Reheating crack sensitivity test method for dissimilar steels

A technology of reheat crack and test method, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of no dissimilar steel, etc., and achieve the effect of reliable test and evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

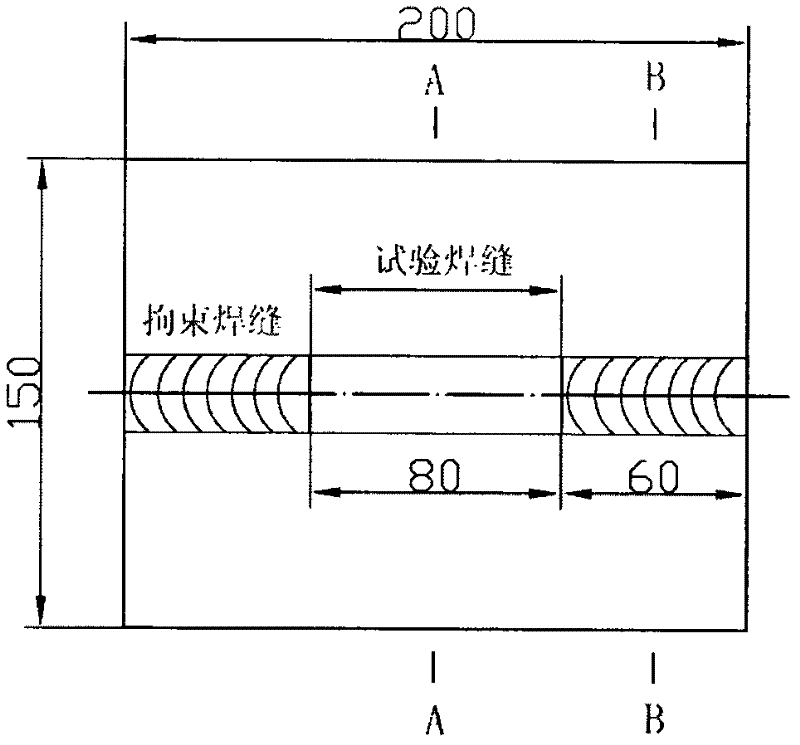

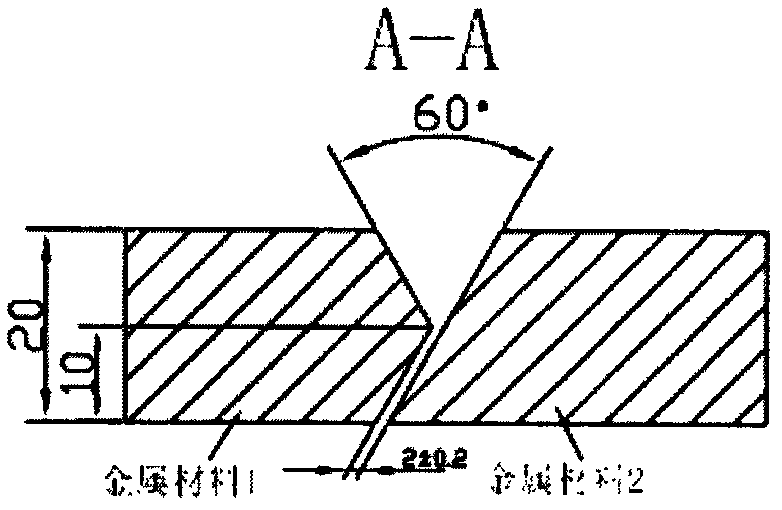

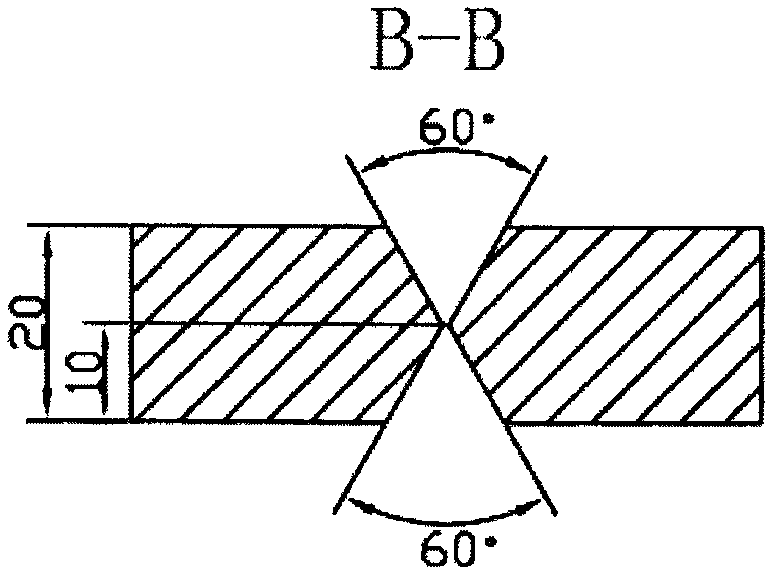

[0028] 1. Prepare the test piece. According to GB 4675.1-84 weldability test oblique Y-groove welding crack test method to prepare the test piece, the form and size of the test piece according to figure 1 As shown, the electrodes used in the test can be selected to match the metal material 1 or the metal material 2 (high matching electrode, low matching electrode), or the electrodes whose grade is between the metal material 1 and the metal material 2 (middle matching electrode ).

[0029] 2. Conduct experiments

[0030] ① press figure 1 Assemble the test piece, that is, assemble the test piece according to the assembly drawing shown in GB 4675.1-84 Weldability Test Oblique Y-shaped Groove Welding Crack Test Method;

[0031] ② Welding restraint welds;

[0032] ③ Preheating before welding according to the preheating temperature + 50°C determined by the cold crack sensitivity test method of dissimilar steels; (this method will be introduced below)

[0033] ④Weld test welds w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com