Cooling tank stirring device with diversion cover

A stirring device and shroud technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of low quenching oil temperature, long quenching time, high quenching oil temperature, etc., achieve uniform temperature, simple structure, and quenching uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

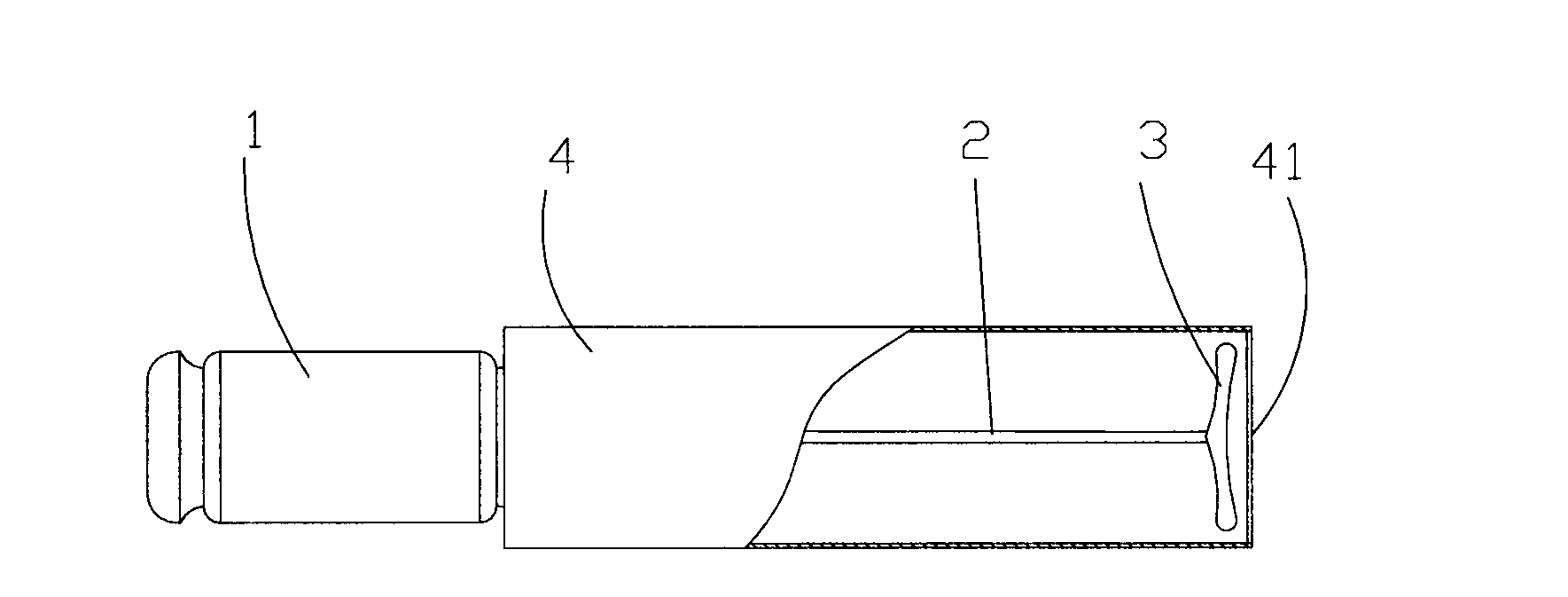

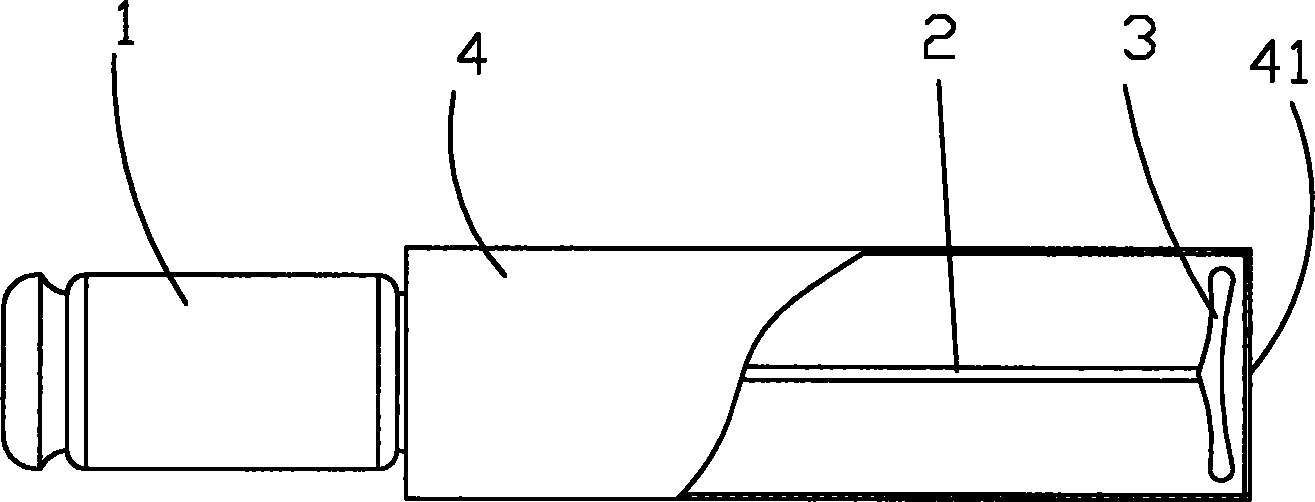

[0015] See figure 1 , a cooling tank stirring device with a shroud, including a motor 1, a rotating shaft 2 fixed on the top of the motor 1, a blade 3 installed on the bottom of the rotating shaft 2, and a shroud 4 surrounding the periphery of the blade 3 , the