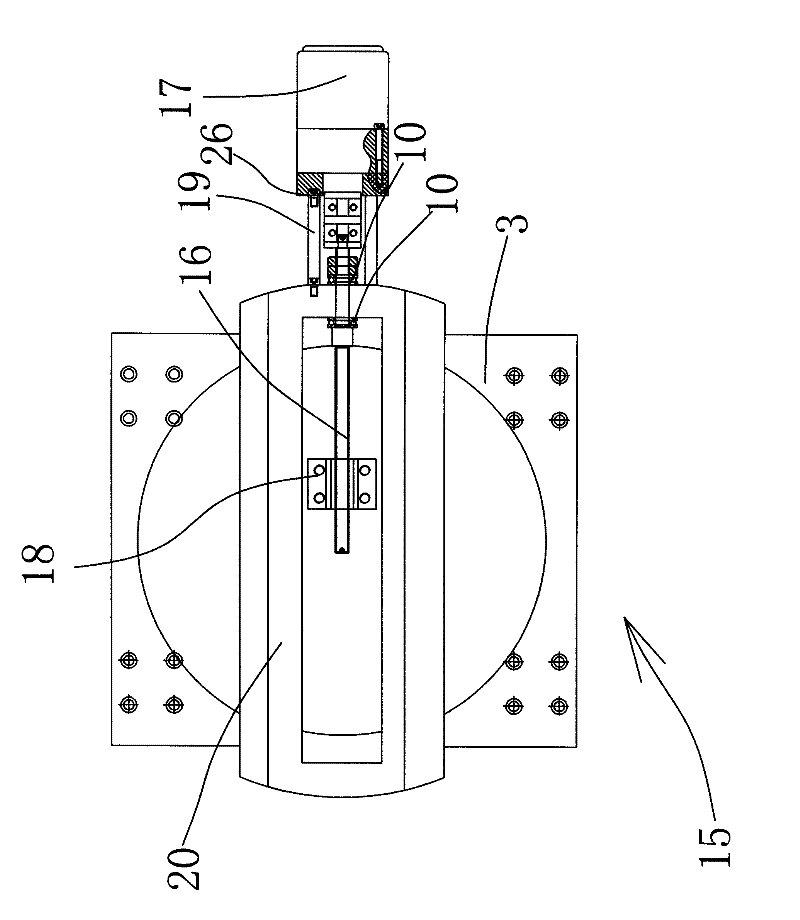

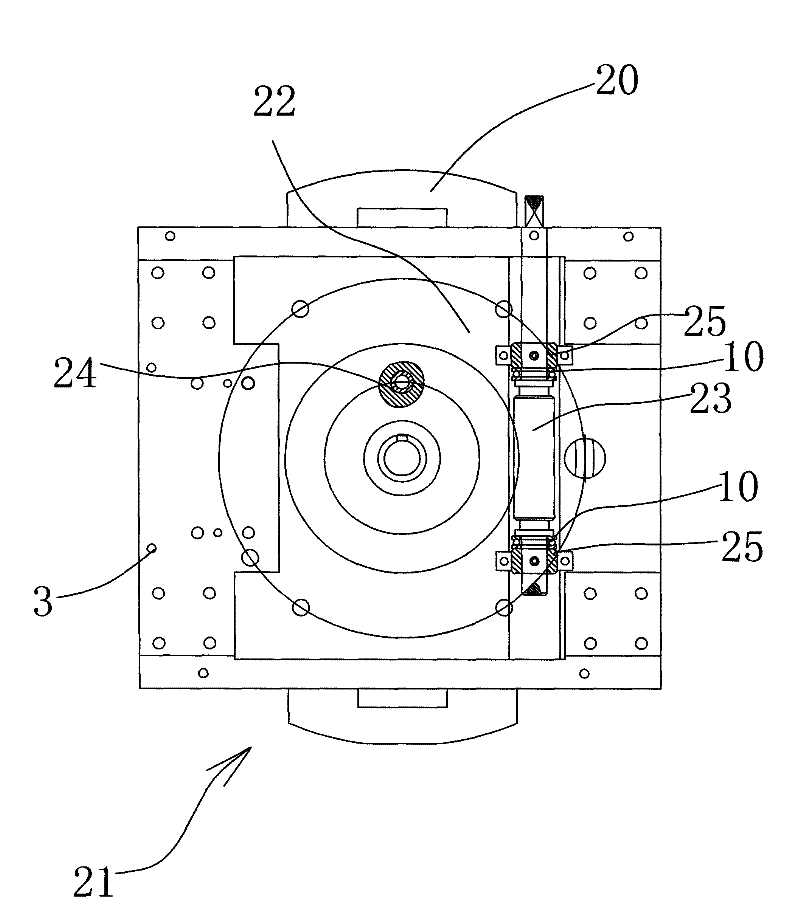

[0021] In the figure, column 1; guide rail 2; slide plate 3; drive mechanism 4; first push mechanism 5; first screw rod 6; fixed seat 7; first motor 8; output shaft 9; ; lock nut 12; connecting sleeve 13; first nut seat 14; second pushing mechanism 15; second screw mandrel 16; second motor 17; second nut seat 18; connecting plate 19; Worm wheel 22; Worm screw 23; Washer 24; Steel sleeve 25;

[0022] Such as figure 1 with Figure 4 As shown, the tool moving device in this gear processing machine is mainly used to drive the tool in the Z-axis, B-axis and rotational movement, including a column 1 and a driving mechanism 4, the column 1 is provided with a slide plate 3, and the tool fixing device is installed On skateboard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com