Packaging bag having handle

A technology of packaging bags and carrying handles, applied in the field of packaging bags, can solve the problems of preventing printing, difficulty in printing, and difficulty in taking out contents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

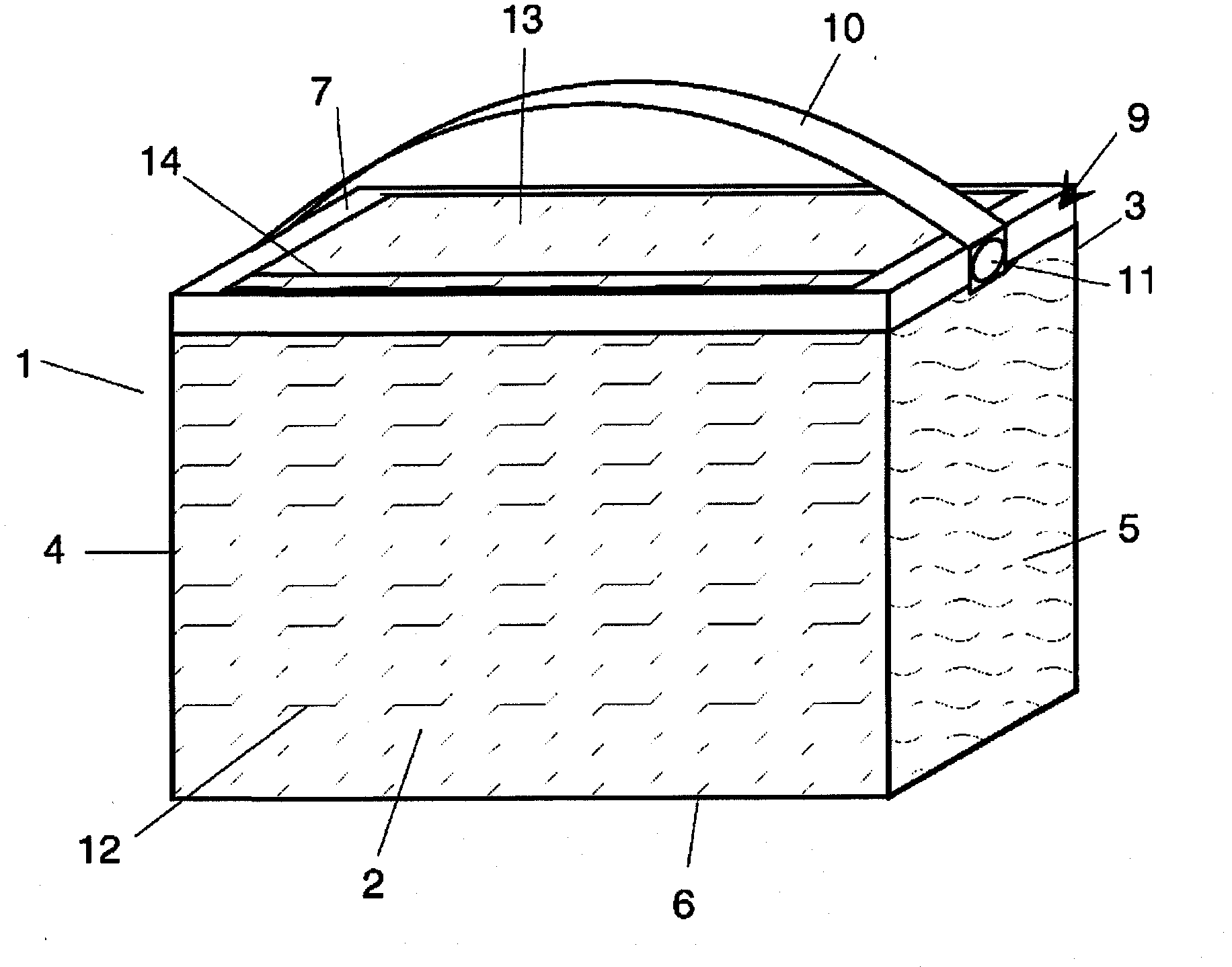

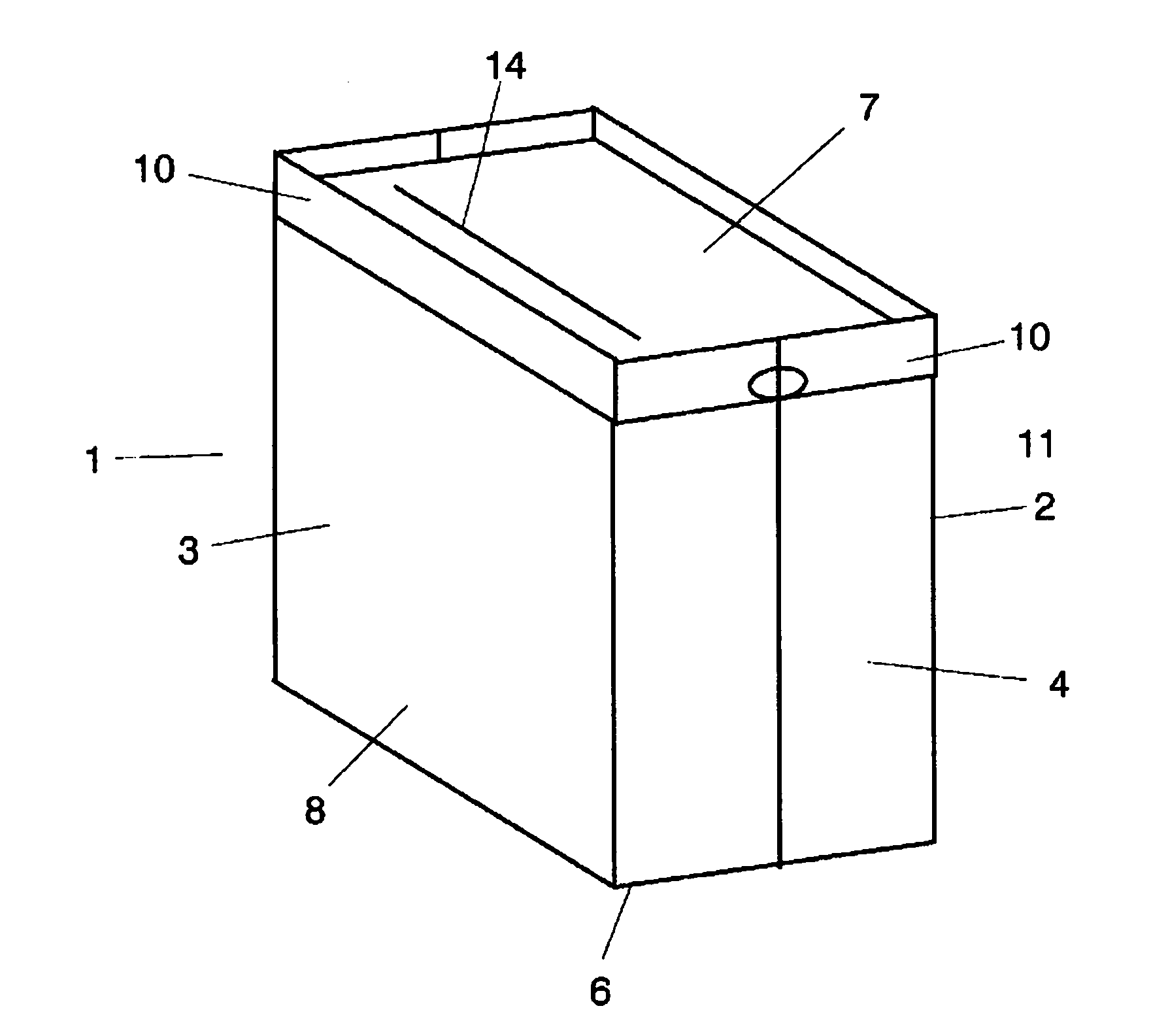

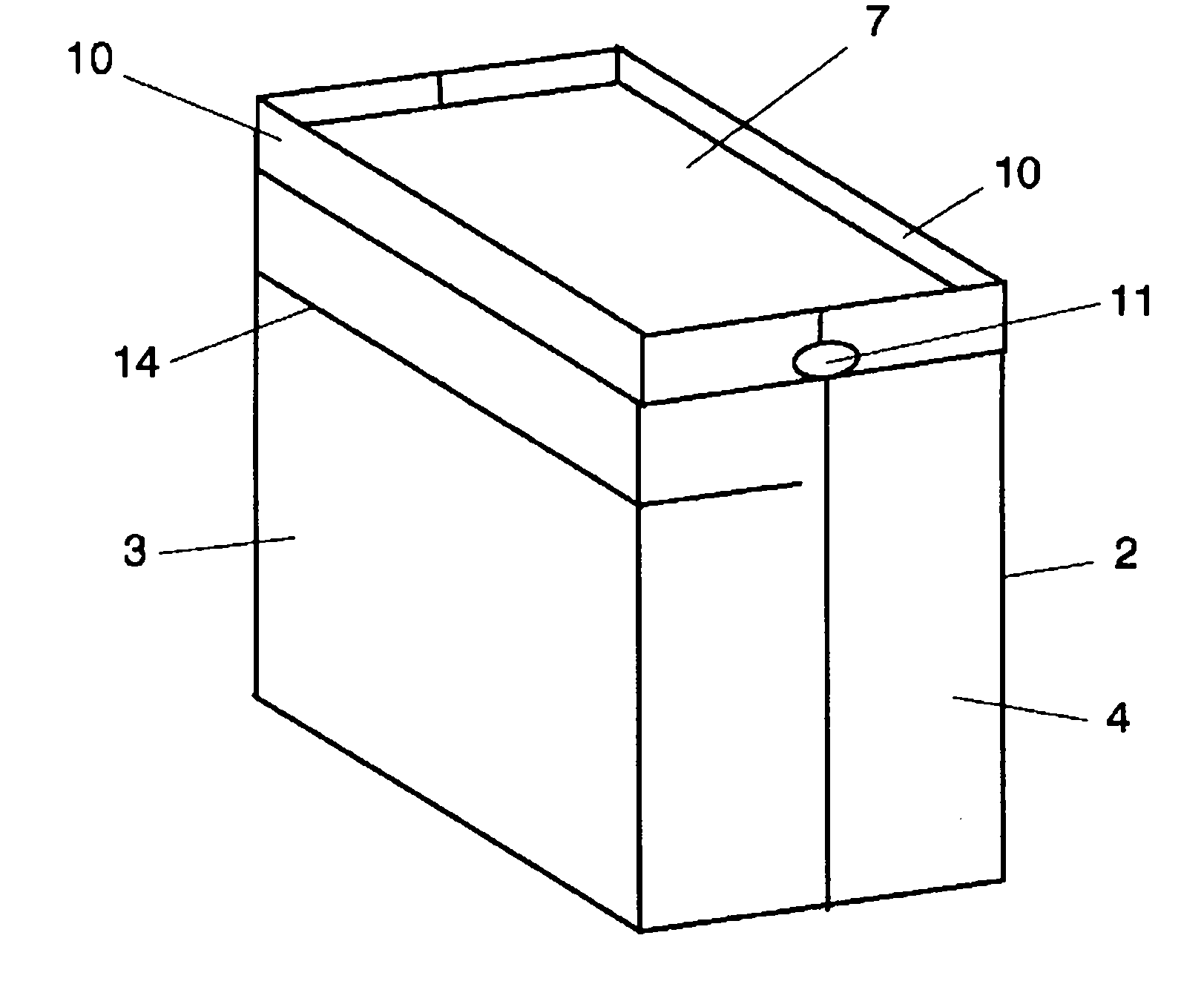

[0042] figure 1 The reference number 1 in is used to designate a packaging bag 1 having two longitudinal side walls 2 and 3 , two narrow side walls 4 and 5 , a bottom side 6 and a top side 7 . The packaging bag 1 is formed from a thin section 8 which is folded to form a top face 7 and to which the longitudinal side walls 2 and 3 are arranged to be hinged. The package 1 is closed at the bottom. The side edges of the thin sections 8 are welded to one another in the region of the narrow side walls 4 and 5 . The bottom side 6 is closed once the bag is filled.

[0043] Overprints 12 are provided on the side walls 2 , 3 , 4 and 5 . A further overprint 13 can be provided on the top surface 7 . It is also possible to provide a pouring opening 14 on the top surface 7 . However, it is also conceivable that image 3 The pour opening 14 is shown provided in the side wall.

[0044] The foil strip 10 is welded on at the edge 9 between the narrow sides 4 and 5 and the top 7 in the reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com