blade 3 is a propeller blade, which has better stirring performance compared to other blades. The shroud 4 is cylindrical in design, and its bottom is provided with an opening 41. In specific use, the quenching oil 8 passes through the opening 41 The inlet and outlet shroud 4 extends from the blade 3 to the bottom of the motor 1 , and the shroud 4 is arranged parallel to the rotating shaft 2 .

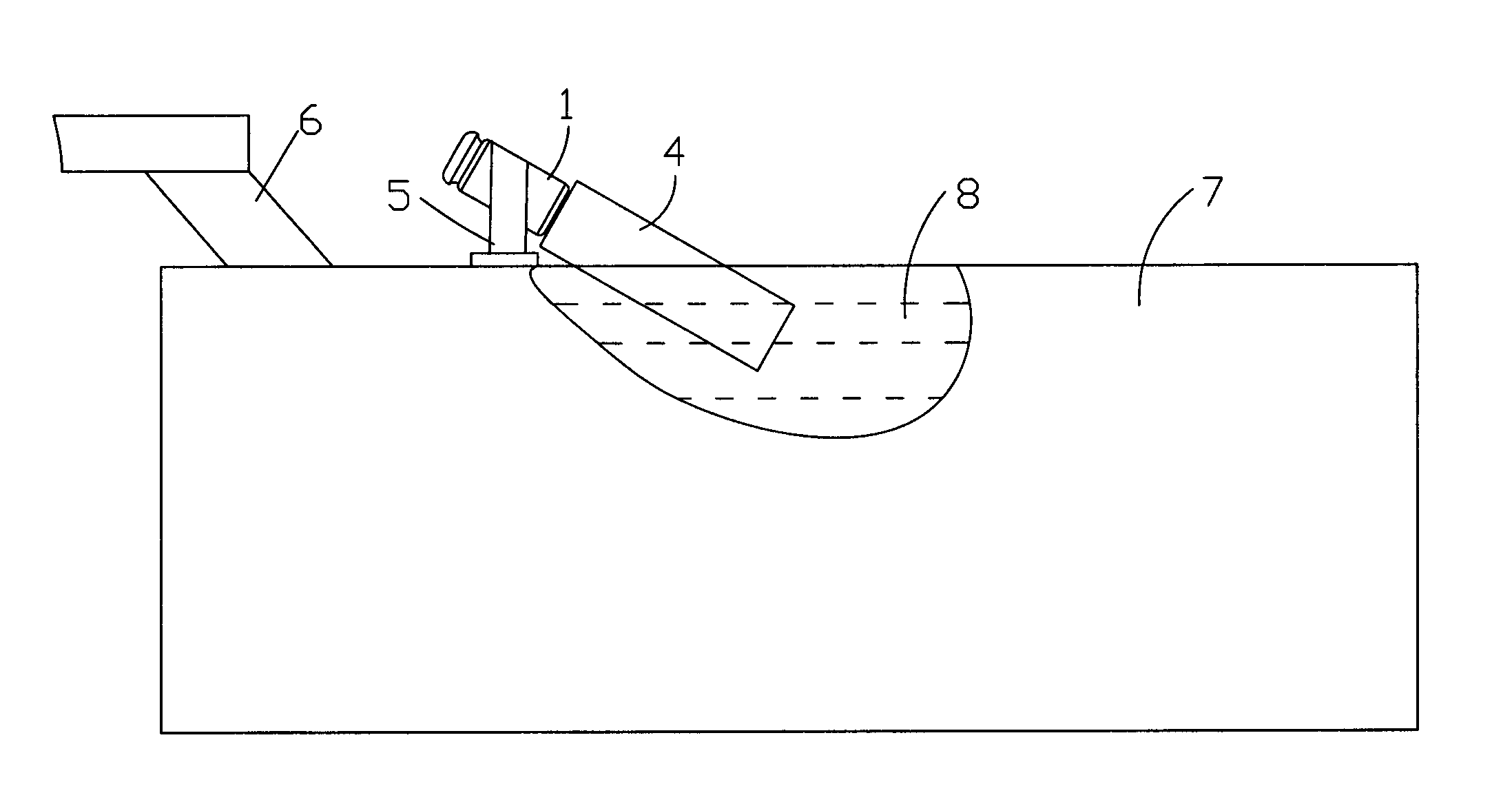

[0016] See figure 2 , the device is arranged in the cooling tank 7, and supported by the support frame 5, in order to achieve the best effect of the device, it can be installed obliquely. During use, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com