Generally spherical barium carbonate particles, and method for producing generally spherical barium carbonate particles

一种制造方法、碳酸钡的技术,应用在碳酸钡、碳酸钙/锶/钡、纤维状填料等方向,能够解决粉碎需要很长时间等问题,达到均匀性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

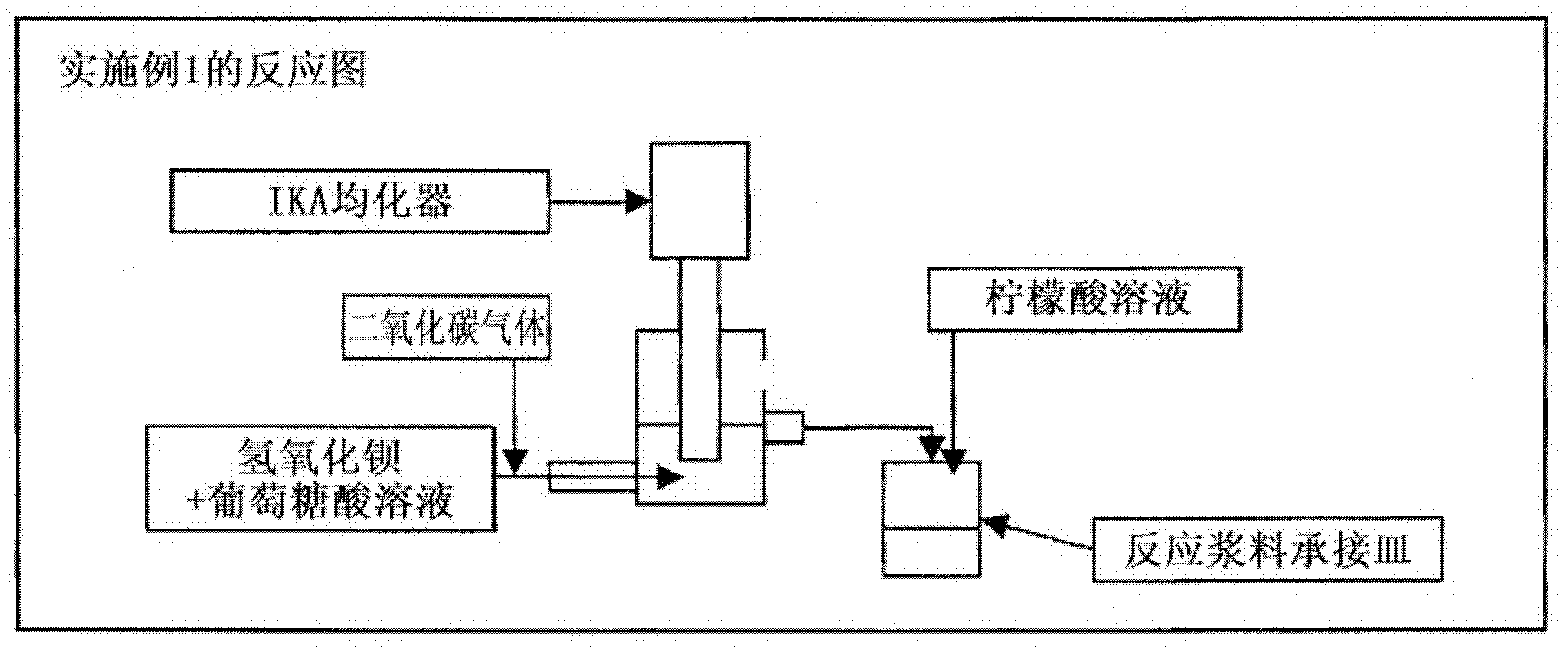

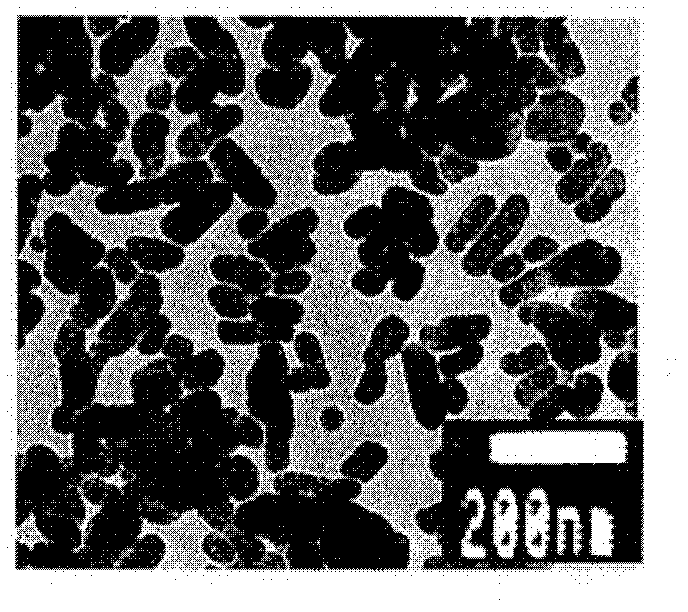

[0108] Barium hydroxide octahydrate was dissolved in pure water, and then 50% gluconic acid solution (manufactured by Fuso Chemical Industry Co., Ltd. ). Next, it was diluted with pure water so that the final concentration of barium hydroxide octahydrate was 120 g / L to prepare a barium hydroxide-gluconic acid aqueous solution (raw material A). The liquid temperature at this time was adjusted to 50°C. exist figure 1 In the shown reaction device, the raw material A is sent into the reaction vessel at a flow rate of 300ml / min. Simultaneously, carbon dioxide gas was also fed into the reaction container at 9 L / min, and the reaction was carried out by high-speed stirring using an IKA homogenizer (manufactured by IKA WORKS.INK, ULTRA-TURRAX T25 basic). At this time, the pH of the slurry at the outlet of the reaction vessel was 10-11. The reaction was carried out for 1 minute, and an aqueous solution of citric acid monohydrate having a concentration of 15 g / L was added to the resu...

