Level rotor provided with pin subassembly

A technology of horizontal rotors and components, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of confusion of separated items and stuck cups, and achieve the effect of reducing secondary confusion and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

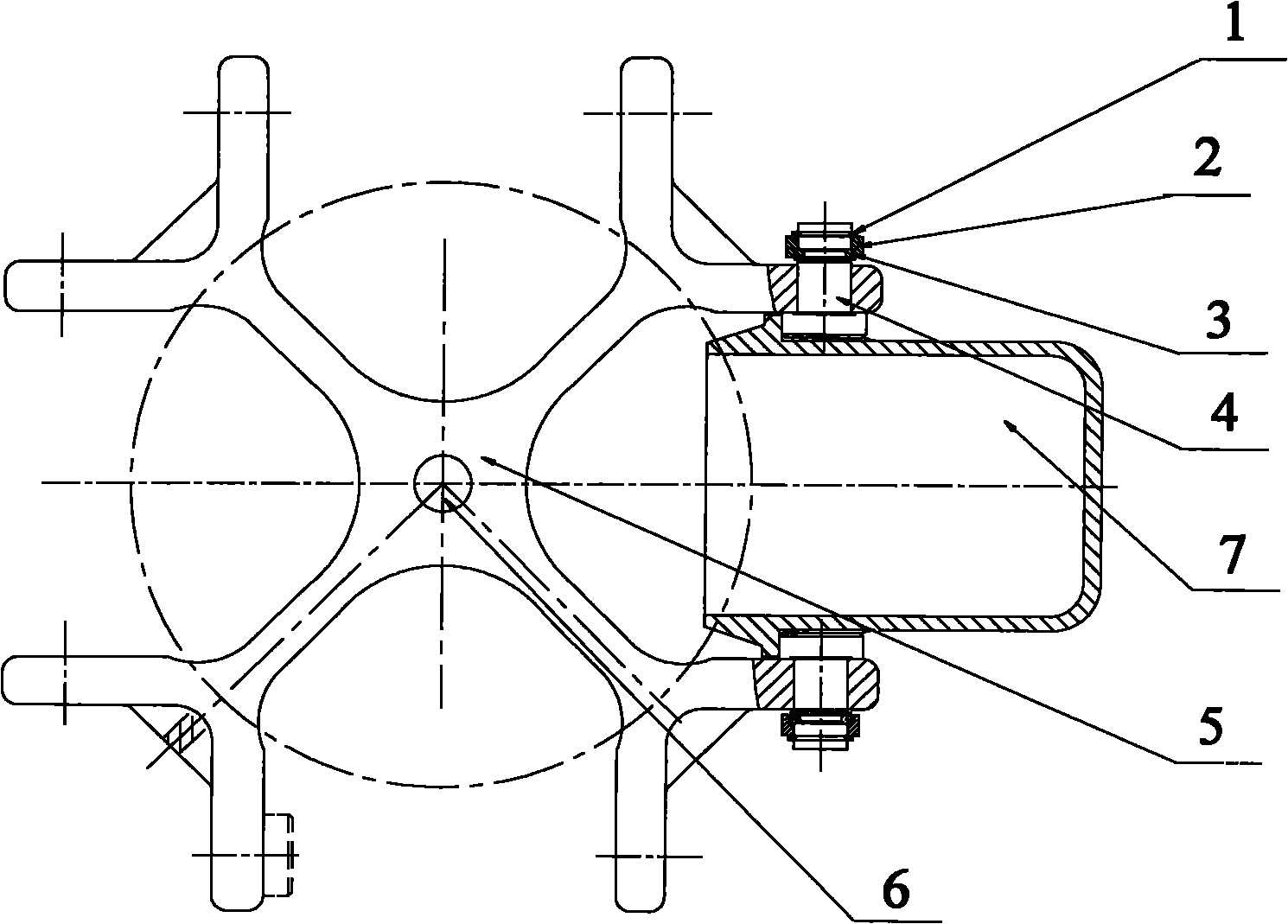

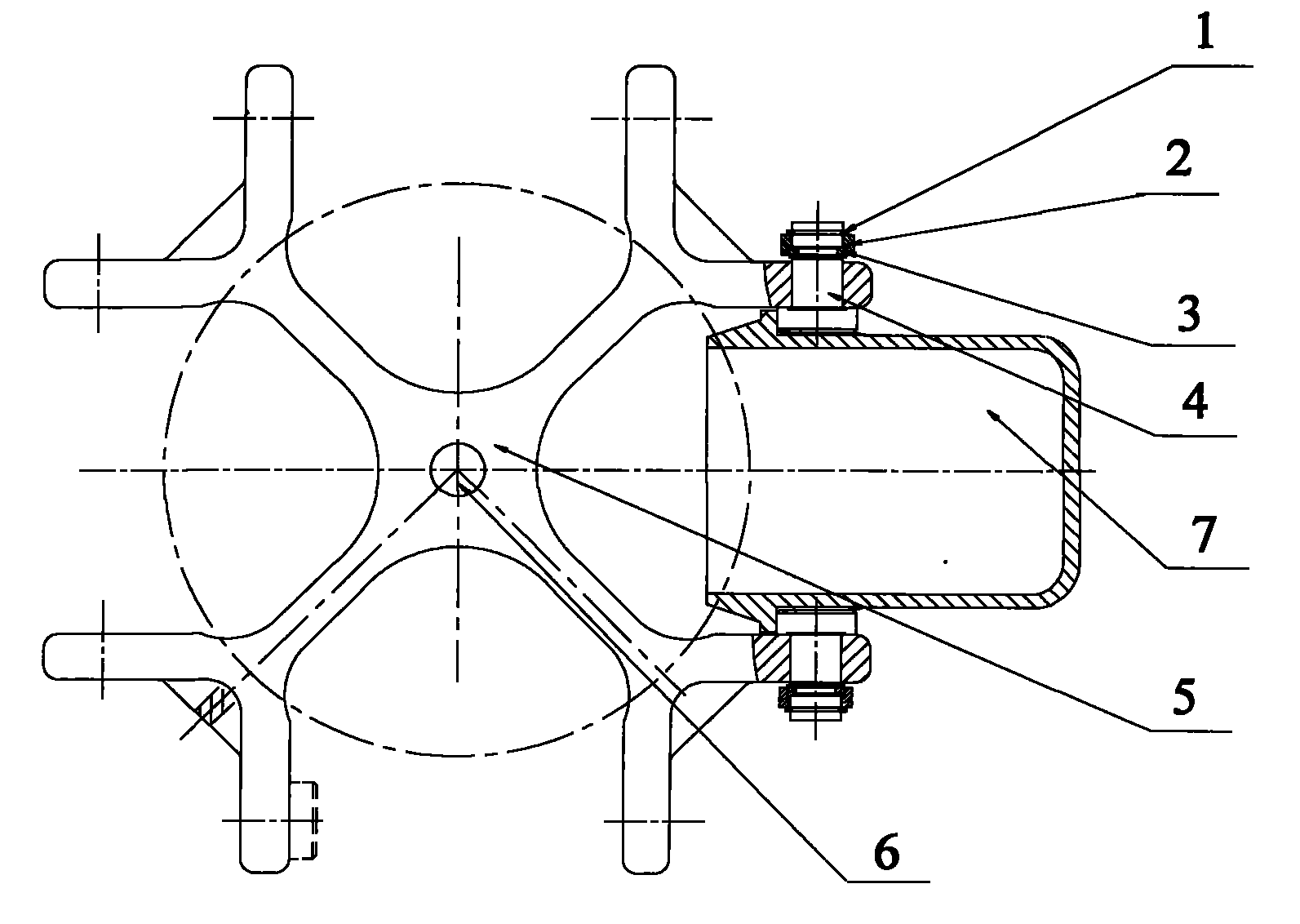

[0015] A horizontal rotor provided with a pin assembly, its structure is as follows figure 1 As shown, it includes a horizontal rotor body 5 and a pin assembly. The horizontal rotor body 5 is composed of four Y-shaped mechanisms that are evenly distributed and connected at the bottom. The center of the horizontal rotor body 5 is provided with a rotating shaft 6 . The pin subassembly is composed of the swivel pin 4, the swivel pin hoop 3, the swivel pin pressure ring 2 and the shaft retaining ring 1. The swivel pin 4 is set in the through hole on the branch on the upper part of the Y-shaped mechanism. , The diameter of the through hole is 15mm. The end of the rotor pin 4 close to the inner side of the Y-shaped mechanism is provided with two 2mm grooves, and a semicircular rotor pin hoop 3 is arranged in the groove, and the rotor pin pressure ring 2 is set on the rotor pin hoop 3 On the outer side of the shaft, the retaining ring 1 for the shaft is inlaid on the top of the turr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap