Dragger for coiling cable pipe

A tractor and cable tube technology, which is used in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of high power consumption, complex and heavy mechanism, and low mechanical efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

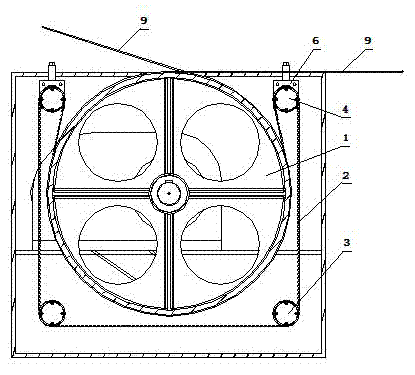

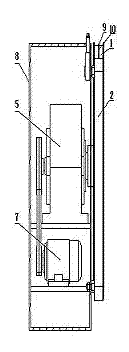

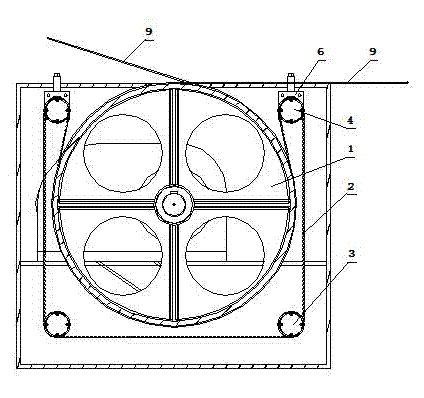

[0011] control figure 1 , a kind of cable tube winding tractor according to the present invention is composed of a traction pulley 1, a timing belt 2, a fixed pulley 3, an adjustment pulley 4, a gearbox 5, a pulley regulator 6, a motor 7 and a frame 8 composition.

[0012] The manufacturing method and process principle of the cable tube winding tractor are:

[0013] The traction pulley 1 is installed on the output shaft of the gearbox 5, the adjusting pulley 4 is installed on the pulley regulator 6, the fixed pulley 3, the gearbox 5, the motor 7 and the pulley regulator 6 are installed on the frame 8, synchronously The back of the belt 2 is closely attached to the outer edge of the traction pulley 1 through the support of the fixed pulley 3 and the adjustment pulley 4. The traction pulley 1 is driven to rotate by the motor 7 and the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com