Sliding positioning mechanism

一种定位机构、滑动件的技术,应用在支承机器、机械设备、机台/支架等方向,能够解决系统构造复杂、成本高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The sliding positioning mechanism of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

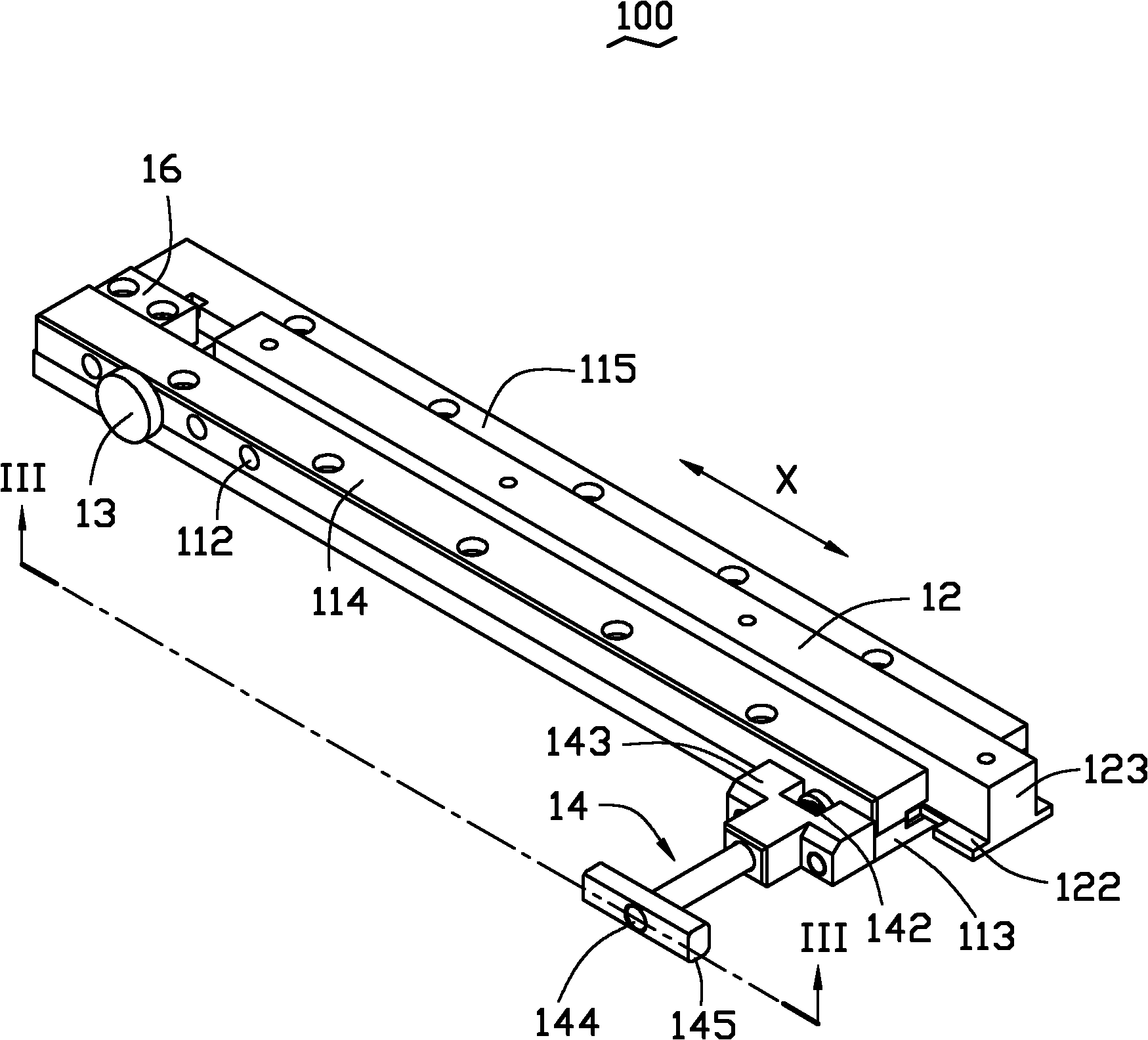

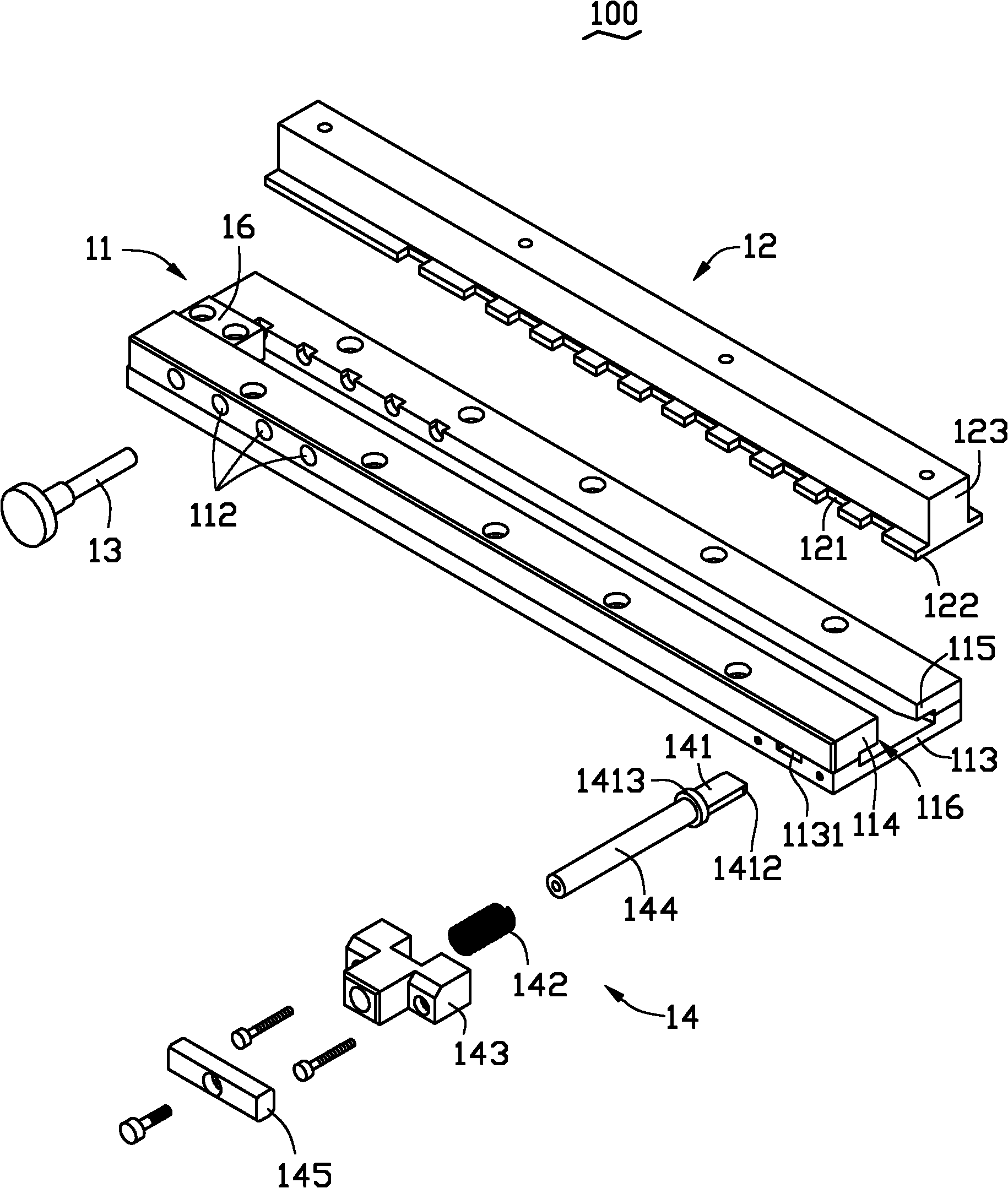

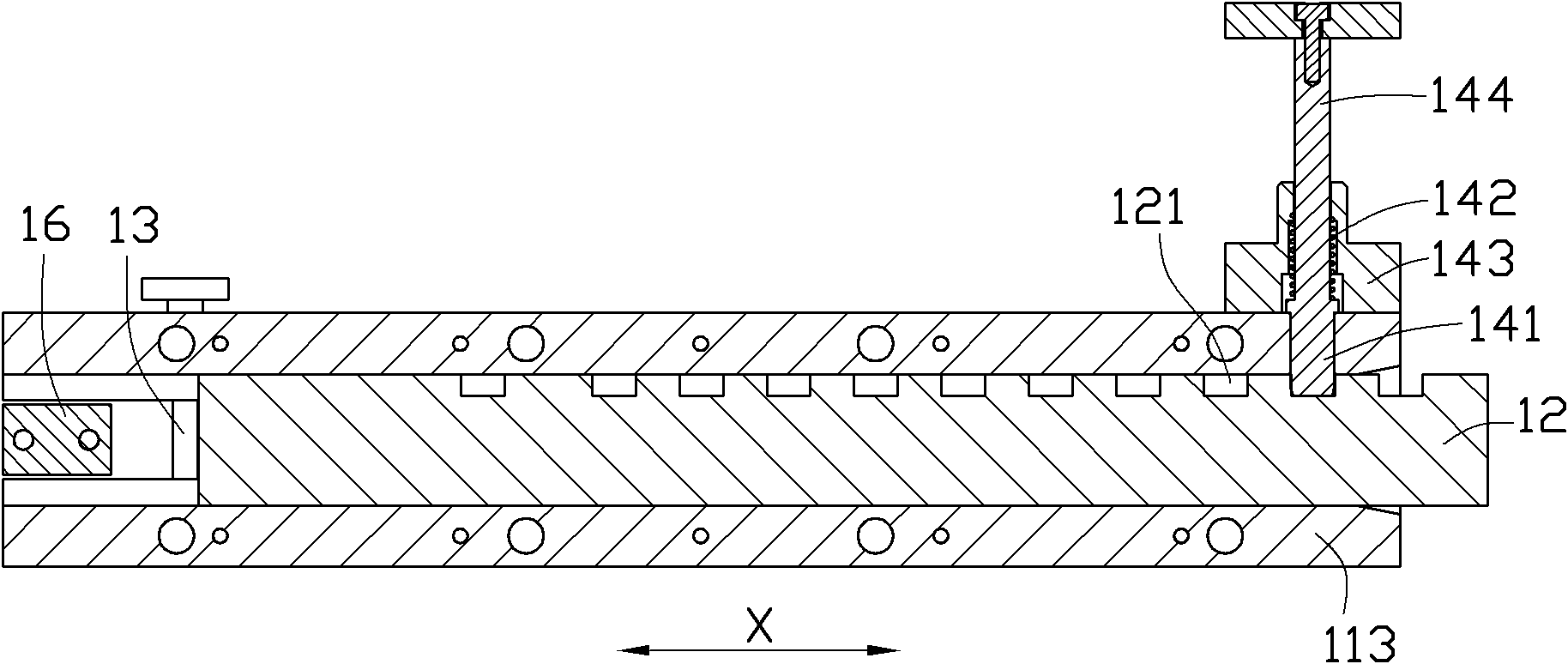

[0012] See Figure 1 to Figure 3 , the sliding positioning mechanism 100 according to the embodiment of the present invention includes a main body 11 , a sliding part 12 slidably fitted with the main body, a coarse positioning part 13 and a precise positioning component 14 . The sliding member 12 can slide along the sliding direction X relative to the body 11 . The coarse positioning member 13 and the precise positioning component 14 respectively roughly and precisely position the sliding member 12 relative to the main body 11 , so as to jointly position the sliding member 12 .

[0013] The main body 11 defines a plurality of positioning holes 112 arranged along the sliding direction X. As shown in FIG. The coarse positioning member 13 passes through one of the positioning holes 112 and cooperates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com