Blow mold

A technology of blow mold and bottom mold, which is applied in the field of blow mold, which can solve the problems of large installation space and achieve the effect of shortening the cycle time, saving the time of locking the bottom mold, and spending less time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

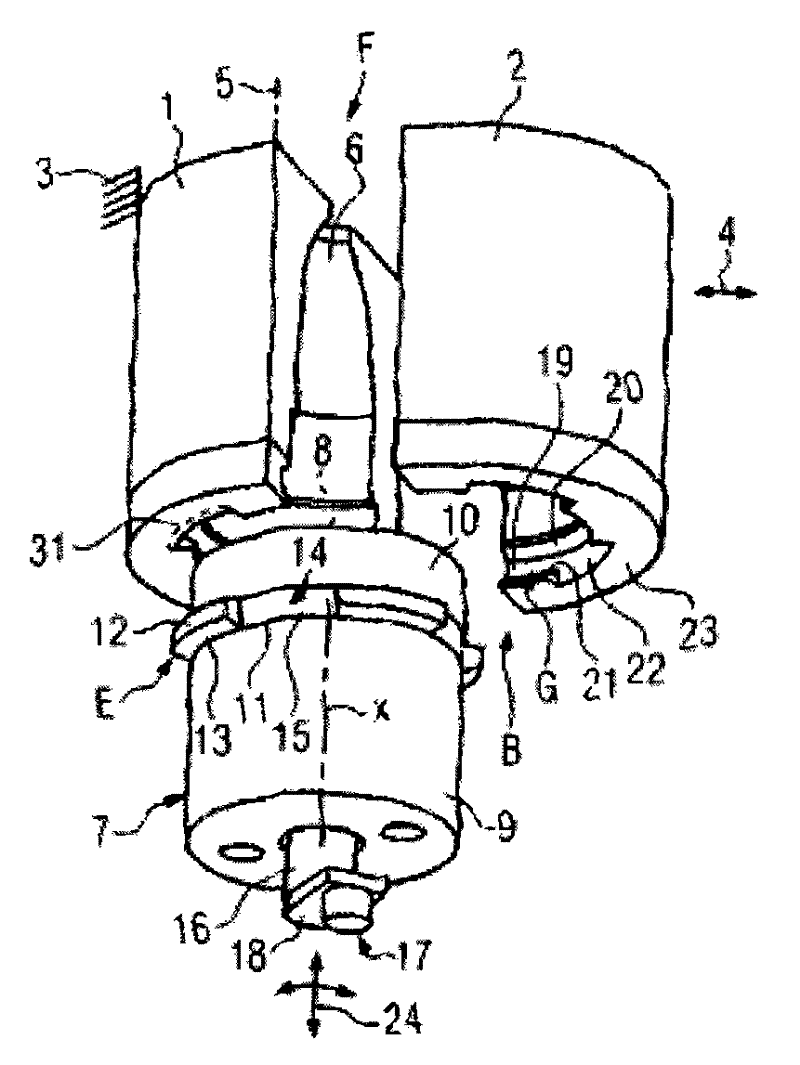

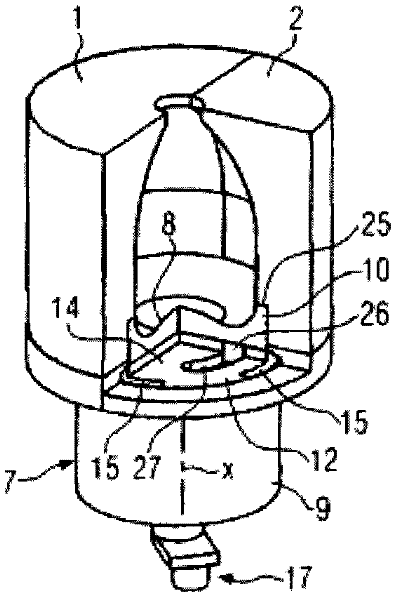

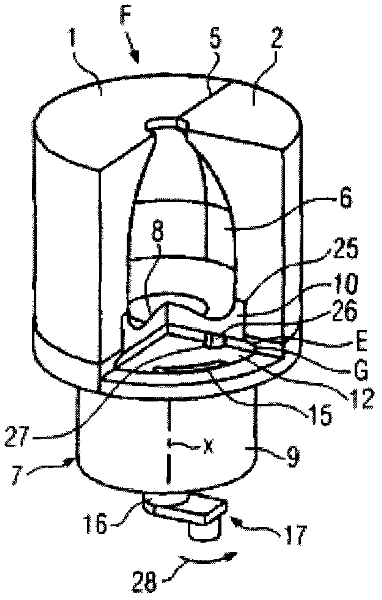

[0023] figure 1 The blow mold F in is used, for example in a blow molding operation or a stretch blow molding operation, to manufacture containers from preforms, which blow mold F is mounted in a blow molding station not shown of the blow molding machine. Here, the blow mold F is shown in the state without the normally provided mold support device and includes a fixed mold half 1 (also called a shell mold) as a main part and can be positioned relative to the fixed Mold half 1 moves the other mold half 2. The movable mold half 2 can be folded open about a not shown axis or moved linearly (as shown) by means of a kinematic drive 4 not shown in more detail. The mold halves 1 , 2 can be closed in a closed position with the other mold half 2 in the mold parting plane 5 and can be locked to each other under the action of locking pressure, for example by means of not shown mold support means. The stent half 1 is fixed to a support 3, for example.

[0024] The bottom mold 7 is anot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com