Sliding rail assembly with fast mounting structure

A technology of slide rail assembly and structure, applied in the direction of rack/frame structure, etc., to achieve the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

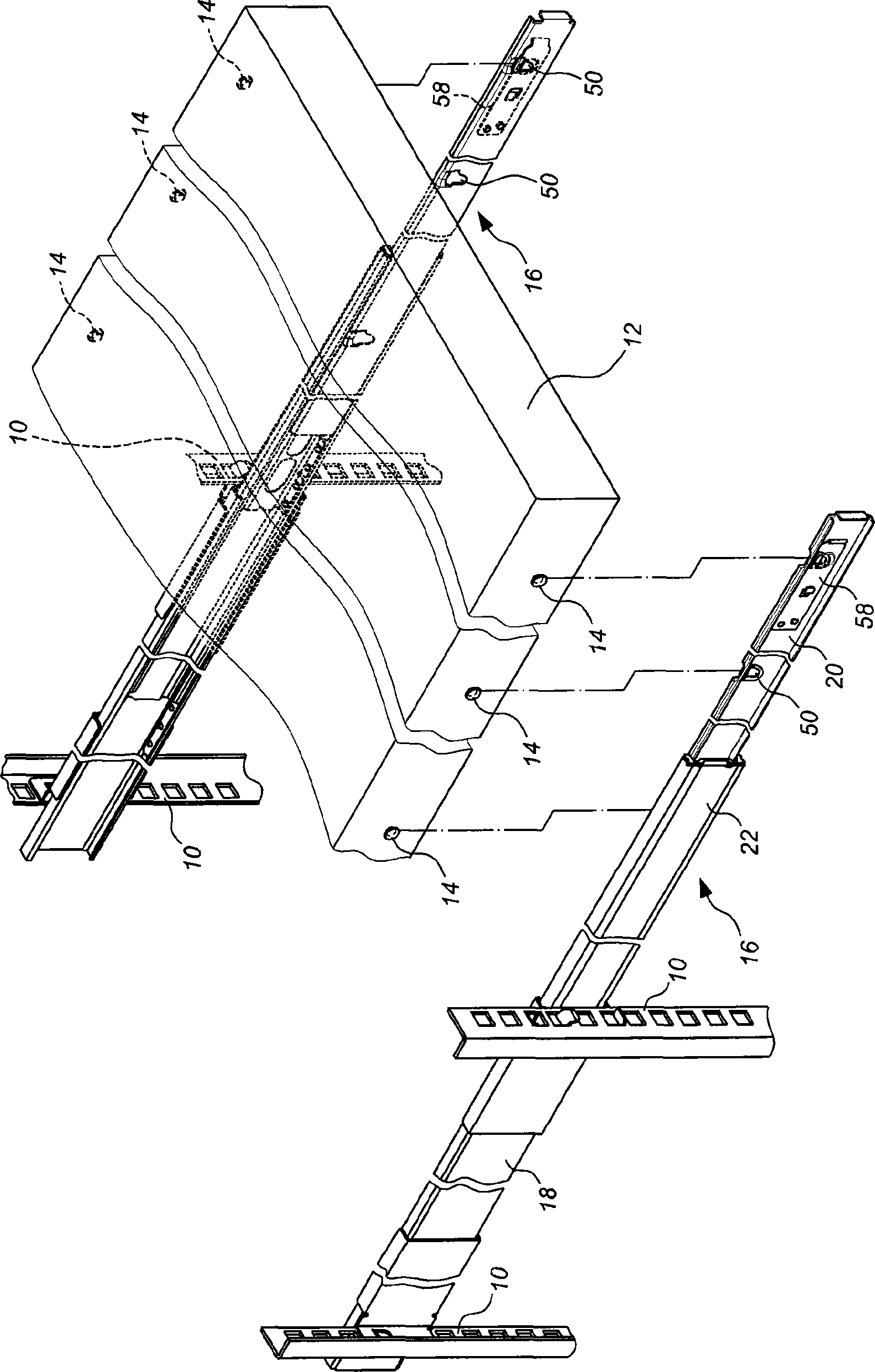

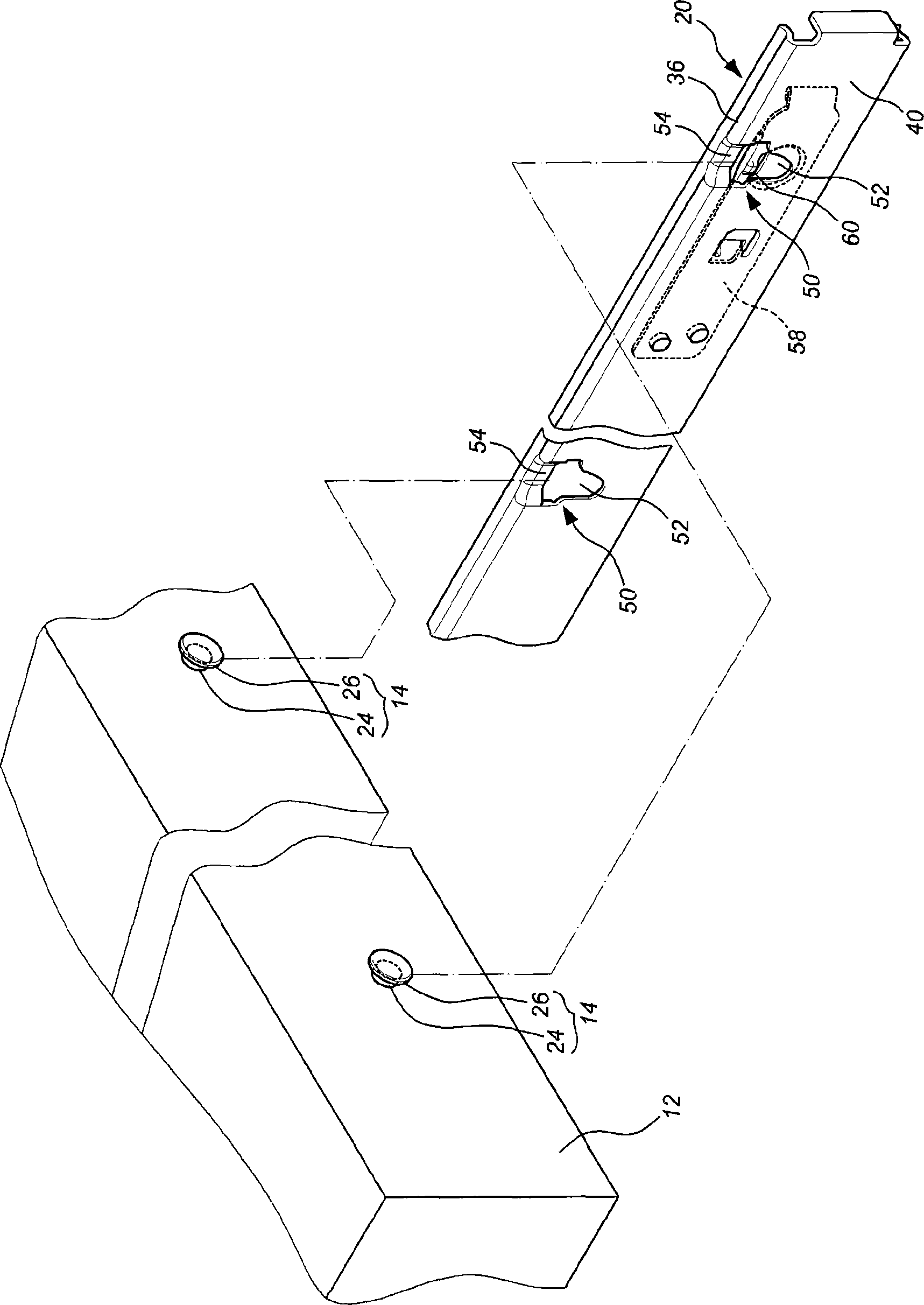

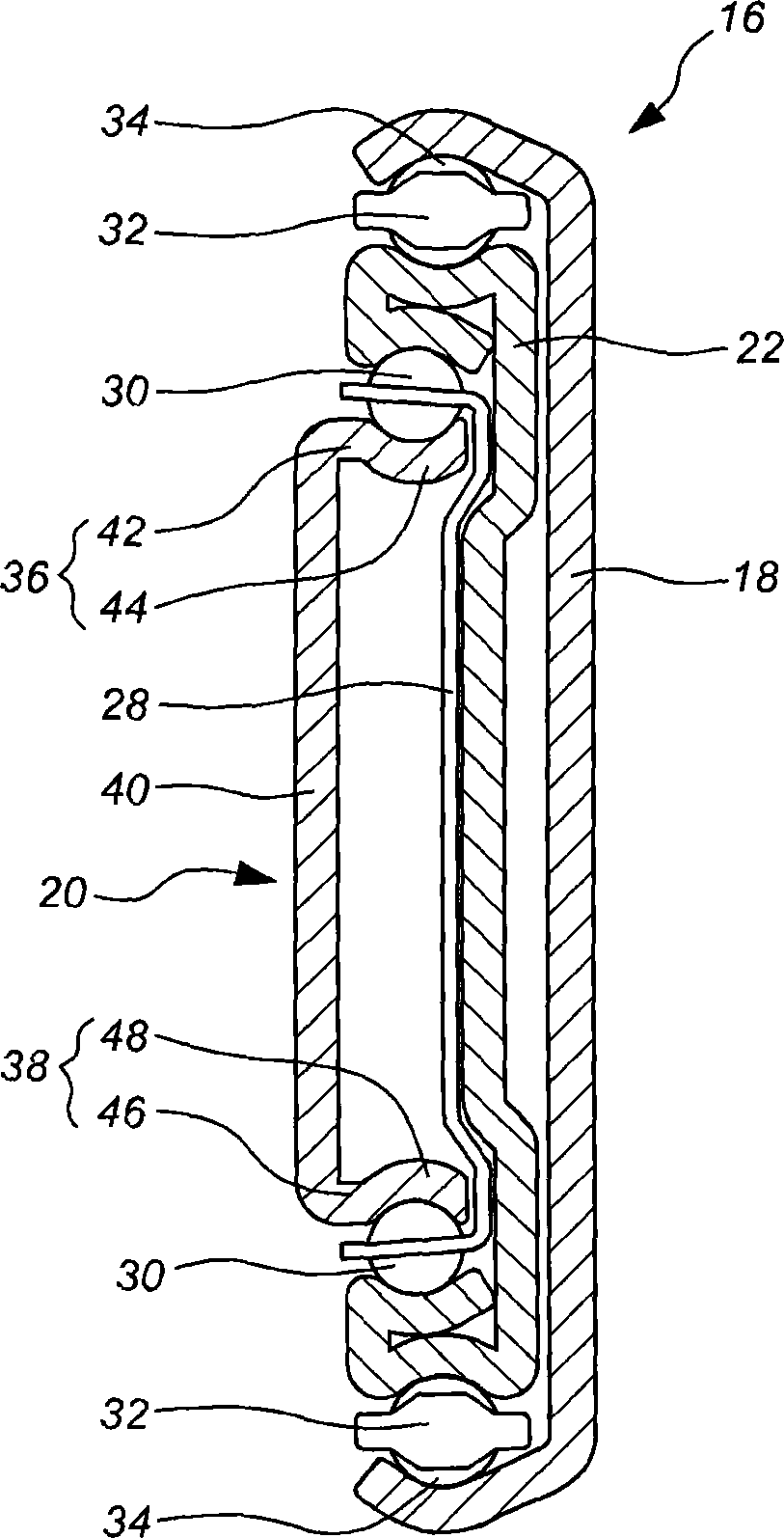

[0035] Such as figure 1 As shown, four pillars 10, a cabinet 12, a plurality of mounting parts 14 of a cabinet (not shown in the figure) are shown, and a plurality of mounting parts 14 are fixed on both sides of the cabinet 12, and at least one pair of slide rail assemblies 16 are respectively installed on For the front and rear pillars 10 on both sides, each sliding rail assembly 16 at least includes an outer rail 18 and an inner rail 20 that can slide longitudinally relative to the outer rail 18 . Preferably, a middle rail 22 is movably connected between the inner rail 20 and the outer rail 18 , so that the inner rail 20 can be pulled out to a longer distance relative to the outer rail 18 .

[0036] In this embodiment, the mounting parts 14 on both sides of the chassis 12 can be installed on the inner rails 20 of the slide rail assembly 16 on both sides of the pillar 10, so that the chassis 12 can be pulled out through the pair of slide rail assemblies 16 or push to collaps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com