Anti-sticking method for testing integrated circuit (IC) element and anti-sticking IC element test seat thereof

A component testing and component technology, applied in the direction of the measuring device shell, etc., can solve the problem of unobvious effect of the release type, and achieve the effect of simple structure, easy control and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below through embodiments in conjunction with the accompanying drawings.

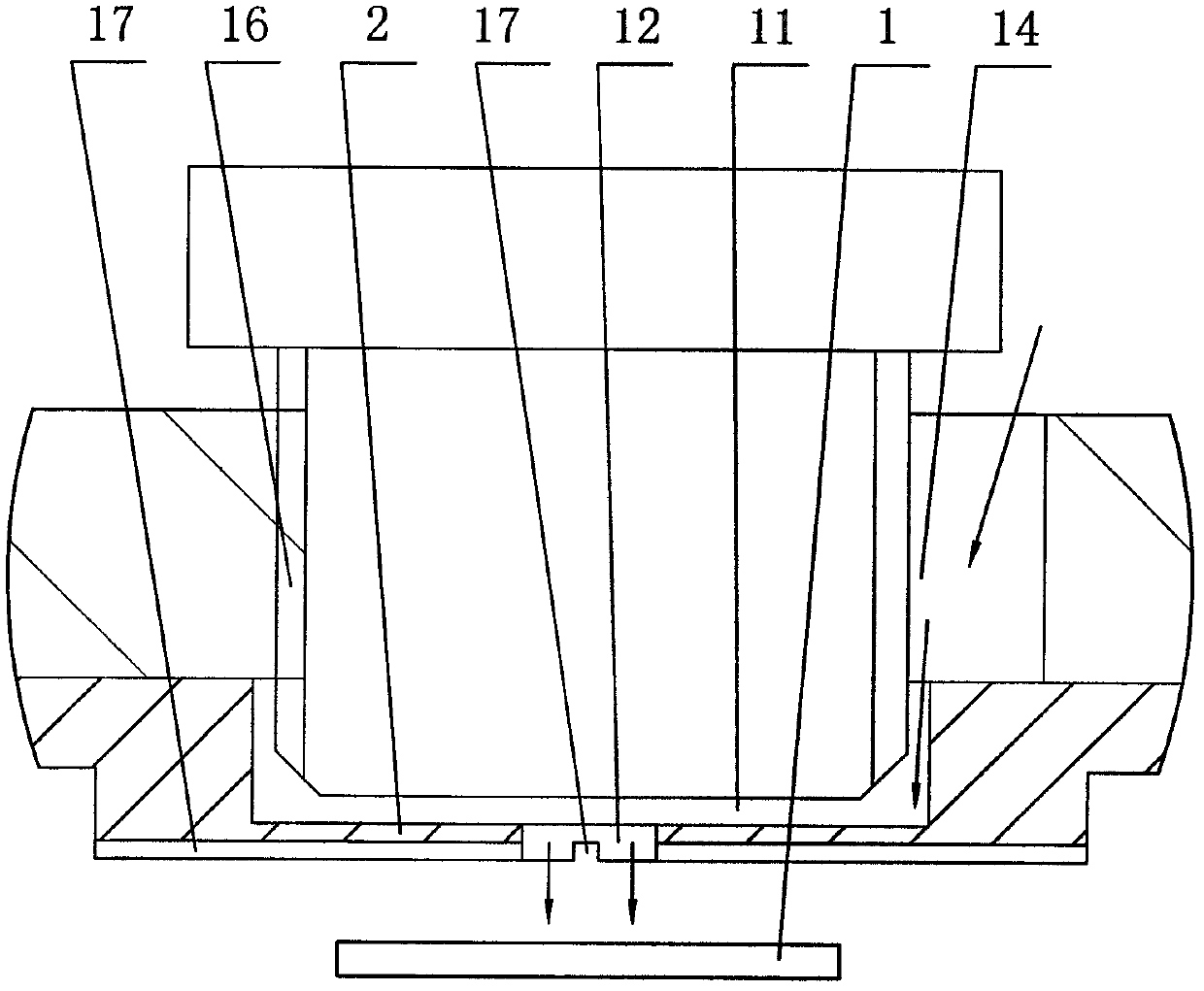

[0019] The technical solution adopted in the present invention is: introduce compressed air at the rear end of the contact surface of the IC component 1 and the upper mold, and use the compressed air to blow out the airflow between the contact surfaces of the upper mold to separate the contact surface of the IC component 1 and the upper mold. fall off. The contact surface of the upper mold is the lens mounting plate 2 .