Embodiment 2

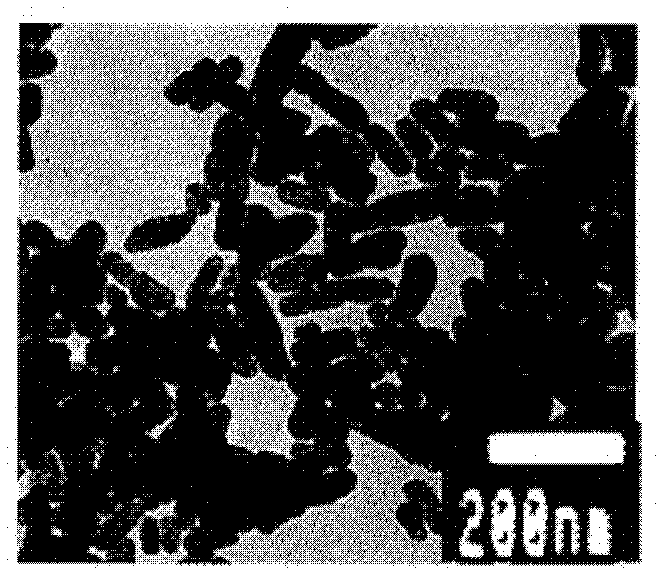

[0119] Scale-up based on the results of Example 1. Such as Figure 15 As shown, the reaction device uses a device in which pumps P1, P2 and P3 are connected in three stages. The details of each pump are as follows. In addition, 1 inch = about 2.54 cm.

[0120] (a) Pump P1 of the first stage: Centrifugal pump (manufactured by RASA Shoji Co., Ltd.), suction port diameter 1.5 inches, discharge port diameter 1 inch, discharge volume 170 L / min, impeller rotation speed 2080 rpm

[0121] (b) Pump P2 of the second stage: Centrifugal pump (manufactured by RASA Shoji Co., Ltd.), suction port diameter 1 inch, discharge port diameter 3 / 4 inch, discharge volume 30 L / min, impeller rotation speed 1420 rpm

[0122] (c) Pump P3 of the third stage: Centrifugal pump (manufactured by Pacific Metal Co., Ltd.), suction port diameter 1 inch, discharge port diameter 3 / 4 inch, 30 L / min, impeller rotation speed 1420 rpm

[0123] 48 kg of barium hydroxide octahydrate was dissolved in pure water, 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com