Lower roll driving mechanism of down-adjusting plate bending machine

A driving mechanism and roller-driven technology, applied in the field of forging machinery, can solve the problems such as the inability to offset the staggered force of the steel plate, the complex structure of the lower roller transmission mechanism, and the easy slippage of the rolled small tube sheet, so as to achieve a small footprint and avoid installation. And the effect of adjusting and preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

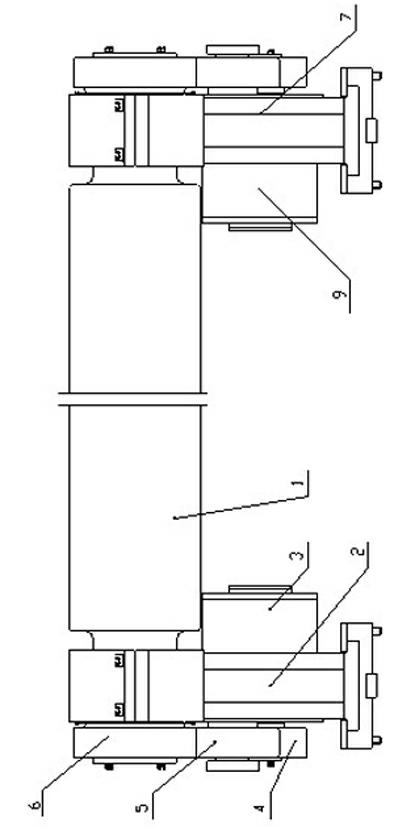

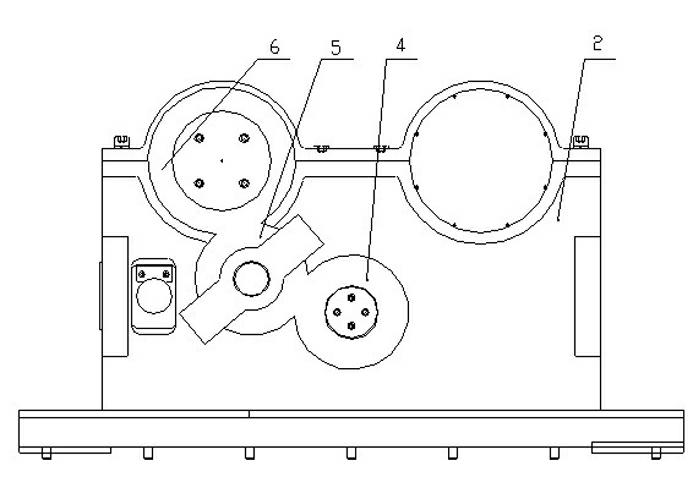

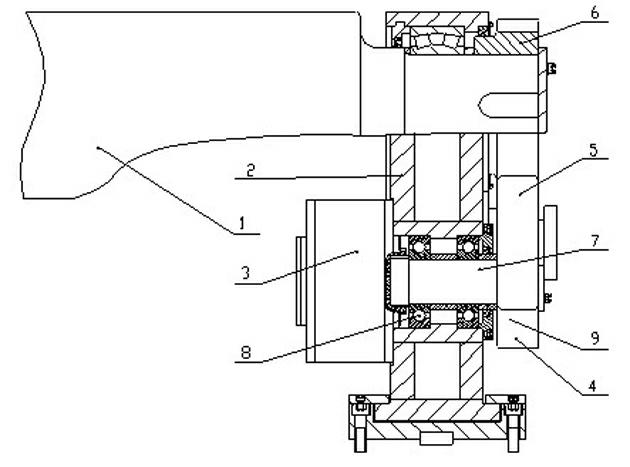

[0011] Such as figure 1 , 2 , 3, the drive mechanism for the lower roll of the down-adjustable plate rolling machine includes a lower roll 1 and two brackets 2, and the two brackets 2 are respectively supported under the left and right ends of the lower roll 1, and the drive mechanism is set on the left and right brackets 2 respectively. Mechanism 9, the driving mechanism 9 includes hydraulic motor 3, motor gear 4, intermediate transmission gear 5, lower roller gear 6, lower roller gear 6 is fixedly connected to the top of lower roller 1, hydraulic motor 3 is fixed on bracket 2, hydraulic motor 3 The output end of the transmission shaft 7 is connected to the transmission shaft 7, and the output end of the transmission shaft 7 is fixedly connected to the motor gear 4. The intermediate transmission gear 5 is arranged between the motor gear 4 and the lower roller gear 6, and the intermediate transmission gear 5 is rotatably fixed on the bracket through the wheel shaft. 2, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com