Double-disc refining pulverizer

A pulverizer and double-disc mill technology, which is applied in cocoa, grain processing, food science, etc., can solve the problems of high energy consumption, difficulty in obtaining ultra-fine powder, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

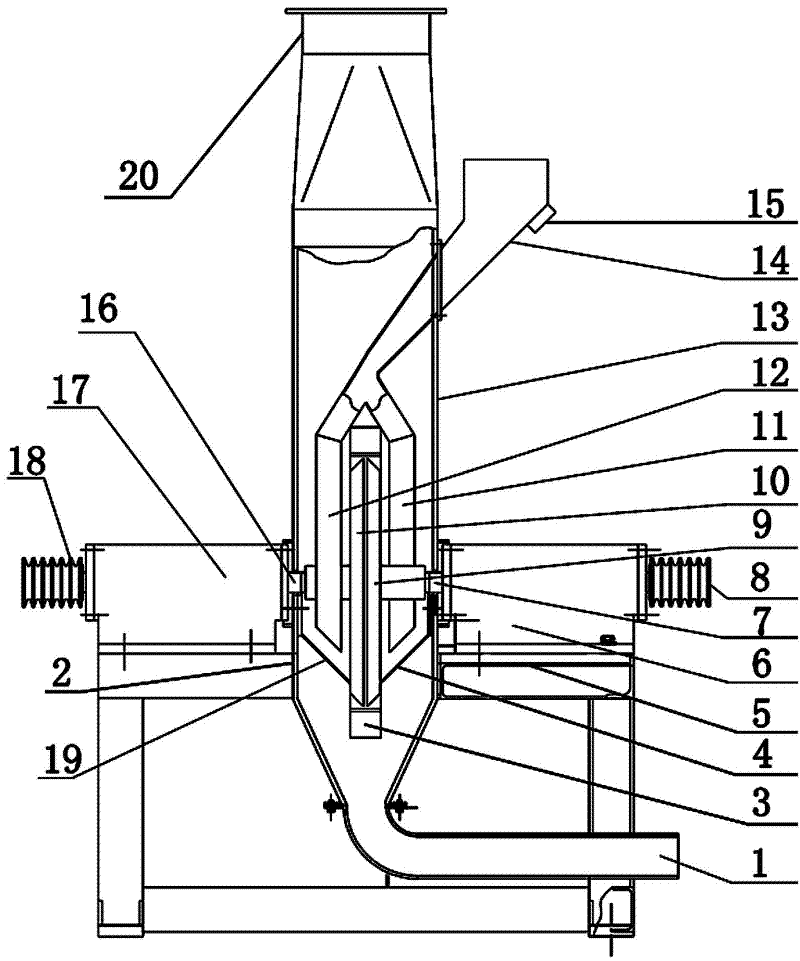

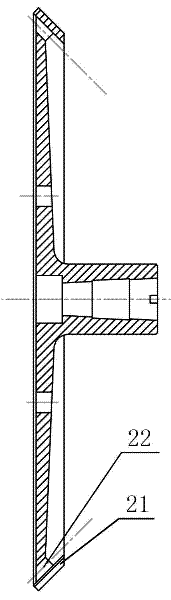

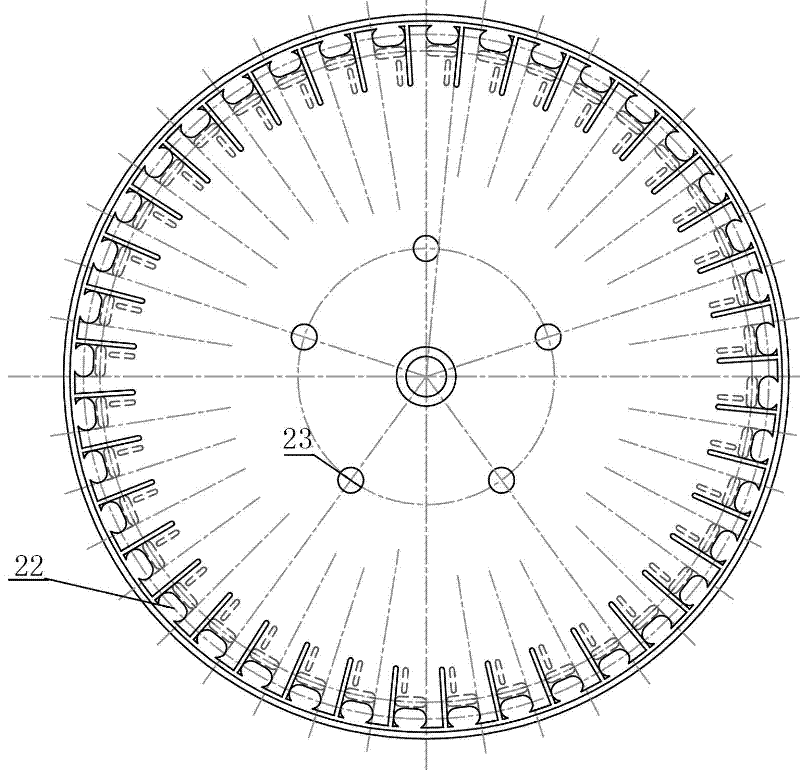

[0014] The structure of the present invention is as figure 1 As shown in -3, a double-disk mill pulverizer includes a base 5, and the cabinet consisting of an upper box 13 and a lower box 2 is installed on the base 5, and the upper part of the upper box 13 is provided with a discharge port 20, The lower part of the lower box body 2 is provided with an air outlet 1, and one side of the upper cabinet 13 is provided with a feed hopper 14, which communicates with the first distribution pipe 11 and the second distribution pipe 12, and the lower part of the first distribution pipe 11 The first diversion groove 4 is installed, the second distribution pipe 12 bottom is equipped with a second diversion groove 19, the first parabolic disk 9 is connected with the first main shaft 7 installed on the first bearing seat 6, the second parabolic disk 10 Be connected with the second main shaft 16 that is installed on the second bearing seat 6, first parabolic dish 9 and second parabolic dish 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com