Energy-saving type spinning die head for spinning box

A spinning die head and spinning box technology, which is applied to the field of energy-saving spinning dies for spinning boxes, can solve the problems of low thermal conductivity, slow thermal conductivity, unfavorable energy saving, etc., and achieves high thermal conductivity, not easy to block, The effect of convenient processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

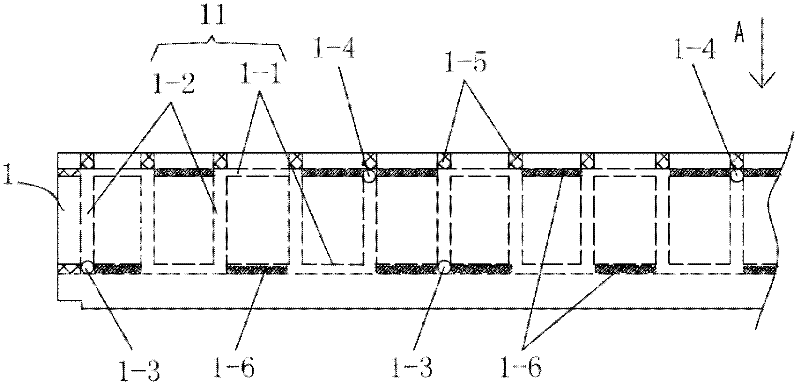

[0027] See Figure 1-4 , the energy-saving spinning die head for the spinning box of the present embodiment comprises: a pair of die head bodies 1 with symmetrical structures, and a plurality of sections of square wave heat transfer oil passages 11 are distributed in the inner wall of the die head body 1; , The liquid outlet holes 1-3, 1-4 are respectively connected with the heat transfer oil inlet pipe 12 and the heat transfer oil outlet pipe 13.

[0028] The liquid inlet 1 - 3 is adjacent to the bottom of the die head body 1 , and the liquid outlet 1 - 4 of the heat transfer oil channel 11 is adjacent to the top of the die head body 1 .

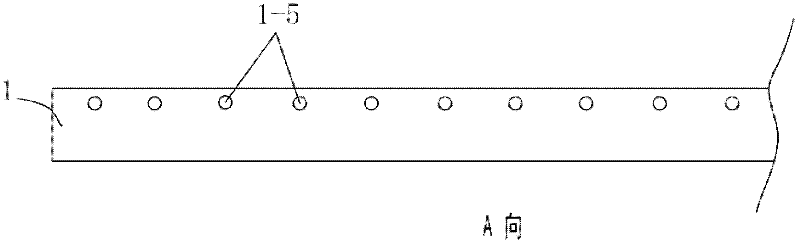

[0029] The heat transfer oil passage 11 includes: a pair of transverse passages 1-1 distributed up and down, a plurality of longitudinal passages 1-2 connected between the pair of transverse passages 1-1; the process holes 1 of the longitudinal passages 1-2 -5 is on the top surface of the die body 1 and is sealed in use, and the process ho...

Embodiment 2

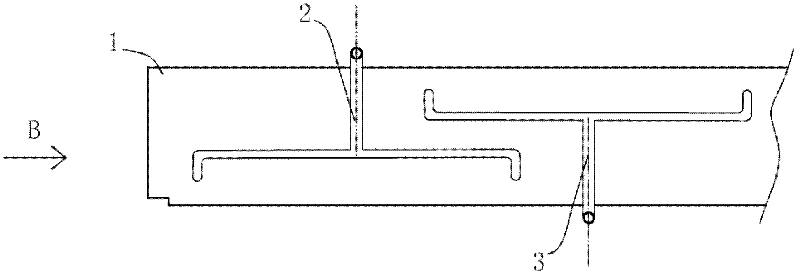

[0031] See Figure 5-9 , on the basis of Embodiment 1, the spinning die head for the spinning box of this embodiment has the following modification, that is: only a melt inlet 2 is provided at the central upper end of the inner wall of one die head body 1, and a melt inlet 2 is provided on each die head On the inner wall of the head body 1 and symmetrically distributed on both sides of the melt inlet 2, there are multi-stage conveying grooves 4 suitable for communicating with the melt inlet 2 during use, and the openings at both ends of the conveying grooves at each stage face The lower outlet is connected to the central part of the conveying trough of the next stage; the outlets of the conveying trough of the last stage are evenly distributed.

[0032] 200 mesh or 250 mesh filter screens 6 are arranged at the lower ends of the outlets at both ends of the final conveying tank in turn, and distribution plates 3 and spinneret plates 7 with through holes are evenly distributed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com