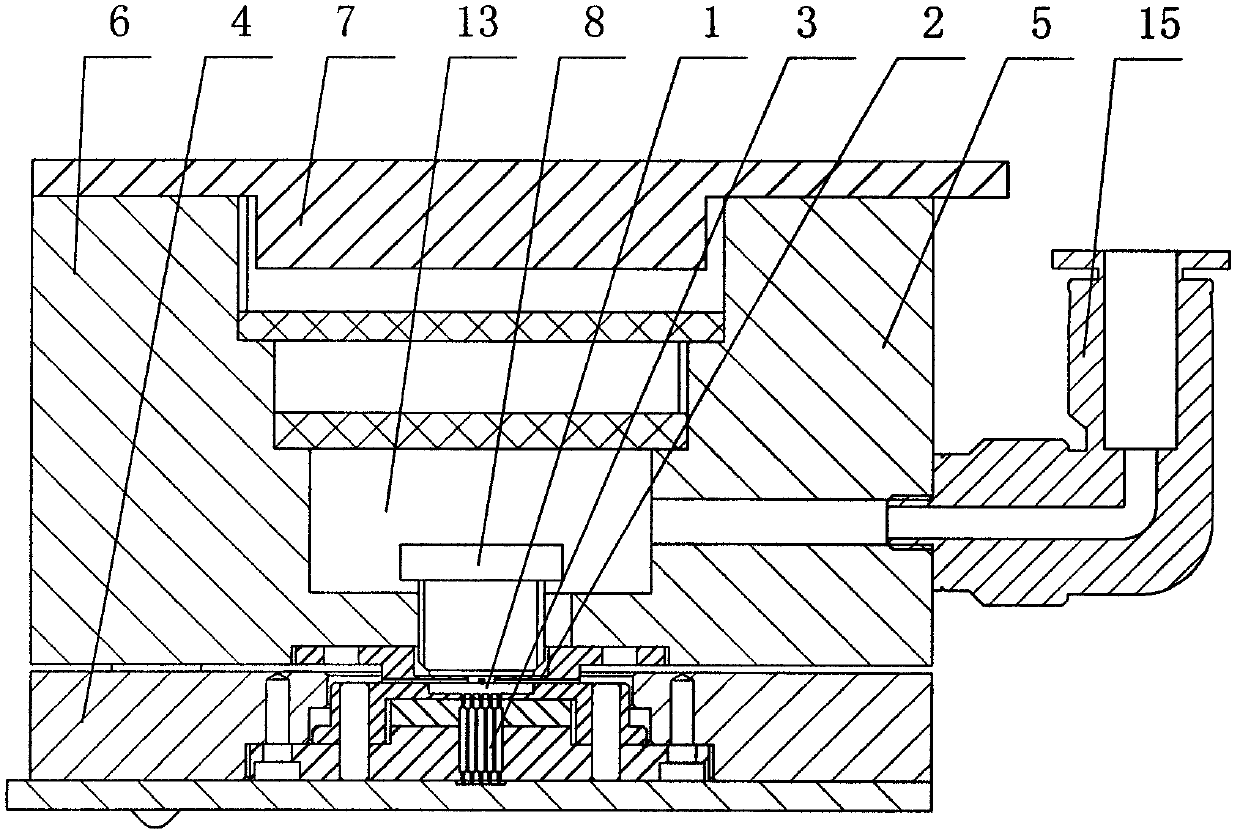

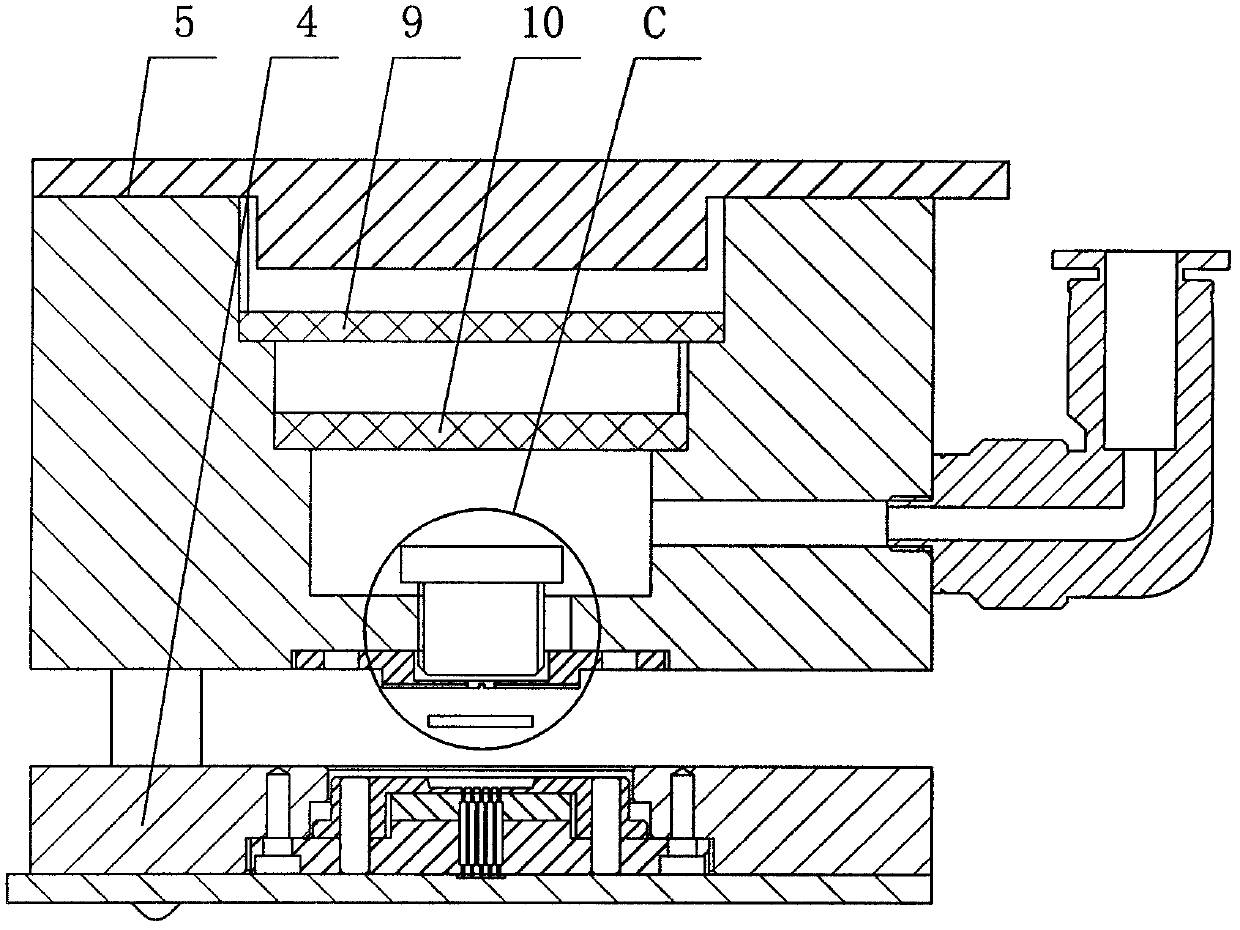

[0020] figure 1 , figure 2 It is a structural schematic diagram of the anti-adhesive IC component 1 test seat manufactured by the anti-adhesive method for testing the IC component 1 . It includes a lower mold 4 for placing the tested IC component 1 and installing the test probe 3, and an upper mold 5 matched with the lower mold 4. The upper mold 5 includes an upper mold base 6, and the upper mold A light source PCB board 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com