Shift selection and changing operation mechanism for heavy-duty gearbox

A technology for operating mechanisms and shifting gears, applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems of complex overall mechanism, inconvenient assembly and maintenance, etc., and achieve easy maintenance and repair, The effect of increasing security and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

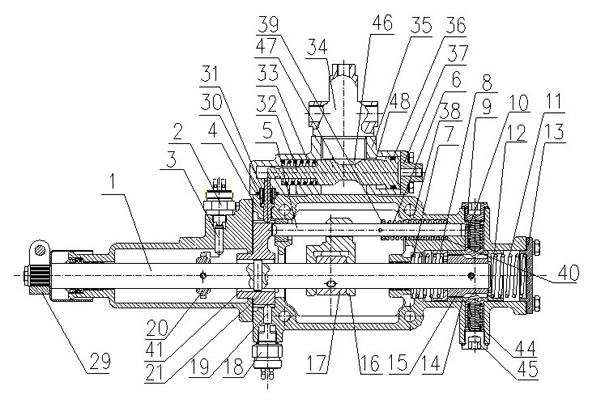

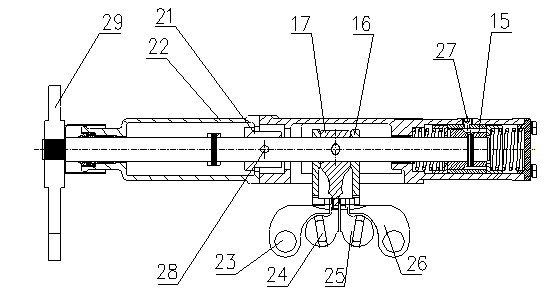

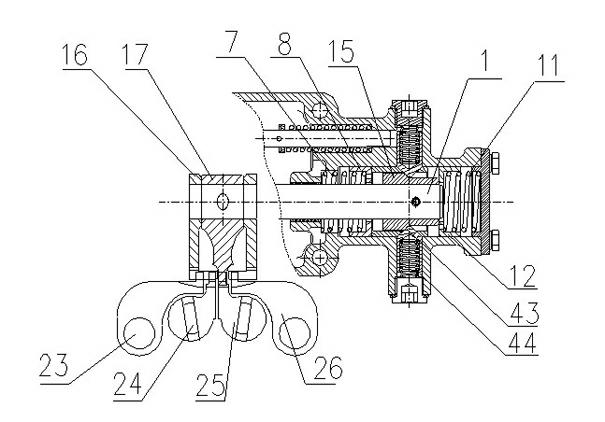

[0032] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

[0033] As shown in the accompanying drawings, a heavy-duty transmission gear selection and shifting operating mechanism includes a small cover housing assembly composed of a small cover housing 4, a left end cover 22 and a right end cover 13, and a gear selection dial 17 is fixed. The shift shaft 1 of the reverse gear signal drive ring 20, the selector shift rocker 29, the self-locking mechanism, the interlock mechanism and the reverse gear lock mechanism, the reverse gear lock mechanism is located in the small cover housing assembly, and the shift gear Gear shaft 1 is fixed in the small cover housing assembly through spring seat Ⅰ8, spring seat Ⅱ12, centering spring Ⅰ7, and centering spring Ⅱ11 installed at both ends of the reverse gear lock structure, and one end of shift shaft 1 is connected to The reverse gear lock s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com