Hinged quick-opening machine head

A hinged, machine head technology, applied in the field of hinged quick-release heads, can solve the problems of increased workload, cumbersome process, affecting the service life of equipment, etc., and achieves the effect of convenient and quick use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

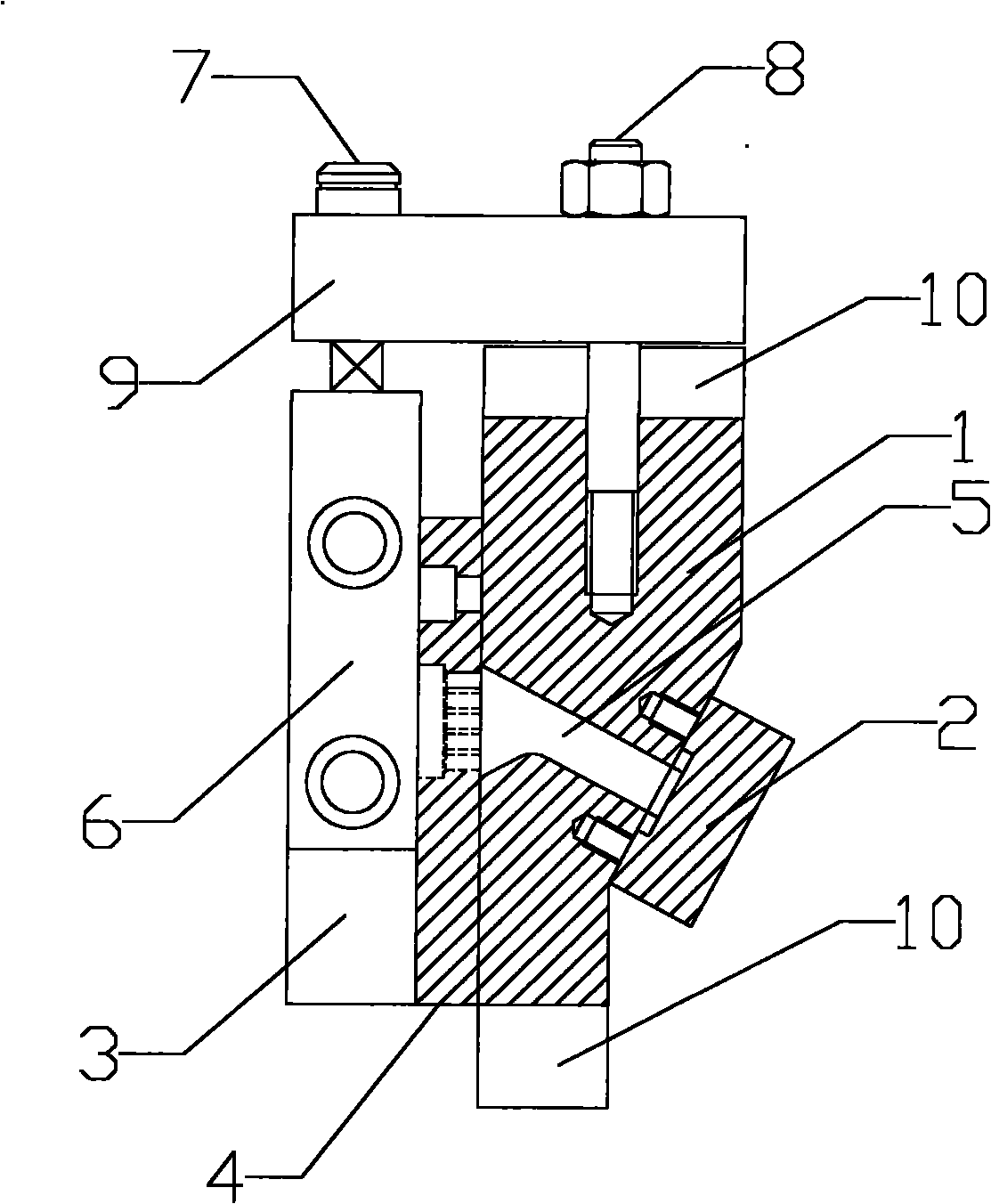

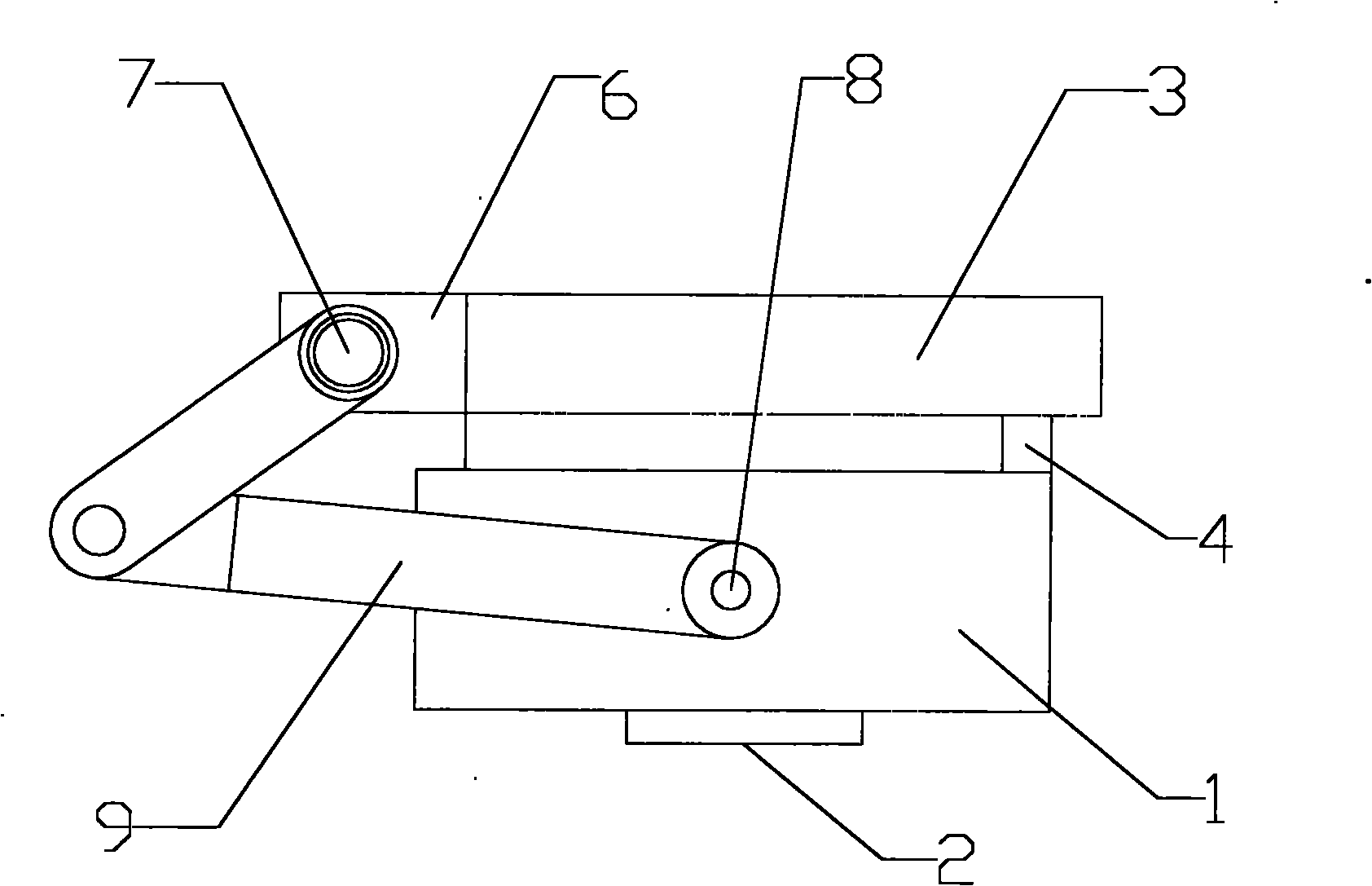

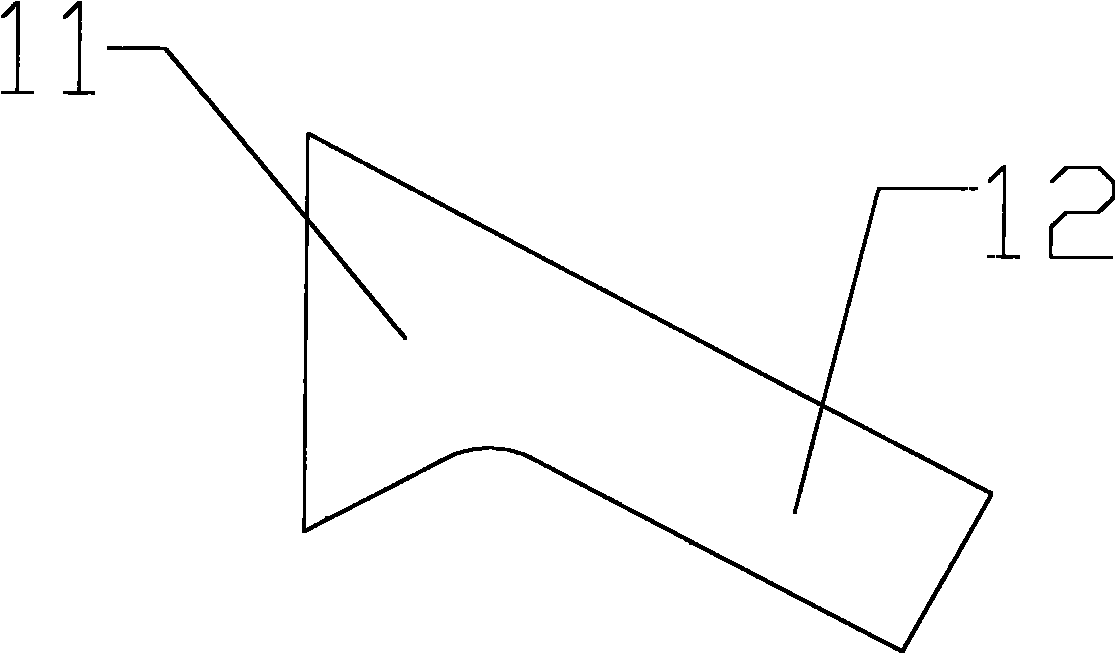

[0014] figure 1 It is a schematic diagram of the side view structure of the hinged quick-start head of the present invention; figure 2 It is a top view structure schematic diagram of the hinged quick-start head of the present invention, image 3 It is a schematic diagram of the extrusion channel of the hinged quick-start head of the present invention; Figure 4 It is a structural schematic diagram of the hinge connecting rod connection end of the hinged quick-start head of the present invention.

[0015] refer to figure 1 , The hinged quick-starting head of the present invention includes a cooling head 1 , a drawing die 2 , a transition body 3 and a perforated plate 4 . The transition body 3 is connected with the barrel of the extruder, and has a flow channel inside it, and the flow channel communicates with the inner cavity of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com