Electric vehicle pantograph

A technology for electric vehicles and pantographs, applied to electric vehicles, vehicle parts, collectors, etc., can solve the problems of unbalanced load, no protection, normal lifting and other problems, and achieve the effect of prolonging the service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

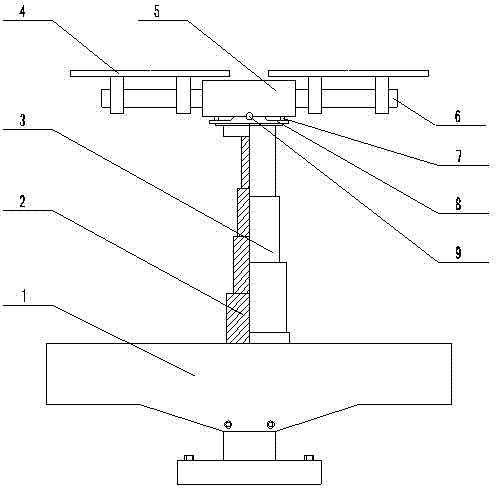

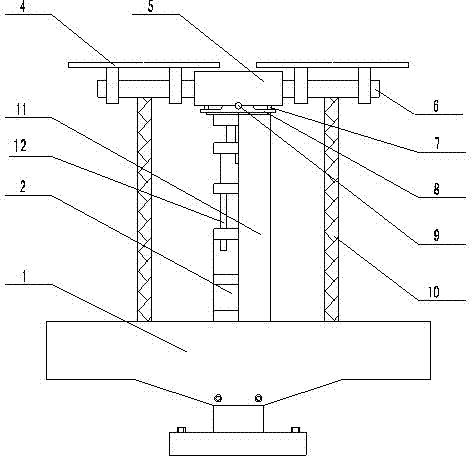

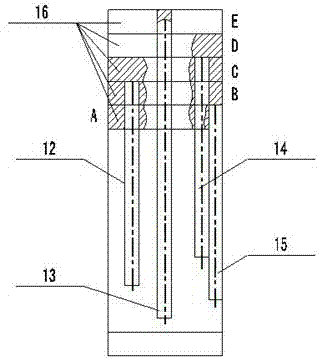

[0017] Such as figure 2 As shown, an electric vehicle pantograph of the present invention includes a shield 1 , a transmission device fixed on a base, a receiving plate 4 , and a beam frame composed of a beam 5 , a pin shaft 9 , and a support seat 8 . The transmission device is a multi-stage air (or hydraulic) cylinder 2, and there are multiple guide rods 12 on the multi-stage air (or hydraulic) cylinder 2. Such as image 3 Shown, off-center guide rod 12,13,14,15 is fixed on the flange 16 (comprising A, B, C, D, E five stages) of multistage gas (or hydraulic pressure) cylinder, and multistage gas ( (or hydraulic) cylinder structure integration, instead of the original multi-stage gas (or hydraulic) cylinder of the original pantograph linkage multi-stage telescopic guide column. The multi-stage air (or hydraulic) cylinder is not easy to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com