Line head wiping method

An inkjet head and line type technology, applied in printing and other directions, can solve the problems of not being able to wipe the line type inkjet head cleanly and ink residue, etc., and achieve the effects of prolonging life, preventing premature wear, and preventing the surrounding area from being stained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

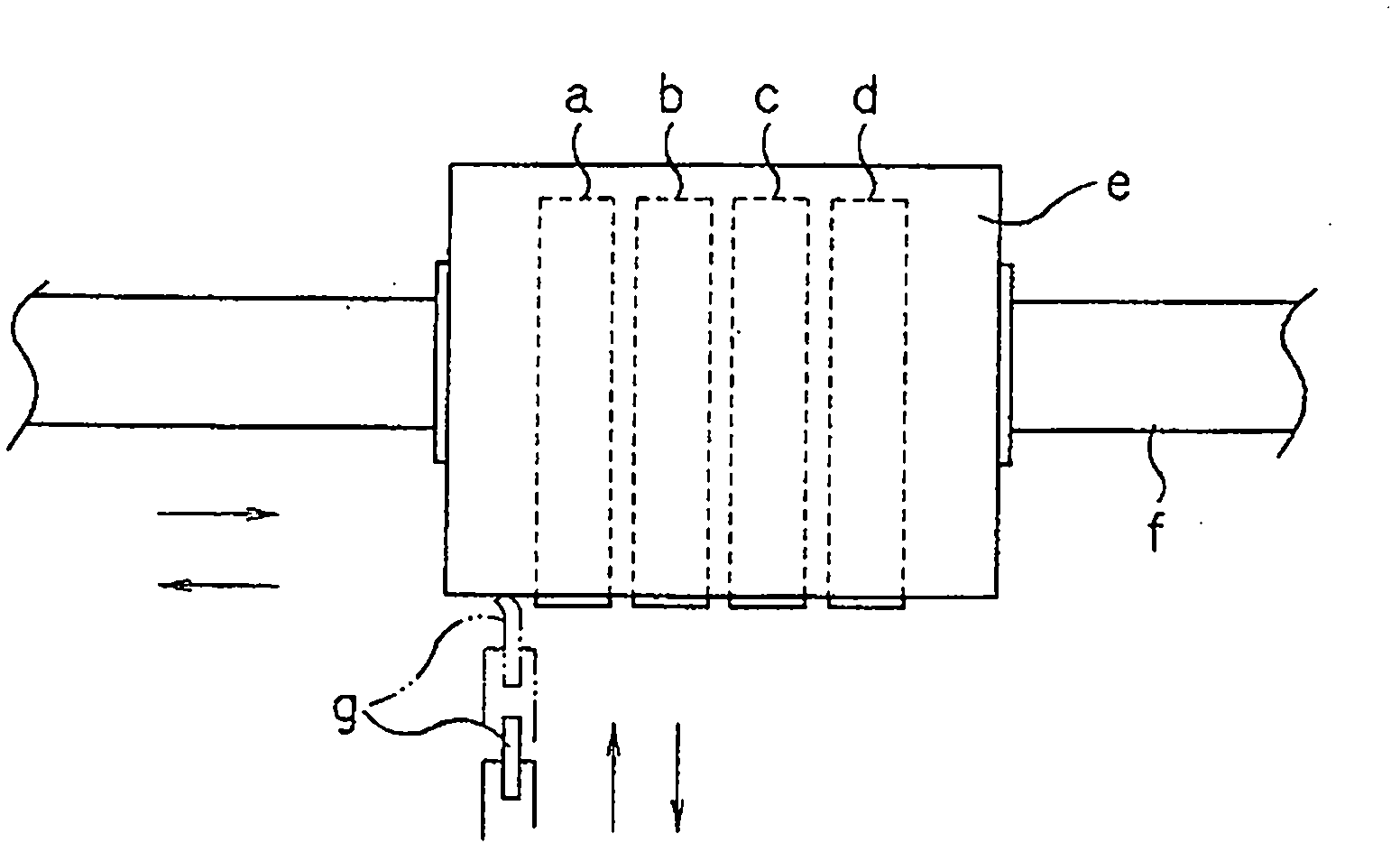

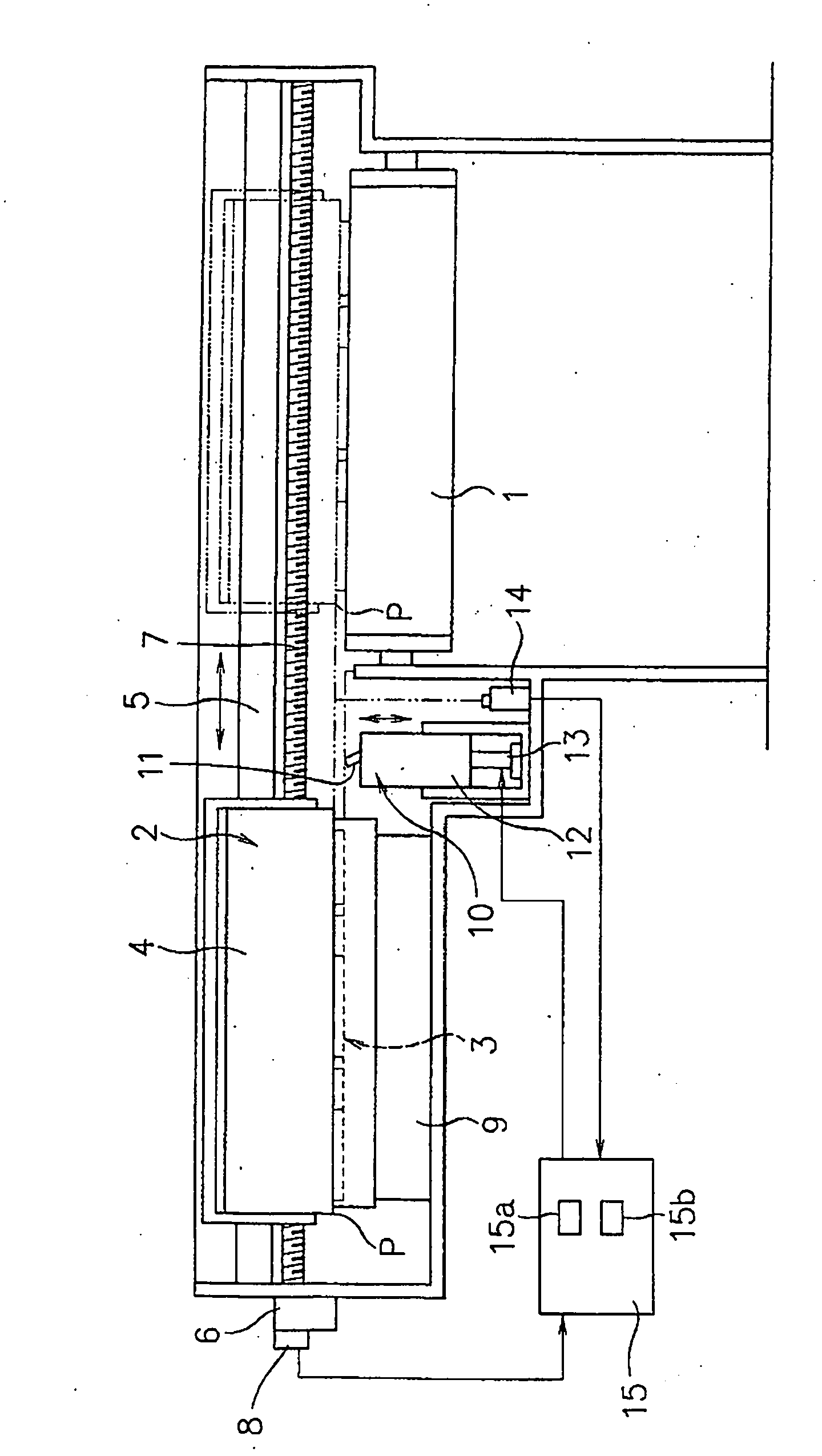

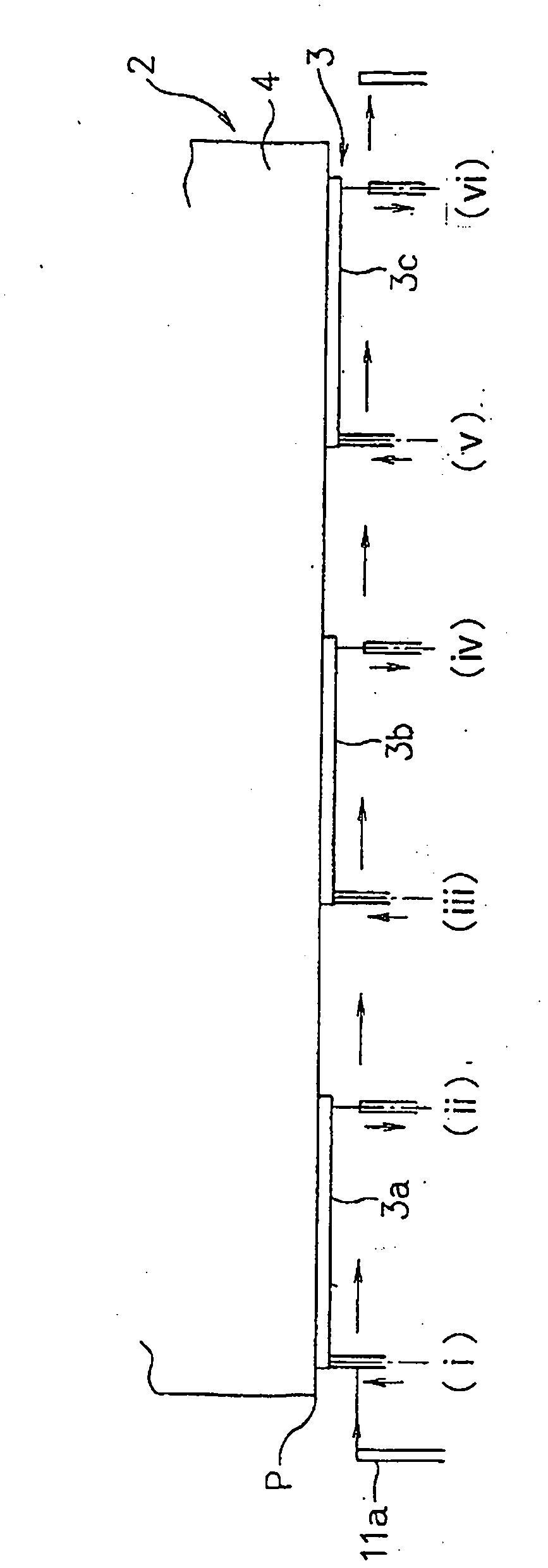

[0024] figure 2 It is an explanatory diagram schematically showing an inkjet recording apparatus for carrying out the method of the present invention. Reference numeral 1 in the figure is a conveying device (platen) for conveying a recording medium (recording paper) in a direction at right angles to the figure, and reference numeral 2 is located on the upper side of the conveying device 1 and spreads over the conveying device. 1 print head that prints across the entire width of the conveyed recording medium. A line inkjet head 3 facing across the entire width of the continuous paper is provided on the lower surface of the print head 2 via a carriage 4 supported by the print head 2 .

[0025] The print head 2 is guided by the guide rail 5 between the printing area and the maintenance area, and moves under the action of the feed screw 7 driven and rotated by the motor 6. An area where the head 3 prints with a predetermined printing width on the recording medium, and the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com